|

|

|

01-21-2015, 09:59 PM

|

|

US Veteran

|

|

|

Join Date: Mar 2008

Location: Illinois

Posts: 1,887

Likes: 22

Liked 1,355 Times in 451 Posts

|

|

Smith & Wesson Quality...New Forged Parts

Smith & Wesson Quality...New Forged Parts

This afternoon my LGS got in a new 686 Plus with a 3" barrel. I looked at one of these a couple years ago and was not impressed with the fit and finish. The one today though was beautiful, even with the dreaded lock and MIM parts. I think S&W must be stepping up their quality control as of late. I usually prefer the older dash revolvers but have to say the fit and finish was as good as any stainless Smith I've ever owned. Even the action was glass smooth with perfect timing. I think a lot has to do with whoever assembled the revolver, but whoever did this particular one had pride in what he/she was doing. I may just go back and buy it.

Last edited by mag318; 01-22-2015 at 08:42 AM.

|

|

The Following 10 Users Like Post:

|

|

01-21-2015, 11:14 PM

|

|

US Veteran

|

|

|

Join Date: Mar 2008

Location: Illinois

Posts: 1,887

Likes: 22

Liked 1,355 Times in 451 Posts

|

|

I was just perusing Davidsons "Gallery of Guns" site and they are showing the 686 Plus with forged hammers and triggers. Is S&W moving away from the MIM parts, this is the first I've heard of this.

|

|

The Following User Likes This Post:

|

|

01-22-2015, 12:56 AM

|

|

Member

|

|

|

Join Date: Jun 2011

Location: The Midwest

Posts: 1,977

Likes: 4,273

Liked 1,275 Times in 810 Posts

|

|

They still make a good revolver. But, like anything else sometimes you have to send one back. If you do have one with an issue they do make it right.

|

|

The Following 3 Users Like Post:

|

|

01-23-2015, 04:04 AM

|

|

Member

|

|

|

Join Date: Aug 2012

Location: US of A

Posts: 2,210

Likes: 7,002

Liked 2,483 Times in 1,147 Posts

|

|

Quote:

Originally Posted by mag318

I was just perusing Davidsons "Gallery of Guns" site and they are showing the 686 Plus with forged hammers and triggers. Is S&W moving away from the MIM parts, this is the first I've heard of this.

|

Saw a new 686+ (fresh off the truck, even) with a long barrel yesterday. Regular MIM bits, with which I have zero issues. That revolver, whilst well timed, with good action, and well installed barrel, did have a new odd defect: The aft end of the forcing cone had impact damage from a rectangular object! Twice! Likely won't affect shootability, as that area shouldn't interact with the bullet, but it was not pretty. Had to have been done before installation. (It also had some horrible new style factory laminate wood stocks, with ".357" markings on either side. Ewww!)

I suspect there's somebody unhappy with their job...

Last edited by jaymoore; 01-23-2015 at 04:10 AM.

|

|

The Following User Likes This Post:

|

|

01-23-2015, 08:35 AM

|

|

Member

|

|

|

Join Date: May 2013

Location: Northern GA

Posts: 2,841

Likes: 2,025

Liked 4,843 Times in 1,479 Posts

|

|

Performance Center guns are often forged, with some dealer exclusives and Pro Series guns being flash chromed MIM.

|

01-23-2015, 08:39 AM

|

|

US Veteran

|

|

|

Join Date: Mar 2008

Location: Illinois

Posts: 1,887

Likes: 22

Liked 1,355 Times in 451 Posts

|

|

Check out Davidsons "Gallery of Guns" they're showing 686s with forged hammers and triggers. At first I thought perhaps a distributors exclusive perhaps.

|

01-23-2015, 10:04 AM

|

|

Member

|

|

|

Join Date: Mar 2012

Posts: 5,831

Likes: 3,902

Liked 5,902 Times in 2,543 Posts

|

|

I don't believe S&W is using any forged hammers or triggers any longer, Performance Center or otherwise.

|

01-23-2015, 10:06 AM

|

|

US Veteran

|

|

|

Join Date: Nov 2013

Location: South Central Texas

Posts: 1,185

Likes: 2,688

Liked 1,114 Times in 501 Posts

|

|

Quality Control? Fixable but take note when buying new.

Quality Control? Fixable but take note when buying new.

I have owned my 686 4" since 1986 and have nothing but praise for the workmanship/milling that S&W put into their guns back then. HOWEVER...

That said, I just bought a new 642CT and found the quality was NOT what I expected. After shooting 50 rounds at the range and running caps for 200-300 rounds, I started getting a pronounced catch/lock on the trigger pull of this "brand new" revolver.

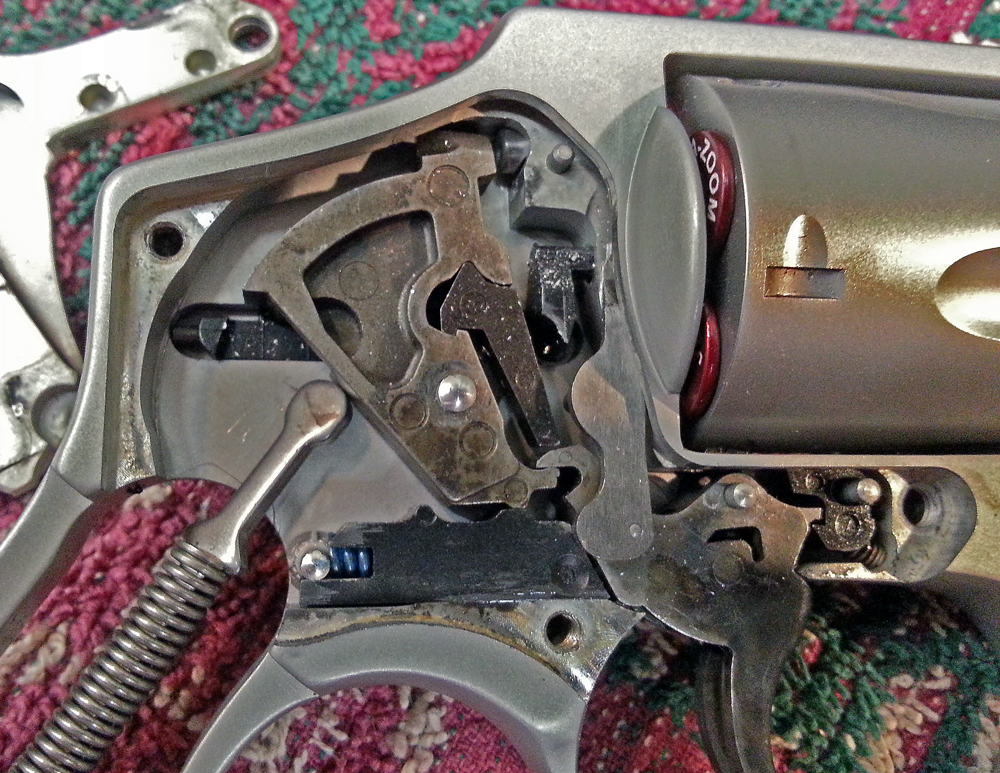

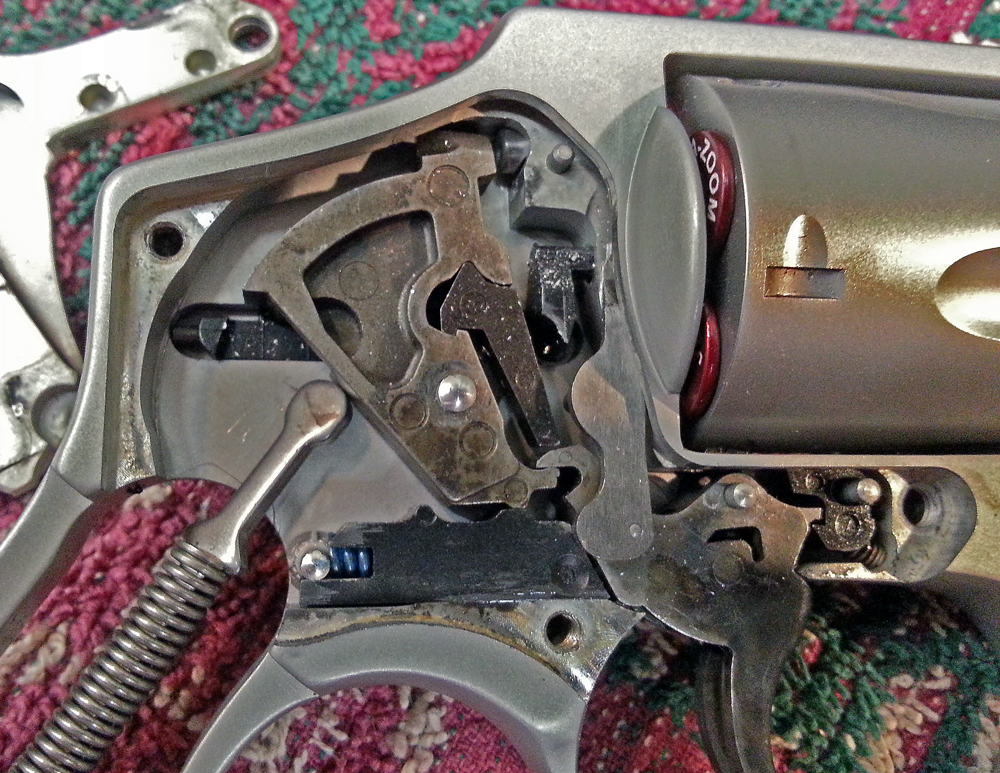

HOWEVER, being rather anal, I immediately decided to pull this "brand new" 642CT apart to find out what was going on. As you can see in the image below, there are plenty of shavings to go around. On closer inspection I found much in the way of rough edges on both milled and cast parts, but mostly on the cast pieces.

The Thumb activator/release cast piece had actually started to gouge the back of the frame's channel because of the castings elevated rough edges. Took some 600grit and a small rat-tail file and cleaned/smoothed some of the edges on the thumb release mechanism that was digging into the frame. Also cleaned up the trigger mechanism's working edges where I could see how the wear pattern was developing.

After the cleaning/fitting, I lubed everything with a touch of CLP. I think this did much more for ease of use than wearing out my finger snapping all those caps...

NOTE: If you look closely at the aft end of the thumb release, you can clearly see some of the casting edges standing proud. The backside of this piece had the same and was actively gouging the aluminum frame. Remember that I have had this gun less than one week.

|

|

The Following 4 Users Like Post:

|

|

01-24-2015, 11:04 AM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

All my guns are lubed with a moly paste or anti-sneeze. These two blends of moly has a higher percentage of moly in it.

Moly,

1.Eliminates all Wear,

Moly gets into the microscopic pores of the metal so there is no metal to metal contact, it's moly wearing against itself thus the wear is eliminated.

2.Reduces Friction,

Reduces all the stiction between the metal to metal moving parts. The action and trigger pull will be much smoother. Applied to the trigger sear it will lessen the trigger pull by up to 50% right away and more was it works into the pores of the metal.

3. Prevents Galling

4. Fights Corrosion

5. Stays were we apply/put it.

6. Does not attract dirt

Oil does nothing to reduce wear. My semi-auto's cycle faster and smoother. My bolt action rifles, the bolts operate more smoother. All the triggers feel awesome on the let off too. It actually makes us more accurate.

Last edited by BigBill; 01-24-2015 at 11:09 AM.

|

|

The Following 4 Users Like Post:

|

|

01-24-2015, 11:20 AM

|

|

Member

|

|

|

Join Date: Mar 2012

Posts: 5,831

Likes: 3,902

Liked 5,902 Times in 2,543 Posts

|

|

Quote:

Originally Posted by BigBill

All my guns are lubed with a moly paste or anti-sneeze...

|

Your guns have allergies?

I know I've asked before, Bill, but can you remind me: which specific brands do you favor?

|

|

The Following 7 Users Like Post:

|

|

01-24-2015, 11:35 AM

|

|

US Veteran

|

|

|

Join Date: Dec 2010

Location: Vermont

Posts: 1,214

Likes: 4,309

Liked 1,730 Times in 475 Posts

|

|

Quote:

Originally Posted by BigBill

All my guns are lubed with a moly paste or anti-sneeze. These two blends of moly has a higher percentage of moly in it.

|

Any way you could provide a link to these products?

Thanks!

|

|

The Following User Likes This Post:

|

|

01-24-2015, 11:19 PM

|

|

US Veteran

|

|

|

Join Date: Nov 2013

Location: South Central Texas

Posts: 1,185

Likes: 2,688

Liked 1,114 Times in 501 Posts

|

|

Jet Lube 50MP

Jet Lube 50MP

Quote:

Originally Posted by BigBill

Moly,

1.Eliminates all Wear,

Moly gets into the microscopic pores of the metal so there is no metal to metal contact, it's moly wearing against itself thus the wear is eliminated.

2.Reduces Friction,

Reduces all the stiction between the metal to metal moving parts. The action and trigger pull will be much smoother. Applied to the trigger sear it will lessen the trigger pull by up to 50% right away and more was it works into the pores of the metal.

3. Prevents Galling

4. Fights Corrosion

5. Stays were we apply/put it.

6. Does not attract dirt

Oil does nothing to reduce wear. My semi-auto's cycle faster and smoother. My bolt action rifles, the bolts operate more smoother. All the triggers feel awesome on the let off too. It actually makes us more accurate.

|

Bill, are you talking about Jet Lube MP50 paste? If so, I happen to have that critter. I use it on my telescope tracking gears, but will consider using in on my 642CT if this is the right stuff. It surely has the heat tolerance capacity.

|

|

The Following User Likes This Post:

|

|

01-25-2015, 11:29 AM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

There are many different brands of moly paste and moly anti seeze.

McMaster Carr industrial supply offers some.

I mainly use the TS-70 moly from T.S. Moly Lubricants Inc. it's roughly $25 a can.

Try the action first without it. Then remove the side plate, clean and apply moly on all the metal to metal contact parts. Put some moly on the trigger sear. Assemble the gun and run the action by hand till it works into the pores and it will free up. The action and trigger will be very smooth.

If the action remains tight you have too much moly in it. Don't forget to lube the cylinder studs, the swing out stud and the lever and turn star on the rear of the cylinder. And the cylinder release system too. The center lock engagement and the end of the extractor rod. The cylinder will open and close much smoother.

The moly test on a 1911 or any auto pistol.

Disassemble the pistol. Take the bare frame and empty slide and run them by hand. You will feel the drag, the roughness of the slide on the frame. Now apply the moly on the frame rails and slide grooves. Now run the two parts together. You will feel the moly doing its job as it gets smoother as we run the slide.

|

01-25-2015, 11:34 AM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

Quote:

Originally Posted by HorizontalMike

Bill, are you talking about Jet Lube MP50 paste? If so, I happen to have that critter. I use it on my telescope tracking gears, but will consider using in on my 642CT if this is the right stuff. It surely has the heat tolerance capacity.

|

HM, that will work. Bill

|

|

The Following User Likes This Post:

|

|

01-26-2015, 10:04 AM

|

|

US Veteran

|

|

|

Join Date: Nov 2013

Location: South Central Texas

Posts: 1,185

Likes: 2,688

Liked 1,114 Times in 501 Posts

|

|

Quote:

Originally Posted by BigBill

HM, that will work. Bill

|

Great! Thanks Bill!

FWIW, I had just completed a complete trigger job following a YouTube gunsmith, stoning all the appropriate contacts but using only gun oil. That got me through my CHL class without any major catches/glitches.

Scored a 230 on the range with the misses all at the 15yd line. THAT was only my second box of rounds through this revolver. I thought that was good considering this is my first J-frame, but I do realize that I need to work on my DA skills with this gun.

Sure love having a CT on this revolver. While I was not allowed to use it in the CHL class, I am sure it will help me, along with my snap-caps, to improve my DA skills without breaking the bank...

Will pull it apart today and apply the moly paste. Think I'll wear some nitrile gloves since I know how messy this can get.

Oh, and one last thing... Thanks again for the bricks of 22LR I got off of you last year. Looks like the 22LR drought is over this year, but at twice the price over last year!

|

01-27-2015, 12:54 AM

|

|

Member

|

|

|

Join Date: Jul 2012

Location: Illinois

Posts: 85

Likes: 492

Liked 66 Times in 33 Posts

|

|

Sad Situation

Sad Situation

Quote:

Originally Posted by HorizontalMike

I have owned my 686 4" since 1986 and have nothing but praise for the workmanship/milling that S&W put into their guns back then. HOWEVER...

That said, I just bought a new 642CT and found the quality was NOT what I expected. After shooting 50 rounds at the range and running caps for 200-300 rounds, I started getting a pronounced catch/lock on the trigger pull of this "brand new" revolver.

HOWEVER, being rather anal, I immediately decided to pull this "brand new" 642CT apart to find out what was going on. As you can see in the image below, there are plenty of shavings to go around. On closer inspection I found much in the way of rough edges on both milled and cast parts, but mostly on the cast pieces.

The Thumb activator/release cast piece had actually started to gouge the back of the frame's channel because of the castings elevated rough edges. Took some 600grit and a small rat-tail file and cleaned/smoothed some of the edges on the thumb release mechanism that was digging into the frame. Also cleaned up the trigger mechanism's working edges where I could see how the wear pattern was developing.

After the cleaning/fitting, I lubed everything with a touch of CLP. I think this did much more for ease of use than wearing out my finger snapping all those caps...

NOTE: If you look closely at the aft end of the thumb release, you can clearly see some of the casting edges standing proud. The backside of this piece had the same and was actively gouging the aluminum frame. Remember that I have had this gun less than one week.

|

It's truly sad to see that S&W's quality has gone down hill. Like it's been said here many times, they just don't make'em like they used to.

|

|

The Following User Likes This Post:

|

|

01-27-2015, 01:56 AM

|

|

Member

|

|

|

Join Date: Aug 2012

Location: US of A

Posts: 2,210

Likes: 7,002

Liked 2,483 Times in 1,147 Posts

|

|

I've seen much worse in new revolvers during the 1980s and '90s. But have seen better as well. Consistency has not been a S&W trait for some time! Probably sometime before WWII.

|

01-27-2015, 03:12 PM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

I have no problem with my new s&w n frames. Even the older ones and the newer ones are lubed with moly. Don't forget to run it by hand. The trigger sear will show the biggest improvement right away.

|

|

The Following 2 Users Like Post:

|

|

01-27-2015, 04:08 PM

|

|

US Veteran

|

|

|

Join Date: May 2009

Location: Arlington, Texas

Posts: 434

Likes: 150

Liked 582 Times in 218 Posts

|

|

[QUOTE=BigBill;138345291]Reduces all the stiction between the metal to metal moving parts.

Stiction - I guess that is another way of saying the parts don't move freely, or maybe the moly breaks up the glue adhering the parts together.

|

01-27-2015, 04:38 PM

|

|

Member

|

|

|

Join Date: Oct 2014

Location: South of Rochester , NY

Posts: 1,229

Likes: 77

Liked 1,342 Times in 559 Posts

|

|

Definition of STICTION from Webster's online dictionary

: the force required to cause one body in contact with another to begin to move

__________________

1st smiles,lies.Last,gunfire.

|

06-25-2017, 04:22 AM

|

|

Member

|

|

|

Join Date: Aug 2016

Posts: 131

Likes: 6

Liked 65 Times in 29 Posts

|

|

S&W quality.... these days not good.

S&W quality.... these days not good.

My brand new 629-6 was a disaster.

Forcing cone misfiled. right side cylinder gap .006 left side .009.

Muzzle crown marred by machine tool mark, burrs on lands.

Front sight blade miss milled off center.

Barrel canted off center, probably to get front sight blade centered.

Threaded hole in front of N frame for barrel not set 90% to frame.

Trigger sear negatively engaged.

I keep hearing how the new milling machinery is now near perfect.... well it's obvious no one is checking the parts to see if they are in spec.

Sent the gun back to S&W for warranty repair with detailed letter but only muzzle crown and trigger fixed.

Full fix would require a new barrel and frame and that they did not do.

I will be looking for an older S&W 629 or 29. New guns today are very hit and miss.

|

|

The Following User Likes This Post:

|

|

06-25-2017, 06:24 AM

|

|

Member

|

|

|

Join Date: Mar 2013

Location: Ohio

Posts: 363

Likes: 1,466

Liked 381 Times in 142 Posts

|

|

Use Moly!

Use Moly!

I use moly on all revolvers. I like the dry moly spray but paste works good also. Moly gets into the metal and stays put and has great anti friction properties. Does not attract dust or dirt and is not temperature sensitive.

|

|

The Following User Likes This Post:

|

|

06-25-2017, 08:33 AM

|

|

Member

|

|

|

Join Date: Jun 2016

Posts: 40

Likes: 72

Liked 30 Times in 16 Posts

|

|

Getting back to this Moly. Is this the same stuff they used to put on bullets and in barrels? That stuff used to collect moisture and turned into an acid and causes pitting if I remember right. Was OK if you were in a dry climate. Been a long time since then. I don't claim to know it all, and probably wrong. That's why the question

|

06-25-2017, 09:36 AM

|

|

US Veteran

|

|

|

Join Date: Aug 2006

Location: West Central IL

Posts: 22,789

Likes: 18,494

Liked 22,382 Times in 8,266 Posts

|

|

Many years ago, 1960's, I used a lot of molylube when working on the J71 Jet Engine for the B66 Bomber. We had to coat the teleflex cable (that controlled the extension and retraction of the exhaust nozzle). The heat from the exhaust would harden the molly and it would cake up badly and we often had to scrape it off with a tool. One of the reasons I never tried the molly bullet coating when they popular a few years ago.

__________________

H Richard

SWCA1967 SWHF244

|

06-25-2017, 10:46 AM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: MN

Posts: 1,833

Likes: 1,062

Liked 2,109 Times in 860 Posts

|

|

Quote:

Originally Posted by mag318

This afternoon my LGS got in a new 686 Plus with a 3" barrel. I looked at one of these a couple years ago and was not impressed with the fit and finish. The one today though was beautiful, even with the dreaded lock and MIM parts. I think S&W must be stepping up their quality control as of late. I usually prefer the older dash revolvers but have to say the fit and finish was as good as any stainless Smith I've ever owned. Even the action was glass smooth with perfect timing. I think a lot has to do with whoever assembled the revolver, but whoever did this particular one had pride in what he/she was doing. I may just go back and buy it.

|

I favor 3" revolvers and own a 586L comp from the performance center. It does have forged parts. A month or so ago I bought a new 3" 686+ Talo unfluted cylinder and the gun does have MIM parts. It was perfect in every test I gave it. As with every new gun, I removed the sideplate, cleaned out any debris, smoothed the rebound slide and frame, and installed a 15# rebound slide spring.

Although the performance center 568 is a tiny bit smoother (I believe that is due to the ribbed mainspring), the actions are both very close to identical. MIM or forged, lock or no lock, all I want is a smooth DA trigger and a gun that is timed and shoots where I intend the bullet to go.

|

|

The Following 3 Users Like Post:

|

|

06-25-2017, 07:38 PM

|

|

Member

|

|

|

Join Date: Mar 2013

Location: Ohio

Posts: 363

Likes: 1,466

Liked 381 Times in 142 Posts

|

|

Quote:

Originally Posted by jban357

Getting back to this Moly. Is this the same stuff they used to put on bullets and in barrels? That stuff used to collect moisture and turned into an acid and causes pitting if I remember right. Was OK if you were in a dry climate. Been a long time since then. I don't claim to know it all, and probably wrong. That's why the question

|

No expert here but I think it had to do with high temperatures generated in barrel to much heat for moly ?I know it's high temp range is 700-750 degrees,inside revolver not so much heat.

|

06-25-2017, 08:04 PM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

I use TS-70 moly paste or Antiseeze. T.S. Moly Lubricants

Moly fights corrosion.

Eliminates wear

Reduces friction

Prevents galling

On the worst triggers it can reduce the trigger pull by 50% right away and more as it works into the metal pores.

Any moly paste or antiseeze will do. It has a higher percentage of moly in it.

On pistols one must be aware about how much moly you lube it with. Just a little will do. Then run the action 50 to 100 times to burnish the moly into the metal pores. Try the feel of the empty slide on the frame. Then apply the moly. You can feel the difference.

|

06-25-2017, 08:14 PM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

The problem with moly coated bullets no one knew how to use them. Moly coated bullets burnish the moly into the metal pores in the barrel. Once the moly is in the pores most would clean the bore and remove the moly that's in the bore defeating the purpose we use moly for. I just swab the bore with a mop and leave the moly coating in the bore. Less wear in the bore, faster fps, more constant accuracy.

|

06-25-2017, 08:18 PM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

Quote:

Originally Posted by hassiman

My brand new 629-6 was a disaster.

Forcing cone misfiled. right side cylinder gap .006 left side .009.

Muzzle crown marred by machine tool mark, burrs on lands.

Front sight blade miss milled off center.

Barrel canted off center, probably to get front sight blade centered.

Threaded hole in front of N frame for barrel not set 90% to frame.

Trigger sear negatively engaged.

I keep hearing how the new milling machinery is now near perfect.... well it's obvious no one is checking the parts to see if they are in spec.

Sent the gun back to S&W for warranty repair with detailed letter but only muzzle crown and trigger fixed.

Full fix would require a new barrel and frame and that they did not do.

I will be looking for an older S&W 629 or 29. New guns today are very hit and miss. |

Today's machinery, CNC machinery is programmed by a human. So garbage in, garbage out sometimes. If it's not located correctly in the fixture then the machined off.

|

06-25-2017, 08:24 PM

|

|

Absent Comrade

|

|

|

Join Date: Jan 2011

Location: Planet earth

Posts: 13,869

Likes: 2,079

Liked 13,354 Times in 5,549 Posts

|

|

Fact, I purchased two new s&w revolvers with the mim & loc. A m58 and a m57. Both had different feeling triggers. One was smoother than the other. I applied moly to both trigger Sears. Now they both have the same smoothness. There's a big difference in accuracy with smoother triggers.

I lube every gun with moly. Every metal to metal moving part gets a little moly on it.

Last edited by BigBill; 06-25-2017 at 08:33 PM.

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

|

|

|

|