|

|

|

03-09-2016, 11:21 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,228

Liked 6,220 Times in 1,043 Posts

|

|

PC4506 Gets a new pair of shoes - Installing Karl Nill grips

PC4506 Gets a new pair of shoes - Installing Karl Nill grips

I've been meaning to get rolling on re-furbushing the PC4506 so I figure now's a good a time as any. What we're gonna tend to here is installing a set of Karl Nill's lovely walnut grips.

Here's what you get when you order a set of these. A little plastic doodad for the mainspring plunger to sit in, Four metric M4x.07 machine screws, and of course the grips. You'll note these are affixed to the frame in similar fashion to the panels on a 1911 with two screws for each side. Now since our 4506 has no hole for these screws, some meddling is in order

First order of business, detail strip the frame.

Then get my tools together. From left to right we have:

4mm transfer punch, Starrett wiggler, #30 HSS Co drill, M4 .07mm tap, Starrett 93A tap wrench, Brown & Sharpe spring loaded adjustable tap guide. One more thing you'll need is either a mill or a drill press. I'll be using my bench mill.

Now we're gonna use that transfer punch to mark the frame for drilling. Here, with the right grip half on the frame, I'll place the transfer punch in the screw hole and taking care to insure it's perfectly perpendicular to the frame, give it a couple whacks with a small hammer.

We wind up with a little 60° conical punch mark.

Moving over to the bench, load these three tools into the appropriate collet. Were I to use a drill press instead I'd merely change tools in the chuck. As it is here I'll swap collets for each step.

Now you may ask... How in hell does that wiggler thingy work and what's it for anyway? Well, you use that to precisely locate the center of the quill on a drill press or milling machine directly on a line or mark. Install the wiggler and spin it at about 1000rpm and it'll be plenty flappy

Now take some soft tool, stick or whatever and gently nudge the probe until it stops being flappy and runs true on center.

Here I'm using a Sharpy marker, the machine is running about 1100 rpm and now the probe is spot on center.

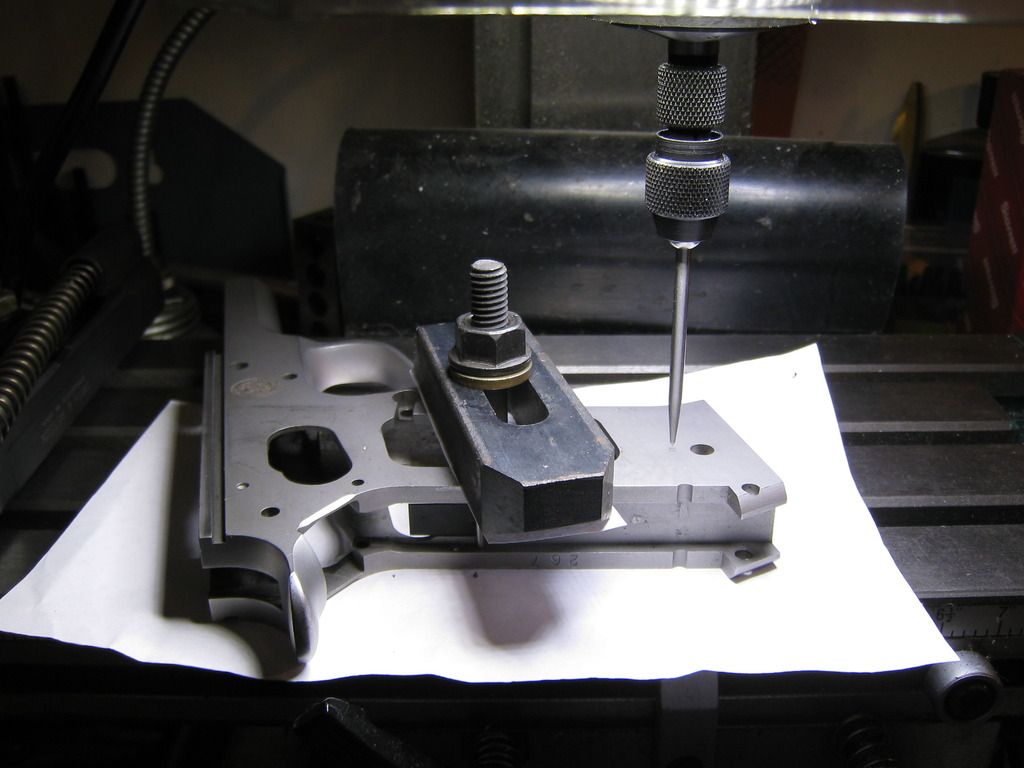

Now we'll clamp the frame down to the mill table and being careful not to bump the probe off center, we'll use that probe to locate one of the punch marks directly below the center of the quill by adjusting the x & y axes on the table. On a drill press with a fixed table you'd align the mark by hand then clamp it in place before drilling. On the mill, I lock the table x & y axes until I'm done with that hole.

Switch tools again. Now we load the drill bit.

Slow the machine speed down to about 600rpm, apply some cutting oil and drill the hole. Just apply gentle pressure and let the tool do the work.

Change tools again. This time load the tap guide in the spindle. The tap guide has a 60° angle point on the spring loaded plunger that fits precisely into a matching 60° recess in the end of the tap wrench.

Raise the tap guide up enough to get the tap wrench with tap underneath and started in the hole. Then lower the quill some to preload the tap guide so it applies even downward pressure on the tap.

Put some cutting oil on there (I'm using Brownells Do-Drill) and start turning the tap. As the tap advances deeper you'll need to lower the quill to maintain even spring pressure with the tap guide.

I try to keep the tap guide compressed about half way as I screw the tap into the hole.

Once through and the tap turns freely, get in there with small brush or something to knock the chips off the tap before backing it out. Don't want the pull any trash up into the nice new threads and bugger them up.

raise the quill up out of the way and back out the tap. Clean up and check the freshly tapped hole. Perfect!

I repeated all those steps three more times then tossed the thing in the kitchen sink with some dawn & hot water for a good scrubbing. Got her all cleaned up and dried off then slapped the grips on there.

Everything lined up perfectly.

Hand feel is really nice. I mean REALLY nice!

Well friends, that takes care of the "how to" on Karl Nill grips install.

This is gonna be one sweet rig when I get her all fixed up.

Notes:

Use good quality cutting fluid no WD40 or used motor oil. I use either Brownells Do-Drill or Renton's Rapid Tap Heavy Duty.

Don't force anything, let the tools do the cutting. especially with the little tap, if you feel it start to bind back off some to sever the chips off the side of the hole then continue.

Always securely clamp the workpiece (frame in this case). Using a drill press might require some imagination for secure clamping if you don't have an x,y table. Perhaps fastening the frame to a wood block like a piece of 2x4 that can in turn be securely clamped to the press table. You want to have and maintain everything in perfect alignment to the machine's quill until all operations are completed on a particular hole before redepositing the frame for the next hole.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 25 Users Like Post:

|

03Fatboy, 18DAI, Big Shrek, BLUEDOT37, cpeblue, DUSTYDOGDAN, Ed Fowler, gasaman, GeoJelly, gtoppcop, Hill_Country, ishootblanks, just plain joe, mjk5757, mlk18, RedCardinal, Rock185, Sevens, Shorty 45 MK2, TAROMAN, timn8er, Trinidad Bill, TTSH, Turn & Bank, vigil617 |

03-09-2016, 11:35 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: Long Beach, CA

Posts: 1,386

Likes: 876

Liked 994 Times in 442 Posts

|

|

Outstanding and your timing is perfect

__________________

USS ZELLARS

DD-777

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 02:57 AM

|

|

Member

|

|

|

Join Date: Mar 2015

Location: Ohio

Posts: 7,856

Likes: 9,472

Liked 14,859 Times in 5,051 Posts

|

|

Well, every one of your detailed projects is just an amazing episode of discovery. But I feel dumbfounded and blindsided here--

Just what the heck is a PC4506 and where can I read -MORE- about it?!

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 03:14 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,332 Times in 3,497 Posts

|

|

Great thread (again), very informative. This is better than watching "How It's Made" on the Science channel!

The grips look good! Wish I knew how they felt in my hand.

Now if you just had a 3D photo I could feel.

.

__________________

Waiting for the break of day

|

|

The Following 4 Users Like Post:

|

|

03-10-2016, 09:28 AM

|

|

US Veteran

|

|

|

Join Date: Nov 2014

Location: Trinidad, CO Raton Pass

Posts: 137

Likes: 208

Liked 99 Times in 56 Posts

|

|

Amazing Bill! You do a wonderful job with pictures and text describing the entire process. You truly have a gift.

As a young engineer in the early 70's I remember working with the old German Tool & Die makers at Cutler Hammer. Their skills, as yours, are truly amazing and I would guess, becoming a lost art. Most young people are not willing to spend the time required to learn these old world skills.

__________________

Vietnam Veteran, 68-69

|

|

The Following 5 Users Like Post:

|

|

03-10-2016, 04:36 PM

|

|

Member

|

|

|

Join Date: Mar 2015

Location: Wyoming

Posts: 77

Likes: 231

Liked 106 Times in 49 Posts

|

|

BMCM

As usual a perfect job and right on the money. I can't believe we can get this kind of "how to" and don't have to pay for it! So what's the next project???

Take Care,

T&B

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 05:30 PM

|

|

Banned

|

|

|

Join Date: May 2014

Location: Central NC.

Posts: 3,207

Likes: 37,672

Liked 4,393 Times in 1,851 Posts

|

|

I'm looking forward to how this one turns out!

Those do look mighty spiffy.

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 05:30 PM

|

|

Member

|

|

|

Join Date: Mar 2013

Location: s.w.Ohio

Posts: 1,932

Likes: 4,003

Liked 2,809 Times in 1,169 Posts

|

|

thanks for the tutorial......top shelf info for sure  ........and this my friends is how all 3rd gen. grips should install

__________________

witty signature goes here

|

|

The Following 2 Users Like Post:

|

|

03-10-2016, 05:54 PM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Holy cow!  How nice it must be to be so skilled.

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 06:04 PM

|

|

Banned

|

|

|

Join Date: May 2014

Location: Central NC.

Posts: 3,207

Likes: 37,672

Liked 4,393 Times in 1,851 Posts

|

|

Quote:

Originally Posted by TTSH

Holy cow!  How nice it must be to be so skilled.  |

I know, think of all the money he "saves" doing all his cool projects.

|

|

The Following 4 Users Like Post:

|

|

03-10-2016, 07:54 PM

|

|

Member

|

|

|

Join Date: Mar 2014

Location: NW Florida

Posts: 649

Likes: 4,977

Liked 710 Times in 362 Posts

|

|

Some enterprising rich young men should send him a box of Omaha Steaks or something

__________________

Marlin & Calico Specialist

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 08:02 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,228

Liked 6,220 Times in 1,043 Posts

|

|

Quote:

Originally Posted by Turn & Bank

So what's the next project???

|

Gonna be tinkering with this piece for a while. Grips are done but still need to re-assemble the receiver. The top end will be a little more work and I'll probably start a separate thread for that.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 2 Users Like Post:

|

|

03-10-2016, 09:59 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,228

Liked 6,220 Times in 1,043 Posts

|

|

Assembling the frame and a fix for the grip pin

Assembling the frame and a fix for the grip pin

I was going about getting the frame all put back together and ran into a minor problem with the grip pin.

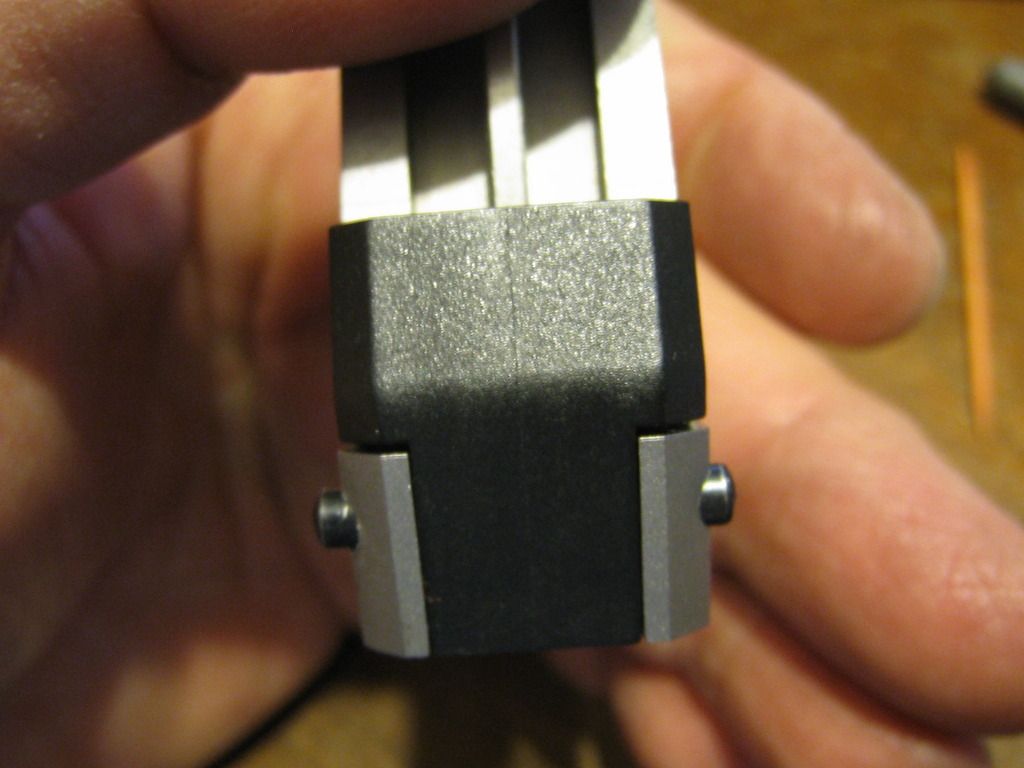

You can see here with both grip halves layed out, the spot I'm pointing at is a shallow clearance hole for the grip pin which is re-used with these grips to affix the little plastic doomherflatcher.

As it turned out, those clearance holes weren't quite deep enough. Either that or my grip pin is a tad overly long.

Here with the plastic thingamabob pinned to the frame using the standard grip pin, you can see here just how much stickout there is on each side. There was in fact enough stickout to keep the grips slightly gapped towards the bottom. Obviously this needs fixin'

Well, I really didn't want to go drilling on the grips and these days I'm certainly not inclined to cut up any factory parts, even something as minor as a grip pin. So...hmmmm. Oh wait  , I bet I have a spare trigger pin in the bin somewhere, I bet that'll work.

Yup, same diameter & profile, just a little shorter, this'll do just fine.

So, here we have the composite gizmotron pinned in place with a trigger pin. The mainspring & plunger are also installed and the substitute pin clicked right in place under the plunger. It's not going anywhere

The grips are a very tight fit and one must be careful not the damage them while pulling them off the frame. I use a method similar to how one properly removes the sideplate from a revolver. With a small plastic dead blow mallet I'll tap on the bottom of the trigger guard from the side until the right half pops free.

Here with the right half off you can see how precisely machined these are to provide clearance for everything under there.

Hammer down.

And at full cock.

I also like having the mainspring anchored in place with the grips off so I can look things over and evaluate the inner workings under full spring tension.

Virtually zero gap in the parting line.

Very close fit all around.

Helluva big improvement over the grips it came with

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 8 Users Like Post:

|

|

03-10-2016, 10:31 PM

|

|

Member

|

|

|

Join Date: Oct 2009

Location: Long Beach, CA

Posts: 1,386

Likes: 876

Liked 994 Times in 442 Posts

|

|

Since not mentioned I assume the grip screws are properly sized. Meaning, they are not dragging on the magazine.

"Thingamabob" my kids favorite word.

__________________

USS ZELLARS

DD-777

|

|

The Following 2 Users Like Post:

|

|

03-10-2016, 11:13 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,228

Liked 6,220 Times in 1,043 Posts

|

|

Quote:

Originally Posted by 03Fatboy

Since not mentioned I assume the grip screws are properly sized. Meaning, they are not dragging on the magazine.

|

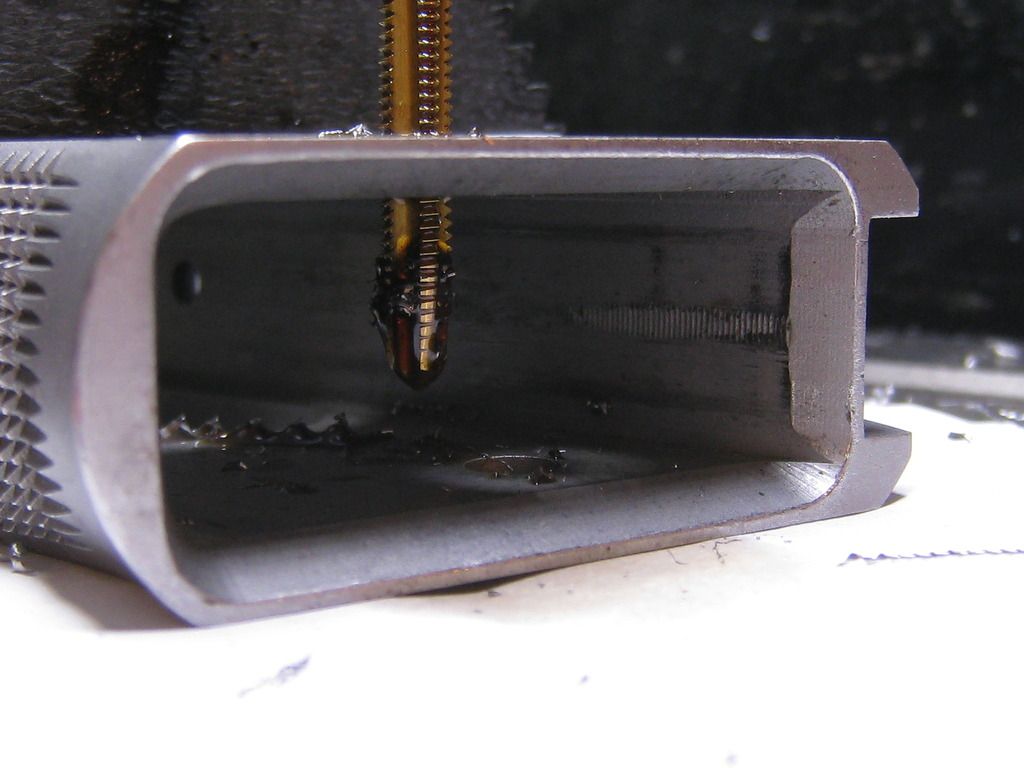

Interesting exercise in photography trying to capture this but I think I got it.

You can see the upper two holes here, magazine catch on the upper left, backside of the sear & bottom of the disconnector on the right. No interference with the magazine.

The screws are probably 2 or 3 threads shy of flush with the inner wall.

Those screws are plenty tight right now and as with any nice wood grips, care must be taken not to overtighten the screws beyond whats needed to keep the grips secure. You don't want to crush the wood under and around the screw heads and possibly deform the grips.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 3 Users Like Post:

|

|

03-10-2016, 11:20 PM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,218 Times in 4,509 Posts

|

|

Thanks for the great pictures of the inside and outside of those grips, Master Chief. Some mighty fine machining on that wood, especially the way the angles blend so well on the beavertail and the butt, and how the inner components fit like a hand in a glove.

I'm assuming the Nill grips were produced for the standard 4506 frame, but just in case: did you have to order these special made? What kind of walnut is that?

__________________

Ukraine -- now more than ever

|

|

The Following User Likes This Post:

|

|

03-10-2016, 11:45 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,228

Liked 6,220 Times in 1,043 Posts

|

|

Quote:

Originally Posted by vigil617

I'm assuming the Nill grips were produced for the standard 4506 frame, but just in case: did you have to order these special made? What kind of walnut is that?

|

No special orders, they're a catalog line item. They do have two versions, these I have here are the ambidextrous model. The other are pure target grips with a thumbrest on the left. For the 4506 frame yes, so should fit fine on any other like sized arm ie. 4566, 4596, 4505, 10xx etc.

I have a couple other Nills on both my 629s I ordered direct from Nill-Griffe in Germany since I've had an account there for a few years. However now it seems one must go through the US distributor. Nill's web store would not allow me to complete my order this time so I ordered these through Mactec Sales.

Took about 5 weeks for them to arrive. I've no idea what variety of walnut is used but they are pretty aren't they  It's also quite clear from looking at the grain lines that these are cut from a single block of wood as well.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 2 Users Like Post:

|

|

03-11-2016, 02:05 AM

|

|

Member

|

|

|

Join Date: Dec 2012

Location: N.E. OKLA.

Posts: 6,484

Likes: 5,882

Liked 9,332 Times in 3,497 Posts

|

|

Quit a difference in the grip profiles. Does the Nill's grip shape feel similar to that of rubber Hogue's, excluding the material's difference? Just wondering if it adds much more distance, or reach, when pulling the trigger in DA mode?

The "plastic thingamabob" looks just like the ones you get with rubber Hogue grips. They call their's a mainspring retainer.

.

__________________

Waiting for the break of day

|

|

The Following User Likes This Post:

|

|

03-11-2016, 12:16 PM

|

|

Member

|

|

|

Join Date: Jul 2009

Posts: 64

Likes: 48

Liked 51 Times in 27 Posts

|

|

Always wondered why Nill never offered a set for a 645. Seems like a slam dunk with the way the 645 has its grips affixed. Great work BMCM.

|

|

The Following User Likes This Post:

|

|

08-07-2022, 01:16 PM

|

|

Member

|

|

|

Join Date: Oct 2005

Location: A Burb of the Burgh

Posts: 14,788

Likes: 1,669

Liked 19,897 Times in 8,797 Posts

|

|

BMCM NICE!!!!! Missed this thread in 2016. Only Set of Nills I have are on an all steel Sig 220 (Ernest Langdon model)

|

|

The Following User Likes This Post:

|

|

|

Posting Rules

Posting Rules

|

|

|

|

|