Ahoy there Gents,

I've had this M1006 here for a while. It's been sitting on the shelf while we waited for the new sight set to come in which by chance was delivered yesterday. Seems Trijicon's canned delivery time for out of stock sight sets is 4-6 weeks so I'm pleasantly surprised when stuff shows up in 3 weeks

This was a recent acquisition by the owner. It had some issues and wasn't running right so it was sent to me for sorting out.

First order of business was to make some parts. The original recoil spring guide assembly was long gone and the gun was assembled with a Menck buffer. So a couple weeks ago I made these parts out of some hardened 416 stainless...

To replace that thing and restore to factory condition...

So now that the sights are in, I'd better get going on this before the owner gets riled up. The goal here is to restore appearance & function to factory++ condition.

Oh, and peaking of riled up... I don't mind some minor cleaning here and there now and again but... This piece is really REALLY dirty. Look, I don't expect every gun sent to me to be squeaky clean but at least have the courtesy to clean the thing before sending it to me. I know of some guys that add on some hefty charges for working on a dirty gun and some others that will outright refuse to work on a dirty gun.

Ok, enough bitchin', on with the show... So here's what we got...

Pretty yucky but I note the old version of the 23019 ejector, the trigger play spring is the two fingers version bent out of shape, sideplate is the 10699 part and seems to be ok

grip pin was missing so there was really nothing securing the rubber Hogue grips to the frame. The grips could be pulled off the back of the frame as an assembly

Bits of brass and a few copper brush bristles amongst the goo...

Expected to find a bunch of goo on the firing pin but it was actually ok...

Slide flats have been wiped on both sides. Cratering around the rollmark is sanded smooth...

And the laser etch lawyer warning on the starboard side is gone...

Yeah... there's this thing called a brass punch that will prevent one damaging stuff like this

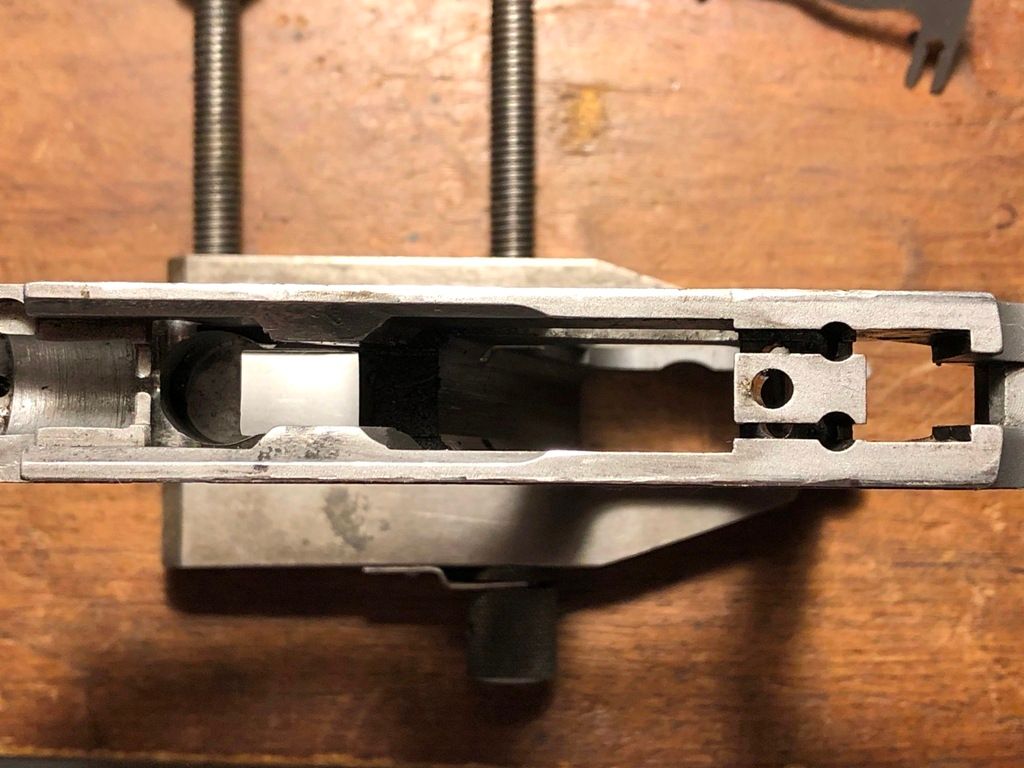

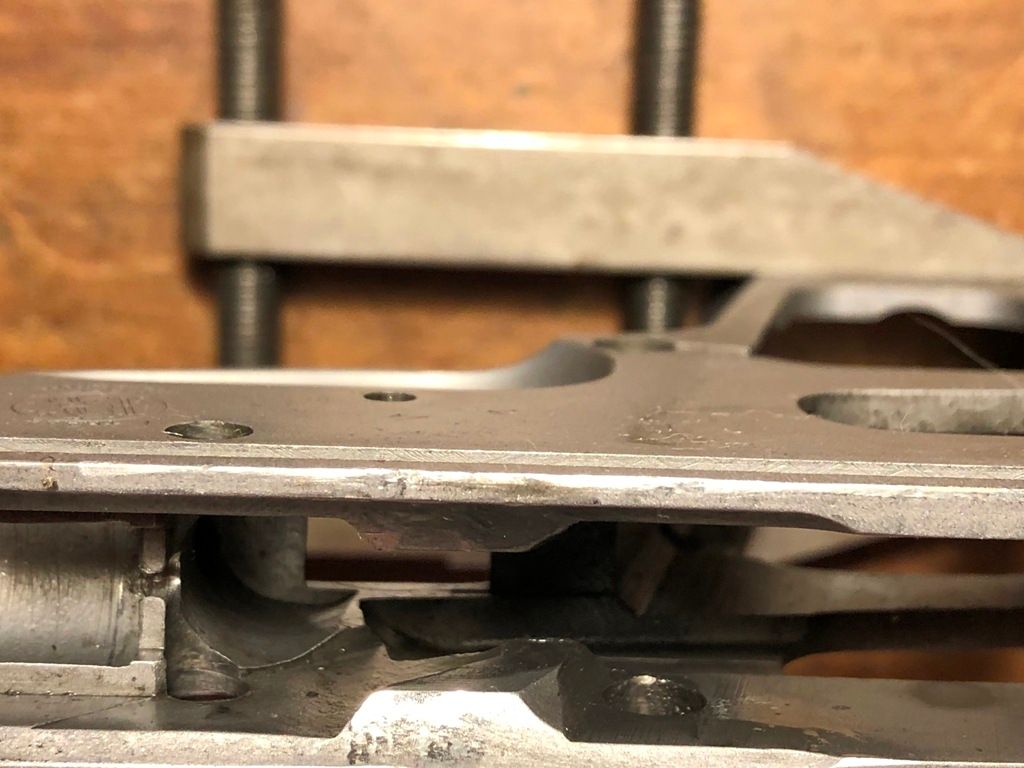

None of that stuff is especially shocking however, this is somewhat baffling... I find a lot of denting sort of random on the upper surface of the frame rails on both sides...

And here...

This dent here, among others...

Is peened such that its rolled over to the side of the rail...

The only thing I can think of is some ill conceived and poorly executed plan to peen the frame rails as some halfassed means to tighten the slide to frame fit.

There's nothing going on with the slide that might have caused this. I only see some slight burnishing caused by the few high points bent up on the frame rails. On occasion I've seen some damage on other guns on the right side rail top caused by a protruding extractor pin impinging on the frame rail or by a large burr protruding from that pin's bore hole but, this damage is not that. This was done intentionally by someone with a hammer or hammer & punch

pointless, utterly pointless

I'll carefully stone down the few high points to smooth things out after cleaning & degreasing but before blasting.

The slide is over by the lathe right now marinating in some Kroil in preparation for bumping off the old sights then that gets the degreaser treatment as well.

Bench & deadlift training tomorrow so I'll get to pulling the sights and some cleaning but not much more. Probably will be media blasting on Thursday.

More to follow.

Cheers

Bill