This is an assembly of my grips files --

REPAIR DAMAGED CHECKERING

We have seen checkering repaired by inletting a piece of wood and checkering it to blend with the original. To do a good job that way is beyond our skill and patience. I had a nice 1911 with a couple patches of checkering damaged or gouged out. Instead of inletting wood, I filled the areas with a batch of glue/sawdust mix, leveled it off and extended the checkering to cover the added area. Since then I have used this method on several 1911s, a 1905 and two Savage .45ACPs.

Here is what works for me, the glue fill and a little tool I made. I use clear epoxy glue, not the 5 minute kind, mixed with sawdust to make a paste thick enough to almost peak up when you pull out the stick you mix it with. You don't want it to run after you apply it. You can mix light wood sawdust with dark to get different final color. It is a good idea to do a couple of test batches to learn how it looks when it is set up and cut into. For a patch quarter inch square a couple of drops of the epoxy mixed with about twice as much sawdust is a good working amount. Mix glue then add sawdust.

Clean the area on the grip with alcohol or acetone and apply the mix. After it sets up, either overnite or under a light bulb for couple hours, carefully file it level with the surrounding checker area. Maybe protect around it with scotch tape while filing.

With the tool you make described below, you use the part without teeth as a guide, while you carefully hold it in line with the cut you are making. Little by little draw the cutting area of the tool over and into your now-hard patch material. Don't go too deep till you have established your overall recheckered area - then do all your cuts to match the depth of the original part.

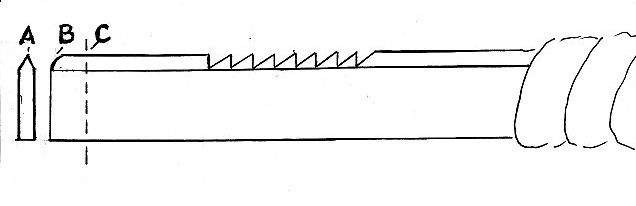

I made the tool from a strip of 1/16x3/8" spring steel because I have a huge amount of it. That might be a little thicker than it need be, but don't use too thin. One edge I filed a sort of knife edge of about 60 degrees to fit, more or less, the valleys between the checker diamonds. The sketch shows it at "A". The first 3/4" is left smooth, polished a little, and about 1/2" or a bit more has the teeth filed in about 1/16" apart, the far end is wrapped with tape for a handle. The working end "B" I rounded to protect from damaging the original grip. When your job is almost complete you can grind the end off square "C" to work into cuts that end abruptly as against the screw hole diamonds on a 1911.

The tool is so simple you will probably experiment with other configurations. Because it seemed right for me, I made the teeth to cut as shown but could be otherwise. I can imagine when it might make sense to have the teeth out on the end, with the guide section inboard.

The epoxy paste filler cuts much like hard wood. As with anything for the first time, it is good to check it all out on scrap to get a little experience before attacking a serious job. This applies as much about the final color match as it does to the checkering job workmanship. It is worthwhile knowing that epoxy is tolerant of most color additions that are not water-based. I have used various artists colors, leather dye, oil & acrylic colors to get a desired color in epoxy fills.

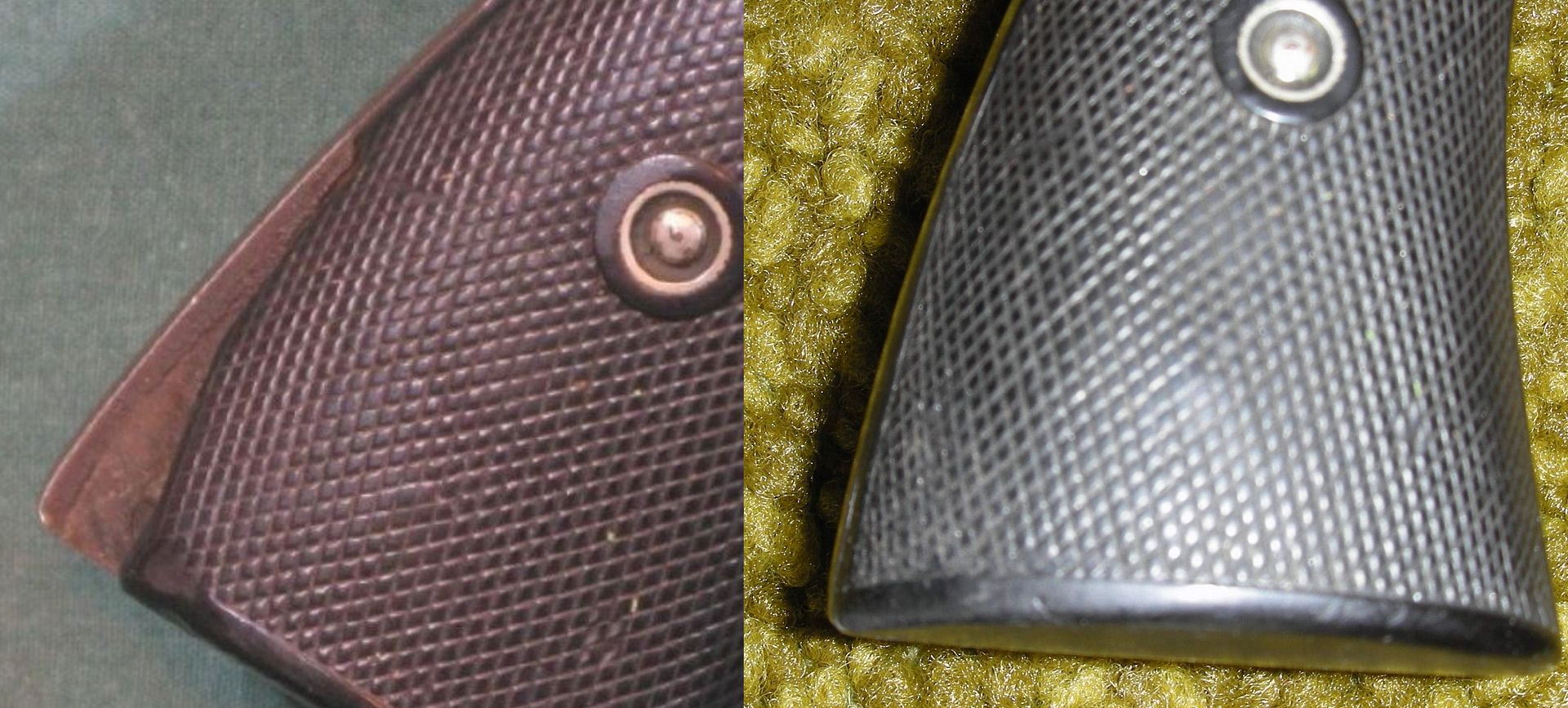

REPAIR HARD RUBBER GRIPS

I have repaired a lot of old colt grips using clear epoxy glue, not the 5 minute kind. For a simple crack I put the glue on the inside and let it fill the crack, wiping off what comes thru to the outside. If the cracked piece is loose I clamp it. Otherwise I would just settle for having the crack filled and the piece stabilized.

For worse problems with Colt grips, like a piece missing, cracked away from a corner, etc.: I fix them by cleaning and roughing up the broken surface, wax a piece of foil and place it on the gun frame. Use plent of wax to avoid glue running away or sticking. Put the grips on, position them to avoid run-off, then fill the missing area with epoxy mixed with lamp black or carbon black. It may be necessary to do more than one application to get a good fill.

After it hardens, like overnight, you re-shape the area and polish it. An invisible repair is possible. If your job extends into the checkered area you are on your own, depending on your skill and artistry.

After notes: Do a couple dry runs on scrap the get the hang of it before you risk messing up a job. Epoxy glue is very tolerant of mixing in color so long as it is not water based. Artist colors, powder and liquid, oil paints and acrylic work OK. Any additive weakens the glue but strength is not much of a factor in grip repair and only a little of the black is needed.

A New Sevice grip repair --

IVORY GRIPS

Hardly any ivory activity, it's tough enuf for its elephant job & later the best for gun grips. It is subject to corner abasion which can be repaired with an epoxy filler dyed to match. The example below had been dropped & a big piece broke along its grain lines & lost.

The added piece is ivory of good color match, with visible parting line. I might have made it less visible by adding color in the epoxy.

Mother of Pearl Grips

Like any other repair, the extent of damage can affect the quality of repair. The procedure is simple for the usual small knocked off corners. Basically I grind the surface of the break and glue in a piece of MOP and re-shape/polish it. An almost invisible repair is possible,

First need is a piece of MOP to glue in. Old pearl buttons are a good source. In big-city department store button shops I have found a huge variety. I've paid couple bucks per button, generally several on a card. Your grandma may have just what you want. Maybe internet auctions, yard sales.

Devcon 5 minute epoxy is best. It is water-transparent when it sets up. The slow one has a yellow tinge. With a reasonably good fit, the joint can be invisible - you see thru transparent glue.

An accomplishment is a pair of S&W N frame MOPs, damaged. The curved part at the top was badly chipped away with some missing. I found a big old pearl button, the kind with a thread tab on the back and no thru-hole. I carefully ground away a good fit to the grip and to the gun and epoxied it in place. It defies detection as a repair.

Pair of SAA grips I bought for $125 with corners broke off & missing - taking half of a horn & ear. I added the missing MOP & then added the horn with a thin piece of MOP.

On the Gun

WOOD GRIPS

Mostly limited to sharpen worn checkering as discussed above. This shows how it upgrades a guh refinish.

To illustrate the possibility of total re-surfacing a grip, this was my fix to a bad finish to someone's sound repair.. I cleaned the surface & added about 1/8" paste of epoxy & sawdust mix, made a new surface then checkered.

The finish I apply to wood chekering is clear epoxy thinned with alcohol enuf to soak in & almost disappear, for its added strength ---->