Well, my 4566TSW project is on the back burner until I get some parts back from Houston so, I'll proceed to mess with some other stuff.

What we have here is a couple old 40xx uppers. As you can plainly see, one's a 4013 and the other a 4014.

Both are early versions with the fat 0.290 staked guiderod, one being aluminum and the other stainless with a single roundwire recoil spring.

Narrow barrel hood/tab and standard three dot low-mount Novaks.

What were gonna do here is turn both of these into 10mm pocket rockets. And along the way fix up a few more things; Lots of cleanup, new sights, cut for spring loaded decocker, sort out a new recoil assembly, and a bit of polish here and there. And of course re-chamber the barrels to 10mm auto.

First order of business, I'm going to see to the recoil spring setup. Big surprise... Were gonna use a ISMI spring

I'm not going to cut up any factory parts for this so I'll be making the guiderods completely from scratch.

Now since the flatwire spring runs on a quarter inch diameter guiderod, I will need to do something about those huge holes in the end of the spring tunnels.

I know!... lets make some bushings.

I have a couple stubs of 416 stainless in the bin I think will do nicely. So lets dust off my little lathe and make some swarf.

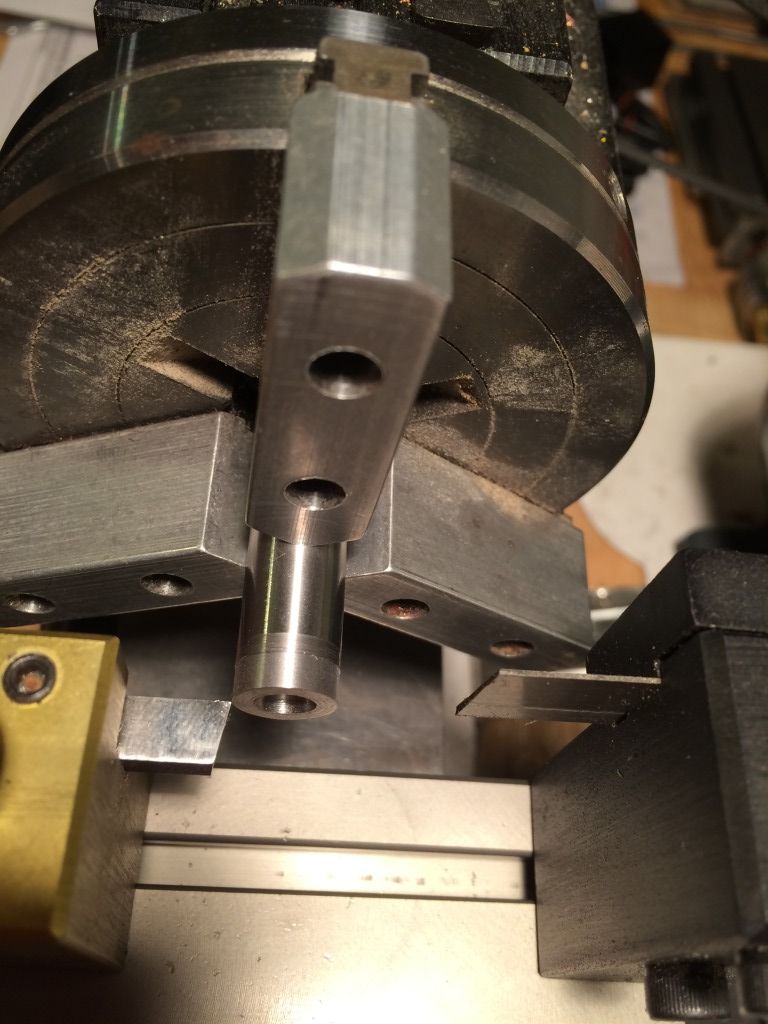

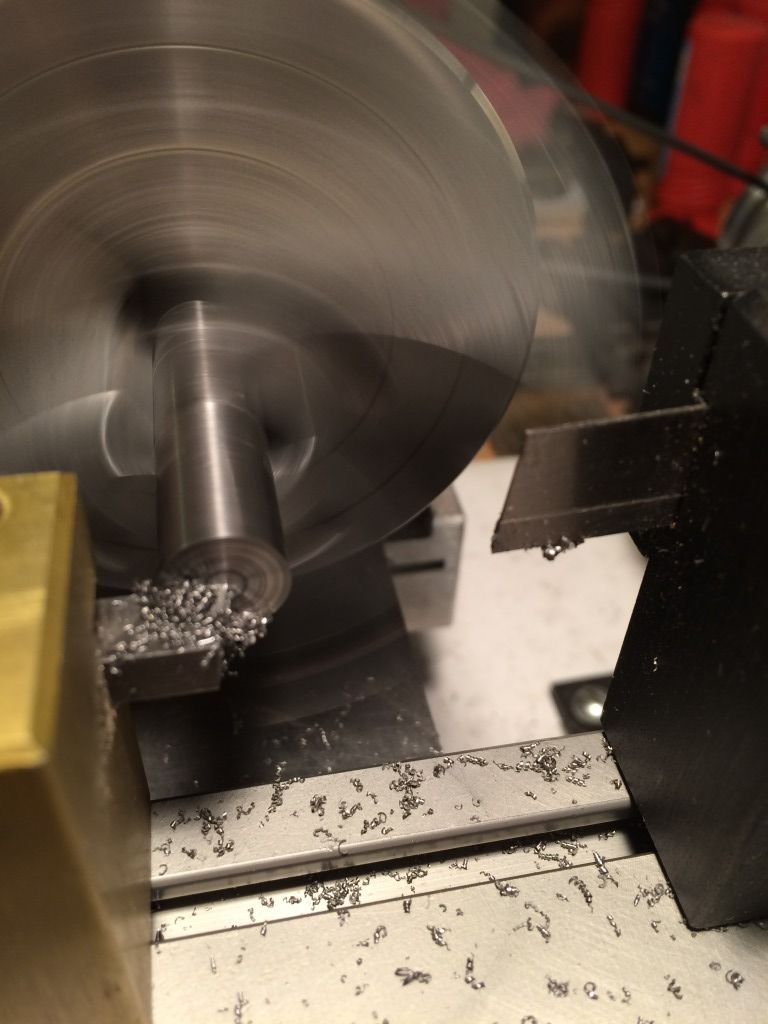

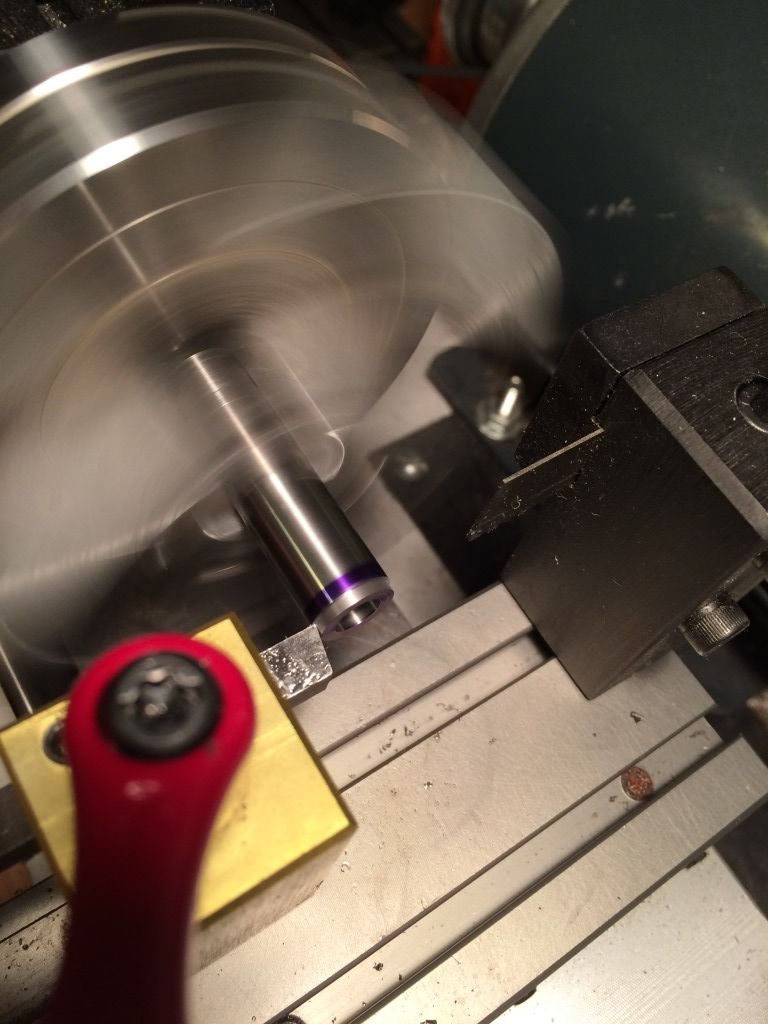

Here's a piece in the chuck indicated to withing 0.0005". This is a leftover piece from the last time I made some bushings. I think I can squeeze one more out of this. I've already faced the part and turned the OD down to 0.427 to fit the 4013 slide.

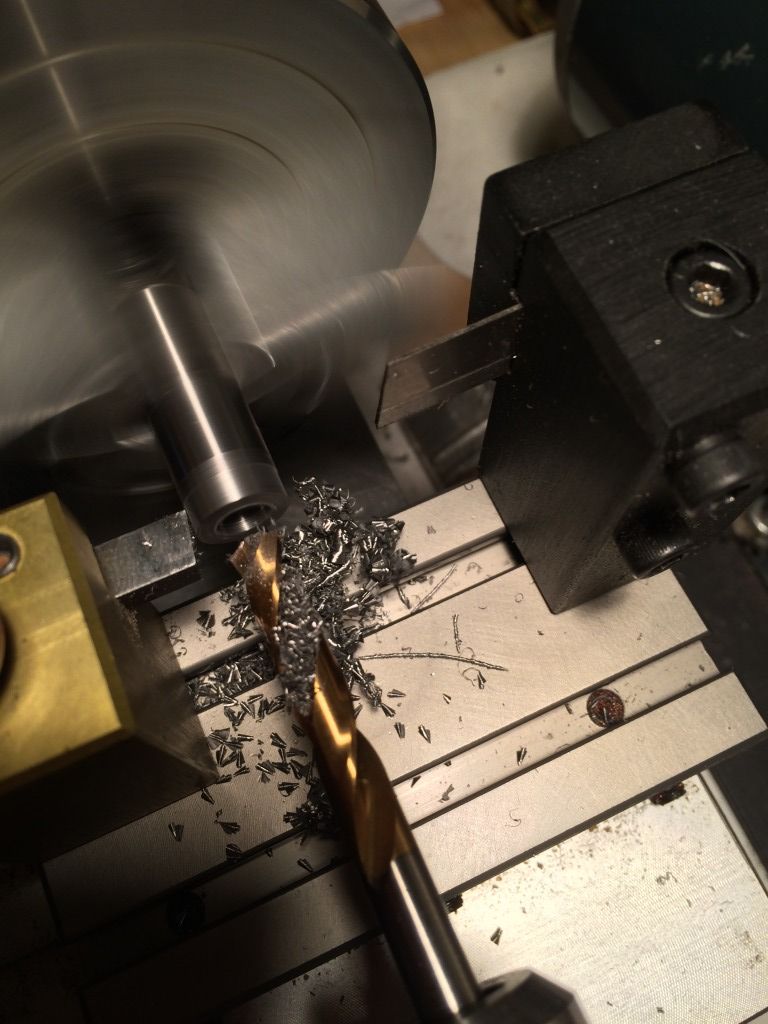

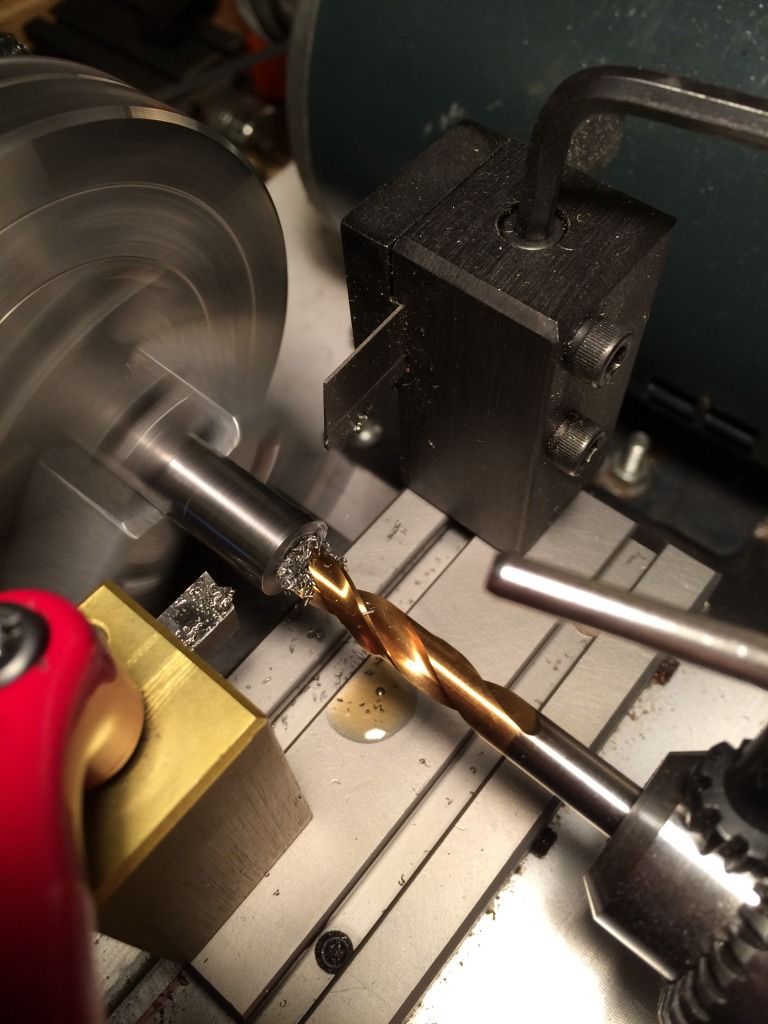

Need to deepen that hole first. Spinning the part at 500rpm and using a 1/4" cobalt bit here.

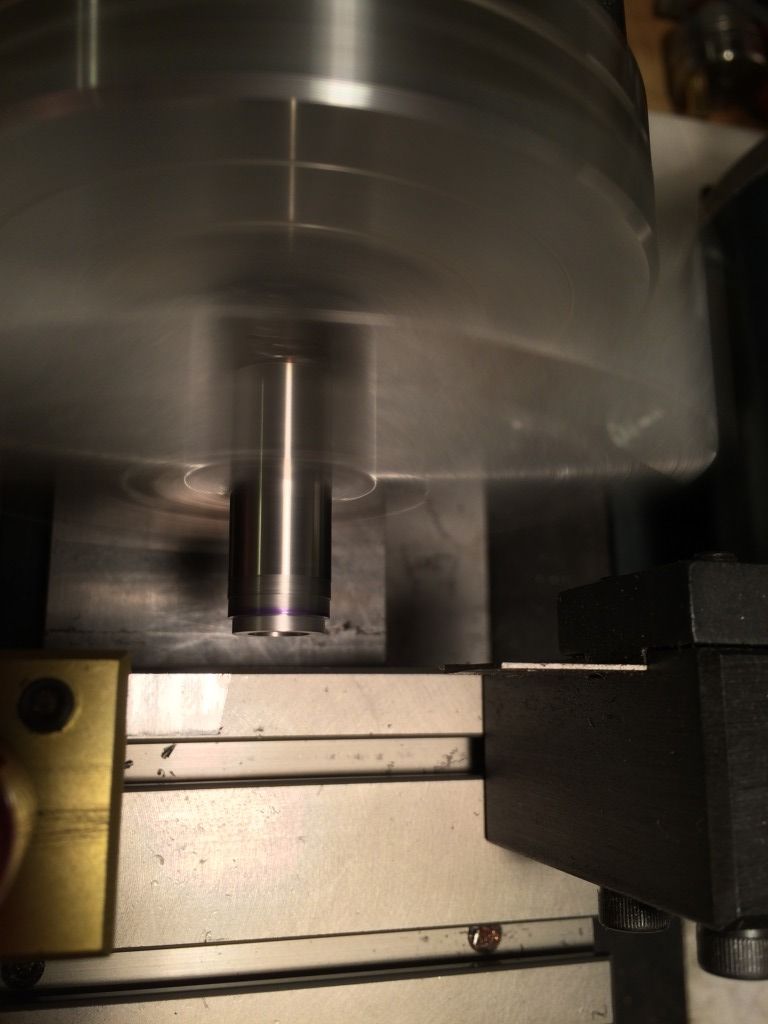

Ramp up the speed to 1375rpm and cut the shoulder back seventy thousandths and reduce the diameter down to 0.297 to fit tight in the 4013 slide.

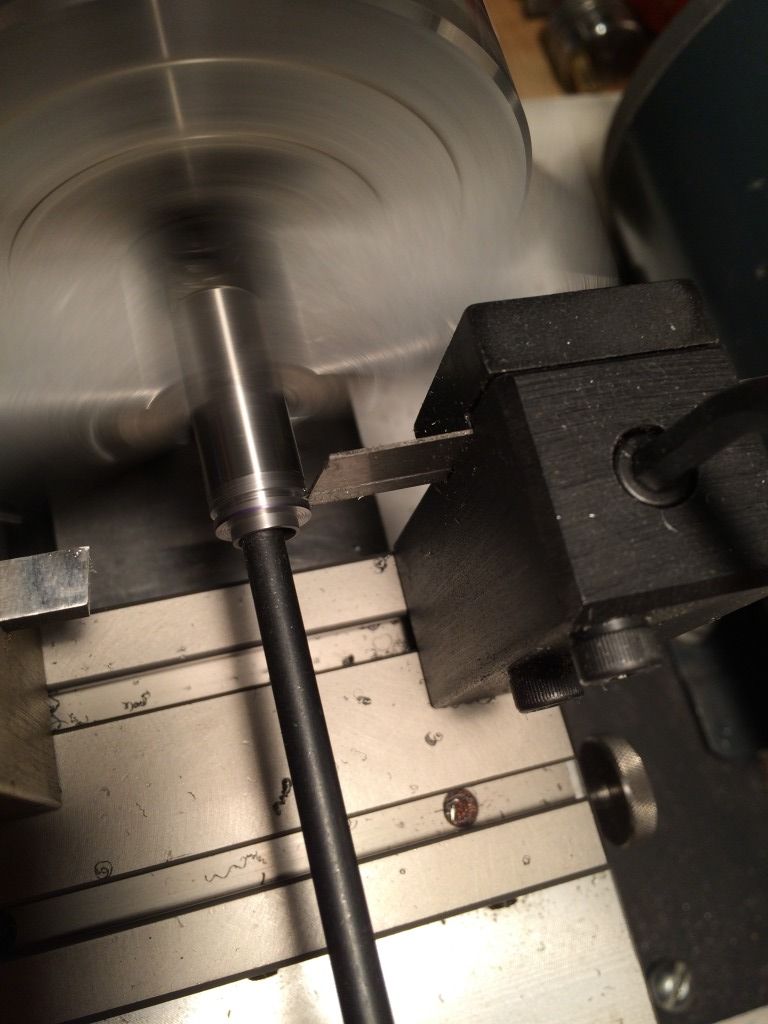

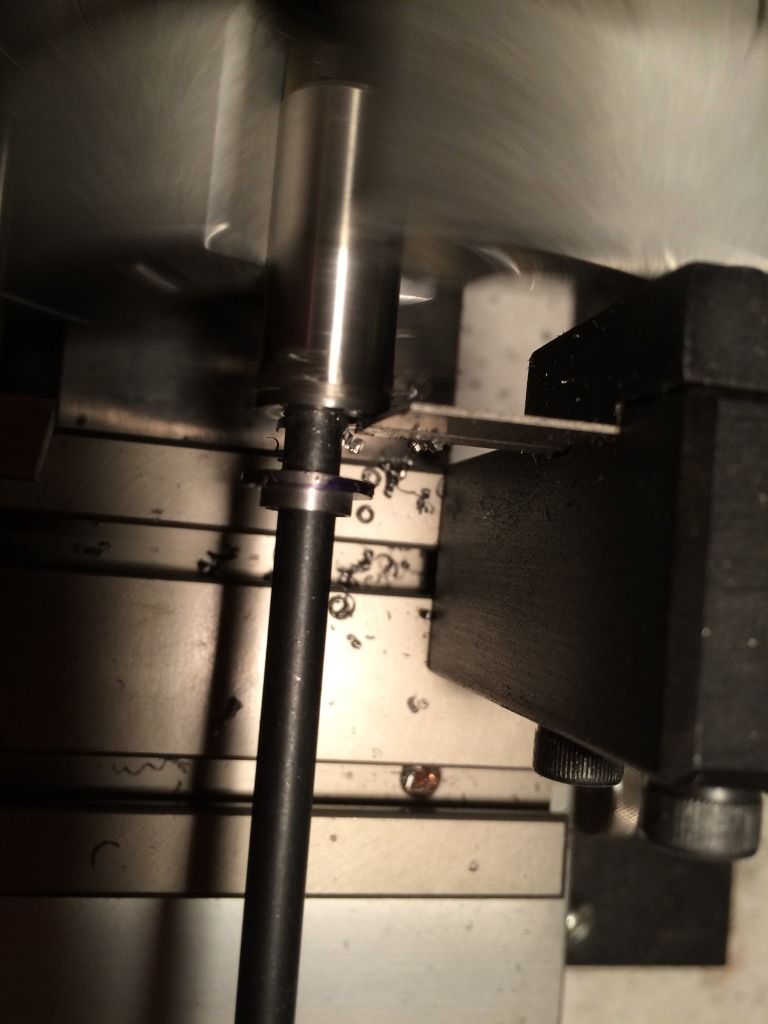

Got it cut to the right size so now we'll part if off the stub. I stuck a little piece of rod in the tailstock chuck and ran it into the stub to capture the part when it comes free. Slowed the speed back down to 500rpm and ran the parting tool in there leaving flange about .050 thick.

There it is.

There's not enough meat left on that stub to cut another one so I need to set up another stub to cut the bushing for the 4014. The dimensions on that 4014 are also a bit looser so I need the cut the bushing a couple thousandths larger in the diameters to get a tight fit.

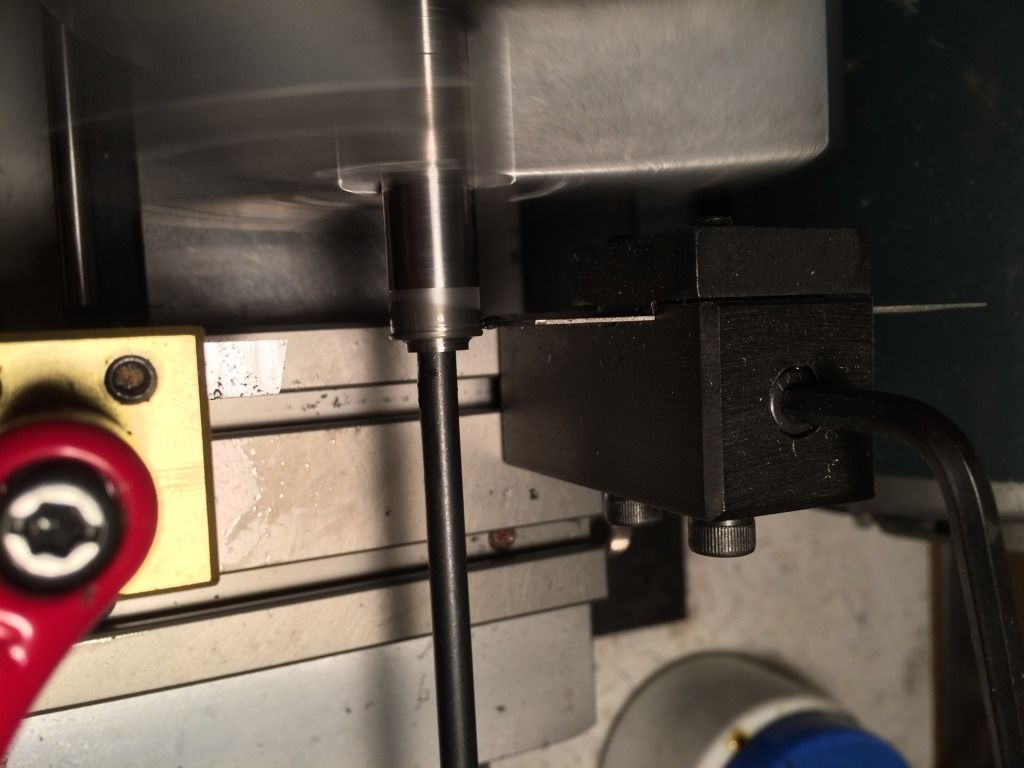

Here's the second stub already indicated in and I'm facing off the hacksaw marks at 1375rpm.

A little more drilling.

Splash on some layout dye and scribe my reference line. This time I'm only cutting back sixty thousandths since the 4014 is about 0.010 thinner than the 4013 is at the front of the spring tunnel.

Gettin' there

Good enough, lets chop it off.

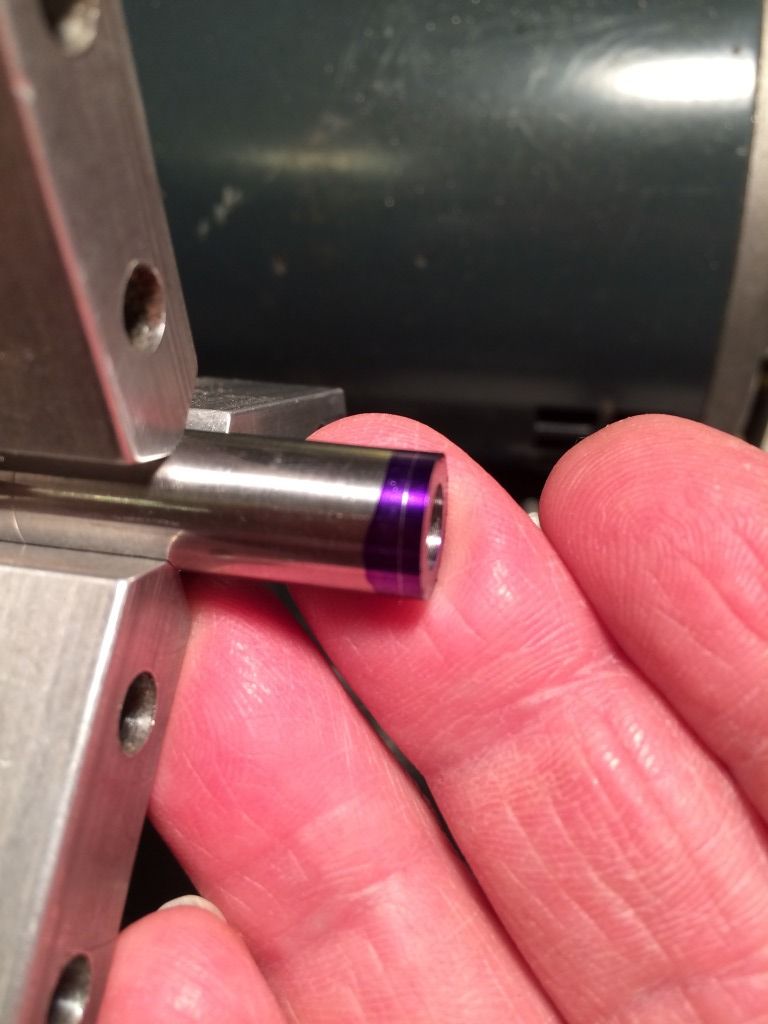

All done. While they look identical, the one on the right is a couple thousandths bigger in both outside diameters to fit the looser 4014 tunnel.

When installed it'll look something like this.

That concludes tonight's episode

For the next installment well get started making the guiderods. Assuming my order from Mcmaster-Carr gets here.

Cheers

Bill