|

|

|

10-23-2013, 03:28 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Springs binding in my Shorty 45

Springs binding in my Shorty 45

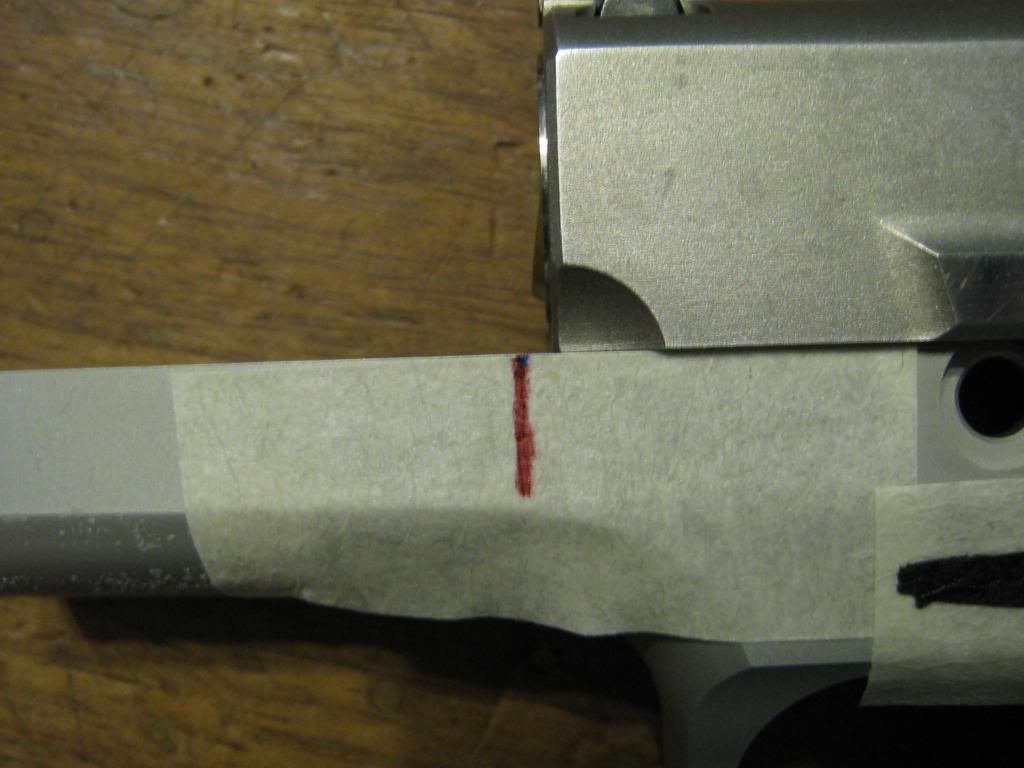

So I've got this Shorty 45 mk.2 with the standard fare 4513 nested recoil springs in it (pn10866 & 10867) specified & ordered from S&W. I observe about an 1/8" difference is slide travel with the springs out.

Here's a photo to illustrate. The slide bottoms out at the red line with the springs installed. Without the springs it bottoms out where you see it in the picture.

Now having been weaned on 1911's many moons ago, I know that spring bind/stacking is often fatal to a 1911. I'm not sure what the effect might be on a 3rd gen but I can't imagine it's a good thing and I know I bloody well don't like it. The only other gun I have that had this problem was my 4516-1 with an aftermarket extra power spring and that was resolved.

I had just fit a set of 2006 night sights and some factory low profile controls with the intent of putting this piece to more use.

I was very pleased with the results until I noted the spring stacking issue.

Anyway, I would like to correct this but first I want to make sure I'm not missing the boat on something or concerning myself with something that's a non-problem. Is there a special set of springs for the Shorty's I'm not aware of? I'm also curious if any other Shorty 45 owners have experienced this or could perhaps check their guns for stacking.

Cheers

Bill

__________________

Because they don't make a .46

Last edited by BMCM; 10-23-2013 at 09:01 PM.

|

10-24-2013, 11:13 AM

|

|

Absent Comrade

|

|

|

Join Date: Sep 2005

Location: GSO NC

Posts: 6,106

Likes: 23,604

Liked 13,195 Times in 2,860 Posts

|

|

Hi BMCM,

I will admit ignorance of the binding/stacking issue you are referring to. Well.........I understand how a binding spring could present problems, but what is "stacking"? And why is it problematic?

My Shorty 45 MKII is in storage, so I will go check it this weekend for you and let you know if the results mirror your experience.

I did try what you asked with my 4566 and my 4513TSW. Both slides went back a little bit further, approximately the amount you illustrated, without the springs and guide rods installed.

For myself and perhaps some other shooters who do not understand why this is a problem, would you please explain it to us. I always learn from your posts and this one appears to be another lesson to take advantage of.  Regards 18DAI

__________________

7 +1 Rounds of hope & change

|

|

The Following 2 Users Like Post:

|

|

10-24-2013, 03:32 PM

|

|

SWCA Member

|

|

|

Join Date: Aug 2013

Location: Foothills of the Ozarks

Posts: 3,596

Likes: 10,663

Liked 5,587 Times in 2,179 Posts

|

|

Bill's post and 18's reply raised a three point question in my mind that for me, admittedly, doesn't have an answer:

A. Was the recoil spring(s) intended to be the limiter of slide travel at coil bind?

B. Is there some other positive, mechanical limiter of slide movement?

C. Was there some intentional designed balance between spring resistance and charge pressure so that with "proper" loads the slide shouldn't reach the physical limit of travel?

Inquiring minds want to know.

John?

|

|

The Following 3 Users Like Post:

|

|

10-24-2013, 04:36 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Lots of precision measuring & ciphering of numbers going on at my bench. more to follow later

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 2 Users Like Post:

|

|

10-24-2013, 08:34 PM

|

|

Member

|

|

|

Join Date: Jun 2012

Posts: 79

Likes: 40

Liked 69 Times in 17 Posts

|

|

The base of the guide rod, spring and inner face of the dust cover takes all of the brunt of a hot load and only thing that stops the travel of slide or you would have macerated surfaces on the frame and slide so if you remove such then the slide will smash the frame this is perfectly normal and as designed

Last edited by Dukesamson; 10-24-2013 at 08:47 PM.

|

|

The Following User Likes This Post:

|

|

10-24-2013, 10:02 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Ok, I did a bunch of measuring today comparing my Shorty with 3 different 4513 uppers and I'm confident I've identified the cause of this issue.

To start with I'll define a few things how I view them regarding recoil springs so were all on the same page?

1. Spring stacking or bind; This is when a recoil spring is completely compressed.

2. Spring stack height; This is how tall/long the spring is when completely compressed. Quick & dirty way to determine this is multiply the wire diameter by the number of coils.

3. Installed Space; The room available for the spring to occupy when the slide is fully forward in battery at rest.

4. Compressed Space; This is the space available for the spring to occupy with the slide fully retracted with the spring tunnel resting solidly against the the mechanical stop in the frame. Where we run into trouble is when the spring's stack height is greater than this space.

So why is spring stacking or bind a bad thing?

Well, here are my thoughts; I think for the most part this ought to be common sense. A spring's purpose is to store & release energy. In this case, when the spring has stacked solid it's in effect full. Having reached it's max capacity for stored energy any overflow is transferred into the surrounding structure.

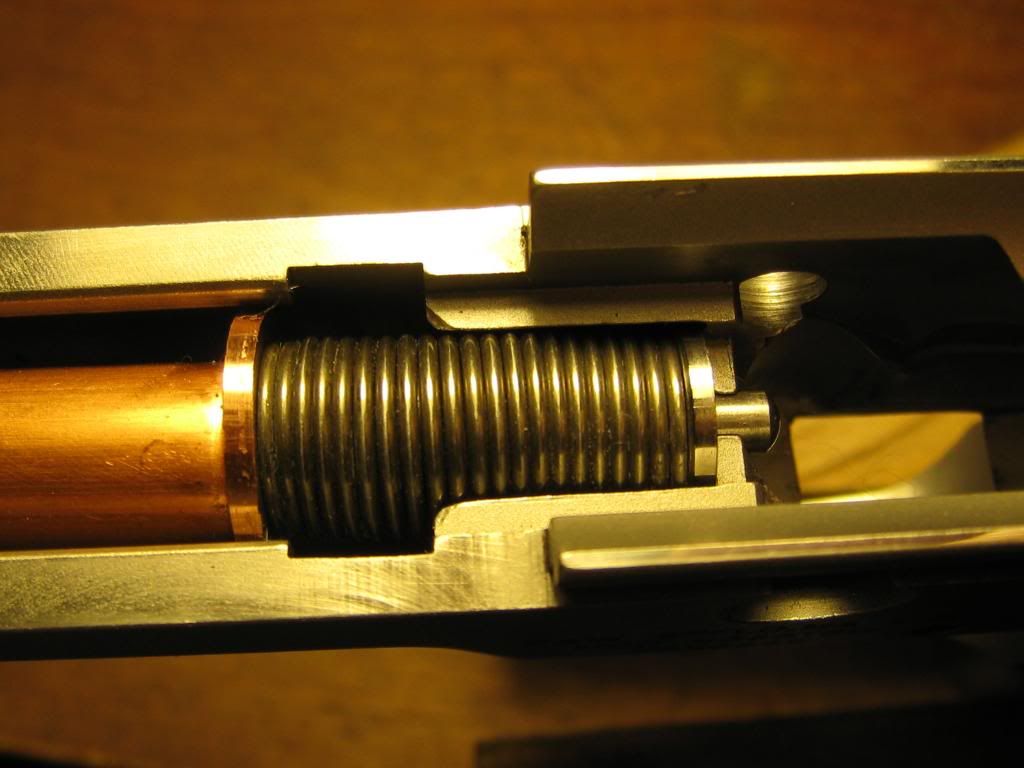

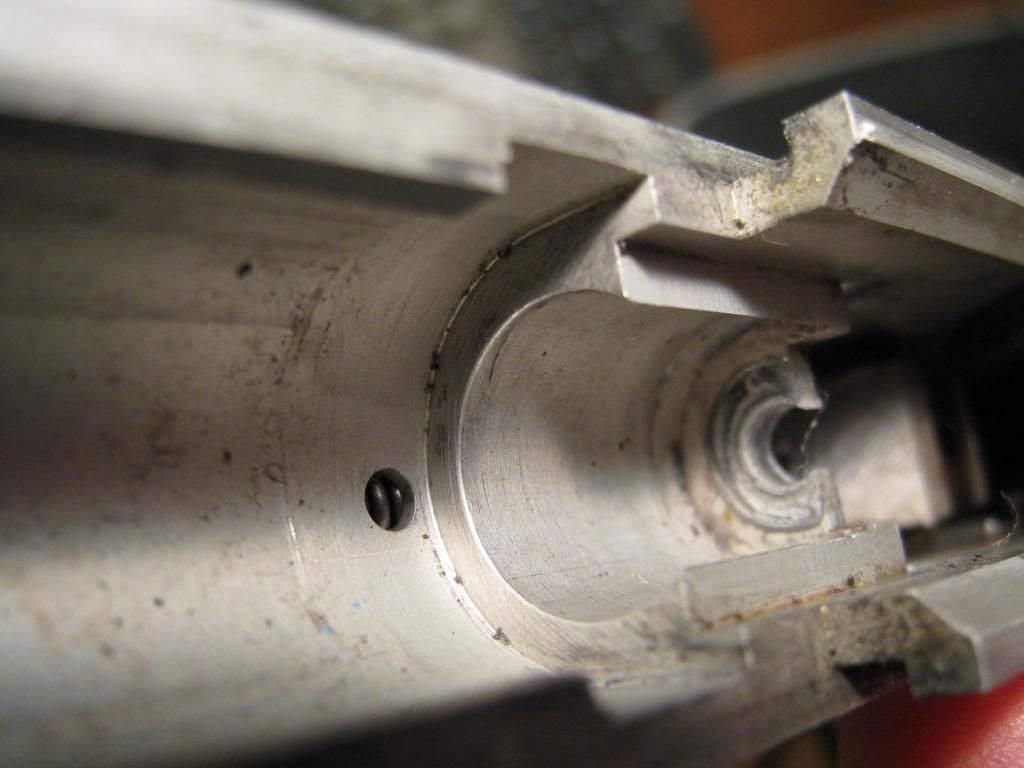

So what happens then? When your recoil spring looks like this before the slide has reached it's mechanical limit.

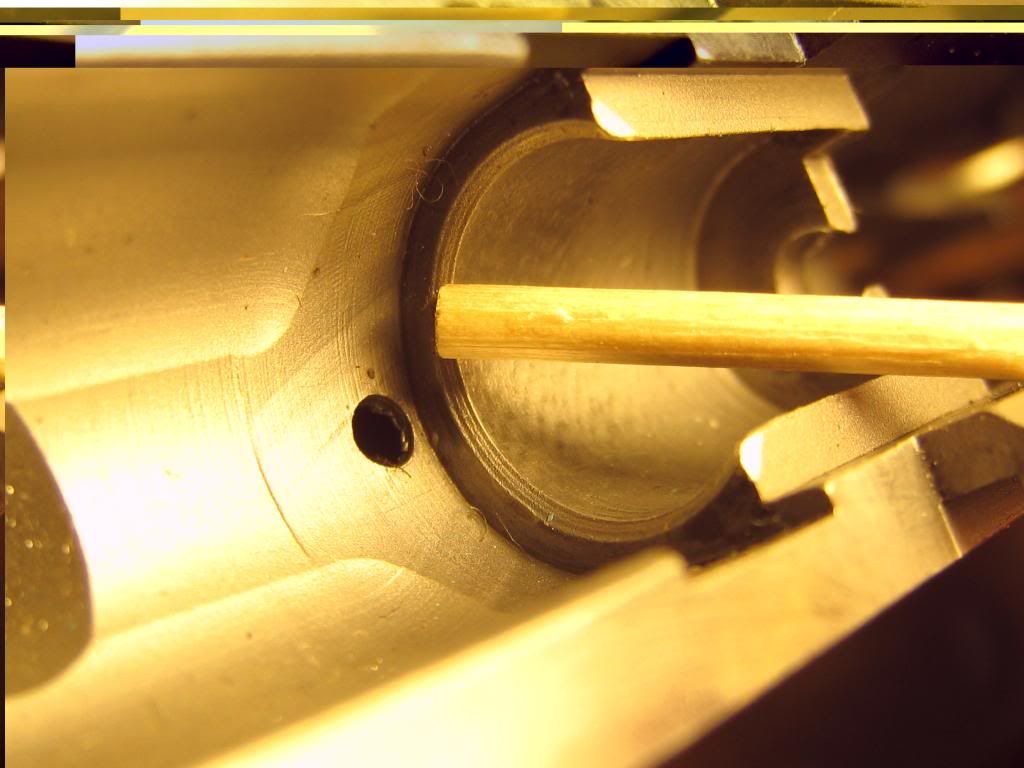

This is the slide's mechanical limiter. All that impact force that should normally be going here.

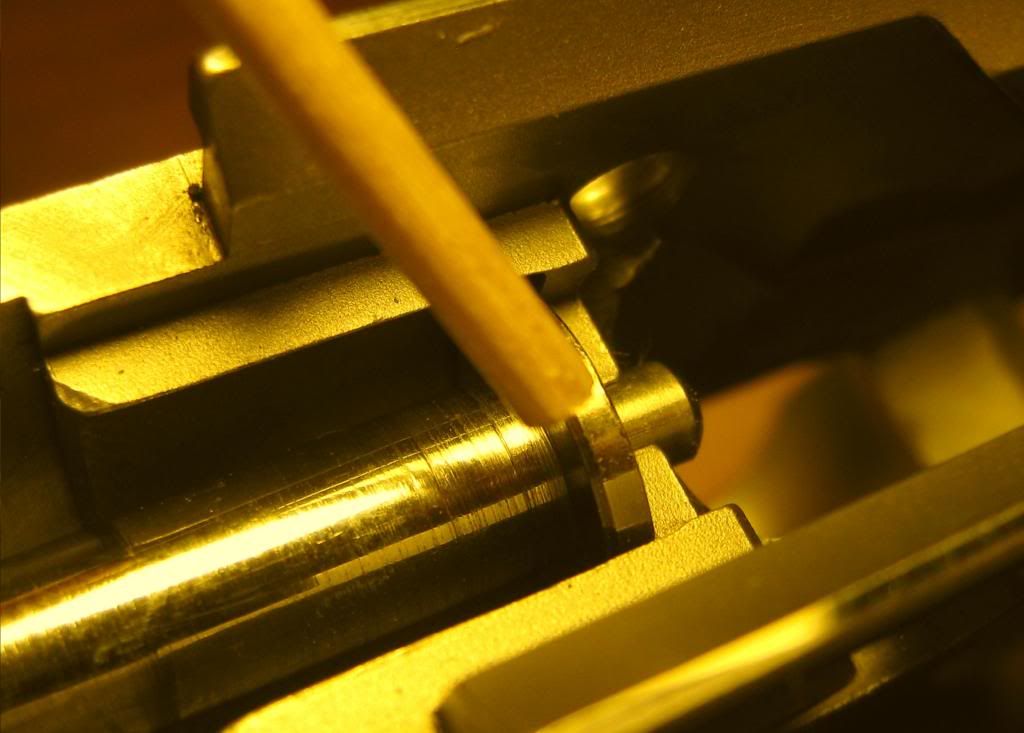

And here when the slide bottoms out on the frame.

Is now being directed into the front inside face of the slide's spring tunnel and into the frame through the flange on the guiderod here.

In short, when the spring stacks solid before the slide reaches the mechanical limit of it's rearward travel, things will get battered that aren't supposed to be. Repeated stacking also damages and accelerates spring weakening.

I think there are two primary considerations for selecting a recoil spring.

1. Does it fit the gun? I contend that a spring that stacks before the slide reached it's mechanical limit does NOT fit.

and

2. Is it the proper weight? A spring that's too weak will wind up with slide battering the frame. A spring that too strong will cause battering of the locking lugs both on the barrel and slide as well as the slide stop cross pin and the mating cam on the barrel underside as the slide is flung forcefully back into battery. Either extreme also comes with a host of functioning problems in addition to the battering.

I want my spring to fit the gun properly and be of sufficient strength to halt the slide at or near it's mechanical limit and send it back into battery without any stacking or undue battering of any components.

We trust the factory engineers to make these selections for us and assume the OEM replacement parts are "good 2 go" and 99 percent of the they are.

I'll just blame the beancounters for the remaining 1 percent.

Now taking a look at these nested springs. These springs (108660000 & 108670000) were/are used in a bunch of different guns. All the compact 40's, and all the compact 45's except for the 4516-1. Plus the Shorty & the Recon45 and I assume the Shorty 40 as well. That's maybe 14 different models by my count. Maybe when they were building the Shorty's the beancounters just made 'em use whatever was in the bin

I have no stacking issues with these springs in any other gun it's only the Shorty where there's a problem.

On to the spring measurements.

pn 108660000 outer 0.37wire x 22 coils, stacks at .814"

pn 108670000 Inner 0.32wire x 25 coils, stacks at .800"

ISMI #18 flatwire 0.26flatwire x 31 coils, stacks at .806"

Shorty 45 mk2

Installed space 2.817"

Compressed space .774"

4513TSW

Installed space 2.876"

Compressed space .941"

As you can see, the 4513 has ample compressed space for any of those springs. The Shorty however comes up a little uh short  .

And the source of those differences between the two gun is this.

Here's the front of the spring tunnel on a 4513, note the thickness of the front face, it's 0.68" thick.

And here's the same view of a Shorty45 slide, note the thickness here, it's over double the 4513's at .138"

Well there it is. You know I think there will come a day when those nested springs we use in so many of our favorite guns go the way of the dinosaur just like the factory 4516-1 spring did.

I think I'll get to looking for an alternate part for my Shorty. For all the other guns, I've had superior results with the ISMI flatwire springs and I intend to keep using them.

I was kinda hoping an old retired S&W PC guy or engineer would chime in, I sure like to hear some insight from anyone who was working at the PC back in the day, Ah well. If anyone who has a Shorty, or anything else that runs on those nested springs for that matter, feels like measuring or checking your spring fitment I welcome your input.

Conversely, if/when I source a suitable replacement spring I'll post that info here. In the meantime, the Shorty goes back in the box

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 16 Users Like Post:

|

03Fatboy, 10xatten, 18DAI, Big Shrek, BLUEDOT37, dragonjo74, Gunhacker, JohnHL, ladder13, mjk5757, RedCardinal, scwv67, Steve912, TercGen, timn8er, tom 45 |

10-24-2013, 10:46 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: Long Beach, CA

Posts: 1,386

Likes: 876

Liked 994 Times in 442 Posts

|

|

Springs binding in my Shorty 45

Springs binding in my Shorty 45

Very interesting Bill, I follow this for the most part but I'm getting a little stuck in the weeds on some of it as well.

Since the Shorty45 has less compressed space it is unable to take Full advantage of the springs capability to absorb and release energy therefore it is more susceptible to slide /frame contact? Bind/stacking is a bad thing but in the Shorty45 the spring will never have a chance to completely bind? So is you goal with finding an alternate spring one that will function reliably, not bind and work up to or close to the compressed length?

The TSW is able to take Full advantage of the springs stack height however if not at proper weight it will be allowed to bind and also have potential for frame and slide contact? The goal here is to allow the spring to function without going beyond the stack height, close but not past?

Also, Is the spring tube on the Shorty45 thinner or thicker? Not sure I interpreted the dimensions correctly?

__________________

USS ZELLARS

DD-777

Last edited by 03Fatboy; 10-24-2013 at 11:10 PM.

|

|

The Following 2 Users Like Post:

|

|

10-25-2013, 04:11 PM

|

|

Member

|

|

|

Join Date: Sep 2009

Location: I Can See The Alamo

Posts: 556

Likes: 303

Liked 372 Times in 188 Posts

|

|

I wouldn't have noticed that the 457 uses the same spring set except that replacement springs have been backordered from S&W since July and I was Googling around looking for an alternate source. Just as a datapoint, it appears that the 457 stacks up approximately the same amount as shown in your photos.

My new to me 457 appears to have been fired very little, but it doesn't look like the flange has been hammered on - though it is pretty thin and a very light alloy. Doesn't look like it would take a lot of abuse. Could it be that this is not a problem unless the springs have gotten very very soft? Even then, would there be enough energy left in the slide to do any damage by the time the spring is fully compressed?

This does reinforce the need for regular spring replacement. If anyone knows of a source of springs, I'd appreciate a heads up. The 10866/7 set is backordered from S&W, Brownells and Midway. Wolff doesn't make this spring.

BTW, Bill, how did you ever find this problem? You need to get out more - go to the range - get a girlfriend or something. <G> Thanks for sharing, though. I always learn something from your posts.

|

|

The Following User Likes This Post:

|

|

10-25-2013, 09:19 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by 03Fatboy

Since the Shorty45 has less compressed space it is unable to take Full advantage of the springs capability to absorb and release energy therefore it is more susceptible to slide /frame contact? Bind/stacking is a bad thing but in the Shorty45 the spring will never have a chance to completely bind? So is you goal with finding an alternate spring one that will function reliably, not bind and work up to or close to the compressed length?

|

Slide to frame contact is not a bad thing so long as it's controlled. A soft landing on the frame by a properly sized spring of the correct weight for the loads is the goal. Nothing is getting battered and you get the all the advantages of the slides full range of travel. Cleaner ejection and easier to download. I gotta tell ya, clearing live rounds from the shorty is a major pain compared to any of my other 45s.

I think you may have misunderstood me a bit. The spring in the Shorty can do nothing but bind. There's simply not enough room in that gun for that spring. It may be the correct weight but It's simply too big.

Quote:

Originally Posted by 03Fatboy

The TSW is able to take Full advantage of the springs stack height however if not at proper weight it will be allowed to bind and also have potential for frame and slide contact? The goal here is to allow the spring to function without going beyond the stack height, close but not past?

|

Spring bind is when the spring is compressed to the point where it behaves not like a spring but like a solid piece of steel. When your spring stacks solid in there it's the same as having a solid steel tube on your guiderod instead of a spring. The stack height of the spring should always be less than the available compressed space in the gun this way it is physically impossible for the spring to bind. Again, slide to frame contact isn't bad. Uncontrolled slide to frame battering is. The two are not the same.

Quote:

Originally Posted by 03Fatboy

Also, Is the spring tube on the Shorty45 thinner or thicker? Not sure I interpreted the dimensions correctly?

|

The difference was the thickness of the front face of the spring tunnel where the guiderod protrudes, It's twice as thick on the Shorty tahn on the 4513. What I was attempting to illustrate Looking at the measurement differences in measurements between the two guns I posted the chief noteworthy thing is the Shorty has much less room than the 4513TSW to accommodate the exact same spring set.

And yet they both are 4513s

Quote:

Originally Posted by Hill_Country

I wouldn't have noticed that the 457 uses the same spring set except that replacement springs have been backordered from S&W since July and I was Googling around looking for an alternate source. Just as a datapoint, it appears that the 457 stacks up approximately the same amount as shown in your photos.

|

Quote:

Originally Posted by Hill_Country

My new to me 457 appears to have been fired very little, but it doesn't look like the flange has been hammered on - though it is pretty thin and a very light alloy. Doesn't look like it would take a lot of abuse. Could it be that this is not a problem unless the springs have gotten very very soft? Even then, would there be enough energy left in the slide to do any damage by the time the spring is fully compressed?

|

Quote:

Originally Posted by Hill_Country

This does reinforce the need for regular spring replacement. If anyone knows of a source of springs, I'd appreciate a heads up. The 10866/7 set is backordered from S&W, Brownells and Midway. Wolff doesn't make this spring.

|

Yep, I've looked too, Out of stock everywhere. I'll find something that'll run in there. Fortunately the gun doesn't care what springs are inside, only that they fit and they work.

Quote:

Originally Posted by Hill_Country

BTW, Bill, how did you ever find this problem? You need to get out more - go to the range - get a girlfriend or something. <G> Thanks for sharing, though. I always learn something from your posts.

|

After working out the replacement recoil spring for my 4516-1 I guess I look at springs a little more critically these days, especially since it seems our parts supplies are drying up and I intend to keep my toys running regardless.

I may try hunting up some springs to test out next week assuming I feel better. Seems I've caught a bug this week... Bleh.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

10-25-2013, 10:00 PM

|

|

SWCA Member

|

|

|

Join Date: Aug 2013

Location: Foothills of the Ozarks

Posts: 3,596

Likes: 10,663

Liked 5,587 Times in 2,179 Posts

|

|

Hi, Bill!

I appreciate your analytical expedition into this matter and I did some checking on my own guns to see if I was experiencing the same phenomena as you.

The only pistol I have that sports the 6/7 S&W double spring is a pre-rail 4013TSW.

With or without springs the slide stops on the frame stop.

I also have a CS40. As you know it uses a single spring and yes it does the same as the 4013TSW. The slide stops on the frame stop.

However I also have both a 457 top end assy. and a late 4516-1 top end assy. that fit the CS40 frame. Both of these, as you know, use the S&W 6/7 double spring combination.

Both of these top ends exhibited approx. the same slide stop difference as shown in your picture with and without springs when installed on the CS40 frame indicating coil bind.

I suppose the ideal would be a spring/load combination which caused the slide to just kiss the frame on the backstroke before returning forward.

I also agree that finding a suitable flat spring would be preferable to cutting .050" off the inside face of the slide spring tunnel.

I'm with you. I don't like coil binding whether it's on guns, engine valves, suspensions, or anyplace a spring is installed to absorb and release energy. And in most cases, unlike engine valves, there is a positive stop in the system to keep the springs from bottoming.

John

Last edited by JohnHL; 10-25-2013 at 10:35 PM.

|

|

The Following User Likes This Post:

|

|

10-25-2013, 10:44 PM

|

|

SWCA Member

|

|

|

Join Date: Aug 2013

Location: Foothills of the Ozarks

Posts: 3,596

Likes: 10,663

Liked 5,587 Times in 2,179 Posts

|

|

BTW, Bill, when I look at the picture of the face of the spring tunnel on your Shorty, I think I see an annular groove running around the lower curvature of the guide rod hole at approx. the same depth as the 4513.

Is this a streak on my monitor or could there be a spacer somewhat like that on earlier 4516s except its purpose would be to pre-load the spring to increase its working pressure?

John

|

10-25-2013, 10:59 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Hi John,

Glad you chimed in, I think your comments are spot on and

I couldn't agree more. Nothing good can come of coil bind.

Most any machine that depends on coil springs will grenade if the springs bind. As in, valve train springs bind and puking engine parts on the highway grenade. Luckily these pistols are somewhat forgiving in this regard in that once or twice usually won't destroy anything. Unless it's a 1911, once or twice can cause you to need plug & bushing or worse case a new slide.

Oh and not to worry, I have zero intention of machining the Shorty to fit a consumable part (spring).

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

10-25-2013, 11:15 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

I see what you're looking at. I have that image here on the PC at stoopidhigh resolution. Zooming in on that area I see some tooling marks evident under the bead blasting that look like fine pitch screw thread. Evidently from whatever tool was used on that hole. I had another look at the slide too under the loupe and it's solid for sure. No spacer or bushing in there. It's not a streak on your monitor just a flaw in the image I think. That's just a real hard spot to get a good in focus shot, my camera keeps wanting to focus on other junk.

Cheers

Bill

Quote:

Originally Posted by JohnHL

BTW, Bill, when I look at the picture of the face of the spring tunnel on your Shorty, I think I see an annular groove running around the lower curvature of the guide rod hole at approx. the same depth as the 4513.

Is this a streak on my monitor or could there be a spacer somewhat like that on earlier 4516s except its purpose would be to pre-load the spring to increase its working pressure?

John

|

__________________

Because they don't make a .46

Last edited by BMCM; 10-25-2013 at 11:50 PM.

|

|

The Following User Likes This Post:

|

|

10-25-2013, 11:44 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: Long Beach, CA

Posts: 1,386

Likes: 876

Liked 994 Times in 442 Posts

|

|

Thanks Bill, the additional input makes sense. I was thinking about things backwards I guess. Often a problem for this left hander.

Anyways, I'm staying tuned to see what you come up with!

__________________

USS ZELLARS

DD-777

|

12-13-2013, 12:33 PM

|

|

Absent Comrade

|

|

|

Join Date: Sep 2005

Location: GSO NC

Posts: 6,106

Likes: 23,604

Liked 13,195 Times in 2,860 Posts

|

|

Hi BMCM,

It took me awhile but I finally made it over to where my guns are stored and took out the Shorty 45 MKII.

I HAVE SPRING STACKING!!  But here is the weird thing, only with the brand new factory OEM dual springs....????

The springs that were in it don't stack.....as far as I can tell, going by your your photo examples. I suspect the springs that were in it were the originals as this Shorty 45 MKII has not been shot much. They were almost a 1/2 inch shorter than the new factory springs I tried putting in.

The original springs in it have no color left on them. The new springs are a light blue color. I think maybe you are onto something with these current production factory springs being too long. I got this batch last May from S&W.

These new springs matched the springs in my other 4513TSW's and those guns run fine.....although I had not checked them for spring stacking in the manner you have demonstrated here. I guess I will now.

I did notice that when reassembled the tip of the guide rod does not protrude from the slide at the Shorty 45's muzzle like my standard production 4513TSW's. It almost looks semi recessed. Is that how it is on your Shorty 45?

I will watch this thread anxiously to see what you come up with to rectify this situation. Ideally, I'd like to purchase a drop in replacement flat wire spring for the Shorty 45. I don't want to mill the guide rod or alter the gun in any way. But the Shorty 45 is too nice a pistol to let it become a safe queen. Regards 18DAI

__________________

7 +1 Rounds of hope & change

|

|

The Following 3 Users Like Post:

|

|

12-13-2013, 05:14 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Hi 18DAI

I'm still on the case.

Your Shorty sounds about the same as mine. I get a little more travel with the old set of springs too. With a new set of springs in there I lose nearly an 1/8" of travel vs no springs at all.

My guiderod is slightly recessed also. I think that is due to the front end of the Shorty slide being just a bit longer/thicker. I've got a couple other 4513 rods I checked it with. They're all about the same length and recess somewhat in the Shorty slide.

The guys at ISMI are sending me some stuff for T&E. I'll post results when I get the parts and have opportunity to get the the range.

Spoke with S&W today which wasn't of much help. I need to check back with them next week when the 3rd gen expert is back in the office.

Stay tuned

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 2 Users Like Post:

|

|

12-17-2013, 01:01 AM

|

|

Member

|

|

|

Join Date: Feb 2002

Location: Victoria, Texas

Posts: 3,322

Likes: 380

Liked 1,016 Times in 358 Posts

|

|

I been out of the SW game for a while but when I was running my CQB hard, I called SW with my serial number and ordered springs for my PC CQB.

since it was a 4", I am sure they were not 4.25" 4566/4563 springs.

they would come in a ziploc type baggie with no part number.

back then you could talk to someone in the PC……I don't think you can do that anymore.

good luck

__________________

if you're gonna be a bear...

|

01-14-2014, 09:20 PM

|

|

Member

|

|

|

Join Date: Feb 2006

Location: East river South Dakota

Posts: 678

Likes: 6

Liked 107 Times in 57 Posts

|

|

What word young William? Any luck other than bad?

Cat

__________________

Think for yourself.

|

01-15-2014, 12:47 AM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by Catshooter

What word young William? Any luck other than bad?

Cat

|

Hiya Cat'

Nope, no bad luck here just too many irons in the fire as usual

Here's my test setup. ISMI sent me a 22lb rate 30 coil spring to try out. After some test fitting I eventually took off three coils and now have full slide travel.

No coil bind and no short stroking. Slide retracts fully to my reference mark.

So now I just need to get my poop together for a range outing.

I got a couple other things I need to wrap up for testing out so it'll be a bit longer before I can head across the river and give'er a thorough thrashin'.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 5 Users Like Post:

|

|

01-16-2014, 09:38 PM

|

|

Member

|

|

|

Join Date: Feb 2006

Location: East river South Dakota

Posts: 678

Likes: 6

Liked 107 Times in 57 Posts

|

|

Looks pretty good. Let us know, please.

Cat

__________________

Think for yourself.

|

05-06-2014, 02:19 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Well I guess it's about time I updated this thread. I've had several range sessions with the shorty running a 27 coil flatwire spring, the latest just this past Saturday and I can tell you it works just fine.

Just to illustrate my point why coil bind is a bad thing.

Here's a picture of three springs. All the exact same spring too, an ISMI CCF22.

The left one is a brand new, never been in a gun 30 coil spring.

The right one is a 30 coil spring cut to 27 coils and had about 300 rounds on it when this picture was shot.

The middle spring has been fired a mere 14 rounds and is ruined.

So how can this be? Well, I'll tell ya...

Remember the Shorty only has .774" of space for the spring to occupy at full slide retraction. A 30 coil spring binds at .780". So instead of landing on the frame's impact abutment, the slide is landing on the spring every shot when the spring has no room to compress any further. While six thousandths of an inch doesn't sound like much, the net effect is the same as manually compressing the spring fully and with the spring in a state of coil bind, striking it with a hammer 14 times. While You can plainly see some deformation and loss of free length there, what you can't see is the the loss of strength that's apparent by simple hand manipulation compared to the other two springs. That spring has become a noodle.

Now the 27 coil homemade version which binds at .702" has plenty of room to work in the Shorty. I've not had a one single malfunction of any sort since running this spring and as you can see there's not a single blemish on the frame's impact abutment.

And no effect on accuracy

I'm satisfied these springs perform perfectly thus I went and stocked up.

I'll be contacting ISMI to see about a regular stock item of this weight rating and 27 coils. I think the only improvement to be made here is NOT having to trim springs to size when I want to replace one so we'll see what they have to offer soon.

Cheers

Bill

__________________

Because they don't make a .46

Last edited by BMCM; 05-06-2014 at 11:25 PM.

|

|

The Following 5 Users Like Post:

|

|

05-06-2014, 03:12 PM

|

|

Absent Comrade

|

|

|

Join Date: Sep 2005

Location: GSO NC

Posts: 6,106

Likes: 23,604

Liked 13,195 Times in 2,860 Posts

|

|

BMCM was kind enough to send me his aftermarket recoil springs to try in my Shorty 45 MKII.

Sunday I put 42 rounds through the Shorty 45 with BMCM's spring installed. I fired 7 rounds slow fire and the rest in fast pairs.

Accuracy was stellar, as usual and the Shorty 45 MKII functioned flawlessly. Again, as usual.

Many thanks to BMCM for solving this potential problem for all of us!

I will try another of BMCM's springs in my rail free, 7-round 4513TSW next outing. I expect it will exhibit the same perfect function. Thanks again BMCM!! Best regards, 18DAI

__________________

7 +1 Rounds of hope & change

|

|

The Following 5 Users Like Post:

|

|

05-06-2014, 03:35 PM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,217 Times in 4,509 Posts

|

|

Verrrrrrrry interesting, Master Chief.

And so, I hope you'll find, is this: on my first-run Shorty 45 (not the Mk 2, as yours is), it does not appear that I have spring stacking. I just replaced springs with brand new ones from Numrich. Comparing the points of maximum travel of the slide with springs and without springs, my slide without springs bottoms out approximately 7/32" forward of the point of bottoming out with springs. (To refresh everyone's memory: this is the opposite of what Bill observed on his Mk 2, where the slide bottomed out without the springs approximately 1/8" rearward of the point with springs.)

I don't have the more sophisticated measuring tools you have, so take the next for what it's worth, but as best I can measure the end of my spring tunnel, it is 3/32 of an inch thick -- definitely not the thicker dimension of your Mk 2 slide tunnel end. Maybe that's the key to the whole issue here.

Admittedly, the springs I just put in were what I ordered from Numrich as the inner and outer "4516" springs and though they came in painted blue as I believe the S&W springs were, I don't know if in fact they are OEM S&W parts.

Anyway, FWIW....and thanks for a very instructive thread....

__________________

Ukraine -- now more than ever

Last edited by vigil617; 05-07-2014 at 06:20 AM.

|

|

The Following User Likes This Post:

|

|

05-06-2014, 03:36 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

If you still have it, try that 30 coil spring in your 4513. That gun has more room and can accommodate more spring. That's the exact same spring I run in my SSV which has a 4513 upper.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

05-06-2014, 10:56 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: Long Beach, CA

Posts: 1,386

Likes: 876

Liked 994 Times in 442 Posts

|

|

I only hope to one day find a Shorty 45. It's good to know we are in good hands. Many thanks to Bill for that.

So, are you using any ISMI springs for the 4506?

__________________

USS ZELLARS

DD-777

|

05-06-2014, 11:24 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by 03Fatboy

I only hope to one day find a Shorty 45. It's good to know we are in good hands. Many thanks to Bill for that.

Better be fast on the draw, I won't hesitate to grab another one if'n I see it first if'n I see it first

So, are you using any ISMI springs for the 4506? |

Not at the moment. There's really no need, I've got plenty of standard weight Wolff springs plus a tuning pack for that gun. and so long as anyone is making fullsize 1911 recoil springs, I can keep that gun running.

Cheers

Bill

__________________

Because they don't make a .46

|

05-07-2014, 03:54 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,331 Times in 3,497 Posts

|

|

1076 stacking

1076 stacking

Bill,

Glad you got back with us & updated this. I got a couple questions & then I'll tell you my story.

- do you think this gun (Shorty) always had the stacking/binding issue with factory springs & you just noticed it?

- were you able to get anything from S&W (the 3rd Gen. experts) as to whether the factory replacement spring dimensions changed causing this issue?

- I'm guessing that guns vary in their thickness at the spring tunnel opening but the recoil spring should be designed to allow for this, within reason?

I recently got a 1076 (single recoil spring) & ordered a compliment of replacement springs from Wolff for it before I shot it. After I put Wolff's standard 17# spring in & racked the slide I noticed it didn't feel/sound "right" when it stopped it's rearward motion. I remembered this thread & marked the slide/frame & found the slide was stopping about 1/2 a pencil mark's thickness too soon with the Wolff spring in, verses with no spring. I then put the gun's original spring (factory?) back in & it was actually a hair worse, instead of better. A heavier Wolff spring was no different either, of course.

I don't have a new factory spring to try & I haven't measured the spring tunnel thickness (I don't know what a good measurement is anyway) but I'm wondering if I should try to cut a turn off of one of the springs to see if that helps? I think that's all it would take to allow it to stop on the frame.

What do you guys think? I've never noticed this on my other 3rd Gens & I just went thru double checking & racking them all again & they're fine, even the one's that I went to the ISMI flat springs "conversion" in.

|

05-07-2014, 08:55 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by BLUEDOT37

- do you think this gun (Shorty) always had the stacking/binding issue with factory springs & you just noticed it?

|

I only really noticed this when I replaced the original springs. I installed a new set and immediately noted the dull thud as I exercised the slide fully to the rear. Sensing something was amiss I started measuring stuff and saw that the springs were too long, were binding and causing short stroking. Perhaps when these guns were built the springs were specifically tuned for these models or each model run. No way to tell since the PC of 20 years ago is long gone.

Quote:

Originally Posted by BLUEDOT37

- were you able to get anything from S&W (the 3rd Gen. experts) as to whether the factory replacement spring dimensions changed causing this issue?

|

Nope. I have spoken with S&W reps countless times and they consistently decline to give me any measurement or dimensions on anything. Won't even confirm or deny accuracy of a measurement I have taken on one of my own guns. "We don't give out that kind of information" is the canned response.

Quote:

Originally Posted by BLUEDOT37

- I'm guessing that guns vary in their thickness at the spring tunnel opening but the recoil spring should be designed to allow for this, within reason?

|

I don't think there's any problem with the guns. I think it's manufacturing variables in spring production. From the steel mill that draws the steel into wire and spools it to the contractor who winds that wire into finished springs. Could be tolerance stacking in production machinery or variables between the spring contractor of two decades ago and whoever is the current spring contractor. In any event, I don't get the impression that anything having to do with 3rd gens even 1st & 2nd gen for that matter is very high on the S&W list of stuff that needs doing. More likely it's on the list of stuff to ignore until it goes away.

Quote:

Originally Posted by BLUEDOT37

I recently got a 1076 (single recoil spring) & ordered a compliment of replacement springs from Wolff for it before I shot it. After I put Wolff's standard 17# spring in & racked the slide I noticed it didn't feel/sound "right" when it stopped it's rearward motion. I remembered this thread & marked the slide/frame & found the slide was stopping about 1/2 a pencil mark's thickness too soon with the Wolff spring in, verses with no spring. I then put the gun's original spring (factory?) back in & it was actually a hair worse, instead of better. A heavier Wolff spring was no different either, of course.

|

Had the exact same experience with those springs in my 4566TSW a couple years ago. Factory springs were not available at the time so I ordered a couple standard weight plus a tuning pack and they were too big for the gun. Well, by the time I was nearing completion of that project I was able to source a couple OEM springs and that's what went in the gun.

Saw the same thing with my 4516-1 project. Extra power Wolff spring would bind so I left the original tired factory spring in there until I had sorted out the flatwire arrangement and turned a guiderod for it.

Quote:

Originally Posted by BLUEDOT37

I don't have a new factory spring to try & I haven't measured the spring tunnel thickness (I don't know what a good measurement is anyway) but I'm wondering if I should try to cut a turn off of one of the springs to see if that helps? I think that's all it would take to allow it to stop on the frame.

|

That factory spring for your 1076 is S&W pn:895240000. I still have one or two here in the wrap. It's the exact same spring that's specified for my 4566TSW, also goes in the 4006TSW and the M4006CHP and a bunch of others. Basically, every one of the 4 inch forties and all the 4.25 inch 10mm's & 45's call for that spring. In my experience "one size fits all" doesn't always mean it's going to fit well in everything.

Don't get to wrapped around the axle with how thick the face of your spring tunnel is. The dimension you really need to know is how much room is actually in the gun for a spring, any spring, with the slide all the way back and bottomed against the frame's impact abutment.

Here's how to find that out... First your going to need a caliper. Dial or digital, it doesn't matter so long as you have the little rod that extends out of the end when you open the jaws. This enables you to take depth measurements.

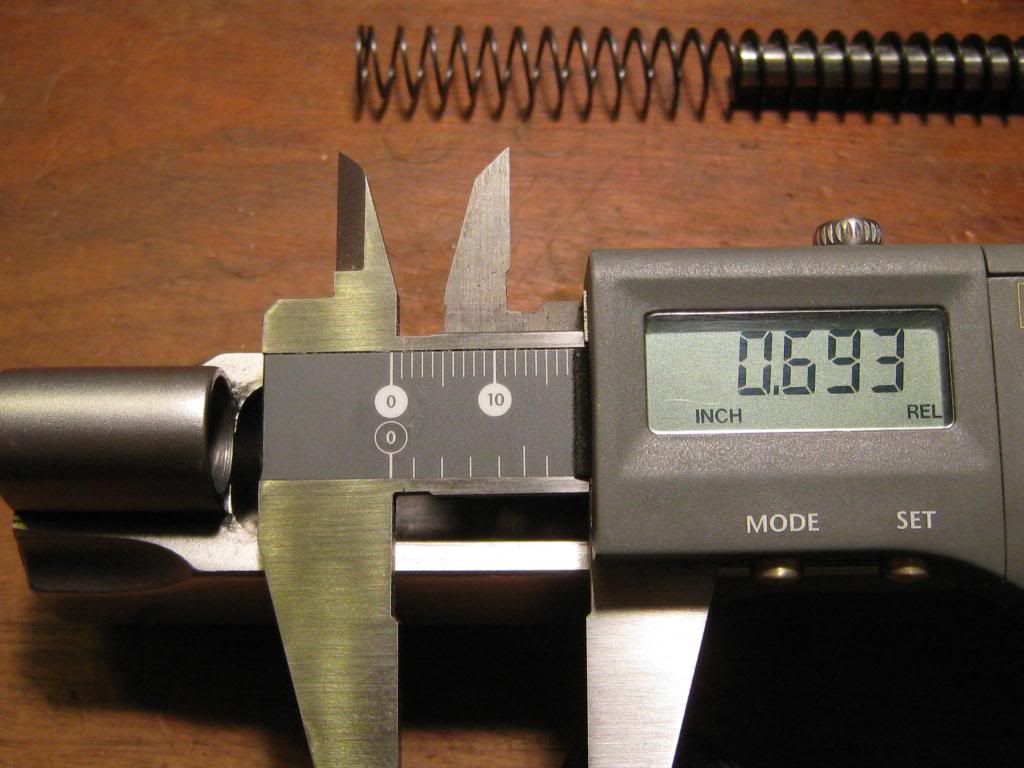

Now we'll field strip our 4566TSW and first, measure the inside depth of the spring tunnel on the slide.

I get 0.693"

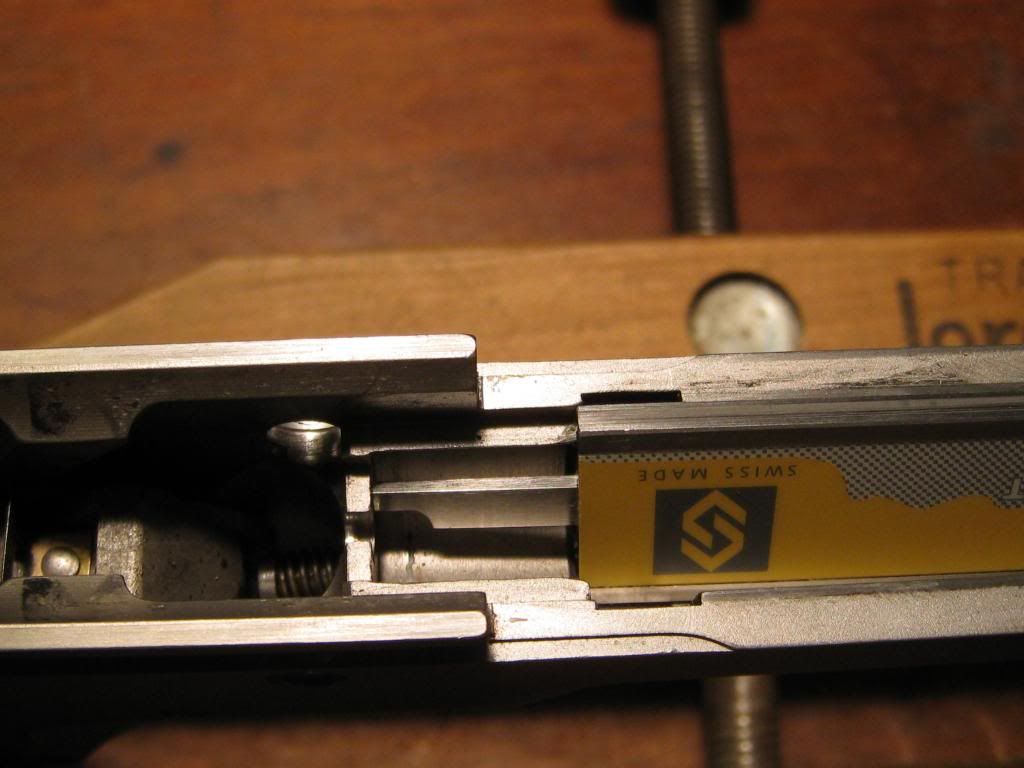

Now I'll measure the spring tunnel on the frame from the impact abutment to the lip where the guiderod sets. Like so.

Got 0.556 here.

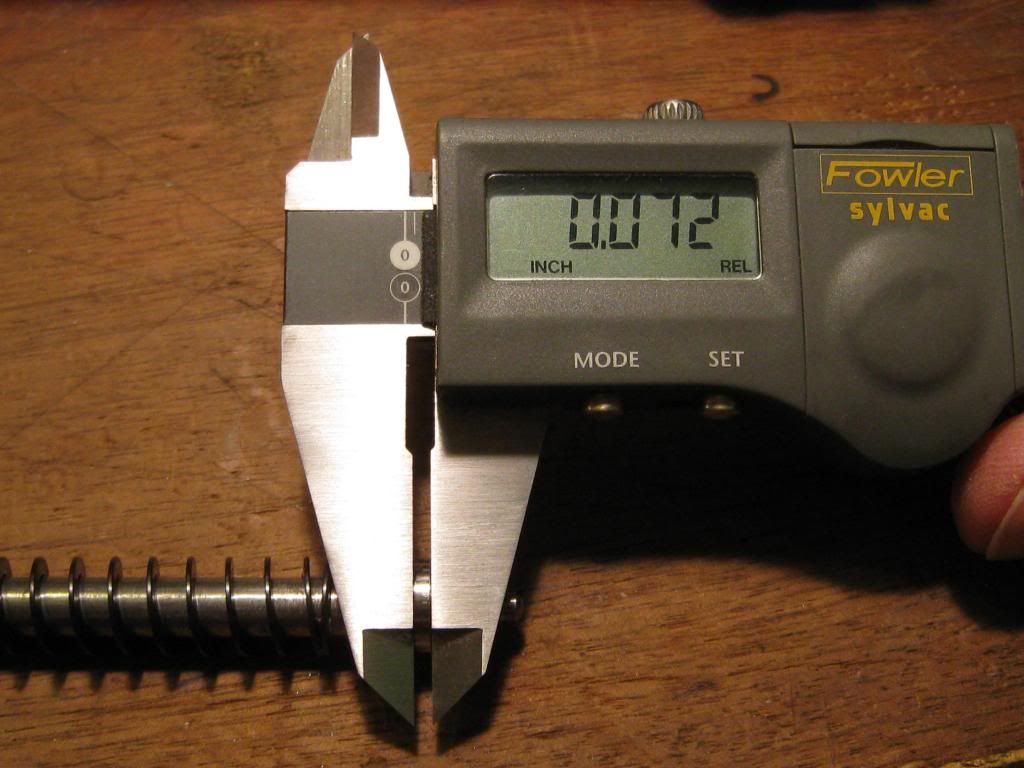

Last measurement you need is the thickness of the head on your guiderod. Mine is 0.072"

Now I dust off my math skills

0.693+0.556=1.249-0.072=1.177

Now I know there is 1.177 inches for my recoil spring to live in with the slide all the way back hard against the frame. So any spring of the proper rating that stack less than 1.177 inches will fit in this gun. Your 1076 ought to pretty darn close to this.

A simple matter really to measure the springs to insure they fit.

Just multiply wire diameter my number of coils to find the stack height.

S&W pn: 895240000 26 coils of 0.0415 wire, stacks at 1.079 inch, this will fit ok

ISMI spring that's in the gun now: 36 coils of 0.026 flatwire,

stacks at 0.936, more spring in even less space, Me like

Wolff 17# spring 27 coils of 0.044 wire, stacks at 1.188 Houston, we have a problem  Not going to run this one.

Sure, I could cut a coil or two off and make it work I just prefer closed coils on both ends when using roundwire springs. In fact, I recall something fastbolt posted recently about open coils doing strange things in these guns and tying them up hard. Like the open coil getting past the guiderod flange or working out the front the the slide. mechanically speaking, a closed coil isn't a spring anymore it's basically a washer or spacer. Even so I prefer a closed coil on each end. Although the flatwire springs seem much less susceptible to riding over or off the guiderod due to the nature of the wire. At least I've had no issue with the ones I've trimmed and run in the Shorty.

If you do cut a coil there's a couple things I recommend. Carefully debur the cut end so there are no sharp edges to damage your guiderod. If your gun has an aluminum guiderod I'd put the open coil on the guiderod first. I think you're less likely to have a problem if the open coil is not running along the length of the aluminum rod. If it's a one piece steel guiderod I think I'd put the open coil out at the muzzle end.

There's a tool used in the jewelry industry called a burr cup. It's basically a tiny cup shaped cutter you can spin in a Foredom or Dremel to debur and round over the cut end of a wire so it wont tear up stuff inside the gun. Very handy for cleaning up cut ends. Just be sure the get the size that will fit the spring wire you're working with.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 9 Users Like Post:

|

|

05-08-2014, 02:55 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,331 Times in 3,497 Posts

|

|

Spring tunnel length

Spring tunnel length

Thanks for the info & detailed response!

I'll measure my 1076's spring tunnel & let you know what it is, FWIW.

.

Quote:

Originally Posted by BMCM

Had the exact same experience with those springs in my 4566TSW a couple years ago. Factory springs were not available at the time so I ordered a couple standard weight plus a tuning pack and they were too big for the gun. Well, by the time I was nearing completion of that project I was able to source a couple OEM springs and that's what went in the gun.

Saw the same thing with my 4516-1 project. Extra power Wolff spring would bind so I left the original tired factory spring in there until I had sorted out the flatwire arrangement and turned a guiderod for it.

|

Haven't run into this until now, with the Wolff springs, & I've installed them (standard & extra-power) in every single recoil spring 3rd Gen. gun we've got, but now we know what to look for, just in case, thanks to your post.

.

Quote:

Originally Posted by BMCM

That factory spring for your 1076 is S&W pn:895240000. I still have one or two here in the wrap. It's the exact same spring that's specified for my 4566TSW, also goes in the 4006TSW and the M4006CHP and a bunch of others. Basically, every one of the 4 inch forties and all the 4.25 inch 10mm's & 45's call for that spring. In my experience "one size fits all" doesn't always mean it's going to fit well in everything.

|

That is strange, I didn't know that. It's kinda like the magazine springs in the 45's. All the magazines use the same PN# 262600000, irregardless of the round count.

.

Quote:

Originally Posted by BMCM

If you do cut a coil there's a couple things I recommend. Carefully debur the cut end so there are no sharp edges to damage your guiderod. If your gun has an aluminum guiderod I'd put the open coil on the guiderod first. I think you're less likely to have a problem if the open coil is not running along the length of the aluminum rod. If it's a one piece steel guiderod I think I'd put the open coil out at the muzzle end.

|

I ran into this with Wolff's 21# spring (see attached) I had ordered in their tuning set for my 4516-1. That spring didn't have a closed end on both ends, unlike all the others I've ever gotten from them. At first they said it was a bad spring & sent me another, which was exactly the same. Then they said that was what their spec called for & it was probably cut to obtain the 21# rating. When I tried it, I rounded the cut wire's end & then, using two needle-nose pliers, I turned the end in to give the spring a flatened end, as to not gouge the slide's spring tunnel seat. So far it's been fine.

.

.

On the subject of spring cross referencing, I'd make myself dizzy (easy for me) trying to keep things straight, especially with multiple models using the same PN#, so I made a list cross referencing S&W & Wolff PN#s for some of mine. I've attached it here in case anyone else finds it useful.

.

Last edited by BLUEDOT37; 06-12-2018 at 01:29 AM.

|

|

The Following 3 Users Like Post:

|

|

05-08-2014, 11:38 AM

|

|

Absent Comrade

|

|

|

Join Date: Sep 2005

Location: GSO NC

Posts: 6,106

Likes: 23,604

Liked 13,195 Times in 2,860 Posts

|

|

Thanks BMCM!

I will hold onto that package till next week then and give the spring a try. Thanks again for your work and patience in explaining all this to us!! Best regards, 18DAI

__________________

7 +1 Rounds of hope & change

|

|

The Following User Likes This Post:

|

|

05-10-2014, 01:41 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,331 Times in 3,497 Posts

|

|

Spring Tunnel Length (the bind) - Part Deux

Spring Tunnel Length (the bind) - Part Deux

Quote:

Originally Posted by BLUEDOT37

I'll measure my 1076's spring tunnel & let you know what it is, FWIW.

|

I went ahead & checked the available spring space dimensions in my 1076 today. When I did it like you did I came up with 1.214" of spring space. (0.702" + .564" - .052": spring tunnel + abutment-flgr.seat - flgr.flange). The Wolff 20# spring I wanted to use has (27) turns @ .0445" = 1.2015" compressed length. So these figures would indicate that the slide would not stop on the spring, but I knew it was, just barely. I double checked all the readings but they came out essentially the same. (The .564" reading was the only one that wasn't consistent.)

For the heck of it I decided to try a different way, which I figured would be a good double-check & is a little more straightforward. With the slide off & the barrel & spring removed, I put the largest plug gage that would fit (.425") in the spring tunnel & slide it forward until it butted up against the inside of the spring tunnel's seat. Then I measured the thickness of the spring tunnel's seat, from the face of the pin gage (inside the slide) to the face of the muzzle (.178"). Then I placed the guide rod (FLGR) flange in it's seat in the frame & assembled the slide on the frame, with the FLGR existing it's hole in the spring tunnel muzzle. With the slide all the way rearward, & with the slide contacting the frame abutment, I pressed the end of the FLGR rearward, to fully compress it's spring loaded tip, & marked the FLGR with a Ultra Fine Sharpie where it exited the spring tunnel. Lastly I removed the FLGR & measured from that mark to the FLGR's flange face, & got 1.381", then subtracted the spring tunnel's thickness, .178" & got 1.203".

Either way I check it, it's a close fit, so I decided to cut (1) turn off the muzzle end (large closed end) of the 20# Wolff spring (the small closed end goes toward the FLGR flange), smooth out the cut wired end & then bend the end inward, to give it a flat(ter) surface as to not gouge the spring tunnel seat, & reassembled it. Walla, now the slide clearly stops on the frame, not the spring. I'm sure I could have just cut one turn off to try it first, since I knew it was just a hair off, but I wanted to see what the numbers looked like before, just for the halibut. Went to the range today & fired 125 rds. of assorted bullets/powder without issue. Spent cases from full power loads still obtain low-earth orbit, but oh well. Issue resolved.

Last edited by BLUEDOT37; 05-10-2014 at 01:54 AM.

Reason: .

|

|

The Following User Likes This Post:

|

|

05-10-2014, 04:52 AM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by BLUEDOT37

I went ahead & checked the available spring space dimensions in my 1076 today. When I did it like you did I came up with 1.214" of spring space. (0.702" + .564" - .052": spring tunnel + abutment-flgr.seat - flgr.flange). The Wolff 20# spring I wanted to use has (27) turns @ .0445" = 1.2015" compressed length. So these figures would indicate that the slide would not stop on the spring, but I knew it was, just barely. I double checked all the readings but they came out essentially the same. (The .564" reading was the only one that wasn't consistent.)

For the heck of it I decided to try a different way, which I figured would be a good double-check & is a little more straightforward. With the slide off & the barrel & spring removed, I put the largest plug gage that would fit (.425") in the spring tunnel & slide it forward until it butted up against the inside of the spring tunnel's seat. Then I measured the thickness of the spring tunnel's seat, from the face of the pin gage (inside the slide) to the face of the muzzle (.178"). Then I placed the guide rod (FLGR) flange in it's seat in the frame & assembled the slide on the frame, with the FLGR existing it's hole in the spring tunnel muzzle. With the slide all the way rearward, & with the slide contacting the frame abutment, I pressed the end of the FLGR rearward, to fully compress it's spring loaded tip, & marked the FLGR with a Ultra Fine Sharpie where it exited the spring tunnel. Lastly I removed the FLGR & measured from that mark to the FLGR's flange face, & got 1.381", then subtracted the spring tunnel's thickness, .178" & got 1.203".

Either way I check it, it's a close fit, so I decided to cut (1) turn off the muzzle end (large closed end) of the 20# Wolff spring (the small closed end goes toward the FLGR flange), smooth out the cut wired end & then bend the end inward, to give it a flat(ter) surface as to not gouge the spring tunnel seat, & reassembled it. Walla, now the slide clearly stops on the frame, not the spring. I'm sure I could have just cut one turn off to try it first, since I knew it was just a hair off, but I wanted to see what the numbers looked like before, just for the halibut. Went to the range today & fired 125 rds. of assorted bullets/powder without issue. Spent cases from full power loads still obtain low-earth orbit, but oh well. Issue resolved.  |

I tried several different methods for measuring internal spring space. I found the most consistent and accurate results from the method illustrated in my previous post.

I've often found that springs will actually bind a bit longer than the paper calculations indicate. Small variations in the wire diameter along the length of the spring a thousandth or two here and there adds up. I've also had pay special attention to count the coils accurately. It's quite easy to miscount at the closed coil ends and be short by one coil due to overlooking a half wrap at a closed end.

You know, If I were in your place I would give one of these a try for hotrod 10mm stuff  ISMI Glock Full Size 24lb Recoil Spring G17,17L,20,21,22,24,31,34,35,37

ISMI Glock Full Size 24lb Recoil Spring G17,17L,20,21,22,24,31,34,35,37

Just need a solid stainless guiderod turned down to about 0.255ish and it'll be silky smooth. I may have a spare guiderod around here somewhere that'll fit your 1076. Let me know if you'd like to give it a shot.

I did one for my 4566TSW and have one of those springs at 20# rating in there now. Works fine  Keep in mind, all the 4.25inch large frame guns used the same factory spring so I think you'd be golden in the 20# to 24# range. Another thing you can do that will shave off some slide velocity and tame violent ejection is install a heavier mainspring.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

05-11-2014, 03:32 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,331 Times in 3,497 Posts

|

|

ISMI 24# flat spring

ISMI 24# flat spring

I understand what you're saying about the spring count. I kept looking at the closed double looped ends to make sure I was figuring it right (there I go getting dizzy again).

I've bought Wolff's recoil spring calibration pack (#13183) so I have a 22# I can still try. I also got their hammer spring pack #11412 (because I learned when I setup my Colt Series 70 to shoot 45 Super that besides a heavier recoil spring, & a small radiused firing pin stop, a stronger mainspring was needed.) which has a 22 & 23# extra power springs in it I can try.

I might try those ISMI 24# flat springs later though. Did you need to shortened them for the 4-1/4" bbl.?

I appreciate the offer for the FLGR but I know supply is limited & I'd hate to take something you might need later. I did, however, get an extra one (for unknown reason) in the 845's box. Of course it's longer (4.314" OAL, & .287" dia., solid SS) but it doesn't have the plunger & spring in it (I guess I could use my existing ones?). It looks unused & was in a small zip pouch with the number 23135 hand written on it. That number isn't in the S&W parts catalog but it looks the same as what's in the 845, if that's one that could be shortened & turned down instead?

|

05-11-2014, 05:25 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by BLUEDOT37

I might try those ISMI 24# flat springs later though. Did you need to shortened them for the 4-1/4" bbl.?

|

Nope, the 36 coil springs drop right in given the correct guiderod dimentions.

Quote:

Originally Posted by BLUEDOT37

(4.314" OAL, & .287" dia., solid SS) ... if that's one that could be shortened & turned down instead?

|

Can easily be done and I have some spare plungers+springs too. If you want, you can send it to me and I'll fix it up.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 3 Users Like Post:

|

|

05-12-2014, 12:47 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by BLUEDOT37

I double checked all the readings but they came out essentially the same. (The .564" reading was the only one that wasn't consistent.)

|

I have another caliper that just doesn't fit well down inside the dust cover, that why I've been using the fowler digital. Anyway, if you're getting varyings result with your depth instrument you can try this.... Use the outer end of the dust cover as the reference. Take a measurement from there to the impact abutment and then another to the guiderod seat. The difference will give you the frame's spring tunnel depth.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

05-13-2014, 05:41 PM

|

|

Banned

|

|

|

Join Date: May 2014

Location: Central NC.

Posts: 3,207

Likes: 37,672

Liked 4,393 Times in 1,851 Posts

|

|

Wow. Thanks for the write ups and photos. I just bought a Shorty 45 MK2 and was trying to get spare springs, but most places are out of stock.

I'll have to check on those ISMI CCF22's.

|

05-14-2014, 10:13 AM

|

|

Banned

|

|

|

Join Date: May 2014

Location: Central NC.

Posts: 3,207

Likes: 37,672

Liked 4,393 Times in 1,851 Posts

|

|

I've looked for the CCR22 and keep getting springs for glocks, both the full size and the compact. I just want to make sure I'm getting the right ones. Should I get the 22lb for the compact?

Sorry I'm new to fitting springs, so I may have missed something.

|

05-14-2014, 03:06 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

So I was told, those CCF22 springs were a special order item that was never payed for. So ISMI had a bunch of springs that didn't go to anything. I purchased 30 of them to fiddle with and with a little trim they work nicely in my Shorty.

These are just 1 coil shorter than compact Glock flatwire springs ISMI makes. Other than that, they are identical to the GLC22 spring you can get online from several sources.

I spoke with ISMI again today hoping they had a stocked item that would work without modification. Nope, the best we can do is what we have now. Either the 30 or 31 coil 22# spring trimmed to precisely 27 coils.

I'm not sure if ISMI has any more of the 30 coil units but the 31 coil springs are readily available all over, here's but one example.

ISMI Glock Compact 22lb Recoil Spring G19,23,25,32,38

You need to carefully trim these to 27 coils. I prefer using a "hard wire" cutter but a small cutoff wheel will also work. The cut end then will require some dressing to cleanup any burrs and sharp edges so as to NOT gouge anything once installed.

I use a small fine grit mounted stone like this to deburr. Shape of the stone isn't critical, this is just the one that was handy. Use low speed and take care not to let the stone hit anywhere but the end you're deburring.

Doesn't take much at all, just knock off all the sharp scratchy bits.

Then you need to thoroughly clean up the spring to remove any trace of grinding debris before you install it. You certainly don't want any metal dust or abrasive particles milling about inside your Shorty

I think it best here to orient the spring with the closed coil on the guiderod first and the cut end in the slide's spring tunnel.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 4 Users Like Post:

|

|

05-14-2014, 04:03 PM

|

|

Banned

|

|

|

Join Date: May 2014

Location: Central NC.

Posts: 3,207

Likes: 37,672

Liked 4,393 Times in 1,851 Posts

|

|

BMCM,

Thanks a lot!

|

05-27-2014, 09:30 PM

|

|

Member

|

|

|

Join Date: Mar 2010

Location: New England

Posts: 239

Likes: 485

Liked 235 Times in 107 Posts

|

|

quide rod machining question

quide rod machining question

BMCM...

Did you do anything special to turn down the oversized guide rod and still have it fit (look) OK in the larger opening in the slide?

I just measured my 6906 guide rod and it looks about 0.290".

I'm worried that if I turn it to 0.250" for the entire length the face of the slide may look too "loose".

As to the CS9-CS45 springs I purchased the "Glock 17" spring with the idea of getting 2 springs out of it...

We'll see what happens!

Thanks again for all your reports on this subject.

Tom

|

05-27-2014, 09:51 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: Long Beach, CA

Posts: 1,386

Likes: 876

Liked 994 Times in 442 Posts

|

|

Springs binding in my Shorty 45

Springs binding in my Shorty 45

Tom 45,

You might look into modifying an alternate guide rod. The smaller diameter shouldn't be an issue since the ISMI springs will hold it center in the spring tunnel.

Just curious, why do you want to the run the ISMI? I run factory springs in my 6906 with no issues.

__________________

USS ZELLARS

DD-777

|

|

The Following User Likes This Post:

|

|

05-27-2014, 10:43 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,217 Times in 1,043 Posts

|

|

Quote:

Originally Posted by tom 45

BMCM...

Did you do anything special to turn down the oversized guide rod and still have it fit (look) OK in the larger opening in the slide?

I just measured my 6906 guide rod and it looks about 0.290".

I'm worried that if I turn it to 0.250" for the entire length the face of the slide may look too "loose".

As to the CS9-CS45 springs I purchased the "Glock 17" spring with the idea of getting 2 springs out of it...

We'll see what happens!

Thanks again for all your reports on this subject.

Tom

|

All the guns using a single recoil spring have a .290 guiderod. Those calling for the dual nested spring set have a .236 guiderod. Setting up to run a flatwire spring calls for making a guiderod of .250 or so.

Note that this endeavor is a workaround for the lack of the nested dual spring set. Additionally the most recent spring sets from S&W would coil bind in my Shorty45.

6906 springs are still readily available from Wolff so, I too am curious as to why you're looking into this for that particular gun.

Also be aware you must use a late version solid one piece stainless guiderod for this. An aluminum or steel staked unit simply will not work.

Nothing special about the machining. For my most recent one, I turned it to .260 for a little bit nicer & closer fit on the spring. Yes there's a little bit of gap at the slide tunnel exit hole if you look closely but the spring is such that it also serves as a bushing to keep the guiderod in perfect alignment, just like this:

That one is my 4566TSW with a guiderod turned to .255 and inside there is a 17# 36 coil ISMI spring.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 4 Users Like Post:

|

|

05-28-2014, 11:21 AM

|

|

Member

|

|

|

Join Date: Mar 2010

Location: New England

Posts: 239

Likes: 485

Liked 235 Times in 107 Posts

|

|

There is no real reason to convert the 6906 to flat springs.

I'm kind of planning for the future.

I did order a replacement spring from Wolff...

I guess I'm just a tinkerer.

If I did it I'd make a new guide rod.

Of course I'd have to figure out how to do the inner end!

My big concern was the look at the front of the slide...

That fear is over... That slide looks excellent.

Thanks guys.

|

|

The Following User Likes This Post:

|

|

05-29-2014, 04:41 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,331 Times in 3,497 Posts

|

|

Slide velocity

Slide velocity

Quote:

Originally Posted by BMCM

Slide to frame contact is not a bad thing so long as it's controlled. A soft landing on the frame by a properly sized spring of the correct weight for the loads is the goal... Uncontrolled slide to frame battering is. The two are not the same.

|

I was just reading a July 1989 article in Shooting Times on the development of the 10mm & S&W's autoloader for it. The prototype was a modified 4506. The related fact mentioned was that the slide to frame impact velocity of a 45ACP slide was found to be about 18fps. The 10mm was about a third greater at about 24-25fps. (The slide's top speed occurs about midway back in the cycle.) I had wondered how hard they hit the frame but never had seen any numbers. Just a tidbit that made me think of the recoil spring threads here. And by the way, their testing deduced, what's become well known, that the platform was "stronger than it needed to be".

|

|

The Following 2 Users Like Post:

|

|

06-24-2014, 12:42 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,331 Times in 3,497 Posts

|

|

GL-22 in 1076

GL-22 in 1076

Quote:

Originally Posted by BMCM

You know, If I were in your place I would give one of these a try for hotrod 10mm stuff.  ISMI Glock Full Size 24lb Recoil Spring G17,17L,20,21,22,24,31,34,35,37

ISMI Glock Full Size 24lb Recoil Spring G17,17L,20,21,22,24,31,34,35,37

Just need a solid stainless guiderod turned down to about 0.255ish and it'll be silky smooth... I did one for my 4566TSW and have one of those springs at 20# rating in there now. Works fine  . Keep in mind, all the 4.25inch large frame guns used the same factory spring so I think you'd be golden in the 20# to 24# range.

Cheers

Bill |

.

Just an update to say I installed a GL-22 (full size, not the GLC compact) ISMI flatwire spring in my 1076, on a modified guiderod (turned down to .255" dia.), & it installed without having to cut any coils. Test fired without issue. I also bought a 24# spring which I plan to try next trip to the range.

|

|

The Following User Likes This Post:

|

|

|

Posting Rules

Posting Rules

|

|

|

|

|