|

|

|

|

05-08-2016, 12:03 AM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Two month update - Ejection issues solved

Two month update - Ejection issues solved

Evenin' Gents,

A couple months back I mentioned having occasional ejection faults. It didn't seem to matter what ammo I was using, I kept seeing the same problems with fired cases failing to leave and tying up the gun.

This kinda bovine excrement is bad for my blood pressure

Over the past few weeks I had tried correcting this fault by addressing a number of things.

Today, I went to the range and burned through 100 rounds of 165gr Speer FMJs in Underwood's loading (perfect training companion to Underwoods 165gr GDHP loading BTW. Thanks to 6actual for bringing that to my attention  ). Anyway, The gun ran perfectly, not a single hiccup so I thought to share the things it took to get it running right.

Initially, I suspected the recoil spring weight might be at issue. I was thinking perhaps the spring was too heavy and either preventing full travel of the slide or closing the slide faster than the brass can leave. I tried progressively reducing the weight of the recoil spring from the original 30 coils to 28, 26, 24 and the 20 coil Wilson spring. This tack was a dead end. None of this meddling had any effect of the ejection problems. In fact the lighter I went in spring weight the further I had the chase brass and I started to see signs of early extraction in the cases.

Clearly messing with recoil springs wasn't the answer so the problem or problems must lie elsewhere. I closely examined the breechface area under the loupe, Right away I noticed the area opposite the extractor was very rough with a significant burr overhanging the breechface.

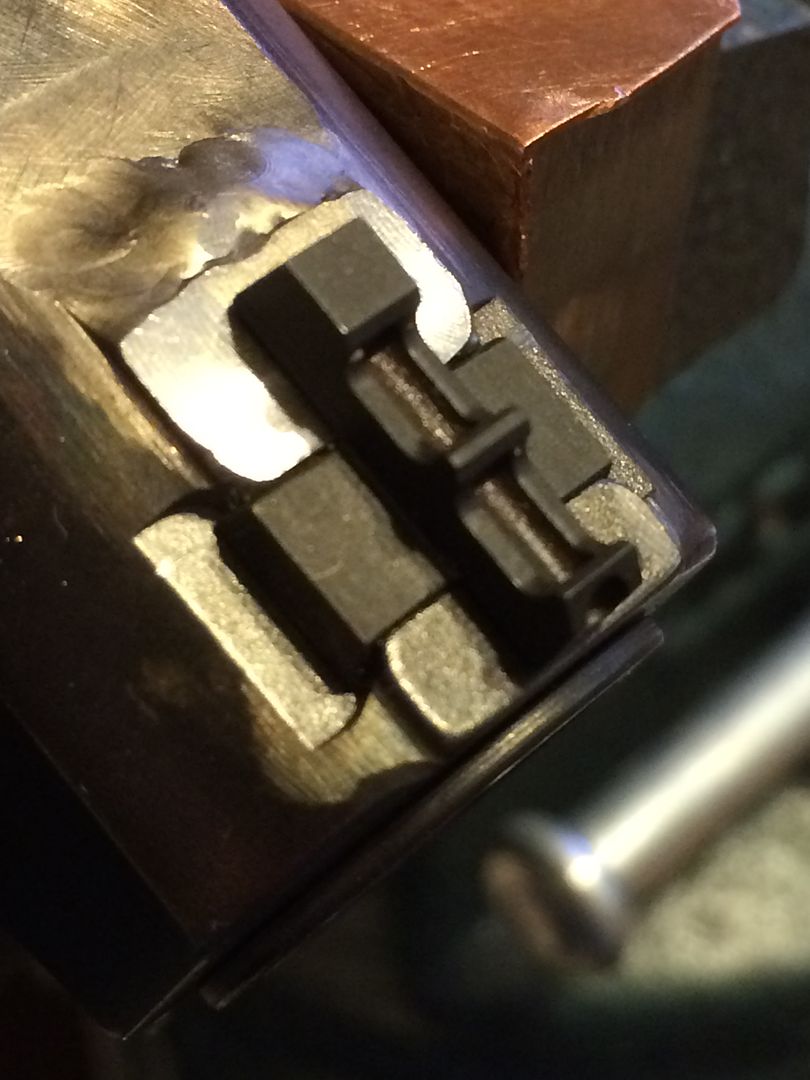

This is the the spot right here already smoothed out but still dirty after today's range session.

That overhanging burr acted somewhat like another extractor. With the slide off I could slip a case up the breechface under the extractor and as I tipped the casemouth towards the ejection port the rim would catch firmly on that burr.

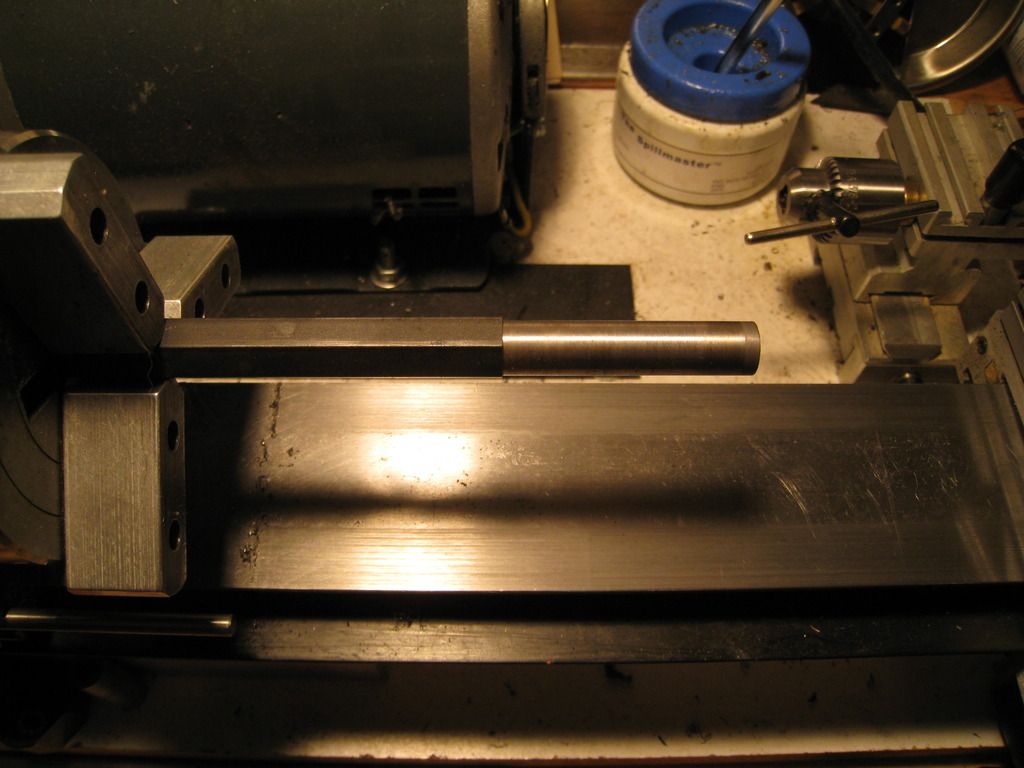

So, how to fix that... No way to get at that with a file and I certainly didn't feel good about going in there grinding with a mounted stone. What I did was turn down a piece of mild steel hex bar to about the diameter of a 10mm case, chucked that in my lathe and with a little dab of 400 grit lapping compound on the end I carefully ran the slide up over the spinning bar and lapped the roughness and burrs away.

Here's a closer look. It's that shallow radius cut right above the ejector. Nice and smooth now.

I wish I had taken a picture of that area before I cleaned it up, it was truly nasty. Of course everything looks worse under magnification but that cut looked like it was gouged out with a broken hacksaw blade.

Waited for another Saturday to come by and back to the range for testing. Once again I'm back to a full length 30 coil 22# spring installed in the gun. Ejection faults were much less frequent but I was still seeing problems so I turned my attention towards the extractor.

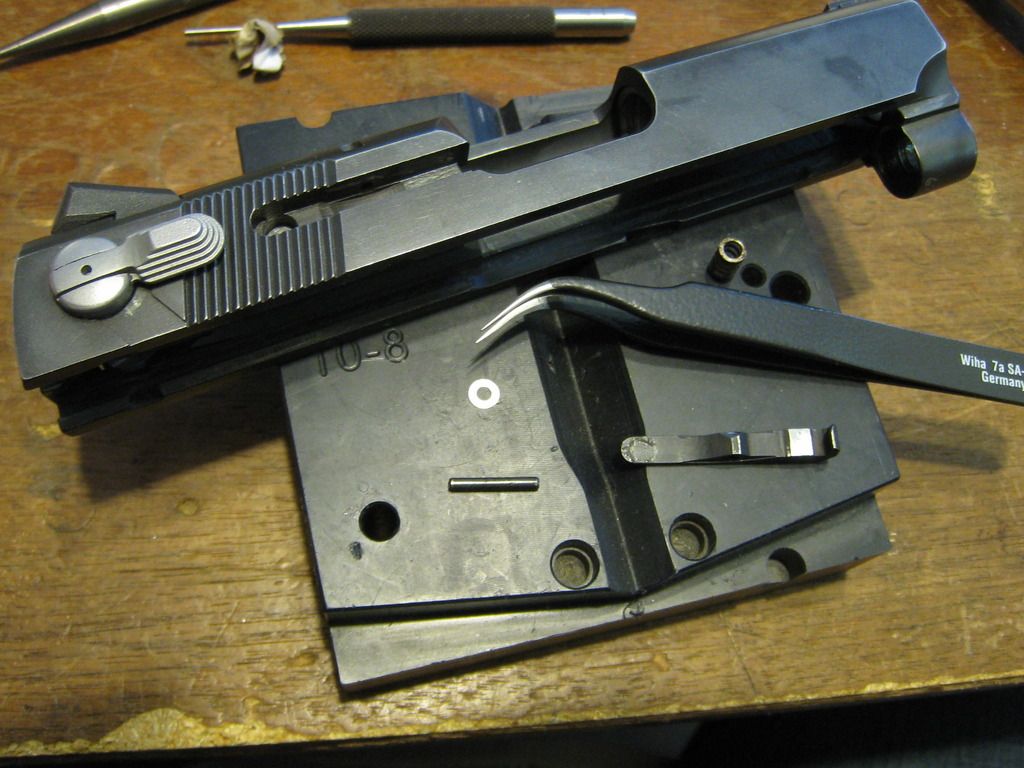

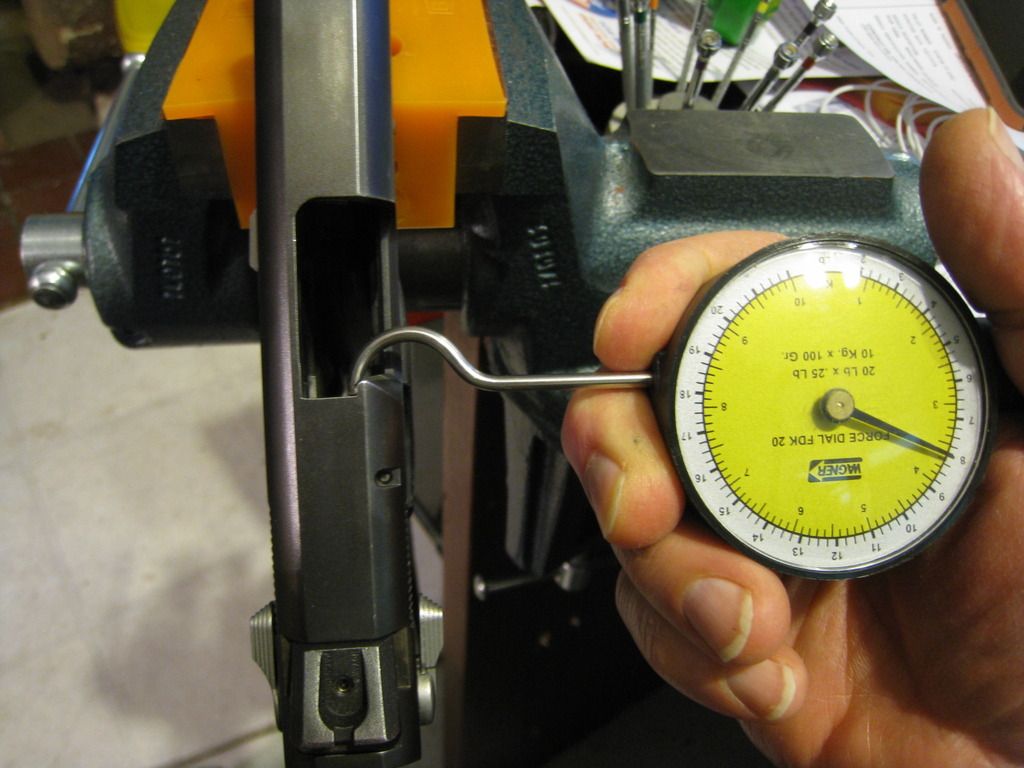

I didn't note any binding and the extractor pivoted freely. Checked the weight at deflection and it was just a hair over 5#. I pulled the extractor for a closer examination. Nothing out of the ordinary. Everything is clean & corrosion free, red spring installed (heavy), only thing I noted was whomever fitted this extractor did not know how to keep a file level & true when cutting on a part. The adjustment pad on the extractor was rolled on the edges with file marks going every which way. Hmm says I, methinks I be needin' a bar gage. For those who don't know, the bar gage is a tool for setting how far the extractor hook reaches across the breechface.

Anyway I eventually got around to calling S&W on the remote possibility I might be able to order a bar gage. No such luck, not even available. But was lucky enough to get a knowledgeable fellow on the phone and not some beancounter. While I didn't get a bar gage I did get the critical dimensions so I can machine one. In discussing my problem It was mentioned that during production, they were looking for at least 8# at deflection for the extractor weight on the 10mm guns and if a one didn't gage there even with the heavy spring they'd shim up the spring to make weight (lightbulb moment).

After thanking the gentleman I navigated right over to McMaster-Carr and added some 316 stainless miniature shaft shims to my running order.

In the meantime while waiting for that stuff to show up and knowing the specs for the GO and NOGO on the bar gage I was able to sort of halfassed gage the extractor with a caliper. Not exactly precise but it looked to me like the extractor did not reach in as far as it should however, I'll not mess with the adjustment until I've made a proper gage to go up in there.

Shims got here a couple weeks ago. I got a pack of 0.005" and one of 0.008". That tiny silver washer on the bench block is one of them.

Just drop 'em in the recess under the extractor spring.

A little bit of trial and error and were spot on with 8# at deflection with 0.024" of shim under the extractor spring

All good to go and cleared for belt duty  A sharp eye will detect that I've carried on with the "pinto" motif a bit. The original black sideplate is gone in favor of an updated R1 version. I also changed the trigger pin and magazine catch nut to stainless parts. I think I'll make a stainless grip pin tomorrow

Finally getting this thing to run fault free with heavy full power loads is pretty darn satisfying. Still, I need to fab a proper bar gage and double check the extractor reach so there will probably be another update once I get by butt in gear and make the thing.

Cheers

Bill

__________________

Because they don't make a .46

Last edited by BMCM; 05-08-2016 at 01:48 PM.

Reason: fixed missing pics

|

|

The Following 12 Users Like Post:

|

03Fatboy, 18DAI, 6actual, Big Shrek, BLUEDOT37, GaryS, JohnHL, Old_Cop, Shadow1006, TAROMAN, TTSH, vigil617 |

05-08-2016, 07:42 AM

|

|

US Veteran

|

|

|

Join Date: Nov 2011

Location: Stuart, Fla

Posts: 470

Likes: 1,071

Liked 586 Times in 217 Posts

|

|

Nice! I really enjoy that you post in great detail on one of my favorite pistols. Are you getting any slide bounce with the full length 22# recoil spring? I'm using a slightly cut down 24#. My other question is; is it shooting to POA? mine shoots about 2in low @ 7yds with a 165gr bullet, I know I could bring it up with a heavier bullet but the 165gr makes recoil really manageable and its the same bullet weight of my SD rounds

__________________

It is the Indian not the arrow

Last edited by 6actual; 05-08-2016 at 07:43 AM.

|

|

The Following User Likes This Post:

|

|

05-08-2016, 10:40 AM

|

|

Member

|

|

|

Join Date: Nov 2009

Location: Republic of Texas

Posts: 11,363

Likes: 9,380

Liked 17,296 Times in 6,647 Posts

|

|

BMCM, just building the guns that S&W won't!

Terrific work, so I have to ask.

Did you go to school or are you self taught? Your attention to detail is amazing. As is your thought process.

Quote:

Originally Posted by Big Shrek

I'm going to point out a little thing that worries some folks...

HRT's using 10mm know it also does one other thing...

they can shoot thru a victim and into a terrorist pretty easily...

sometimes you have to put a non-lethal wound on a good guy,

to give a fatal wound to a bad guy...

or if the bad guy is evil enough, you'll sometimes have to

give fatal wounds to hostage AND bad guy.

Just the reality of the world since the 1972 Munich Massacre...

|

I'll only say that my friend who has experience in this world told me that they consider this kind of thing a failure. Hurting or killing the hostages is the sign of an amateur operation. Having no first hand experience, I can only go by what he has related.

__________________

Can open, worms everywhere.

|

|

The Following 4 Users Like Post:

|

|

05-13-2016, 02:54 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Quote:

Originally Posted by 6actual

Nice! I really enjoy that you post in great detail on one of my favorite pistols. Are you getting any slide bounce with the full length 22# recoil spring? I'm using a slightly cut down 24#. My other question is; is it shooting to POA? mine shoots about 2in low @ 7yds with a 165gr bullet, I know I could bring it up with a heavier bullet but the 165gr makes recoil really manageable and its the same bullet weight of my SD rounds

|

Thanks!

Nope, no slide bounce with the 30 coil spring. I did speak with ISMI some weeks ago looking for a short heavy spring something like the Wilson but in 24#. No joy, the heaviest is the fullsize 36 coil 24# which won't fit this gun. I asked about shortening one of those 24# spring and was told the compact 31 coil 22# is essentially the same spring only shortened. For now I have a 30 coil spring in there and have ordered a few GLC22 (31 coil) springs to try out.

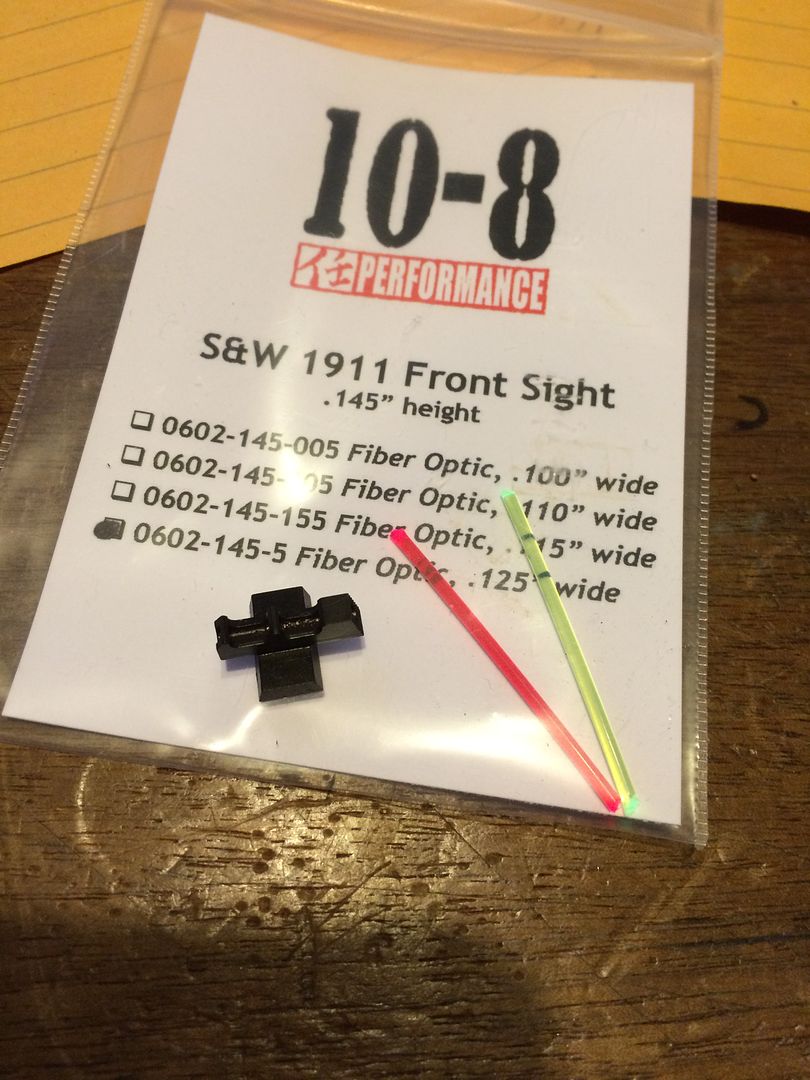

I have the standard Novak sights on the gun. Early on it was shooting about 2-3 inches high at 15yds. I have since changed the front sight to a 0.229 tall blade and it's now spot on POA at 15yds with the factory Underwood 165gr loadings.

No signs of undue battering or wear so far. I keep a close eye on the frames impact abutment after each shooting session and so far so good  . I also closely examining the frame's barrel camming lugs for wear. Lugs are still in fine shape. I do use a heavy EP (extreme pressure) moly grease on the lugs and rails to protect the aluminum from the steel. I'm using Dupont's Krytox® GPL215 or GPL217. Brownells Action Lube Plus™ will also do the job.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 4 Users Like Post:

|

|

08-30-2016, 05:30 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Howdy Gents!

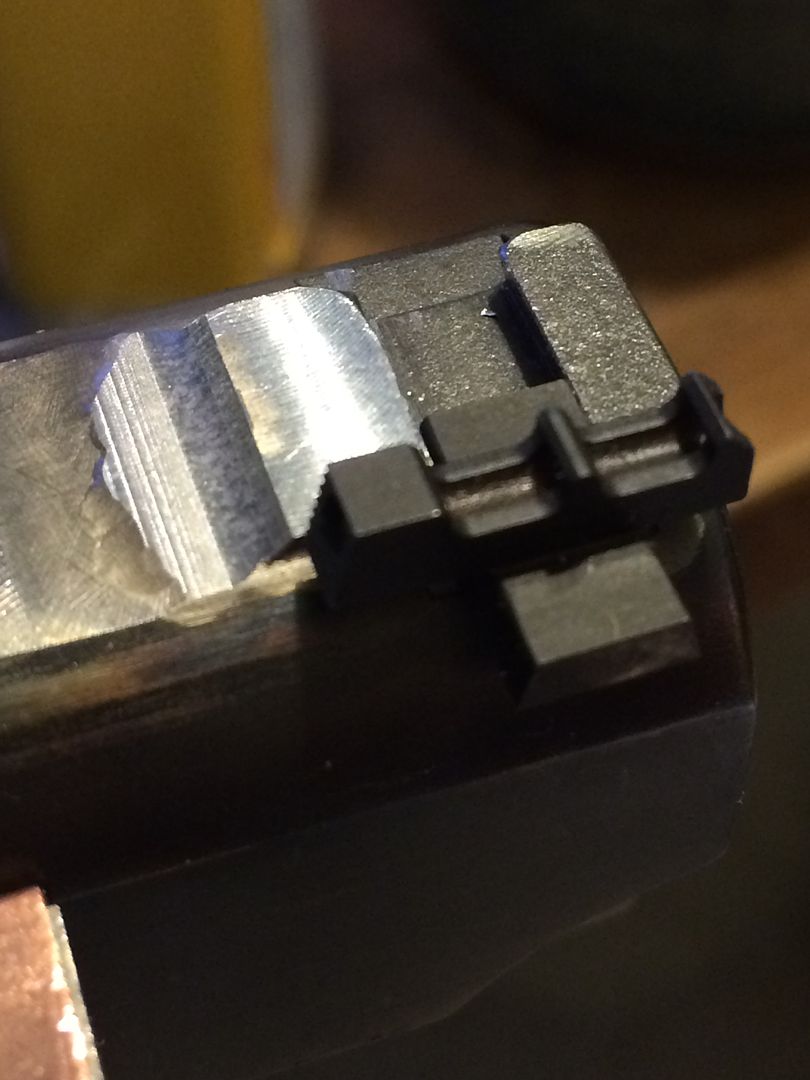

Back in May, this thread 10-8 rear sight on a 3rd gen pistol? got me a-thinkin' about sticking a 10-8 rear sight on this little project gun.

I had used a little 74° dovetail cutter in the mill to re-cut the angles on the 10-8 sight to fit the S&W slide cut. Of course I also had to carve the raised lip off the rear of the slide for this to fit. That first sight I remodeled came out a little loose. I really can't stand seeing daylight under the dovetail on an installed sight  So, I resolved to order another 10-8 rear and do it again. I also changed the tool I was using to a larger diameter 75° cutter. Along the way, I got to thinking about installing a 10-8 front sight too so I also ordered one of those.

The focus of this update is for the most part what it took to get this thing:

to fit my "1014" project and NOT look like ****

It's got the right dovetail base but there's a ridiculous amount of overhang towards the rear.

I'll need to remodel this thing for it to work.

Off to the welding table for a little hot work:

Roughing out that glob on the mill got me close. No more overhang but still a couple spots needing more filler metal.

A tad more filler and some hand fitting on the sight base and it's looking good so far.

Now back to the mill to start contouring and blending.

I found the top of the slide was a little crooked while indicating it in for some cuts so I dusted off a couple thousandths to true it up. Had to position the thing in the vise with the muzzle end tilted up about 2°

All done contouring on the mill, time to hit the blast cabinet.

Along the way, another member sent me a 4013 top end for re-chambering and a 10-8 rear sight mod. Here's the two slides fresh from the blast cabinet.

I don't like cratering around the rollmarks so before I sent these slides off to H&M for nitriding, I wiped the flats up to 600 grit then packaged them up with their respective modified rear sights for a dip in the molten salt bath

Around 10 days later I got this stuff in the mail with a lovely satin black finish

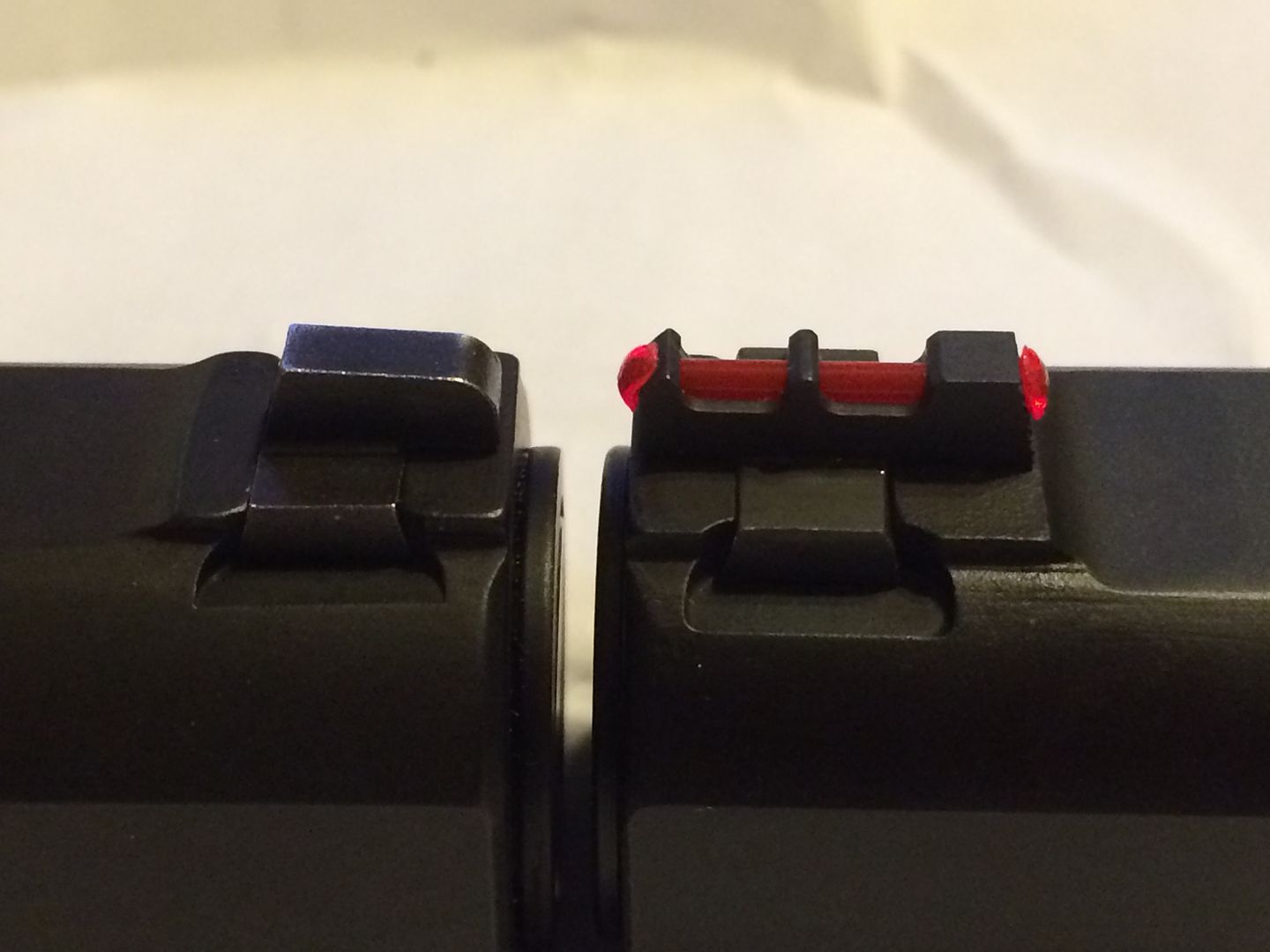

Here's a couple comparison shots after both slides were built up.

I think I can get used to this sight picture

All done here...

A sharp eye might notice I made a stainless grip pin. I made it long so it's a couple thousandths proud of the grip on each side. Seems to prevent crud from collecting in there. I also stuck a stainless magazine catch in there, might have to put a shine in that extractor next

I still haven't got to the range yet, just been too busy with other stuff but am really looking forward to running the new sights.

That's about it for now. I think the next thing is addressing the frame. I'm thinking about a re-do on the sloppy checkering then send it off to Robar for some NP3 Plus. But, I'm enjoying having my "1014" back in service so that stuff will have to wait till later

Wrapping up with a gratuitous shot of the "business end"

Cheers

Bill

__________________

Because they don't make a .46

Last edited by BMCM; 08-30-2016 at 09:17 PM.

Reason: fixed missing pics

|

|

The Following 15 Users Like Post:

|

03Fatboy, 18DAI, 6actual, BLUEDOT37, Brian Parrish, CBus660R, Doug M., Hill_Country, JohnHL, nocents, TAROMAN, TercGen, TexasG, That One Guy, timn8er |

09-01-2016, 12:36 PM

|

|

US Veteran

|

|

|

Join Date: Nov 2011

Location: Stuart, Fla

Posts: 470

Likes: 1,071

Liked 586 Times in 217 Posts

|

|

here is its brother

A truly amazing little hand cannon, a joy to shoot and a very capable pistol making 1207fps w/ Underwood 165gr Golddots in the short barreled S&W

__________________

It is the Indian not the arrow

|

|

The Following 4 Users Like Post:

|

|

09-02-2016, 03:31 AM

|

|

Member

|

|

|

Join Date: Mar 2014

Location: NW Florida

Posts: 649

Likes: 4,977

Liked 710 Times in 362 Posts

|

|

Quote:

Originally Posted by GaryS

...

I'll only say that my friend who has experience in this world told me that they consider this kind of thing a failure. Hurting or killing the hostages is the sign of an amateur operation. Having no first hand experience, I can only go by what he has related.

|

True, it is, but one of the things about rescue is they almost NEVER go as planned

Humans being humans, mistakes occur...squishy hits the fan...

Best thing ever said to anyone who may in the future, get taken hostage,

is that once they start attacking the hostage-takers...hit the deck.

Get low, stay low, and stay out of the way.

__________________

Marlin & Calico Specialist

|

|

The Following 2 Users Like Post:

|

|

09-03-2016, 09:34 PM

|

|

Member

|

|

|

Join Date: Jan 2010

Location: South Carolina

Posts: 9

Likes: 0

Liked 7 Times in 4 Posts

|

|

I would love to send my slide, barrel and magazines for conversion.

I would love to send my slide, barrel and magazines for conversion.

I have a gently abused 4053 (single column magazines) and would love to know if someone is still performing the conversions.

|

|

The Following User Likes This Post:

|

|

09-03-2016, 10:11 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

cw4ski, Welcome aboard good Sir!

Not to be a wiseass but, if you read through this entire thread you pretty much saw me recently make three of them  and I even showed you how to do it yourself if, you're so inclined.

Anyway, I'd be happy to help out. Shoot me a PM or email with what you have in mind and I'll see if I can't take care of it for you

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

09-03-2016, 10:20 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Quote:

Originally Posted by 6actual

here is its brother

A truly amazing little hand cannon, a joy to shoot and a very capable pistol making 1207fps w/ Underwood 165gr Golddots in the short barreled S&W |

The contrast between that shiny extractor and the satin black slide on yours had me hooked so I pulled mine and slapped it to the stone

Much betterer!

Cheers

Bill

__________________

Because they don't make a .46

Last edited by BMCM; 09-04-2016 at 03:15 PM.

|

|

The Following 3 Users Like Post:

|

|

09-04-2016, 10:12 AM

|

|

Member

|

|

|

Join Date: Mar 2007

Location: Southeast, LoUiSiAna

Posts: 686

Likes: 171

Liked 207 Times in 100 Posts

|

|

Absolutely beautiful the way they turned out!

|

|

The Following User Likes This Post:

|

|

08-03-2018, 04:48 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Hiya Gents,

Wow, it's been nearly two years since I finished this project.

You remember this old thing , yes?

Well, there was one more thing that needed tending to in order to truly call it complete. I finally got that 'thing' taken care of this week.

Take a closer look

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 17 Users Like Post:

|

18DAI, 6actual, Big Shrek, CelticSire, cherrypointmarine, Doug M., Mainsail, Mercs, nocents, Poohgyrr, RedCardinal, surfgun, SVT28, TAROMAN, That One Guy, TTSH, vigil617 |

08-03-2018, 07:10 PM

|

|

Member

|

|

|

Join Date: Mar 2015

Location: Ohio

Posts: 7,855

Likes: 9,468

Liked 14,850 Times in 5,049 Posts

|

|

Jeez, your pure SKILL in pictures and documentation of what you've done rivals the work! Ha!!! I may have said that 2 years ago in this or maybe another thread, I will re-read in a minute, but the thread is an absolute treat.

There is no way S&W would ever employ you. Since the demise of the Performance Center, this work shown in the thread is simply MILES beyond their capabilities, and they would be embarrassed in comparison.

|

|

The Following 5 Users Like Post:

|

|

08-03-2018, 07:14 PM

|

|

Member

|

|

|

Join Date: Mar 2015

Location: Ohio

Posts: 7,855

Likes: 9,468

Liked 14,850 Times in 5,049 Posts

|

|

Let me add:

If this was my pistol, I would ship the dang thing BACK and wouldn't accept it in to my gun safe UNLESS AND UNTIL the artist signed his work. I still believe an Anchor is precisely the correct logo and it shouldn't be hidden.

|

|

The Following 5 Users Like Post:

|

|

08-04-2018, 03:42 PM

|

|

Member

|

|

|

Join Date: May 2008

Location: Washington State

Posts: 7,467

Likes: 14,566

Liked 9,287 Times in 3,716 Posts

|

|

I sent a revolver to the Master Chief for some work (RB-ing an M66 SB) - excellent work, low price (about which I counseled him - too low, truly), and great turn-around time. Heck of a job, heck of a guy. BTW, the wide U notch on the 10-8 sights is a great thing generally, and especially for older eyes.

__________________

NHI, 10-8.

|

|

The Following User Likes This Post:

|

|

08-04-2018, 08:12 PM

|

|

SWCA Member

|

|

|

Join Date: Jul 2013

Location: Oviedo,Fl

Posts: 2,321

Likes: 723

Liked 4,951 Times in 1,585 Posts

|

|

I just sent him my CS40 (soon to be a CS10). I've got to say , I own my share of Smiths , PC's , M52 , some really nice ones . I can't remember the last time I was so excited about one .He shot me down on one I wanted done , and luckily the next gun show , last table before I left , there she was . A CS40 with 2 mags . My buddy said I was so happy , he thought I was going to kiss it . So , now the waiting starts . But , I know it will be worth it ! Have to agree with Sevens , even if they hired you to build these , I don't think anyone could afford them .

|

|

The Following 2 Users Like Post:

|

|

08-04-2018, 11:54 PM

|

|

Member

|

|

|

Join Date: Jun 2014

Location: Kentucky

Posts: 173

Likes: 215

Liked 240 Times in 92 Posts

|

|

Quote:

Originally Posted by cherrypointmarine

I just sent him my CS40 (soon to be a CS10). I've got to say , I own my share of Smiths , PC's , M52 , some really nice ones . I can't remember the last time I was so excited about one .He shot me down on one I wanted done , and luckily the next gun show , last table before I left , there she was . A CS40 with 2 mags . My buddy said I was so happy , he thought I was going to kiss it . So , now the waiting starts . But , I know it will be worth it ! Have to agree with Sevens , even if they hired you to build these , I don't think anyone could afford them .

|

Who did you send your CS40 to? I hit a big snag getting my conversion finished when my local smith refused to modify the barrel. Said the CS would be a .41 Magnum snubby and would blow up.

|

08-05-2018, 11:26 AM

|

|

Member

|

|

|

Join Date: Feb 2018

Location: Midwest

Posts: 304

Likes: 252

Liked 533 Times in 171 Posts

|

|

I’m in awe of this thread. I didn’t know anyone was currently doing this sort of work on 3rd gens. Bravo sir!

Sent from my iPhone using Tapatalk

|

08-05-2018, 12:21 PM

|

|

SWCA Member

|

|

|

Join Date: Jul 2013

Location: Oviedo,Fl

Posts: 2,321

Likes: 723

Liked 4,951 Times in 1,585 Posts

|

|

toddstang , this whole thread has been brought to us by BMCM . He's the one doing the conversions . Contact him and he will lay it all out for you . As you can see , his work is above reproach . PM him , you will be glad you did .

|

|

The Following User Likes This Post:

|

|

02-06-2019, 02:27 AM

|

|

Member

|

|

|

Join Date: Feb 2019

Posts: 1

Likes: 0

Liked 1 Time in 1 Post

|

|

Incredible artistry! I hope all is well with BMCM.

|

|

The Following User Likes This Post:

|

|

02-06-2019, 12:31 PM

|

|

Member

|

|

|

Join Date: May 2008

Location: Washington State

Posts: 7,467

Likes: 14,566

Liked 9,287 Times in 3,716 Posts

|

|

Quote:

Originally Posted by toddstang

Who did you send your CS40 to? I hit a big snag getting my conversion finished when my local smith refused to modify the barrel. Said the CS would be a .41 Magnum snubby and would blow up.  |

*

BMCM is the one referred to. PM him for his business address - he is now formally a gunsmith with FFL and all that jazz.

As for the question about his well-being: Other than the "joy" of working on my recovered stolen revolver after 7+ years out of my possession, he seemed fine a couple days ago.

__________________

NHI, 10-8.

|

|

The Following User Likes This Post:

|

|

02-06-2019, 01:37 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Quote:

Originally Posted by toddstang

my local smith refused to modify the barrel. Said the CS would be a .41 Magnum snubby and would blow up.  |

That's crazy talk... I've yet to have one of those blow up in my hand with the hottest ammo I can get, usually Underwood & WW 175gr Silvertips. I personally test drive before sending them home to make damn sure they work right. A CS40 barrel is of the exact same chamber cross section as any of the 10xx guns and 10mm Auto essentially runs at about the same SAAMI Max pressure as 40S&W ... 37.5k vs 35k. That barrel is exactly the same as a 1006 tube, just two inches shorter with a tad shallower chamber.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following User Likes This Post:

|

|

02-06-2019, 01:45 PM

|

|

SWCA Member

|

|

|

Join Date: Jul 2013

Location: Oviedo,Fl

Posts: 2,321

Likes: 723

Liked 4,951 Times in 1,585 Posts

|

|

I can attest to the fact Bill test fires them . I even got the target , with notes as to the distance and ammo used . You couldn't ask for a better gunsmith . I would trust him before I sent something back to you know who .

|

|

The Following User Likes This Post:

|

|

12-16-2022, 08:03 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,213 Times in 1,042 Posts

|

|

Ahoy there Shipmates...

By now I've completed a goodly number of these conversion projects and it occurs to me there are a few things I have refined that perhaps I could share.

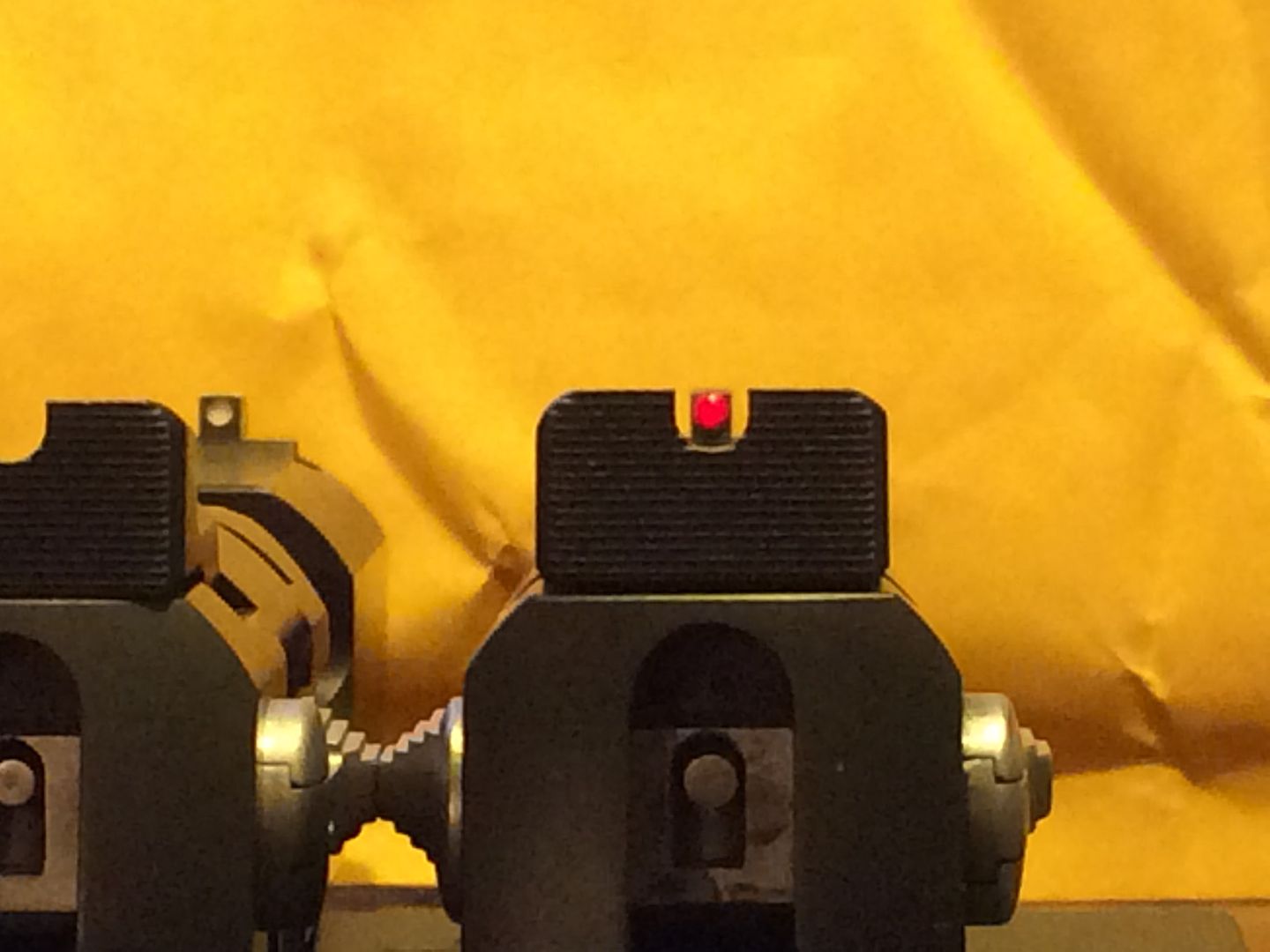

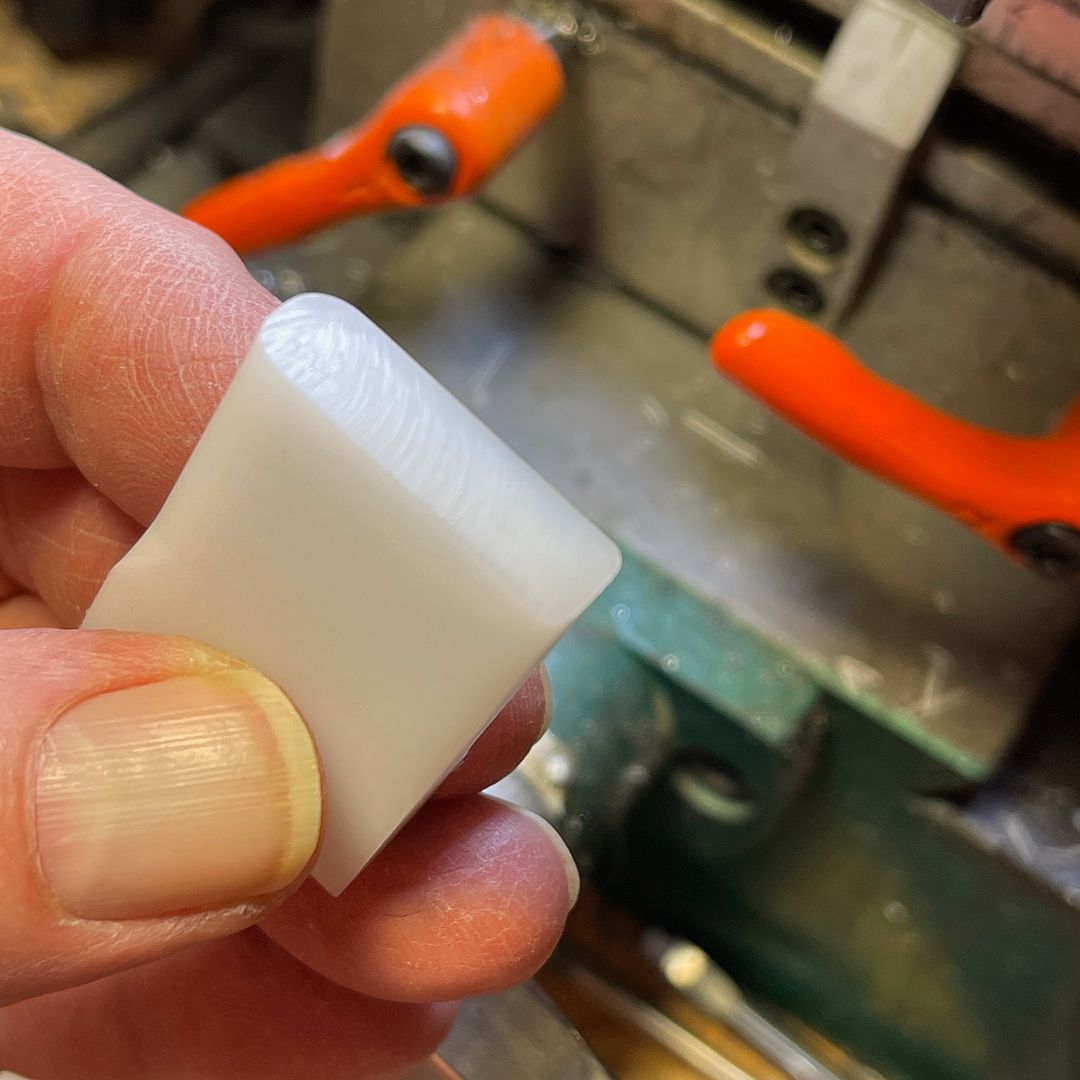

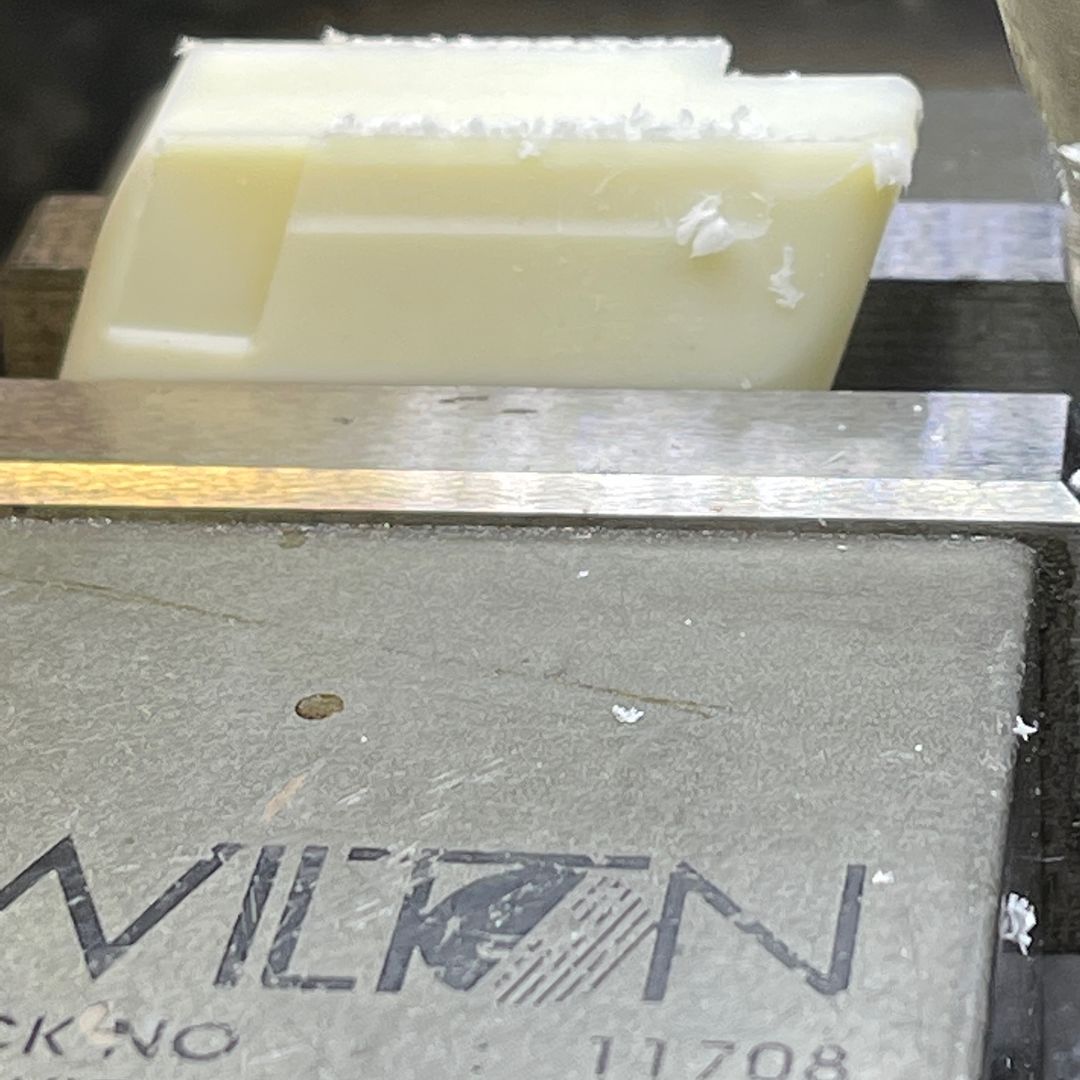

Here we're going to focus on the magazine followers.

Looking back, I find the precess I was using to midify the 10xx white followers to work in the single stack .40 mags kinda crude. The setup was tedious for every single piece and the amount of material removed was simply based on measurements of the orange .40 follower.

What I wanted to do is make the setup fast & simple and remove only the absolute minimum amount of material from the new follower in order to best preserve the strength & longevity of the part.

So, here's what we did...

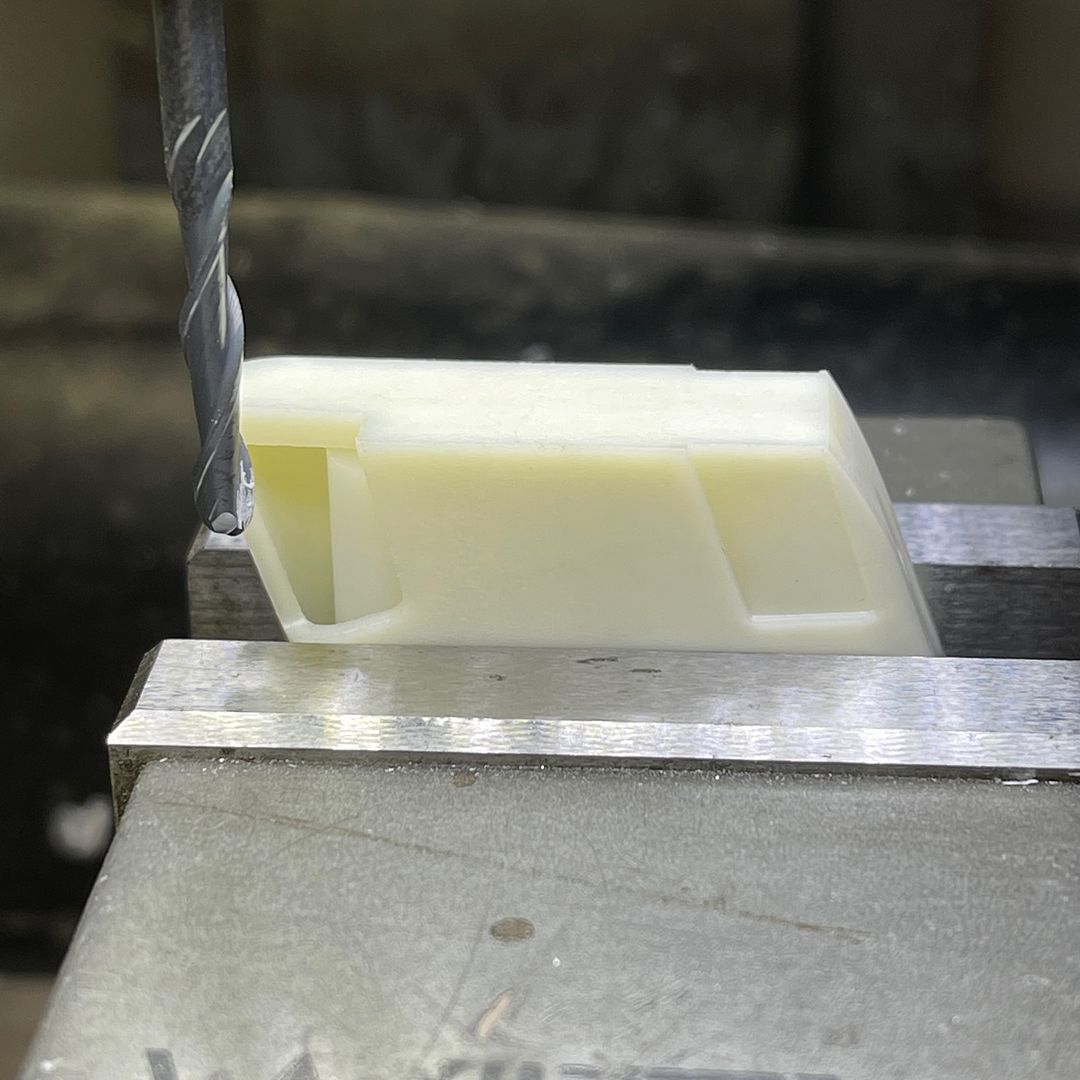

Machined a mandrel of sorts from a block of delrin that when inserted into a follower and clamped in the vise, holds the follower perfectly level at a repeatable height in relation to the cutter.

Clamped in the vise. Now I'm using a 1/8" carbide ball end cutter. On the first part I zero the "Z" axis on top of the follower then lower "Z" 0.125". From this point I don't have to adjust the cutter height again for as many followers as I need to machine.

Spin up the tool then advance the cutter into the work 0.012" and cut the left side.

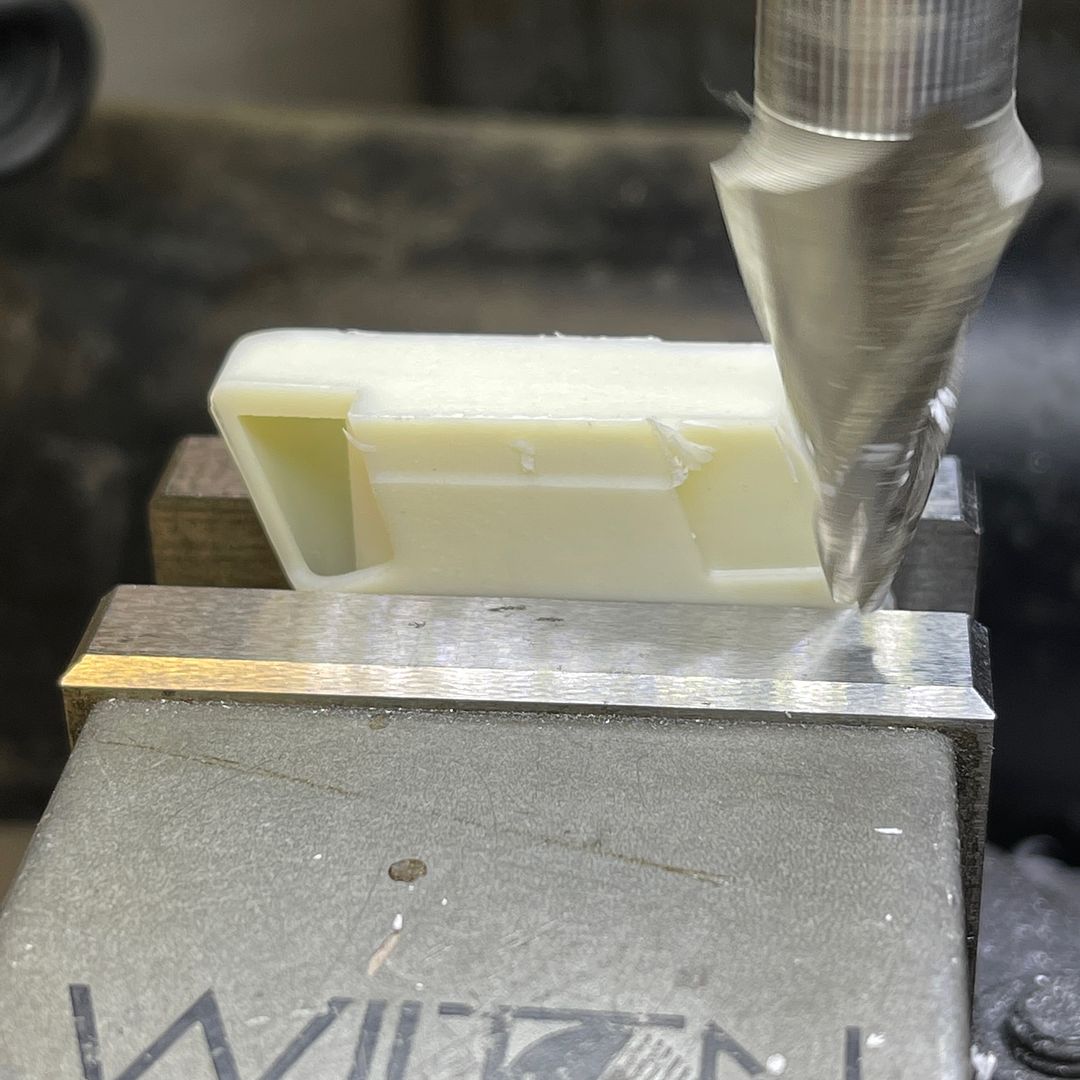

Then without changing anything else. Loosen the vise, flip the part around and cut the other side.

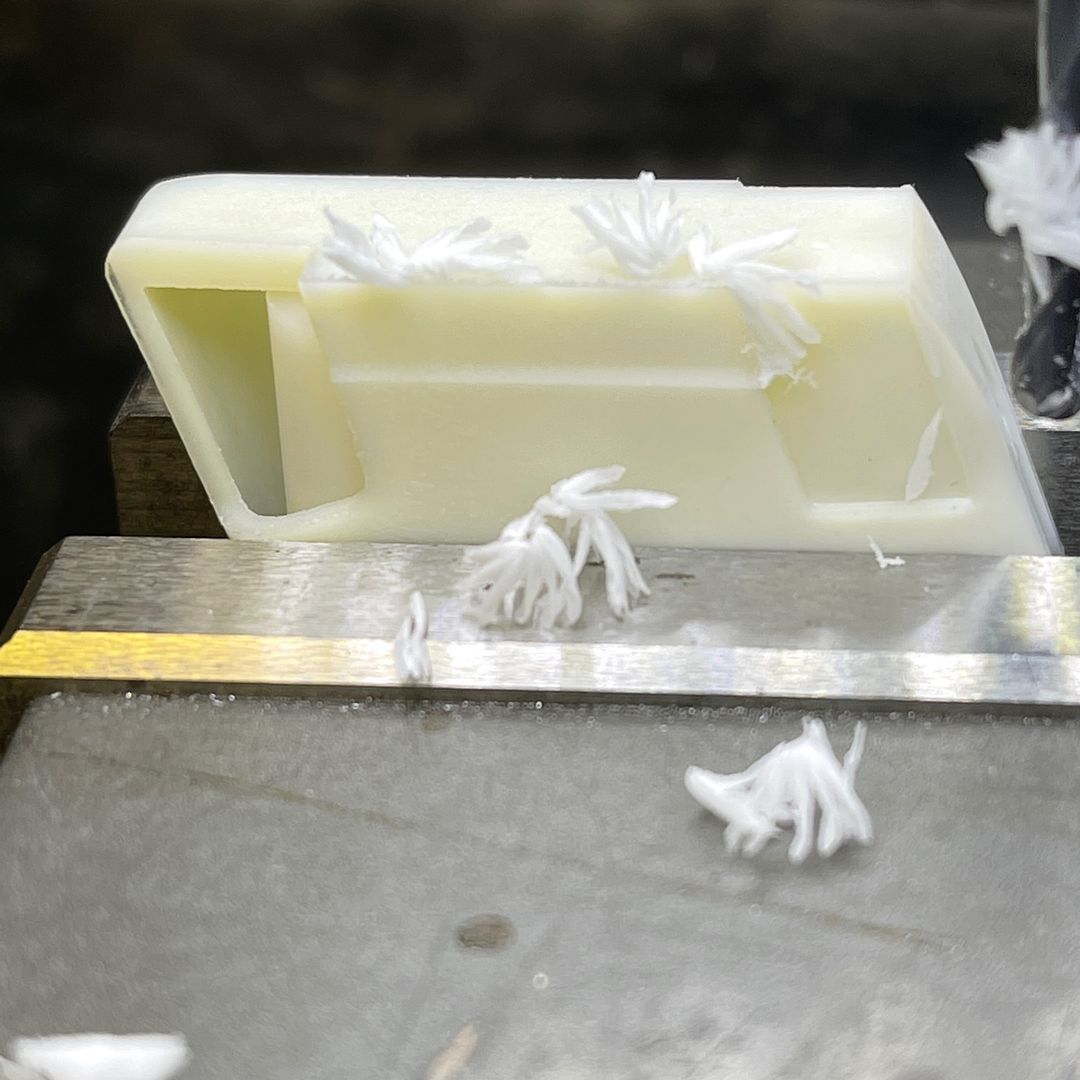

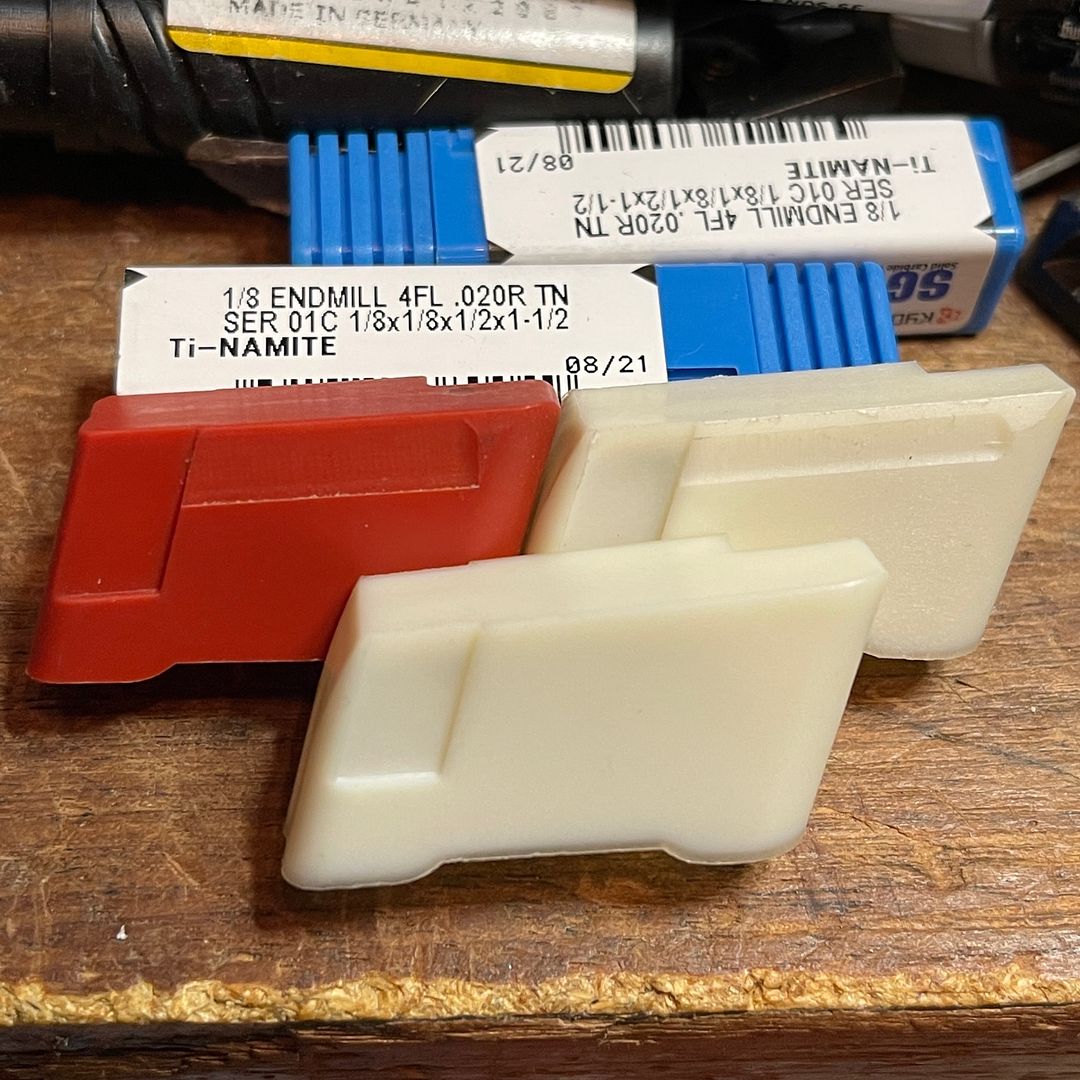

Rinse & repeat for as many followers as needed then we change the cutter to this 15° taper mill.

Then we process all those followers with the taper cutter in the same fashion. Once the first cut is dialed in it's zip & flip & zip again, stick the next follower in the vise & repeat. We're adding a 15° bevel to the top of the follower on both side 0.060 wide or about 1/16".

Flip the part and cut the right side bevel.

Unmodified white follower in the foreground with a orange 40 and a modified white follower behind for comparison.

Repeatable for as many as I need, perfect every time and each precisely identical.

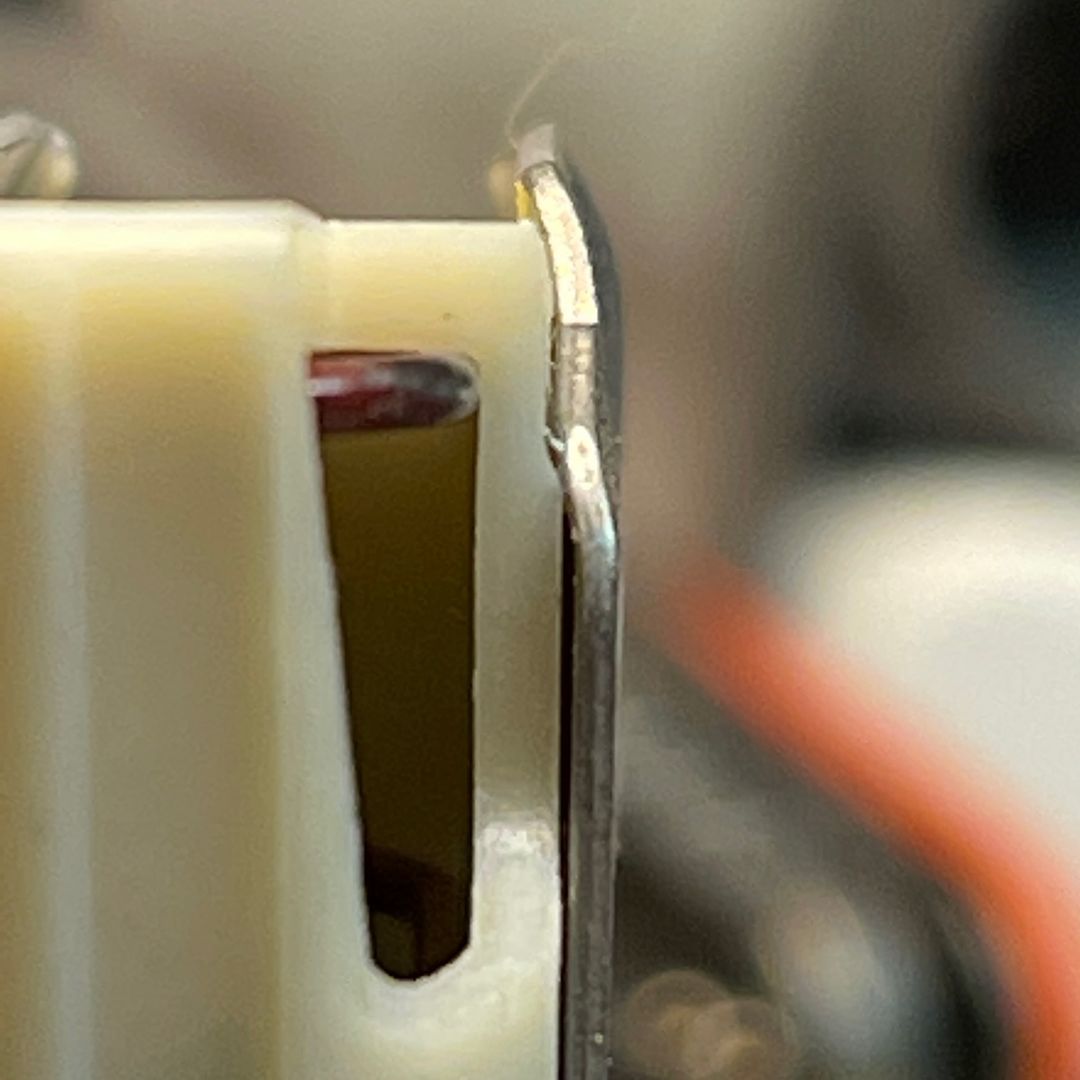

Meshes with the feedlip contour in a single stack 40 mag pretty nicely If'n I do say so myself

So, anyone know of someone handy with 3D modeling and perhaps with a 3D printer? Would be handy to have a backup plan for when the supply of 10xx white followers dries up. Not just for these conversion guns but for all the 10xx guns as well. Followers are a wear item ya know.

That's all for now, Happy Ten Millimetering

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 6 Users Like Post:

|

|

|

|

Posting Rules

Posting Rules

|

|

|

|

|