You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

vibrate or tumble

- Thread starter Jaco1234

- Start date

Register to hide this ad

I use the 18# vibrating tumbler from Harbor freight. Been using it for years as you can clean 500+ Pistol brass at once. I also have an old Lyman small vibrating unit and the original thumbler unit. Use the Harbor freight one the most with walnut hulls. I have a “home-made” SS pin wet tumbler that I mostly use for 223 shells. It’s a process to clean rinse and and dry.

Ivan the Butcher

Member

With Corn Cobb or Walnut Shell, dry vibrate or tumble doesn't really matter. Don't over load and change out the media when dirty! (If the media is too filthy, you get a really shiny shade of green/gray!)

I went to wet with SS pins. It took black powder stained black brass and looks like brand new in 3-4 hours. Once fired to new in 1-1.5. Don't forget the dish soap and citric acid (Lema-Shine)!

The problem with wet tumbled brass is the inside of the mouth is so clean, it can stick on the expander/powder funnel in straight wall calibers. I personally don't mind, but it is a little more effort. At 400-500 per hour, it really adds up in tired!

Ivan

I went to wet with SS pins. It took black powder stained black brass and looks like brand new in 3-4 hours. Once fired to new in 1-1.5. Don't forget the dish soap and citric acid (Lema-Shine)!

The problem with wet tumbled brass is the inside of the mouth is so clean, it can stick on the expander/powder funnel in straight wall calibers. I personally don't mind, but it is a little more effort. At 400-500 per hour, it really adds up in tired!

Ivan

Don’t over think it, they all work. My complaint with the HF is cheap material. The center shaft is made from poor quality metal so threads wear away where the wing nut attaches. Since I use it almost weekly they only last a few years. I can extend that by adding washers so the wing nut finds new threads. Since HF is only a few miles away it’s easier to just buy a new one. Tried to replace the threaded rod with a new one but never succeeded.

- Joined

- Apr 29, 2012

- Messages

- 4,577

- Reaction score

- 7,764

After 40 years of vibrating I went wet. I like it much better. The Harbor Freight unit works fine though you may find the capacity lacking if you have large brass and/or are looking for high production. Even the two drum edition only holds a little over 100 .41 Magnum cases in total. That works for me. It's much quieter than the vibrator. Done in two hours. Then let it lay out and dry.

You'll need a magnet....

Edit: I misstated the capacity on this. Each drum holds 100 .41 magnum cases. I just loaded it up...

You'll need a magnet....

Edit: I misstated the capacity on this. Each drum holds 100 .41 magnum cases. I just loaded it up...

Last edited:

AManWearingAHat

Member

Wet tumble in stainless steel pins. The dust from vibratory polishing is awful and it only cleans the outside of the case. 3 Hours in a wet tumbler and the cases come out looking brand new inside and out.

ArchAngelCD

Moderator, SWCA Member, Absent Comrade

I have never had a problem with using a vibrating cleaner. I use a Berry's 400 Vibrating Tumbler but in green from Cabela's. They are available from Berry's of course and Cabela's, Kempf, Brownells, Sinclair and a few others.

I have found crushed walnut shells clean best while corn cob seems to polish the brass best. I run a 50/50 mix of the two and that works fine.

Like said above, when dry tumbling it doesn't matter if you use a vibrating or rotating machine.

Good luck with your choice.

I have found crushed walnut shells clean best while corn cob seems to polish the brass best. I run a 50/50 mix of the two and that works fine.

Like said above, when dry tumbling it doesn't matter if you use a vibrating or rotating machine.

Good luck with your choice.

I have hot buttered popcorn for the 'monthly' show. Walnut shells for me!

- Joined

- Apr 21, 2021

- Messages

- 4,837

- Reaction score

- 8,216

Have been using a vibratory one for about 30 years? Friend told me about adding rice to mix of walnut shell, corn cob and polishing liquid. Works very well. Let it run over night which reminds me have to go turn tumbler off and get cases out.

I follow a couple of unlimited F-Class shooters, the 1000-yard shooter. National champs and such. They said they don't bother to "clean" their brass, just wipe it off an reload it. One also asked a bunch of competitors how they resize their brass--none neck size anymore. Full length shoulder bumps is all they do.

Kind of makes me wonder how much time and effort I'm wasting in my reloading process.

Kind of makes me wonder how much time and effort I'm wasting in my reloading process.

Maybe it’s just the kid in me but I get a happy feeling every time I open up a box of new Starline brass to load. Well wet tumbling with pins gives me that same feeling even with range pick up brass. It all looks brand new and I like that.

gwpercle

Member

I have both and used both .

The rotating tumbler , Thumbler model B , I've had the longest . I use dry treated walnut shell media but in the Thumbler it is made to polish rocks with water and can be used with water and whatever else is the rage . I don't care for water or pins they have their own problems .

I prefer the dry media and I find the vibrating polisher easier to load / unload and faster working but you need to use a commerical treated nut shell polishing media ... not something from the pet shop or hardware store ... Midway USA sells a good media under their brand name ( Frankford Arsenal ?) Treated Walnut Hull ...be sure and get "Treated" it will clean , polish and leave a non-tarnishing protection on the cases . Water cleaning leaves them wet and they will soon tarnish if not treated .

I find the vibrating machine's large open bowl easier to get the cases out of . Treated media isn't dusty as some keep whining about so don't use pet store stuff that's not made for case polishing .

Hint ... Buy a BIG one ... they do a better job when cases aren't crowded and can circulate freely through the media .

I been polishing since 1967 and the above advice is from experience !

I like clean and shiny brass too .

Gary

The rotating tumbler , Thumbler model B , I've had the longest . I use dry treated walnut shell media but in the Thumbler it is made to polish rocks with water and can be used with water and whatever else is the rage . I don't care for water or pins they have their own problems .

I prefer the dry media and I find the vibrating polisher easier to load / unload and faster working but you need to use a commerical treated nut shell polishing media ... not something from the pet shop or hardware store ... Midway USA sells a good media under their brand name ( Frankford Arsenal ?) Treated Walnut Hull ...be sure and get "Treated" it will clean , polish and leave a non-tarnishing protection on the cases . Water cleaning leaves them wet and they will soon tarnish if not treated .

I find the vibrating machine's large open bowl easier to get the cases out of . Treated media isn't dusty as some keep whining about so don't use pet store stuff that's not made for case polishing .

Hint ... Buy a BIG one ... they do a better job when cases aren't crowded and can circulate freely through the media .

I been polishing since 1967 and the above advice is from experience !

I like clean and shiny brass too .

Gary

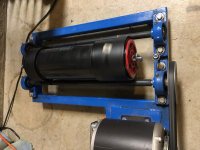

I use both but my rotary is the first I normally grab (I use a HF dual drum rotary with custom drums). For me and my media, my rotary is quieter and works slightly faster than my wobbler (Lyman 1200). I don't often tumble to a glossy shine and I have a mix of corn cob blast media, 14-20, and hard resin pyramids, which cleans fast but leaves a good finish. Last time I used my wobbler was with some 45 ACP brass which I wanted shiny (easy to find in the dirt, pebbles, etc. at the "range"). I used straight corn cob blast media with a dollop of auto wax and ran the wobbler a bit longer for a shine...

I must be extra lucky because the first HF rotary I bought lasted 14 years until I "improved" it (have no idea how many hours worked). Got a dual drum unit and still use it, 10 years later. I made larger "drums" and have no problem with quantity of cases tumbled. Just like any tool if it is kept clean and oiled it will last a very long time (haven't even had to replace a belt)...

I must be extra lucky because the first HF rotary I bought lasted 14 years until I "improved" it (have no idea how many hours worked). Got a dual drum unit and still use it, 10 years later. I made larger "drums" and have no problem with quantity of cases tumbled. Just like any tool if it is kept clean and oiled it will last a very long time (haven't even had to replace a belt)...

Last edited:

Baltimoreed11754

Member

Dry media in a vibrator. Don’t overload it. Brass doesn’t polish brass, just kind of scours it. It’ll be clean but dull.

Which is better for cleaning up brass?

Has anyone use any of the harbor freight devices?

Get a large HF vibratory tumbler and get box of Harbor Freight crushed walnut sandblast abrasive #12 grit.

I pretreat mine with Nufinish, but there are lots of other additives that will work. Used dryer sheets cut into fourths collect a lot of dirt.

I like the wet method. I just build this for tumbling small batches. Made out of a 12" piece of leftover 4" ABS, an end cap, a connector, and a test plug. Used a piece of 1 1/2" PVC for the paddles.

Attachments

Similar threads

- Replies

- 26

- Views

- 1K

- Replies

- 17

- Views

- 708