I've been studying firearms metal finishes for a few decades both to do my own for my custom guns and rifles and to write about the subject for magazine stories. Mr. Adair's info shows (may he RIP) that he really didn't know what carbonia bluing was (neither do I) and I don't agree with some of what is posted on Rons gun shop site, from my personal experience.

Here are pix of a single shot I hand-polished to 600 grit and had Steve Moeller (IN) charcoal blue about 20 yeas ago. (I made the custom French walnut grips. It also has gold inlaid lettering and nitre blued screws unlike factory S&W's). The bluing is very close to the original S&W bluing and involves heat at about 600 degrees, charcoal, oil and carding (as with rust bluing). As I understand it, the Am. Gas Furnace process rotated the parts in a both of charcoal and oil at heat , but I am not certain of this.

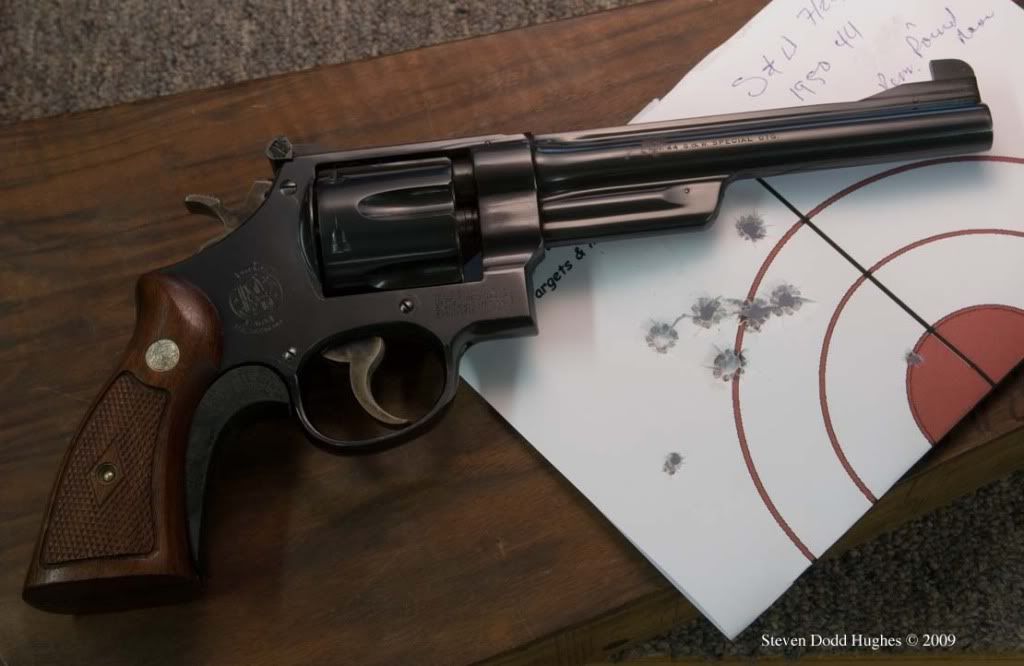

There are a couple more guys doing this charcoal bluing today including Doug Turnbull (although his is more the bright blue of Colt's) Peter Mazur in CA and Mike Hunter in MO. it is my understanding that Dave Chicoine used a hot blue with salts similar to normal hot bluing with superb polishing. I have achieve a blue very similar to S&W early matte blue (like my Model of 1950, .44 HE) using a rust bluing technique. Original shown.

One fact in the posted info is that preparation, polishing, is absolutely imperative to great results. the early S&W polisheres used huge wheels and this is a completely lost trade in today's firearms world.

In any case, I am also very interested in these processes and hope to learn more, and help if I can.

Best,

Steve