|

|

|

03-07-2016, 01:24 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Sandblasting media for 6906 (?soft alloy frame?)

Sandblasting media for 6906 (?soft alloy frame?)

Hi,

I need to get some ugly gold paint off of this gun. I've given up on chemicals and bought a little sandblaster. I plan to post some restoration pictures here.

Does anyone have a suggestion on what type of media will not hurt the soft alloy frame?; baking soda, walnut shells, etc?

Thanks

Ernie

|

03-07-2016, 02:36 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Gold paint??? Yecchh!

Chemical wise, you'd want something containing DCM aka. methylene chloride. That rules out hardware store paint stripper. You'd be after an industrial gasket remover. Loctite makes a product called "Chisel" in a spray can that would do it. Nasty stuff though, don't get it on you, don't breath it and be sure to test it in a hidden spot like inside the dust cover to make sure it wont hurt the anodizing before you hose down the hole piece.

Blasting... Trouble is you can't use anything with tooth. Any media toothy enough to handily remove paint will also strip the anodizing and beat up the underlying metal. I'd lean towards baking soda. I don't know what kind of blast equipment you have but unless you have a cabinet to continuously re-cycle the media you're liable to need a bunch of it.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 3 Users Like Post:

|

|

03-07-2016, 03:45 PM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Quote:

Originally Posted by Erniekim

Hi,

I need to get some ugly gold paint off of this gun. I've given up on chemicals and bought a little sandblaster. I plan to post some restoration pictures here.

Does anyone have a suggestion on what type of media will not hurt the soft alloy frame?; baking soda, walnut shells, etc?

Thanks

Ernie

|

I'll simply second what BMCM said: Anything coarse & rough enough to remove that nasty gold paint is practically guaranteed to ruin the anodized finish on the frame as well.

|

|

The Following User Likes This Post:

|

|

03-07-2016, 03:52 PM

|

|

Member

|

|

|

Join Date: May 2012

Location: South Sound, WA

Posts: 641

Likes: 371

Liked 1,383 Times in 332 Posts

|

|

I did some chemical duracoat removal with Jasco Stripper on a 2206 with good results. See this thread:

2206 Rescued

|

|

The Following User Likes This Post:

|

|

03-07-2016, 04:03 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Location: Middle Georgia

Posts: 91

Likes: 90

Liked 81 Times in 44 Posts

|

|

I've got a small soda blaster I use to use on motorcycle parts. You can buy soda in different grades of coarseness and it will take off some paints. It's much, much slower at doing so than glass beads or sand. Some paints won't come off completely or at all. Guess it depends on how it was originally prepped and type of paint. Not sure your sandblaster will work with soda media, size of tips and such related to the size of media. If you haven't already, check the owners manual for the blaster for types of media it can spray. If it will, maybe try a little area thats normally hidden to see how it effects the original finish? Perhaps this is of some help.....

|

03-08-2016, 02:41 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

THANKS for your help.

I tried the chemicals y'all suggested; didn't touch the paint.

I tried blasting with baking soda and walnut shells; didn't touch it. I ended up using 80 grit glass beads and it came off.

The SS slide looks great. I'm guessing that I took the plating off the frame. Not sure how to proceed with the frame. Anyone have any ideas/suggestions? I kind of like the mat finish. I'll work on posting some pictures.

Kim

|

03-08-2016, 02:46 PM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Quote:

Originally Posted by Erniekim

THANKS for your help.

I tried the chemicals y'all suggested; didn't touch the paint.

I tried blasting with baking soda and walnut shells; didn't touch it. I ended up using 80 grit glass beads and it came off.

The SS slide looks great. I'm guessing that I took the plating off the frame. Not sure how to proceed with the frame. Anyone have any ideas/suggestions? I kind of like the mat finish. I'll work on posting some pictures.

Kim

|

If you've gone that far with the frame already, and assuming it needs no further prep, you can have it re-anodized.

|

|

The Following User Likes This Post:

|

|

03-08-2016, 02:54 PM

|

|

Member

|

|

|

Join Date: Dec 2014

Posts: 654

Likes: 728

Liked 648 Times in 281 Posts

|

|

Sandblasting media for 6906 (?soft alloy frame?)

Sandblasting media for 6906 (?soft alloy frame?)

Quote:

Originally Posted by Erniekim

The SS slide looks great. I'm guessing that I took the plating off the frame. Not sure how to proceed with the frame. Anyone have any ideas/suggestions? I kind of like the mat finish. I'll work on posting some pictures.

Kim

|

I have a 6906 I will be refinishing too, and I also like the "mat finish".

But my concern is the porosity of the frame after media blasting if not anodized or coated in some way.

Last edited by 85V65Sabre; 03-08-2016 at 02:57 PM.

|

03-08-2016, 04:57 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Does anyone know of a company to re-apply the nickle plating? I called a local company but the asked what alloy the frame is made from. I'd need someone with some experience with this gun.

|

03-08-2016, 06:28 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Your frame, I'm fairly certain, is 7000 series aluminum alloy.

For refinishing, I'd recommend either industrial hard chome or Robar's NP3 finish.

Here's a couple links...

FINISHES - Metal Finishes | APWCOGAN

https://robarguns.com/custom-firearm-finishes/np3/

Cheers

Bill

__________________

Because they don't make a .46

|

03-08-2016, 08:08 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

I called S&W and they said: it's aluminum, do nothing or just clear coat it. That surprised me, seems like it needs something. I don't want to paint it. I'm thinking about a wax or something?

|

03-09-2016, 07:44 AM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Quote:

Originally Posted by Erniekim

Does anyone know of a company to re-apply the nickle plating? I called a local company but the asked what alloy the frame is made from. I'd need someone with some experience with this gun.

|

Quote:

Originally Posted by Erniekim

I called S&W and they said: it's aluminum, do nothing or just clear coat it. That surprised me, seems like it needs something. I don't want to paint it. I'm thinking about a wax or something?

|

Was there really nickel plating under that gold paint?  If so, I don't know what to tell you.

If it was just the standard Model 6906's anodized aluminum frame under all that gold paint... and assuming you've removed all the gold paint and all of the original anodized finish... I would look into having the (now bare) aluminum frame re-anodized. There is a company not far from me that does that kind of work. As I recall, the cost for re-anodizing an aluminum frame... not including any additional required prep or shipping... was something under $100.00.

The other finishes recommended by BMCM would work as well. It just boils down to the look & quality you want and how much you are willing to pay for it.

|

03-09-2016, 10:44 AM

|

|

Member

|

|

|

Join Date: Oct 2000

Location: NOVA

Posts: 1,385

Likes: 5,609

Liked 1,381 Times in 581 Posts

|

|

Quote:

Originally Posted by Erniekim

I called S&W and they said: it's aluminum, do nothing or just clear coat it. That surprised me, seems like it needs something. I don't want to paint it. I'm thinking about a wax or something?

|

Interesting comment from S&W! I have a 4013TSW that I intend to have re-finished later this year. So, I hope and assume they still do "standard" refinishing of aluminum 3rd Gen frames. They still list this as an option on their webpage anyway. From their webpage: Anodize - Aluminum Frames (3rd Gen. or newer) $150.

Someone said, in a different post last year, that they just replace the frames for 3rd Gen's rather than actually refinish them. Either way, $150 isn't too bad to get back basically a new frame...

|

|

The Following 2 Users Like Post:

|

|

03-09-2016, 11:32 AM

|

|

Member

|

|

|

Join Date: Dec 2014

Posts: 654

Likes: 728

Liked 648 Times in 281 Posts

|

|

Quote:

Originally Posted by GeoJelly

Someone said, in a different post last year, that they just replace the frames for 3rd Gen's rather than actually refinish them. Either way, $150 isn't too bad to get back basically a new frame...

|

Thanks for the tip, I will have to check into that.

|

03-09-2016, 11:53 AM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Quote:

Originally Posted by 85V65Sabre

Quote:

Originally Posted by GeoJelly

Someone said, in a different post last year, that they just replace the frames for 3rd Gen's rather than actually refinish them. Either way, $150 isn't too bad to get back basically a new frame...

|

Thanks for the tip, I will have to check into that. |

Man, that sure does sound fishy.  If they are still up to their eyeballs in leftover 3rd Gen aluminum frames, why do they normally offer folks a deal on new plastic rather than replacing cracked 3rd Gen frames?

Or is this supposedly brand new production out of Houlton?

|

|

The Following User Likes This Post:

|

|

03-09-2016, 12:20 PM

|

|

Member

|

|

|

Join Date: Dec 2014

Posts: 654

Likes: 728

Liked 648 Times in 281 Posts

|

|

Sandblasting media for 6906 (?soft alloy frame?)

Sandblasting media for 6906 (?soft alloy frame?)

Quote:

Originally Posted by TTSH

Man, that sure does sound fishy.  If they are still up to their eyeballs in leftover 3rd Gen aluminum frames, why do they normally offer folks a deal on new plastic rather than replacing cracked 3rd Gen frames?

Or is this supposedly brand new production out of Houlton?  |

It's worth making a call

You just never know.

Maybe because on warrantees they make $0 on frame refinishing they make $150?

It's all about the bottom line don't ya know.

Last edited by 85V65Sabre; 03-09-2016 at 01:42 PM.

|

|

The Following User Likes This Post:

|

|

03-09-2016, 01:13 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

I'd like to find some refinishing videos, tutorials or descriptions of refinishing projects. I've sandblasted and am not sure how to finish the aluminum. It's still a bit too rough from the sandblasting.

|

03-15-2016, 12:37 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Here is the stubborn paint.

|

|

The Following User Likes This Post:

|

|

03-15-2016, 01:25 PM

|

|

SWCA Member

|

|

|

Join Date: Feb 2004

Location: NE IL but I'm from Ohio

Posts: 2,071

Likes: 116

Liked 3,072 Times in 890 Posts

|

|

On Refinishing Aluminum

On Refinishing Aluminum

Something to remember; Aluminum Anodizing is NOT plating or coating. It is a conversion of the surface that changes the Aluminum on the surface to a different material (such as Aluminum Oxide or some such) which is dyed as part of the final seal and cure. There are various types of Anodizing from Chem film that is very thin and has a negligible change in size to Hard Anodize which can have a thickness if 0.003 - 0.004. The thickness is tricky because it actually goes into the existing surface as well as building outward so if you have a resulting thickness of say .004 the parts actually gets bigger by about 0.002 per surface. Pre-anodize sizes must be controlled so that the finished part ends up the size you want. This is probably one reason that S&W does not refinish Anodized parts

The problem with stripping anodizing off to pure bare metal is that it will be smaller; smaller even than it was prior to anodize. This is normally not an issue where size requirements are liberal but can cause issues in critical or closely fitted areas.

I am unsure which type of anodize is used on firearms but where wear resistance is required I would suspect it is a hard anodize of some type.

__________________

Sceva

OGCA SWCA NRA

|

|

The Following 2 Users Like Post:

|

|

03-15-2016, 03:11 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Can someone please give me the name of someone to anodize this frame for me? I can't seem to find anyone local so I guess that I'll have to mail it off.

I'm thinking that I won't color it; little scratches won't be so obvious then.

|

03-15-2016, 03:21 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

image.jpgThis is the sandblasted surface. It's kind of light colored but if I leave it alone (no coloring) scratches won't show. Im planning to do a baked on clear coat. Do I need to buy from Brownell or might there be something at a auto store that is as good.?

Thanks

Last edited by Erniekim; 03-15-2016 at 03:37 PM.

|

03-15-2016, 03:40 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

image.jpg here is the slightly "brushed" surface. Done with 400 grit sandpaper. I like it a bit better than the sandblasted finish. Old fashioned I guess.

|

|

The Following User Likes This Post:

|

|

03-15-2016, 05:59 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Unfortunately, you're not likely to find any cheap options to make that frame useful again.

You see, raw bare aluminum is pretty soft and in any application where there is steel bearing against aluminum, the aluminum will quickly wear out.

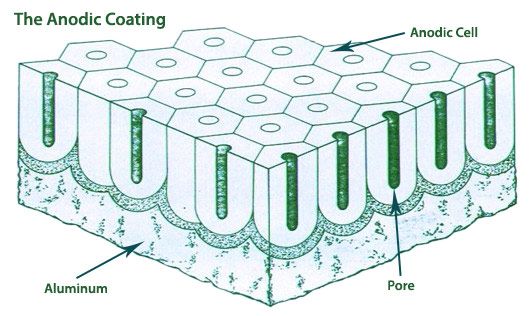

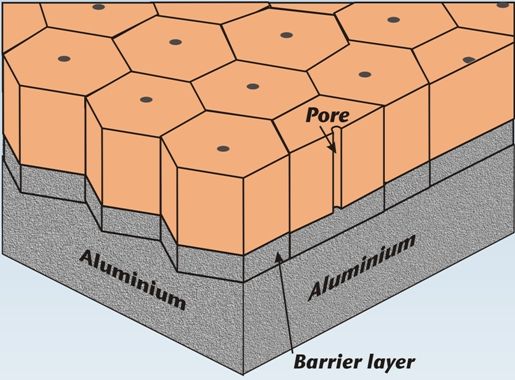

Anodizing is an electrochemical process that essentially grows a very precise layer of interlocking aluminum oxide crystals on the surface of the part from the base aluminum. This layer is covered in micro-pores to permit coloring which are later sealed in another chemical bath such as nickel acetate.

Here's a couple graphics I purloined from the internet showing the tightly packed hexagon crystal structure:

And hard coat anodizing:

Aluminum oxide is otherwise known as carborundum is a very common industrial abrasive. Aluminum oxide is also known as rubies, second in hardness only to diamonds. So you can see when these crystals are grown in a uniform thin precise layer on a surface they impart a great deal of wear resistance to the part.

As an aside, I come across this stuff all the time..... Folks sending sparkling new type III hard anodized gun parts off for some kind of applied finish. If the preparation is done correctly per the coating manufacturers instructions, that layer of anodizing, second in hardness to diamond, is stripped off and replaced with spray paint.

Now, since you've already stripped off much of your anodizing you'll need to have something done to restore it's wear resistance before placing that frame in service, else I'd not expect it to last very long.

I strongly suggest either one of these. Industrial hard chrome or Type III hard coat anodize. I'd lean towards the type III hardcoat anodizing. Back in post #10 I linked an outfit that can do industrial hard chrome.

With the popularity of the modern AR platform there's a huge number of companies anodizing weapon components. Google is your friend in finding them.

Best of luck restoring that frame to useful running condition.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 2 Users Like Post:

|

|

03-21-2016, 12:11 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

I found no evidence of anodizing, the frame conducts electricity everywhere.

When I got the gun, there was no paint where the slide and frame contact. So I didn't sandblast there. I assume that this means the previous owner had the anodizing removed before he/she painted it.

The gun functioned well before I tore it down. I guess if it would have been used like this (with no anodizing or protective paint like ceracote to protect the slide-to-frame contact area) it would have been worn down below specs and ruined.

So should I just proceed to hard anodizing at this point? I don't want to remove any material going through the etching process to remove old anodizing before re-anodizing. Does checking for electrical conductivity and seeing that it does indeed conduct electricity guarantee that there is no anodizing remaining?

If I understand correctly, if I go straight to anodizing at this point, it will only accept anodizing if there is no anodizing present. Also the anodizing process will build up any material lost when the previous owner had the anodizing removed.

Or, should I play it safe and ceracote it?

I hate the idea of painting it.

image.jpg

Last edited by Erniekim; 03-21-2016 at 12:24 AM.

|

03-21-2016, 12:28 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

|

03-21-2016, 11:42 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Did the method I used seem correct? Could someone check their anodized frame to see if it does NOT conduct electricity when metered this way? Mine conducted everywhere.

Last edited by Erniekim; 03-21-2016 at 01:53 PM.

|

03-21-2016, 02:07 PM

|

|

Member

|

|

|

Join Date: Sep 2009

Location: I Can See The Alamo

Posts: 556

Likes: 303

Liked 372 Times in 188 Posts

|

|

Ya'll might be over thinking this just a bit. Based on the 40 years I've been involved in aircraft maintenance - nearly all the aluminum parts on an aircraft are anodized - it really isn't a big deal.

Anodizing – there are several types – is a very thin coating. Thinner even than the Parkerizing type of coating found on black 3d gens. (Which is a layer of phosphate crystals designed to retain oil for lubrication and prevention of oxidation.)

Bare, pure aluminum slowly builds a coating of oxidation. It is kind of like rust on steel except that aluminum oxidation is self limiting unless in the presence of certain chemicals or conditions (like electrosis). Anodizing simply interrupts the oxidation, which on 3d gen frames isn’t going to amount to much more than slight discoloration after many years.

Anodizing is not a very thick or hard coating. It is much thinner than Parkerizing and we’ve all seen how that quickly wears off the rails with no apparent ill effects. If you’re really worried about it, go down to the local paint store that sells coatings used on aircraft and pick up a gallon jug of the dilute acid used to anodize aircraft skin before painting. It comes in several different colors or clear. The colors are just so one can tell that the area has been treated. You won’t see much difference in the surface until the treated surface wears off and it will probably have a polished appearance when that happens. If you want to strip off all the oils and put the gun away for several years, you find that the base metal is dull colored where the anodizing has worn off, but you’ll have to look closely. The dimensional changes will be less than anything you can measure with any tool in your toolbox.

If you’re really, really worried about it, get a bottle of the Birchwood Casey aluminum black touch-up and you can reproduce the same finish S&W puts on their aluminum frames.

BTW, you’ll not measure any change in the surface conductivity using a multimeter.

|

|

The Following User Likes This Post:

|

|

03-21-2016, 10:56 PM

|

|

Member

|

|

|

Join Date: Oct 2002

Location: Southern Oregon

Posts: 81

Likes: 2

Liked 35 Times in 8 Posts

|

|

A little off topic, but if you were going to Cerakote the frame would you media blast the frame or just spray right over the anodizing?

|

03-21-2016, 11:20 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

They sandblast first to give the ceracote something to grip onto. The anodizing is removed if an aggressive blasting media is used.

I've learned a lot since I started this project. It's very apparent that there's a lot of bad information floating around. I did find a forum specifically for people who do plating and anodizing, so I've got good procedures now.

I'm still wavering about the Ceracote though since a lot of coating experts and gunsmiths seem to really like it. I'm just old-fashioned I guess and I like what I like but I don't want to turn into one of those stubborn old guys who won't accept anything new. :-)

Does anyone here think Ceracote is as good as hard anodizing.

Last edited by Erniekim; 03-22-2016 at 12:01 AM.

|

|

The Following User Likes This Post:

|

|

03-22-2016, 10:00 AM

|

|

Member

|

|

|

Join Date: Oct 2015

Location: DeKalb, IL

Posts: 83

Likes: 44

Liked 105 Times in 42 Posts

|

|

Quote:

Originally Posted by NordicG3K

A little off topic, but if you were going to Cerakote the frame would you media blast the frame or just spray right over the anodizing?

|

They publish the Cerakote Training Manual online. It's a pretty interesting read.

Quote:

Begin by plugging the bore at both the chamber and the muzzle end of the barrel prior to blasting. Grit blast the parts with #100 to #120 grit aluminum oxide or garnet sand at 80 to 100 psi. Strive for an even blast pattern over the surfaces of the parts. Lightly blast (30-40 psi) non-metal parts such as: wood, plastic or polymer.

TIP:

• If the part’s surface is still shiny after blasting, you haven’t blasted enough.

• If you use too coarse of grit, the microscopic valleys on the part’s surface will be too deep for the 1.0 mil (.001”) coating to completely fill while covering the corresponding “peaks” sufficiently to assure a satisfactory coating.

• Don’t use sand that has been previously used to clean dirty, greasy or oily parts. Doing so will contaminate your parts.

|

|

03-22-2016, 11:59 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Quote:

Originally Posted by MWater

|

Do this and your hard anodizing is as good as gone. The paint manufacturer makes sure that you will have to use Cerakote forever on this gun or spend 350 dollars to get it hard anodized again; by someone good with a guarantee.

I've only found one trustworthy vendor that will guarantee they won't melt your gun away (reduce dimensions too much) but they're expensive.

Forget about the DIY anodizing you see online, it's not for guns, only pretty bright colors on paintball guns, bikes and flashlights, and it's not that great for those.

I was told early in this thread that it would be costly to re-do the anodizing. After a lot of research, I totally agree with that position. Now, I'm trying to convince myself that Cerakote is good enough until I find a new frame for the 6096.

|

03-22-2016, 12:05 PM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Quote:

Originally Posted by Hill_Country

Ya'll might be over thinking this just a bit. Based on the 40 years I've been involved in aircraft maintenance - nearly all the aluminum parts on an aircraft are anodized - it really isn't a big deal.

Anodizing – there are several types – is a very thin coating. Thinner even than the Parkerizing type of coating found on black 3d gens. (Which is a layer of phosphate crystals designed to retain oil for lubrication and prevention of oxidation.)

Bare, pure aluminum slowly builds a coating of oxidation. It is kind of like rust on steel except that aluminum oxidation is self limiting unless in the presence of certain chemicals or conditions (like electrosis). Anodizing simply interrupts the oxidation, which on 3d gen frames isn’t going to amount to much more than slight discoloration after many years.

Anodizing is not a very thick or hard coating. It is much thinner than Parkerizing and we’ve all seen how that quickly wears off the rails with no apparent ill effects. If you’re really worried about it, go down to the local paint store that sells coatings used on aircraft and pick up a gallon jug of the dilute acid used to anodize aircraft skin before painting. It comes in several different colors or clear. The colors are just so one can tell that the area has been treated. You won’t see much difference in the surface until the treated surface wears off and it will probably have a polished appearance when that happens. If you want to strip off all the oils and put the gun away for several years, you find that the base metal is dull colored where the anodizing has worn off, but you’ll have to look closely. The dimensional changes will be less than anything you can measure with any tool in your toolbox.

If you’re really, really worried about it, get a bottle of the Birchwood Casey aluminum black touch-up and you can reproduce the same finish S&W puts on their aluminum frames.

BTW, you’ll not measure any change in the surface conductivity using a multimeter.

|

Sorry but you must be thinking of something else, you are not referring to hard anodizing here Hillcountry.

|

03-22-2016, 02:43 PM

|

|

Member

|

|

|

Join Date: Sep 2009

Location: I Can See The Alamo

Posts: 556

Likes: 303

Liked 372 Times in 188 Posts

|

|

Quote:

Originally Posted by Erniekim

Sorry but you must be thinking of something else, you are not referring to hard anodizing here Hillcountry.

|

I know exactly what I'm referring to and so do the many, many other people on this forum who have successfully refinished their 3d gens either by beadblasting or chemical finishes.

Feel free to add all the drama you want, but don't say you weren't warned. Make it as difficult as you please. You're looking for a problem where there is none.

|

|

The Following User Likes This Post:

|

|

03-25-2016, 10:40 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

There is SO much misinformation on the Internet. Sifting through comments from self-proclaimed experts can be amusing but can also get annoying when they get belligerent.

In spite of this, I'm ready to go and might go ahead and post the process as I go. I was able to get through to the right folks at Smith and Wesson. I even managed to meet the past CEO of Wesson up at Fusion Firearms in Venice Florida. Google their 1911's, Wow, they are nice.

I now have the actual procedures performed by S&W. The frame is 7076 material and they only did type 2 anodizing originally. I found a calculator on a material finishing forum so with the exact material, I can determine the exact voltage, duration and cathode material.

I'll post pictures of the process as I go through it. Thanks to those who were genuinely helpful.

Last edited by Erniekim; 03-25-2016 at 10:42 AM.

|

|

The Following User Likes This Post:

|

|

03-25-2016, 01:31 PM

|

|

Member

|

|

|

Join Date: Feb 2011

Location: Gatesville

Posts: 649

Likes: 90

Liked 1,032 Times in 328 Posts

|

|

uploadfromtaptalk1458927060985.jpghere is my friend. He helps me travel the internet.

|

03-25-2016, 02:52 PM

|

|

Member

|

|

|

Join Date: Dec 2014

Posts: 654

Likes: 728

Liked 648 Times in 281 Posts

|

|

Quote:

Originally Posted by Erniekim

I was able to get through to the right folks at Smith and Wesson.

|

Did you by chance ask if S&W offers frame refinishing as mentioned earlier in the thread?

|

03-25-2016, 03:21 PM

|

|

Member

|

|

|

Join Date: Jul 2005

Location: NC

Posts: 30,800

Likes: 57,992

Liked 53,067 Times in 16,550 Posts

|

|

As mentioned, I'd go with a hard chrome by Bob Cogan, he does great work.

__________________

Sure you did

|

|

The Following User Likes This Post:

|

|

03-26-2016, 12:45 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Quote:

Originally Posted by 85V65Sabre

Did you by chance ask if S&W offers frame refinishing as mentioned earlier in the thread?

|

Sabre,

Yes they do offer refinishing and it's not a bad price. The regular customer service department will tell you that they don't offer it anymore. I didn't give up so easily, asked to speak to the persons manager and he said "sure, no problem". i was told that they would do the following:

1) set up shipping so that you don't have to go through a FFL entity to ship.

2) tear it down and check dimensions to see if it's in tolerance.

3) sandblast

4) do type 2 anodizing

5) reassemble and polishing

I was told that all of this would be done for 150 dollars. Sounds good to me, what do y'all think?

Kim

Last edited by Erniekim; 03-27-2016 at 12:24 AM.

|

|

The Following 2 Users Like Post:

|

|

03-26-2016, 01:03 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Quote:

Originally Posted by ladder13

As mentioned, I'd go with a hard chrome by Bob Cogan, he does great work.

|

I'll definitely check it out. Thanks

|

03-26-2016, 04:50 AM

|

|

Member

|

|

|

Join Date: Mar 2014

Location: NW Florida

Posts: 649

Likes: 4,977

Liked 710 Times in 362 Posts

|

|

I'm actually starting to wonder if that Gold Paint wasn't actually paint,

but gold anodizing, or plating...

especially since you said it was so hard to remove...

Of course, if it looked good, I'd have kept it gold

Sometimes it is helpful to look like the craziest *** in a room...

__________________

Marlin & Calico Specialist

|

|

The Following User Likes This Post:

|

|

03-26-2016, 06:11 AM

|

|

Member

|

|

|

Join Date: Dec 2014

Posts: 654

Likes: 728

Liked 648 Times in 281 Posts

|

|

Quote:

Originally Posted by Erniekim

Sabre,

Yes they do offer refinishing and it's not a bad price. i was told that they would do the following:

1) set up shipping so that you don't have to go through a FFL entity to ship.

2) tear it down and check dimensions to see if it in tolerance.

3) sandblast

4) do type 2 anodizing

5) reassemble and polishing

I was told that all of this would be done for 150 dollars. Sounds good to me, what do y'all think?

Kim

|

Sound good to me.

Thanks

|

|

The Following User Likes This Post:

|

|

03-26-2016, 11:37 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

I think so too. One side of me still wants to try anodizing myself but this gun is so nice that I'll likely leave it to the experts.

It would probably turn out like that first drywall joint that you do; in hindsight, you wish you had started inside a closet.

|

|

The Following User Likes This Post:

|

|

03-27-2016, 11:16 AM

|

|

Member

|

|

|

Join Date: Feb 2016

Posts: 25

Likes: 0

Liked 10 Times in 7 Posts

|

|

Quote:

Originally Posted by ladder13

As mentioned, I'd go with a hard chrome by Bob Cogan, he does great work.

|

Ladder, thanks for the suggestion. I'm reading some good things about hard chrome plating.

The pictures on his website don't seem to show what color hard chrome plating becomes on 7076 alum. Do you know?

Sounds like it would stand up better than type 2 anodizing. I was hoping that Smith and Wesson did type 3 but no such luck.

Maybe type 2 is good enough? Do y'all keep the slide area lubed to protect it or does lube attract dirt making the area more susceptible to wear?

Any thoughts?

|

03-27-2016, 11:34 AM

|

|

Member

|

|

|

Join Date: Dec 2014

Posts: 654

Likes: 728

Liked 648 Times in 281 Posts

|

|

Sandblasting media for 6906 (?soft alloy frame?)

Sandblasting media for 6906 (?soft alloy frame?)

Quote:

Originally Posted by Erniekim

Do y'all keep the slide area lubed to protect it or does lube attract dirt making the area more susceptible to wear?

Any thoughts?

|

Here is a discussion on aluminum frame lubrication.

Need help!best lubricant for aluminum frames?

Need help!best lubricant for aluminum frames?

I stumbled across another one.Reducing wear on 3rd gen alloy frame rails/ramps?

Reducing wear on 3rd gen alloy frame rails/ramps?

Last edited by 85V65Sabre; 03-27-2016 at 02:35 PM.

|

|

Posting Rules

Posting Rules

|

|

|

|

|