Evening Gents,

Progress update on Doug's M625...

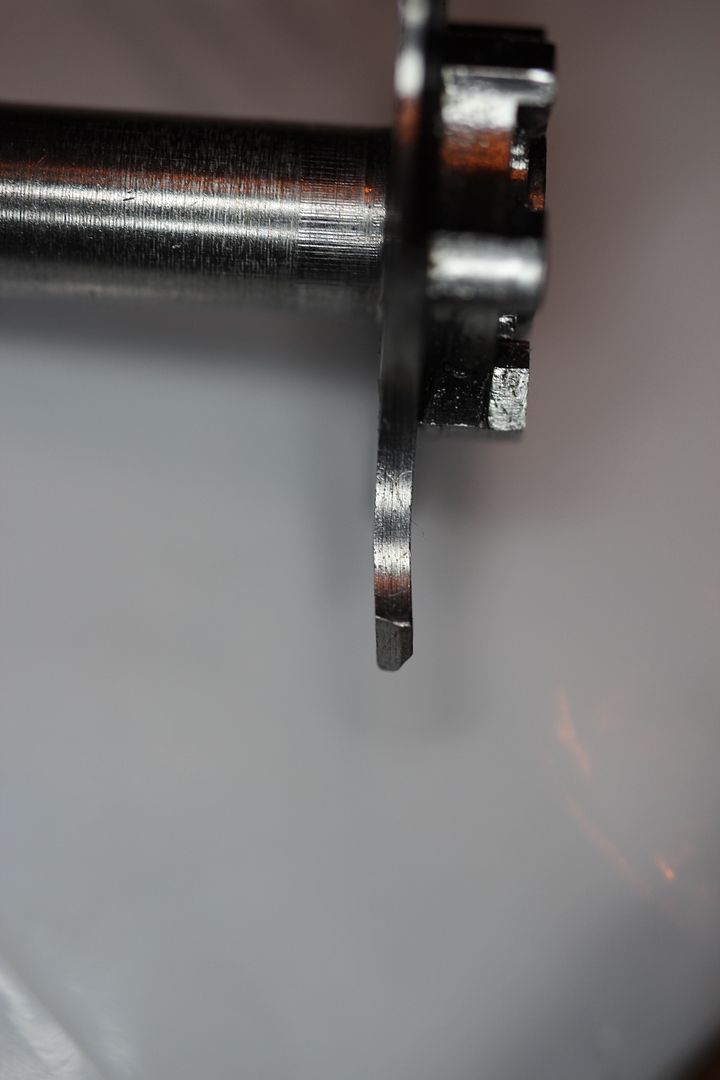

Setting up to chamfer the cylinder's chargeholes and spotted this bent leg on the extractor star. This got by me earlier, good thing I caught it now.

I straightened that out with this parallel jaw plier with the brass lined jaws. Good to go now.

Now over to my bench lathe. Instead of turning the cutter with the little clunky "T" handle, I choose to use the lathe. I have the cutter held in a 5C collet and turn it at about 40RPM. I have a Bodine brushless motor with controller on my lathe which permits infinity variable spindle speed and loads of torque at very slow speed.

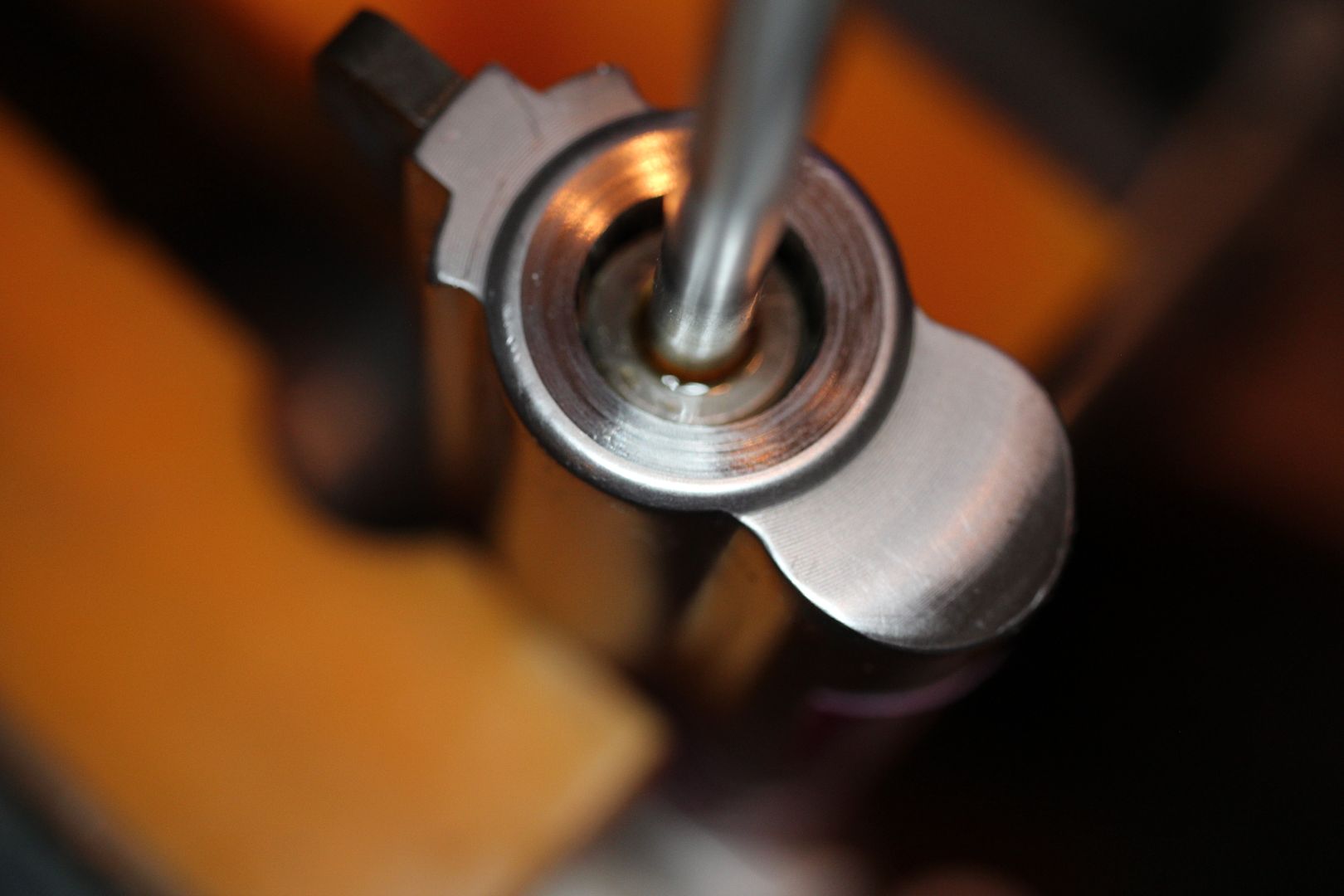

Anyway, 45° chamfer cutter with a 45ACP chamber pilot installed. I put three cases in the cylinder to support the extractor, butter up the cutter & pilot with some cutting oil then cut the chamfer on the other three chargeholes.

Shift the brass cases to the freshly cut holes then do the three remaining.

Looks much better once it's all cleaned up.

The chamfer provides a smooth lead in so the case mouth/s wont catch on the way in.

Reloads just drop right in there slicker than.... Well... slick

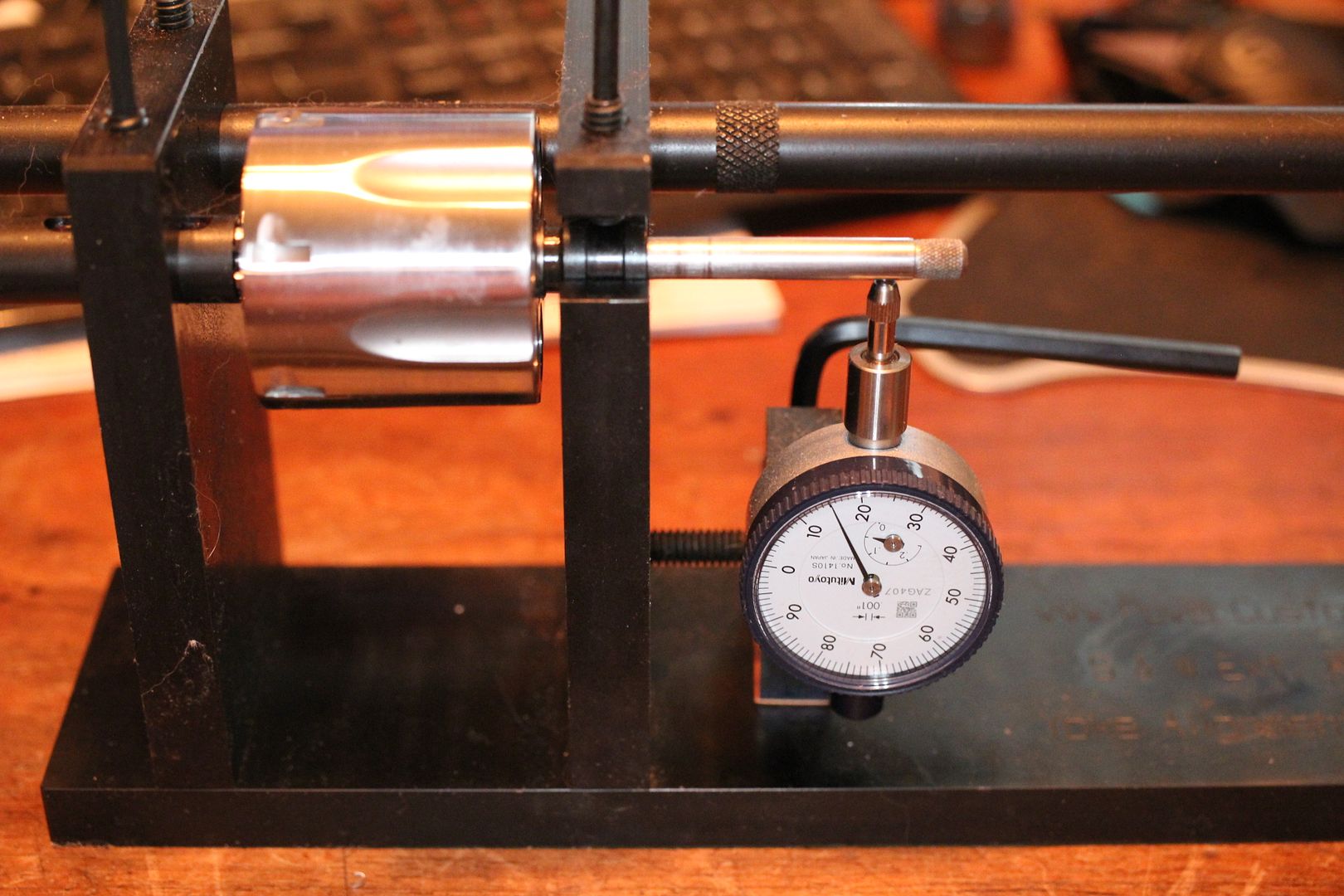

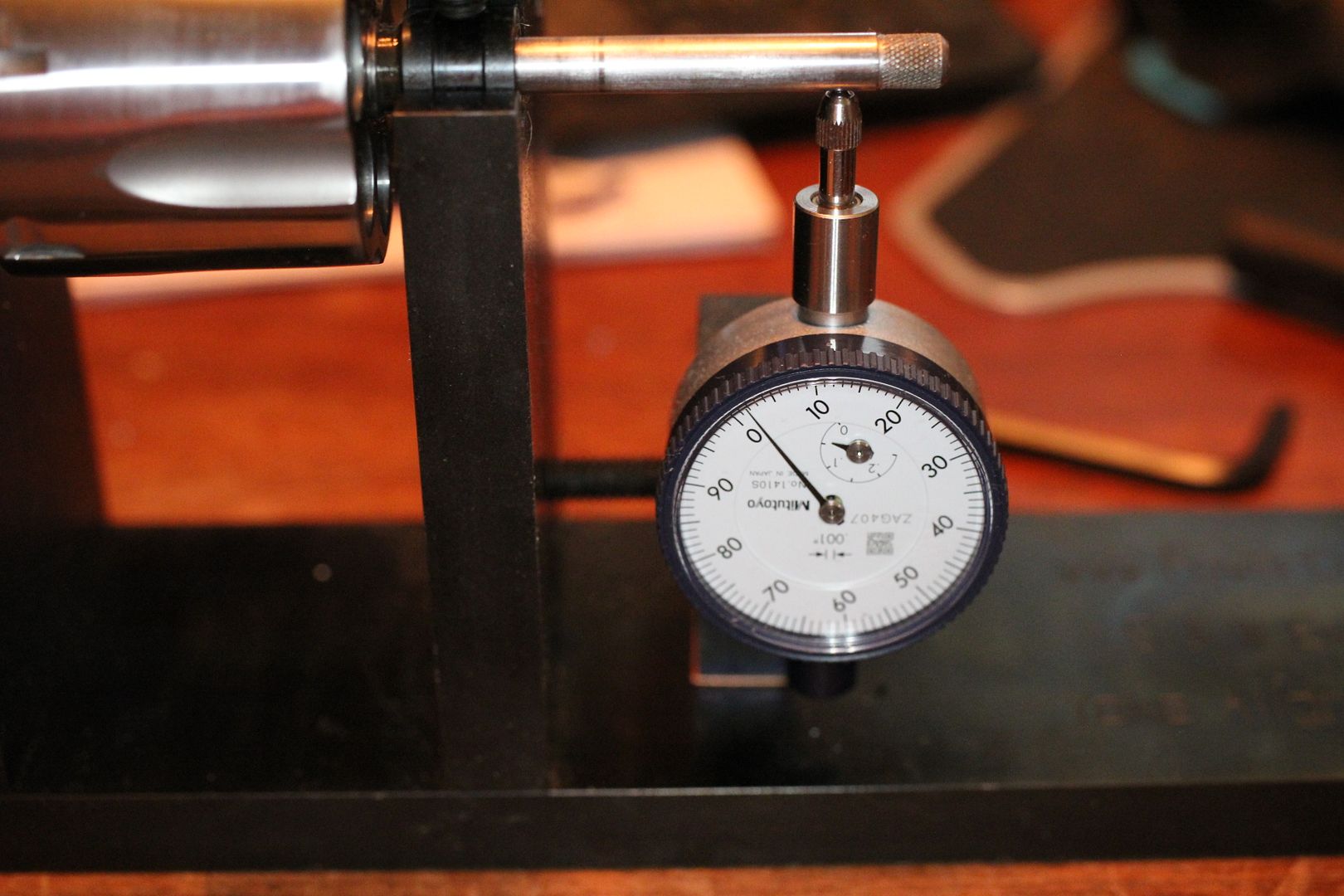

One more thing to check on the cylinder assembly. Put the thing back together and load it into the test fixture. And yep... a bit over 0.015" of runout in the extractor rod. That's no damn good at all.

After about 20 minutes or so of careful un-bending and spinning the thing we are now under 0.002 for runout. Good to go.

Over on the barrel, I fixed a divot on the underlug front bottom with some careful filing and a little buff with some abrasive tape. That rod you see in the bore is the pilot of an expanding mandrel to index a crowning cutter off of.

And now we have an 11° recessed crown.

Next up is prep for some media blasting. I need the mask off the barrel to protect the laser etching and to keep any media out of the locking bolt. Also going the install the yoke, sideplate and the three screws and bead blast that all together except the yoke barrel will also be masked. I will blast the stripped cylinder separately.

My blast cabinet is loaded with mixed media (glass beads + aluminum oxide). That stuff has too much tooth for this surface finish so I'm going to go with straight glass beads. I'll have to do this open air weather permitting with my Paasche hopper gun. I'll get on that perhaps tomorrow or Wednesday, that's all for now.

Cheers

Bill