|

|

|

10-21-2018, 10:42 AM

|

|

SWCA Member

|

|

|

Join Date: Dec 2006

Location: NW Florida

Posts: 2,243

Likes: 6,359

Liked 3,414 Times in 583 Posts

|

|

Gas Check Bullets ?

Gas Check Bullets ?

I have been reloading for about 30 years but have never used gas check bullets. I understand why you use them but, how do you construct them. Is it part of the molding process or is the gas check applied after that process?

I was at the range last Friday with an old (rehabbed circa 1900) Winchester 1894 shooting 38-55 loads that I put together using dia. .378 cast lead bullets. Could not hit the broad side of a barn. So, I figured that she has a bit of wear in the barrel and went to Midway USA and found some .380 gas check bullets. Would like your feedback and suggestions on how to construct the bullets.

|

10-21-2018, 11:04 AM

|

|

Member

|

|

|

Join Date: Feb 2015

Location: NC

Posts: 4,753

Likes: 3,555

Liked 12,667 Times in 3,374 Posts

|

|

Gas checks are crimped on the base of a bullet designed to accept a gas check as the bullet is forced through the sizing die on the lubri-sizer. The rim of the gas check is a bit thicker than the base and is crimped on the base of the bullet when the outside of the rim is sized to the bullet diameter.

However… a gas check may not solve issues created by an over sized bore. The bullet needs to be able to obturate quickly to seal the bore and ideally a cast bullet will be about .001 to .002 over bore diameter, so it helps to slug your bore and then choose a bullet accordingly, specially in a .38-55 as the bore diameters varied a lot - from around .377" to .382".

You also need to select a bullet alloy that is hard enough to withstand the pressure of the load, but still soft enough to obturate quickly in the bore.

If you've got a small bore diameter, you may still have a fairly large throat diameter, and that poses challenges as a large and long throat may result in gas cutting before the bullet ever reaches the bore. In that case a chamber cast and selecting a bullet that is just small enough to allow the round to chamber easily is the way to go, even though it will be over size to the bore. Just develop your loads accordingly.

Alloy wise, I'd start with something close to Lyman Number 2 alloy. Nine pounds of clip on wheel weights and one pound of 50/50 bar solder will get you very close to Lyman Number 2 with about 5% tin and 3% antimony.

-----

Most likely a .378" bullet is under bore size and a .380 to .382 diameter may be needed.

If you have a soft lead bullet in the .375 to .380 range tap it a bit on the ends to flatten and expand it a bit, and the tap it to start it and then push it through the bore. A .36 caliber ball for a cap and ball revolver also works well and is the easiest way to accomplish it. Just flatten it slightly, start it in the bore, push it through, then measure the land and groove diameters. A soft bullet style fishing weight also works great, if it's close in diameter and soft lead.

If you find you have a .379" bore in a .38-55 (common for that era), I'd recommend a .381" bullet. You may or may not need a has check. If you're staying with older factory black powder velocities around 1300 fps no gas check should ever be needed. Even if you approach smokeless powder velocities around 1600-1700 fps you may not need a gas check if you've got the alloy and bullet diameter right. I've pushed the Lyman 250 gr #375248 bullet (a plain based bullet to 1600 fps with no issues.

Last edited by BB57; 10-21-2018 at 11:25 AM.

|

|

The Following 5 Users Like Post:

|

|

10-21-2018, 11:19 AM

|

|

Member

|

|

|

Join Date: Oct 2015

Location: Southern NJ

Posts: 4,684

Likes: 19,020

Liked 4,190 Times in 1,865 Posts

|

|

BB57 offers great advice,but I need to add one item. Not all molds cast bullets that will accept gas checks. Typically, gas check molds have a GC following the mold number, but not all! Check both your mold or bullets cast from it, looking for the base of the bullet to be slightly rebated (smaller in diameter) than the driving bands.

__________________

Judge control not gun control!

Last edited by lrrifleman; 10-21-2018 at 11:26 AM.

|

|

The Following User Likes This Post:

|

|

10-21-2018, 12:28 PM

|

|

SWCA Member

|

|

|

Join Date: Dec 2006

Location: NW Florida

Posts: 2,243

Likes: 6,359

Liked 3,414 Times in 583 Posts

|

|

Data

Data

Outstanding, just the feedback I was looking for. I will slug the bore as a start, agree that .378 is likely under size. I am having the same issues with my Winchester 25-35 and the .257 bullet (rifle is circa 1904). As an aside; I have a Winchester antique bullet mold in 38-55, might try my hand at casting

a few bullets. Thank you for the info.

|

10-21-2018, 01:10 PM

|

|

SWCA Member

|

|

|

Join Date: Jul 2005

Location: Indiana

Posts: 11,953

Likes: 10,136

Liked 10,122 Times in 4,797 Posts

|

|

Just remember, with cast bullets bigger is almost always better. Donít be afraid of bullets a couple thousandths larger than your groove diameter. If the loaded rounds chamber readily, the bullet will safely squeeze down to make a nice, tight seal. Likewise, an excessively hard alloy is not your friend. I doubt seriously a gas check will be needed in your .38-55. I use them in my .308s and .30-06s and Iím just about sure they are unnecessary at the velocities I load for - 1500-1700 FPS.

|

10-21-2018, 05:03 PM

|

|

Member

|

|

|

Join Date: Jun 2016

Location: for now ,Texas

Posts: 2,741

Likes: 186

Liked 3,300 Times in 1,525 Posts

|

|

I kind of had the same problem with my Marlin 336 in 30-30 , micro groove barrel . I tried bullets sized .309 , had mediocre accuracy . I measured the case neck size of a loaded round . Then measured the neck size of that same round after it had been fired , but not deprimed or resized . I discovered a 2 thousandths difference . I added that difference to the size of the cast bullet and came up with .311 . Now it is a tack driver . You might try this to help determine proper cast bullet size you need . Gas checks are not the answer to your problem . Hope this helps , Regards, Paul

BTW : I have a 94 Winchester , 38-55 made in 1897 . I cast and size bullets to .379 . I tried larger and they would not chamber . I use a LEE Mold that will throw cast bullets to .381 . Those bullets are accurate .

Last edited by cowboy4evr; 10-21-2018 at 05:09 PM.

|

10-21-2018, 07:09 PM

|

|

Member

|

|

|

Join Date: Aug 2005

Posts: 7,581

Likes: 4

Liked 8,931 Times in 4,140 Posts

|

|

No need to slug a bore; use the largest diameter bullet that allow a loaded cartridge to chamber without difficulty. Might be hard to get the right diameter bullet without casting it yourself and could require a custom mould if you have any interest in accuracy. Almost always, if you have good bullet fit, the softest alloy that will not lead at your intended velocity will provide best accuracy.

As someone already mentioned, .38-55 guns are notorious for having bores of varying diameters, but I think the ones manufactured in recent years are around .378"-.379".

|

10-21-2018, 10:30 PM

|

|

Member

|

|

|

Join Date: Feb 2015

Location: NC

Posts: 4,753

Likes: 3,555

Liked 12,667 Times in 3,374 Posts

|

|

Quote:

Originally Posted by M29since14

Just remember, with cast bullets bigger is almost always better. Donít be afraid of bullets a couple thousandths larger than your groove diameter. If the loaded rounds chamber readily, the bullet will safely squeeze down to make a nice, tight seal. Likewise, an excessively hard alloy is not your friend.../

|

I agree.

Winchester took an interesting approach when it developed the .375 Winchester for their Big Bore 94. It's essentially a more modern variant of the .38-55 operating at much higher pressures, much like a .357 Magnum versus a .38 Special.

However, where S&W used a .125" longer case for the much higher pressure .357 Magnum to prevent it from being chambered in the shorter .38 Special chamber, Winchester had some maximum length constraints that prevented that approach.

What Winchester did was:

1. Reduce the bore diameter to an honest .375" in the .375 Winchester, rather than the .377 to .380 bore diameters used in the older .38-55s;

2. Reduce the case overall length of the .375 Win to 2.020", compared to the traditional 2.125" length of the .38-55;

3. Shorten their modern .38-55 brass to 2.080"; and

4, Increase the cartridge overall length for the .375 Win chamber to 2.560", compared to 2.510" for the .38-55, to provide for a longer throat.

5. Winchester also reduce the bore in their modern .38-55s to .375".

What his all meant at the time it was introduced was that the new Big Bore 94 in .375 Winchester had a longer throated chamber compared to the .38-55, despite having a shorter case.

Winchester obviously understood that .375 Win ammunition availability might be a bit spotty initially (which it was, in fact to the extent that it was all but unobtainable the first couple years which did not help the new round get off to a good start), and may not be available in some locations.

Consequently, the long chamber and throat in the Big Bore 94s was intended (but not advertised) to allow for Big Bore 94 shooters who would inevitably shoot .38-55 ammo in their Big Bore 94 .375 Win carbines. The large chamber and throat dimensions ensured that even the older, longer 2.125" .38-55 case would fit in the .375 Win chamber with enough room to release the .38-55 bullet which would then get sized down in the .375 bore. That would increase pressure relative to the usual 30,000 CUP for the .38-55, but would still be under the 52,000 CUP pressure for the .375 Winchester.

Winchester also anticipated that .375 Win ammunition might find it's way into older .38-55s. In this case, the smaller .375" bullet would safely exit through the larger .377"-.380" bore without blowing up the rifle or carbine, despite the 22,000 CUP higher pressure of the .375 Win.

For modern .38-55's with .375" bores, Winchester was apparently confident that the regular Model 94 action would not fail at .375 Win pressures - although the long term effects are a little harder to determine. There have in fact been a few people out there converting the standard Model 94 carbine to .375 Win, and I have not heard of any blowing up (yet), but Winchester beefed up the receivers on the Big Bore 94s so it isn't something I'd recommend.

----

I have an early low 4 digit serial number Big Bore 94, and the chamber and throat are indeed generous. However, I can't speak for later Big Bore 94s, so the disclaimer is that if you own one you need to get a chamber cast made before you can determine whether it's safe to shoot .38-55 in your particular Big Bore 94.

.375 Win has become a comparatively rare cartridge that only sees occasional short production runs. .375 Win brass is also hard to find and only occasionally produced and jacketed 200 to 250 gr round nose or flat nose .375" bullets are hard to find as well.

The .375 Win will launch a 250-255 gr bullet at 1900 fps, a 220 grain bullet at 2100 fps, and a 200 gr bullet at 2400 fps, but that is well under the design velocity of the bullets intended for the .375" magnum rounds, so they are not any help.

What that means is that a lot of .375 Win owners end up looking at handloading cast bullets to .38-55 velocities. That can be a bit of a challenge as the large chamber and throat dimensions call for a bullet that is well over the .375" bore diameter in order to reduce leading.

Short 2.080" .38-55 brass can be used, but during the great component shorter several years ago I had about 400 new .30-30 cases that I fire formed in the .375 Win chamber using 8 grains of Unique under a nearly full case of Cream of Wheat, help in place with a small wad of toilet paper. When fired vertically, it produced very nice brass with even case mouths - and a gentle rain of slightly burnt cream of wheat and singed toilet paper. The .30-30 brass fireforms to just short of the nominal 2.020" case length.

I did some water volume and weight comparisons of Winchester .375 Win brass with Winchester .30-30 brass and found that while there was some over lap between .375 Win and .30-30 brass, the .375 case walls are indeed thicker on average. Consequently, I limit the loads I fire in my .30-30>.375 Win brass to the 42,000 psi limit for .30-30 Winchester.

|

|

The Following 2 Users Like Post:

|

|

10-21-2018, 10:41 PM

|

|

Member

|

|

|

Join Date: Jun 2016

Location: for now ,Texas

Posts: 2,741

Likes: 186

Liked 3,300 Times in 1,525 Posts

|

|

About that Winchester mold . I have one as well . It cast really under size bullets . After doing some research about all I could come up with is that it was made that way so sizing the case neck wasn't necessary for a cowboy , hunter in the wilds and reloading . If cast from dead soft lead it was supposed to " slug up " in size to fit the rifle when fired and yet could be easily inserted into a primed and charged case easily . I don't know if this is true or not . So I'm just passing along what I have read in the past . I don't use the mold . I still am using my LEE mold with satisfaction . Paul

|

10-21-2018, 11:06 PM

|

|

Member

|

|

|

Join Date: Feb 2007

Location: SW MT

Posts: 6,734

Likes: 10,507

Liked 6,029 Times in 2,968 Posts

|

|

Quote:

Originally Posted by rockquarry

No need to slug a bore; use the largest diameter bullet that allow a loaded cartridge to chamber without difficulty. Might be hard to get the right diameter bullet without casting it yourself and could require a custom mould if you have any interest in accuracy. Almost always, if you have good bullet fit, the softest alloy that will not lead at your intended velocity will provide best accuracy.

As someone already mentioned, .38-55 guns are notorious for having bores of varying diameters, but I think the ones manufactured in recent years are around .378"-.379".

|

A good starting point would be to measure the ID of a fired case. Use a bullet of the nearest larger diameter to the 0.001".

__________________

Front sight and squeeze

|

10-22-2018, 01:26 AM

|

|

Member

|

|

|

Join Date: Jan 2018

Location: So. Illinois

Posts: 2,611

Likes: 1,399

Liked 3,339 Times in 1,433 Posts

|

|

If your mold drops bullets that are undersized for your bore, look up "How to Beagle a Mold". It's a technique developed by a guy named Beagle. You will learn how to coax larger diameter bullets out of a mold using aluminum tape between the block halves.

I gas check bullets in 22, 30, and 44 calibers. Basically, to do it you need a lubrisizer. But they can also be applied using Lee Push-Through sizing dies. Read-up on the CBA (Cast Bullet Association) Forum, or the Cast Boolits forum. Those guys will help you.

Last edited by max503; 10-22-2018 at 01:36 AM.

|

10-22-2018, 03:52 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,332 Times in 3,497 Posts

|

|

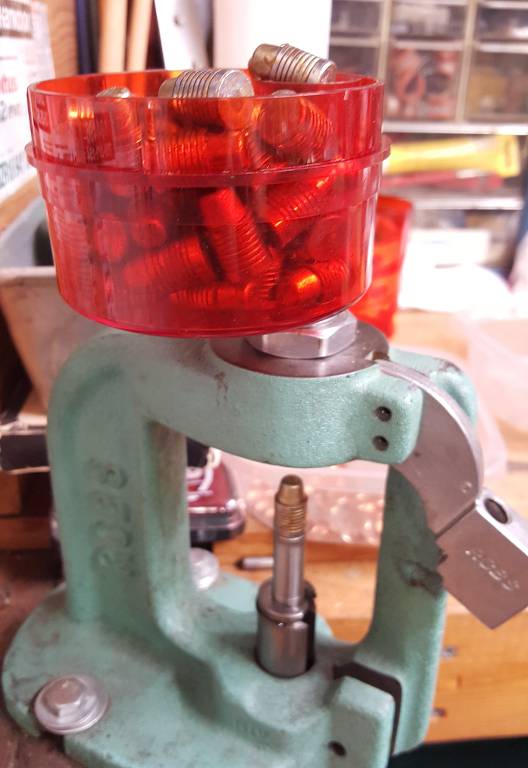

Adding gas checks to non-gas check bullets

Adding gas checks to non-gas check bullets

Concerning the application of gas checks to cast leads bullets. It's correct that bullets intended to have a gas check will have the recessed base for it.

But I had always been curious as the whether you could apply a gas check to a regular flat base cast bullet & have it work.

The situation arose when I purchased some bullets from a local caster at the gun show. Most of those bullets turned out to be of poor or "questionable value" once I sat down to handload them.

Besides being unsized (too large for my needs) they frequently had wrinkles & voids. Hateing to throw them away I sat the unused ones aside until I got this idea to try.

I found a partial package of Hornady gas checks at one LGS. Another LGS had a Lee .429" Sizing (Push-Thru) Kit. Both reasonably priced for this experiment.

.

.

.

First I ran the unsized bullets thru the sizer to have a uniform diameter to work with.

.

.

.

Next I sat the sized bullet on a gas check on the kit's punch that was installed in my RCBS JR3's ram.

.

.

.

Then I pressed the bullet/gas check into the kit's sizing die until it was fully inside. Next I inserted a .427" pin gage into the top of sizing die allowing it to sit on the bullet's nose.

.

.

Lastly I gave the exposed pin gage a hard wack with my wooden mallet & then pushed the bullet the rest of the way thru the sizer with a small wooden dowel.

The experiment was a success. The gas checks were firmly seated on the base & sized correctly. Next trip to the range showed they shot great & without the leading the non-gas checked bullets gave.

Yes it was extra work & added cost to those "questionable bullets" but I got to use them up, have some fun, & was able to answer my original question - it can be done.

.

.

.

__________________

Waiting for the break of day

Last edited by BLUEDOT37; 04-02-2024 at 09:51 PM.

Reason: .re-add lost PB pics

|

|

The Following 4 Users Like Post:

|

|

10-22-2018, 06:45 AM

|

|

Member

|

|

|

Join Date: Feb 2007

Location: Ohio

Posts: 1,467

Likes: 179

Liked 1,661 Times in 691 Posts

|

|

I'd do 3 things:

1. Like others have already said measure the brass thickness of the neck of your brass. Then measure the diameter of the neck of the spent brass.

brass thickness 2x - brass diameter ='s max bullet size.

Your bullet should be .001" under the "max" diameter.

2. Slug your bbl, if the bbl is wore to the point that the bore is larger than the max bullet diameter. Doesn't matter what you do, lead/cast bullets will always be a struggle in that firearm.

3. Cast your own bullets.

Mold Dc 379-250-rf - Lee Precision

Then powder coat them and size them to the max diameter. You don't need a gas check. I have no problem using cast bullets cast with nothing more than range scrap lead that were water dropped when cast (12bhn) in rifles without gc's up to the +/- 1700fps range. While not the greatest groups by any means they're good enough for plinking. Nothing more then 10-shot test targets @ 50yds with cast/pc'd bullets without gc's.

The other thing PC'ing a bullet will do is increase the nose diameter of the bullet which is a good thing when it comes to old/wore/oversized chambers & bbl's. The soft lead home cast bullets stand a better chance of sealing the older bbl's then the commercial hardcast bullets.

You can get setup for +/- $100 to cast and coat your own bullets for that 38-55. That's the cost of 200 bullets from midwayusa.

|

10-22-2018, 10:08 AM

|

|

Member

|

|

|

Join Date: Oct 2014

Location: Monroe cnty. Ohio

Posts: 6,950

Likes: 4,430

Liked 10,068 Times in 3,689 Posts

|

|

I have several old Winchester & Marlin lever actions. The one thing they all have in common is that they won't shoot jacketed

bullets worth a darn. This doesn't have anything to do with the

jacketed bullets except the factory standards are undersized for

the bores. I have a Win 25/20 that has a bore like a new dime.

To get it to shoot I use bullets as cast from a old Ideal mold. I'm

not hotroding so no gas check is needed. We use to shoot gas

checked 240hp in 44mag Ruger SBH, we were shooting full power

loads. Our S&Ws we used for target with WCs which don't require

GCs. So we went with JHPs for hunting loads and don't fool with

GCs anymore.

|

10-22-2018, 10:49 AM

|

|

Member

|

|

|

Join Date: Oct 2008

Location: Denver, CO

Posts: 1,813

Likes: 167

Liked 979 Times in 490 Posts

|

|

Maybe I missed something, but if you bought finished gas check bullets, the gas checks will already be on there. Just load and shoot.

Good luck with your classic.

|

10-23-2018, 05:05 PM

|

|

Member

|

|

|

Join Date: Feb 2015

Location: NC

Posts: 4,753

Likes: 3,555

Liked 12,667 Times in 3,374 Posts

|

|

Missouri bullet sells an affordable 245 gr .38-55 bullet, but it's only available in .379"

Missouri Bullet Company

Rimrock sells a 240 gr .38-55 bullet in sizes from .377 to .382". That downside is they cost about 2.5 times more.

TSH .38-55 240 gr. RNFP-FB 3LG per 100 in a plastic ammo box

Midway sells Hunter Supply 260 gr bullets that are sized .381 and in boxes of 500 they are down around $0.17each. They are designed for a gas check but can be shot without one.

If you are going to gas check them, you could size them to .380, .379, etc since you'll run them through a sizing die anyway.

I prefer heavier bullets in the .38-55 anyway, and 260 is about as light as I want to go.

Hunters Supply Hard Cast Bullets 38-55 WCF (381 - MPN: 0138126041

|

10-25-2018, 12:46 PM

|

|

Member

|

|

|

Join Date: Mar 2011

Location: North Texas prairie

Posts: 1,189

Likes: 2,545

Liked 2,111 Times in 665 Posts

|

|

Quote:

Originally Posted by BLUEDOT37

But I had always been curious as the whether you could apply a gas check to a regular flat base cast bullet & have it work.

|

I don't know about flat base bullets, but I've had success with gas checks and some bevel base cast bullets.

I use a Lyman sizer with the gas check tool. Performance seems on par with standard gas checked bullets. Sorry, I don't have pictures of the operation (Yet).

__________________

I'm with her

|

10-25-2018, 01:49 PM

|

|

SWCA Member

|

|

|

Join Date: Feb 2005

Location: Cocoa Beach, Florida

Posts: 10,584

Likes: 3,072

Liked 22,574 Times in 5,847 Posts

|

|

Quote:

Originally Posted by BLUEDOT37

Concerning the application of gas checks to cast leads bullets. It's correct that bullets intended to have a gas check will have the recessed base for it.

But I had always been curious as the whether you could apply a gas check to a regular flat base cast bullet & have it work.

|

That is a lot of work your way.

ALL my molds are for plain base projectiles. However my 357 diameter bullets can get going pretty fast from a lever gun and the lightweight (350-450 grain) bullets for the 500s can get cooking from the 1" barrel.

I water quench the bullets that I expect to be driven at higher velocities. I have run 1700 FPS with no leading. I just get worried faster than that

So my solution is to gas check my plain base bullets

Pat Marlin makes a little device that lets you make gas checks from thin copper stock or even beer and soda cans. . . Just do not empty the beer cans just before hand loading or going shooting

These gas checks are very thin (.014" max) and easily seat on the plain base projectiles.

Once you shell out that initial cash for the Check Maker you will never spend another penny on gas checks

|

|

Posting Rules

Posting Rules

|

|

|

|

|