|

|

|

03-19-2017, 11:55 PM

|

|

Member

|

|

|

Join Date: Dec 2011

Location: CNY

Posts: 489

Likes: 62

Liked 520 Times in 210 Posts

|

|

TiN coating of MIM parts?

TiN coating of MIM parts?

Titanium nitride seems to be all the rage for racegun accents and glock barrels, but not in many other circles. Has anyone tried applying it to MIM parts?

Kuhnhausen complains about MIMs susceptibility to corrosion, and that is often one of the selling points of TiN, and given that its fairly cheap, I am surprised I haven't seen it pop up on any S&W guns.

Of course its gaudy hell but hey, if its smoother, harder, and more resistant to the elements... I figured someone would give it a try.

|

03-20-2017, 08:15 AM

|

|

Member

|

|

|

Join Date: Jun 2009

Location: CSRA

Posts: 2,125

Likes: 869

Liked 1,629 Times in 779 Posts

|

|

TiN is gaudy. The gold color looks OK on the few coated drill bits..

Not a color l would on one of my S&W revolvers.. MIM parts in my

Magnum Hunter seem to be holding up quite well after almost 10,000

Rds. These appear to be flash chromed maybe. Who knows what Jerry

Michalec's S&W revolvers have inside. TiN or possibly that Super Exotic

Asian alloy called "BAMBOONlUM"

|

|

The Following User Likes This Post:

|

|

03-20-2017, 09:38 AM

|

|

Member

|

|

|

Join Date: Jan 2015

Posts: 46

Likes: 1

Liked 22 Times in 13 Posts

|

|

Quote:

Originally Posted by SquarePizza

Titanium nitride seems to be all the rage for racegun accents and glock barrels, but not in many other circles. Has anyone tried applying it to MIM parts?

Kuhnhausen complains about MIMs susceptibility to corrosion, and that is often one of the selling points of TiN, and given that its fairly cheap, I am surprised I haven't seen it pop up on any S&W guns.

Of course its gaudy hell but hey, if its smoother, harder, and more resistant to the elements... I figured someone would give it a try.

|

Jerry Kuhnhausen is a pen name. AFAIK, it always has been. The 5th ed's updates are ghostwritten like every other shop manual in the series.

I've worn through the surface treatment on an early (1999 or 2000) mim 686 and in the decade or so the metal's been exposed (both the trigger and the hammer) it hasn't rusted. During that time it was my primary IDPA gun. I averaged 4 club matches per month from around 2007 to 2012. Some of the ourdoor matches were shot in the rain, and those that weren't we still had more humidity than most places (Alabama). I expect I would at the very least notice some spekling if corrosion were an issue.

I've had MIM parts (trigger, hammer, rebound) on another 686 melonited with no problem. Mahovsky will do hard chome on them as well. So if you live near salt water those are options. Otherwise just shoot it.

|

03-20-2017, 01:31 PM

|

|

Absent Comrade

|

|

|

Join Date: Dec 2014

Location: Upstate SC

Posts: 12,990

Likes: 17,229

Liked 41,504 Times in 9,146 Posts

|

|

Don't know what the gold color is on these old parts, but as an accent color, I think it looks great.

|

|

The Following 4 Users Like Post:

|

|

03-20-2017, 07:51 PM

|

|

US Veteran

|

|

|

Join Date: Aug 2006

Location: West Central IL

Posts: 22,795

Likes: 18,509

Liked 22,392 Times in 8,269 Posts

|

|

The only Tin coated item I have is a Hornady 32/32SWL/32 H&R/327 Mag sizing die. I do not like it near as well as any other brand carbide sizing die. I feel the need for some Imperial sizing was every so often. (I also do not like the "zip spindle" adjustment). I'll go back to RCBS or Redding dies.

__________________

H Richard

SWCA1967 SWHF244

|

03-20-2017, 08:22 PM

|

|

Member

|

|

|

Join Date: Apr 2011

Location: Indiana

Posts: 362

Likes: 94

Liked 79 Times in 36 Posts

|

|

The temperature that Tin coating is applied may be higher than the binder used in MIM can stand. I have been out of the trade to long to remember what temp TIN is applied and also don't know what type of binder S&W uses. You might want to call S&W and ask.

|

03-21-2017, 12:50 AM

|

|

Member

|

|

|

Join Date: Aug 2012

Location: US of A

Posts: 2,210

Likes: 7,002

Liked 2,483 Times in 1,147 Posts

|

|

Quote:

Originally Posted by JHB51

The temperature that Tin coating is applied may be higher than the binder used in MIM can stand. I have been out of the trade to long to remember what temp TIN is applied and also don't know what type of binder S&W uses. You might want to call S&W and ask.

|

The binder goes away during processing.

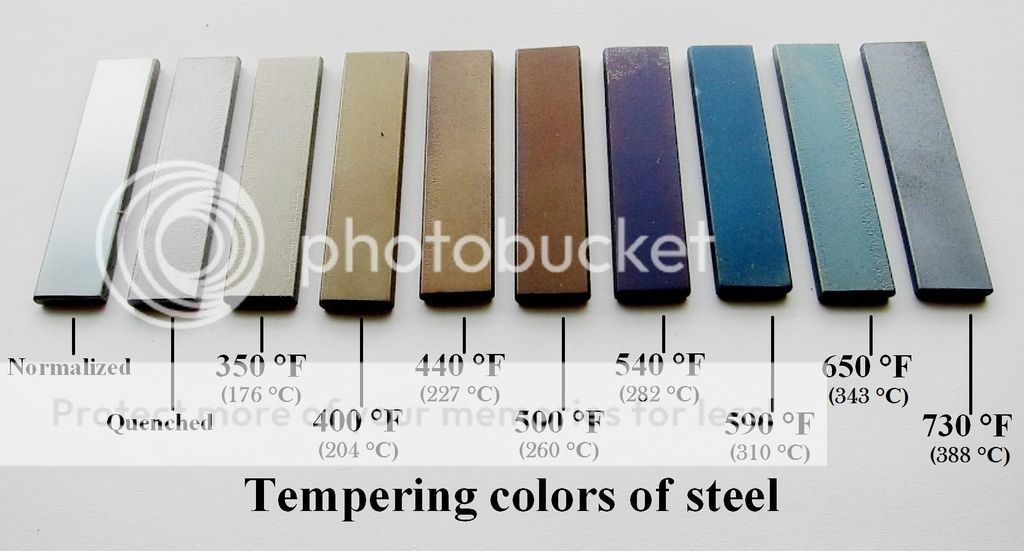

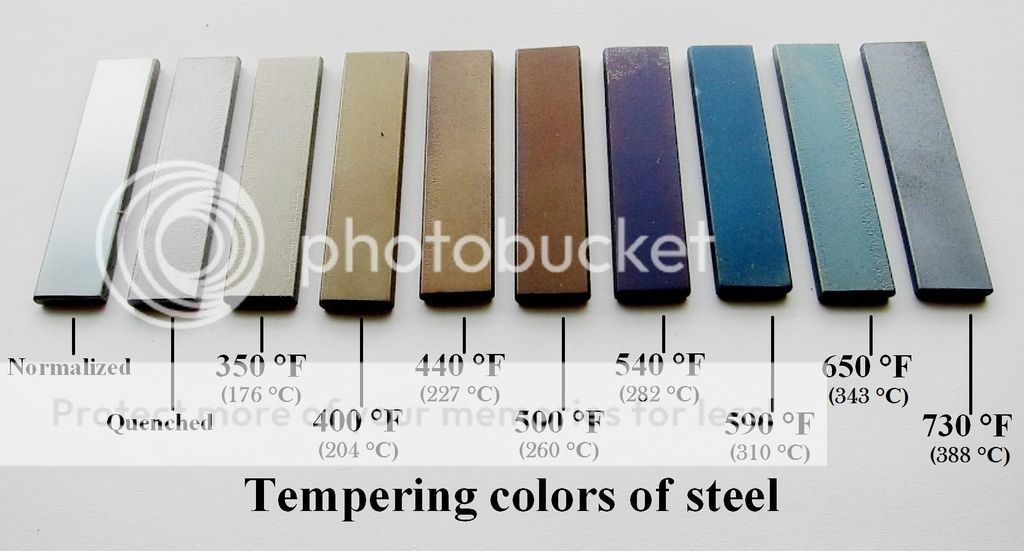

BTW, Bigwheelzip's revolver (Swiss, I think) has yellow tinted ("Straw" colored) parts which are a function of the final tempering process temperature. The color has more to do with the desired hardness than aesthetics. But it does look good.

|

|

The Following User Likes This Post:

|

|

03-21-2017, 08:14 AM

|

|

Absent Comrade

|

|

|

Join Date: Dec 2014

Location: Upstate SC

Posts: 12,990

Likes: 17,229

Liked 41,504 Times in 9,146 Posts

|

|

Quote:

Originally Posted by jaymoore

BTW, Bigwheelzip's revolver (Swiss, I think) has yellow tinted ("Straw" colored) parts which are a function of the final tempering process temperature. The color has more to do with the desired hardness than aesthetics. But it does look good.

|

Cool, I wondered what did it. Thanks.

I took your info and found a graphic for it.

|

|

The Following User Likes This Post:

|

|

03-21-2017, 08:52 AM

|

|

Member

|

|

|

Join Date: Apr 2011

Location: Indiana

Posts: 362

Likes: 94

Liked 79 Times in 36 Posts

|

|

The lube goes away during sintering. Before sintering the part will crumble with finger pressure. The binder holds the powders shape. Another name for the binder is glue.

|

03-21-2017, 10:39 AM

|

|

US Veteran

|

|

|

Join Date: Oct 2013

Location: Central Montana

Posts: 13,702

Likes: 12,850

Liked 39,440 Times in 10,035 Posts

|

|

Quote:

Originally Posted by bigwheelzip

Cool, I wondered what did it. Thanks.

I took your info and found a graphic for it.

|

While those temps MAY cause those colors to appear it is far from hard and fast. The color that can appear in a piece of polished steel when heating depends on the alloy, the atmosphere and any possible contaminates in it (oil, carbon etc) as much as the temperature. Plus the color is extremely thin. I have colors show up all the time tempering knife blades. If I take 1095 and don't do anything about the atmosphere it will USUALLY turn straw at 400f if I put it in a air tight foil packet with a bit of paper the paper will smolder, use up the oxygen and it will probably be blueish. Coloring steel is an art more than a science.

In IMHO Johan Gustafsson is the king. Look at an example of his work.

BladeGallery: Fine handmade custom knives, art knives, swords, daggers

On MIM and spinster metal remember once the binder is gone it is ac completely different animal. Thompson Center has been making spinster frames forever. How many or those fail even firing some crazy rounds for handguns?

Last edited by steelslaver; 03-21-2017 at 10:54 AM.

|

|

The Following User Likes This Post:

|

|

03-21-2017, 03:30 PM

|

|

Member

|

|

|

Join Date: Jan 2015

Location: Oxford, MS

Posts: 265

Likes: 90

Liked 261 Times in 106 Posts

|

|

A lot of those coatings are applied in a vacuum. That lowers the boiling point so less heat is needed.

|

03-21-2017, 04:27 PM

|

|

Member

|

|

|

Join Date: Oct 2011

Location: Sunny Central Florida

Posts: 1,231

Likes: 334

Liked 993 Times in 378 Posts

|

|

However, the TiN can be coated selectively. I have drill bits, reamers and milling cutters that have TiN on the business end while not TiNed on the shanks. Personally, I wouldn't mind seeing the sear surfaces on the hammer or trigger with TiN while the opposing part is finished differently. I don't have any idea how TiN reacts while rubbing against another TiN part. At any rate, I personally haven't found TiN to be some wonder material that makes cutters last significantly longer than quality unTiNed cutters. I think polished nitriding, on one sear surface, to possibly be the way to go.

As a slight aside, my experience with MIM parts goes back to 2012. After many action jobs on my own S&W revolvers, I see no appreciable wear on the MIM parts, at least no more than I see on forged parts, which is also insignificant. Only time will tell.

Some folks just resist change. Myself included, I can't get my head wrapped around smart phones. I feel the phone is laughing at me and saying, ha ha, I'm smarter than you. As far as MIM parts go, I like 'em and if anyone wants to donate their MIM parts to me, I'll take 'em. I like new S&W revolvers. I don't feel in any way handicapped with a new one over an earlier non-MIMed, non-locked model. Ahhh, the locks. Are they MIM? Forget that, it's a subject for another time!

__________________

NRA Benefactor

|

03-22-2017, 12:09 AM

|

|

Member

|

|

|

Join Date: Dec 2011

Location: CNY

Posts: 489

Likes: 62

Liked 520 Times in 210 Posts

|

|

I certainly wasn't MIM hating, so much as wondering why coatings like that haven't made it into the revolver domain when they are so heavily represented in the glock and racegun circles.

However, I do believe that if TiN or any other coatings did come to revolvers, it would show up on triggers/hammers instead of barrels and frames.

|

03-23-2017, 01:54 AM

|

|

Member

|

|

|

Join Date: Aug 2012

Location: US of A

Posts: 2,210

Likes: 7,002

Liked 2,483 Times in 1,147 Posts

|

|

Quote:

Originally Posted by steelslaver

While those temps MAY cause those colors to appear it is far from hard and fast. The color that can appear in a piece of polished steel when heating depends on the alloy, the atmosphere and any possible contaminates in it (oil, carbon etc) as much as the temperature. Plus the color is extremely thin. I have colors show up all the time tempering knife blades. If I take 1095 and don't do anything about the atmosphere it will USUALLY turn straw at 400f if I put it in a air tight foil packet with a bit of paper the paper will smolder, use up the oxygen and it will probably be blueish. Coloring steel is an art more than a science....

|

Much more true now, but in the 1800s through the early 20th century, temper colors were an easy and pretty repeatable method of controlling final heat treat in a production environment. Especially under the watchful eyes of experienced workers and inspectors for military items such as the Swiss revolver above.

As for TiN coating of action parts, it's just another take on case hardening, hard chrome, etc. QPQ nitriding noted above may be an option if the final polish doesn't round off edges of the tiny sear surfaces.

|

03-23-2017, 06:10 AM

|

|

US Veteran

|

|

|

Join Date: Oct 2013

Location: Central Montana

Posts: 13,702

Likes: 12,850

Liked 39,440 Times in 10,035 Posts

|

|

Very true

Those colors and temperatures and colors do run pretty true for tempering steel like 1095 and W2 the most common older plain high carbon tool steels in a regular atmosphere.

For hardening the color is a red shade that can be detected in low light by the well trained. Another interesting fact about heat treating is that all steels become austenitic at about 1425 f and a magnet will no longer tick to them. This is just bellow the proper temperature for simple carbon steels to be quenched from. In the days before pyrometers and well controlled ovens these methods were often used.

Now days a electronic device known as a PID will allow you to control an electric oven to within 1 degree, even gas heated ovens can be controlled with them using a solenoid valve to control the gas flow. This allows for much more controlled and precise HT. Plus a lot of precision HT is now done in an controlled atmosphere with no oxygen to react with the carbon. If O2 is present at higher temps there will be a thin soft layer on the part, lacking carbon, after quench that needs to be removed to get to the harden steel. Kind of the opposite of color case hardening where the part is buried in a carbon rich material, heated andd allowed to soak and become carbon rich.

Many modern stainless steels need temps above 1800 and some as high as 2050f to properly harden. plus tempering into the 800f range. Most of the parts on a revolver even a non stainless one are relatively soft and I suspect tempered to somewhere near 800f. For hard wear surfaces like sears around 400f would give an Rockwell C of around 60 with 1095. 450 f (RC 58) less apt to chip an edge for maybe the bolt and hand? With something like 4140 or 4150 the RC numbers would be lower because of the lower carbon content. I would love to see S&W heat treat and steel specs.

Last edited by steelslaver; 03-23-2017 at 06:28 AM.

|

|

The Following User Likes This Post:

|

|

|

Posting Rules

Posting Rules

|

|

|

|

Similar Threads

Similar Threads

|

| Thread |

Thread Starter |

Forum |

Replies |

Last Post |

|

New coating on new M&P's?

|

PurpleMountainOutdoors |

Smith & Wesson M&P Pistols |

1 |

03-21-2014 01:50 AM |

|

PVD Coating

|

Robert B |

S&W Revolvers: 1980 to the Present |

0 |

04-18-2011 08:51 PM |

|

PVD coating

|

DUNTOV |

S&W Revolvers: 1980 to the Present |

2 |

10-20-2010 02:36 PM |

|

scandium coating

|

cajunfj40 |

S&W-Smithing |

4 |

06-05-2010 01:12 AM |

|

What is PVD coating?

|

Robert B |

S&W Revolvers: 1980 to the Present |

3 |

01-11-2010 08:09 PM |

|