I finally got around to cleaning out my cabinet and changing the blast media to something with more "tooth" and Skjos's thread here seemed the obvious place to share my results.

I had been using some 270+ straight glass beads from Brownells. While that stuff was adequate for cleaning and some removal of light tool marks it would not replicate the original blast profile that S&W did.

Today I loaded my cabinet with the #4 Econo blend from Mcmaster-Carr

McMaster-Carr

This media is a blend of aluminum oxide & glass beads of 120-170 mesh size.

Today I ran some parts through using that media at around 80psi and keeping the nozzle 4-6 inches from the workpiece.

I'm very pleased with the results....

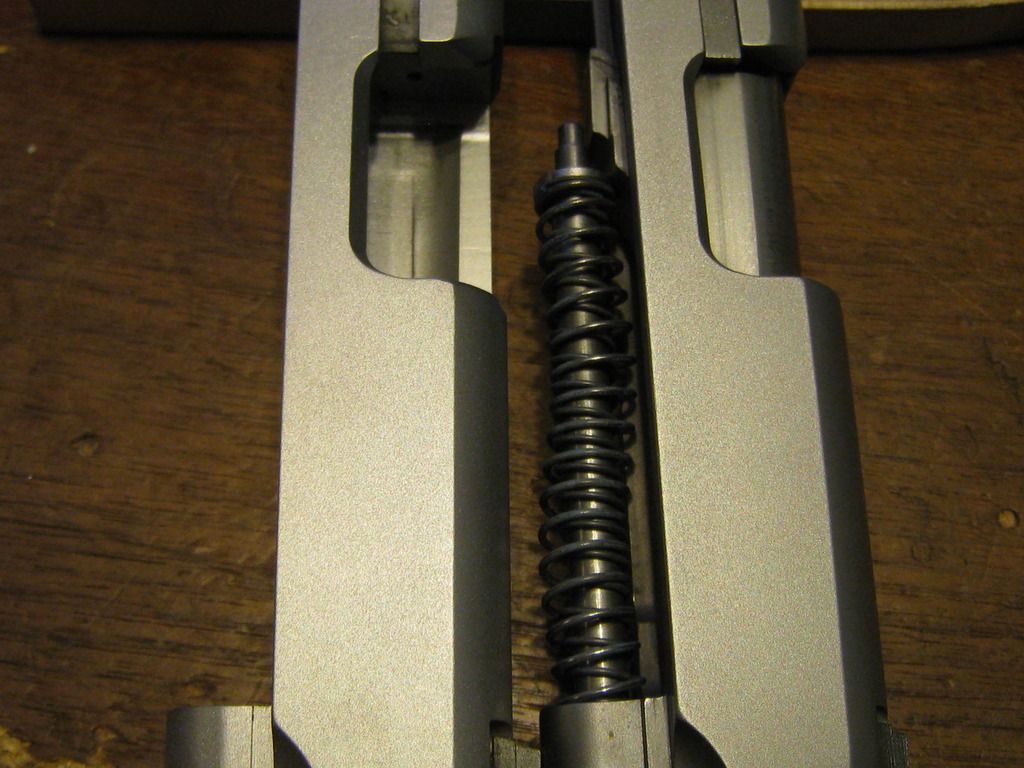

Here on the left is a 4513 just blasted next to a unmolested 4516-2 slide. Near as I can tell the surface profile is identical between the two, just a little brighter on the 4513.

Here is a 1066 slide that had a horrid dremel hack job done to it. It's been welded, ground, milled, filed & sanded. There's no evidence that anything was ever done and the finish is blended perfectly.

If anything I may back off on the air pressure a bit for the next run. In any event, I can't complain a bit with these results.

Cheers

Bill