|

|

|

09-07-2021, 02:23 PM

|

|

Member

|

|

|

Join Date: Feb 2014

Posts: 758

Likes: 100

Liked 710 Times in 348 Posts

|

|

Registered Police lockwork question

Registered Police lockwork question

So, I'm working to rescue this RP. It had cylinder bolt issues and wasn't working in DA properly. I got the bolt issue sorted but the trigger rebound and hand mechanism is unusual compared to my past experience and I'm having trouble figuring out how the spring inside the trigger is supposed to go.

I'm accustomed to a 2-pin hand and the spring in the trigger bearing on the non-pivot one of those, but this hand has just the pivot since the pressure to hold it into the ratchet comes from a plunger on the sideplate.

If I omit the spring entirely (you know it's bad when it works better when you leave parts out), the action mostly works, but the trigger return is spotty if you pull it back all the way in DA.

I did check Kuhnhausen but the I-frame specific information seems a bit spotty.

|

09-07-2021, 02:31 PM

|

|

Member

|

|

|

Join Date: May 2012

Location: Evansville, Indiana USA

Posts: 6,222

Likes: 483

Liked 11,387 Times in 3,520 Posts

|

|

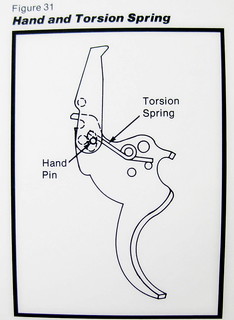

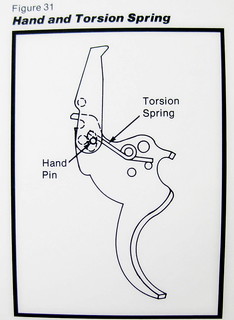

This is the proper orientation for the hand spring......this is a "3 pin" trigger shown, but the orientation is the same.

__________________

Ret. LE, FA Instr, S&W Armorer

Last edited by armorer951; 09-07-2021 at 02:35 PM.

|

|

The Following User Likes This Post:

|

|

09-07-2021, 03:09 PM

|

|

Member

|

|

|

Join Date: Feb 2014

Posts: 758

Likes: 100

Liked 710 Times in 348 Posts

|

|

Quote:

Originally Posted by armorer951

This is the proper orientation for the hand spring......this is a "3 pin" trigger shown, but the orientation is the same.

|

My hand has no pin though and looking at the hand it's pretty clear it never did because of the plunger on the sideplate.

|

09-07-2021, 05:12 PM

|

|

Vendor

|

|

|

Join Date: Jan 2010

Location: Kansas City area

Posts: 6,181

Likes: 54,365

Liked 13,589 Times in 4,281 Posts

|

|

That looks like a MIM trigger and hand spring. I'm not sure if that will work in the older gun. With the hammer out, and the sideplate off, I would cycle the trigger with rebound spring to see what the hangup is. It might be the width of the trigger. Measure the thickness of the hammer and trigger to see if they are the same. If the trigger is thicker, the sideplate may be clamping it down.

You would not be using the spring shown in the picture for that setup, it would be left out, as you say, because of the plunger in the sideplate and nowhere on the hand for the spring to push on.

|

|

The Following User Likes This Post:

|

|

09-07-2021, 07:15 PM

|

|

Member

|

|

|

Join Date: Sep 2005

Posts: 7,748

Likes: 1,642

Liked 9,152 Times in 3,380 Posts

|

|

I'd leave out the torsion spring as well.

I think the width of the trigger may be doing it as Protocall points out.

Maybe the area where the trigger just starts to widen for the finger pad is jamming into the space betw the sideplate and the frame.

That would be when the trigger is all the way to the rear and pulled hardest to the rear because of a pull thru on DA.

It may stick & jam there because of the wedge shape of the trigger

|

|

The Following 2 Users Like Post:

|

|

09-09-2021, 01:23 AM

|

|

Member

|

|

|

Join Date: Feb 2014

Posts: 758

Likes: 100

Liked 710 Times in 348 Posts

|

|

Interesting idea that the trigger might be MIM. It did come with the gun but I guess that doesn't mean it's original at all. Thanks for the idea, I'll have a look.

I fussed with the assembly a bit and noticed the trigger return problem didn't happen with the cylinder open, then that it only occurred on some cylinders and it was in fact the hand that was hanging up. I cleaned up the ratchet a bit and then it was just one cylinder. a little more fussing with a few burs and it's gone. Unfortunately, the other problem that had gone away before I got the trigger return working is back; when I pull the trigger in DA rapidly the cylinder sometimes goes too far. I tried cleaning the bolt plunger and stretching the bolt plunger spring but the problem persists.

|

09-09-2021, 10:08 AM

|

|

Vendor

|

|

|

Join Date: Jan 2010

Location: Kansas City area

Posts: 6,181

Likes: 54,365

Liked 13,589 Times in 4,281 Posts

|

|

When the cylinder goes too far by rotating it quickly in DA, it may be burrs raised up next to the cylinder stop notches. When this happens, the burr on the ramp is bouncing the cylinder stop down, just at the time it should be going up. This can allow the cylinder to continue past the notch.

These burrs are raised by material being displaced from the action being cycled many times. This is normal wear on the cylinder after much use.

The burrs on both sides of the cylinder notches need to be removed. BUT do NOT file them down! The material needs to be put back where it came from, not removed. You can peen the burr on the ramp back down with a 5/16 steel rod, laid over the ramp, and lightly hammer on the rod. For the other side, you can use a flat bottom punch and hammer to bring that burr down to match the surrounding area. The punch can just be a long 5/16 bolt with the threaded part cut off and the cut area made smooth and flat. Then you have both tools in one.

This procedure can be done multiple times on the same cylinder to greatly extend the useful life of a revolver.

Obviously we are having to guess at the cause of the problems, not having any pictures, or the gun in hand. The above seems the most likely for a first guess.

|

|

The Following 2 Users Like Post:

|

|

09-09-2021, 06:47 PM

|

|

SWCA Member

|

|

|

Join Date: Oct 2007

Location: California

Posts: 19,249

Likes: 11,917

Liked 20,594 Times in 8,582 Posts

|

|

Quote:

Originally Posted by teletech

I'm accustomed to a 2-pin hand and the spring in the trigger bearing on the non-pivot one of those, but this hand has just the pivot since the pressure to hold it into the ratchet comes from a plunger on the sideplate.

If I omit the spring entirely (you know it's bad when it works better when you leave parts out), the action mostly works, but the trigger return is spotty if you pull it back all the way in DA.

I did check Kuhnhausen but the I-frame specific information seems a bit spotty.

|

It's pretty clear the gun came to you functioning improperly. The hand looks correct, but doesn't use the torsion spring as you surmised. It's used with your much later issued trigger; post 1986, the new standard .312" wide forged J frame trigger (not MIM which began a couple of parts at a time 1995-96).

2152hq is correct, leave the torsion spring out!

As you said the hand is tensioned by the spring/plunger in the 2nd style side plate mounted hammer block safety which makes your gun a pre war I frame model:

1925 - 2nd style hammer block safety was ordered for the I frame Nov 6th to improve the action. (It was not used in the .22/32 Kit Gun or Heavy Frame Target. There is no new patent date for this style.) It was replaced on all models that used it with the post war 3rd style, hammer block safety with sliding bar.

1st and 2nd style safeties with pics and dates:

http://smith-wessonforum.com/swca-me...er-blocks.html

I frames were built on the J frame beginning late 1960 but still shared almost all the I frame parts except frame, cyl, and extractor rod. Your trigger is a J frame trigger but will function correctly in your I frame w/o the torsion spring. It's a great improvement to the original narrow trigger.

Since we don't know everything that's been done to your gun, you should remove the trigger rebound slide which encloses the trigger rebound spring, to verify if it's also been "monkeyed with". Cut short for example for a lighter trigger pull which could cause a trigger return problem. Pry it up at the rear retention stud in a large zip lock bag because the spring is prone to flying into another zip code!

I agree with Protocall_Design regarding his cyl skipping solution. However I use a flat hard steel plate over the burrs on the cyl notches and peen with small hammer on the plate. Punches usually leave dents and grooves if used directly on the face of the cyl burrs. The flat side of a narrow chisel works well.

__________________

Jim

S&WCA #819

Last edited by Hondo44; 09-09-2021 at 06:56 PM.

|

09-09-2021, 08:35 PM

|

|

Member

|

|

|

Join Date: Feb 2014

Posts: 758

Likes: 100

Liked 710 Times in 348 Posts

|

|

Quote:

Originally Posted by Protocall_Design

When the cylinder goes too far by rotating it quickly in DA, it may be burrs raised up next to the cylinder stop notches. When this happens, the burr on the ramp is bouncing the cylinder stop down, just at the time it should be going up. This can allow the cylinder to continue past the notch.

|

Great thought there. I did flatten the raised areas on the far side of the notches but didn't think to check down on the ramps. I'll have a look.

|

|

Posting Rules

Posting Rules

|

|

|

|

|