spdguns

Member

This project is something I dreamed up a while back. I decided to do it since the COVID has everyone on lockdown.

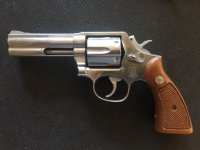

Pic 1. Usable 681-2. It was an agency gun, shooter grade but mechanically sound. There is a number "8" hand engraved under the top strap. I got it from a guy here on my local forum. He said it had a "dead cylinder", which we all know means it had an aftermarket mainspring and the strain screw was backed off. (I still paid too much for it.) Sure enough, that's what it was. An easy fix. The stocks are PERFECT, they are going on another gun.

Pic 2. Clamped up in the fixture. It's fixing to get ugly.

Pic 3. Cutting the rear sight notch

Pic 4. Cutting the groove along the top strap for the sight.

Pic 5. Holes drilled for CS extreme duty sights.

Pic 6. Tapped the holes

Pic 7. Fits like it's supposed to!

Pic 8. Milling off the front sight. Then cut the dovetail for the

FS. The barrel was underclocked about a degree. I had to build a frame clamp, pull the barrel and retighten it to 12 o'clock.

Pic 9. Done. Coming to a symposium in 2021!

Pic 1. Usable 681-2. It was an agency gun, shooter grade but mechanically sound. There is a number "8" hand engraved under the top strap. I got it from a guy here on my local forum. He said it had a "dead cylinder", which we all know means it had an aftermarket mainspring and the strain screw was backed off. (I still paid too much for it.) Sure enough, that's what it was. An easy fix. The stocks are PERFECT, they are going on another gun.

Pic 2. Clamped up in the fixture. It's fixing to get ugly.

Pic 3. Cutting the rear sight notch

Pic 4. Cutting the groove along the top strap for the sight.

Pic 5. Holes drilled for CS extreme duty sights.

Pic 6. Tapped the holes

Pic 7. Fits like it's supposed to!

Pic 8. Milling off the front sight. Then cut the dovetail for the

FS. The barrel was underclocked about a degree. I had to build a frame clamp, pull the barrel and retighten it to 12 o'clock.

Pic 9. Done. Coming to a symposium in 2021!

Attachments

Last edited: