(Updated 10-23-18)

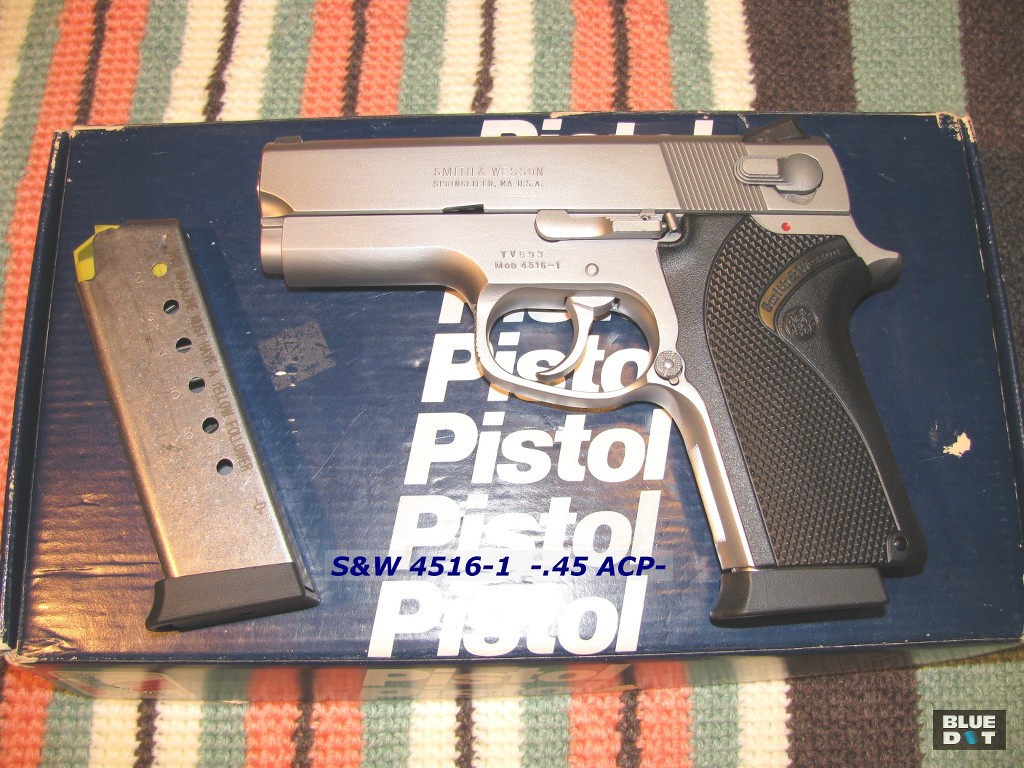

I've been considering converting my large frame compact, 3-1/2" bbl. single stack, 4013(R3) to shoot 10mm but hated to modify it's barrel. Then a forum member here mentioned that Numrich had a used one in-stock & I got one. He had also mentioned the possiblity of pairing the steel framed 4516 with the upper of a 4013, to have a more durable all steel combination. Owning both pistols that sounded interesting.

I then decided to spend some time playing with the two, a 4516-1 & a 4013R3.

.

4013(R3)

.

4516-1

.

.

With the 4013 slide assembly mounted on the 4516 frame & using a factory 4516 magazine I cycled some 40S&W snap caps from the mag with no problems. The rounds feed in & flew out like normal.

This 4013 has the small (.237") FLGR & I normally run a ISMI GLC-22# flat recoil spring in it & a 20# mainspring.

The 4516's frame weighs 7.45oz. more than the 4013's frame, w/o mags.

A couple things I noted:

- the 4013 has a longer ejecter nose than the 4516 (may affect ejection force/direction?)

- the 4516's dust shield is .216" longer from it's tip to the FLGRs seat, which reduces the amount of the lower slide exposed (cosmetic)

.

4516 & 4013 frames, side-by-side

.

.

While the factory 4516 mag seemed to work okay I got an idea. I installed a 10mm (1006) follower (which is the same length, front-back, as the 45's, & just a little narrower), a 4013 mag spring (Wolff +10%) in the 4516 body using a 4516 catch plate & curved butt plate. This composite seemed to work fine & I liked the idea of the longer (full length) follower for the 10mm case to sit on.

.

4516 & 1016 magazine

.

Of course, the downside to the "1016 hybrid" is it takes two pistols to create, but for occasional use I can handle that too since neither one has a dedicated purpose.

.

.

I received the Numrich 4013 barrel I ordered &, other than being dirty, it checked out good. Test fired it in my 4013 without any issues. No additional fitting seemed necessary.

.

Next trip to the range was to fire the 4013 upper with the 4516 lower, just to see if they worked together as a 40S&W. Took a factory 4516 mag fitted with it's normal components & another 4516 body fitted with a new S&W 10xx follower & mag spring, held in place by a 4516 catch plate & butt plate, to try both arrangements.

Took a couple different moderate to full power 40S&W loads. Started with just one round, then two in the mag & everything functioned as it should, the pistol shot fine. Then I added three round to the mag & that's when things started going not so good.

In short, the 40S&W rounds are not held tightly enough at the top of the stack & they slide forward (under recoil) causing live round stovepipes. Sometimes the next round would go in the chamber but the following round would pop-up into a stovepipe. One time a round flew completely out onto the floor. The most I was able to fire before this occurred was (4) rounds with the 5th & final round stovepiping.

I tried the factory 4516 mag first, then the 10xx equipped mag, but there wasn't really any difference in the failure rate.

After I got home I decided to play with using a 4013 mag in the 4516 mag well. The nubs on the side of the 4013 mag were the first to go so it could even be inserted. I cut/ground them off & checked things.

Turns out the real problem is the fact that the 4013's body is .040" narrower than the 4516's. (The depth, front to back, is the same.) The 4013 mag can twist around in the mag well & because it's farther away from the mag catch less of the catch is holding it & it comes loose & falls out easily. Not good.

I decided trying to make the 4013 mags work properly in the 4516 frame has too many problems.

.

.

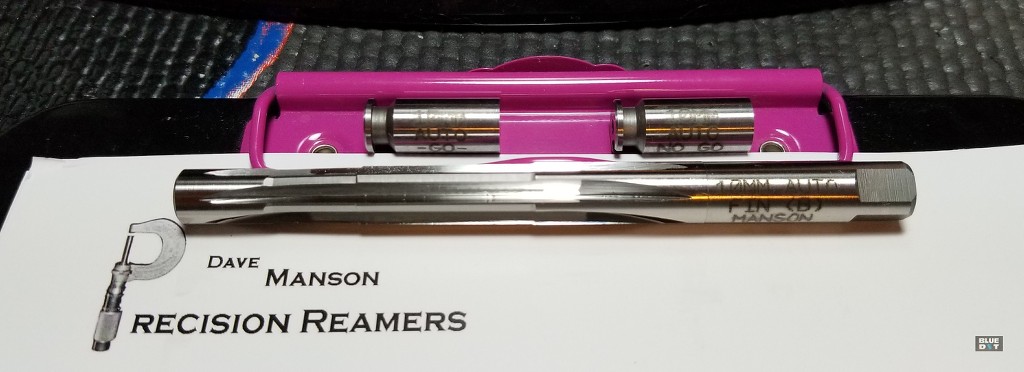

I received my order from Dave Manson: 10mm solid pilot finishing reamer, plus 10mm Auto GO & NO Go gauges. I got their solid pilot reamer because they told me their's is sized .3895" (which it was) & I knew the 4013's bore was right at .3898" using my minus pin gages.

.

Dave Manson reamer

.

.

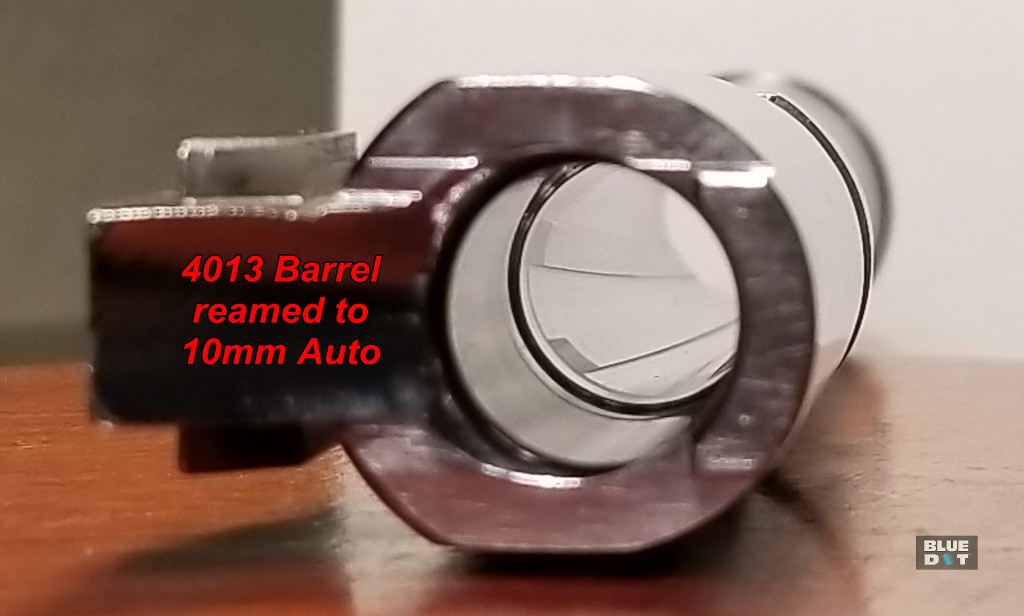

Reaming the 40 S&W chamber to 10mm wasn't too bad. Maybe a dozen or more "cut & cleans" to get close before making the final cuts.

Getting the cut started was a little touchy with the course reamer flutes boucing off the barrel's rifling, but once it got going it smoothed out quickly. The reamer apparently has a slighly different angle to it's cut verses than the factory's. I marked were the reamer stopped, when lightly inserted into my 1006's chamber, but once I was all done cutting the 4013 barrel it went in past that mark.

The Go gauge mic'd at .9922" & the No-Go at 1.0039" long, with both at .4180" in dia. The gauges have a notch for the extractor to slip thru but the S&W extractor is a tad to wide so I just slipped the gauge's head (which is a little thinner than a cartridge's rim) under the extractor to check the headspace each time.

I ended up with minimal clearance between the Go gauge's head & the slide's face when closed. Probably about .0005" ?? The gauge would drag slightly when I turned from below (with a dental pick in the head's extractor notch) with the barrel smoothly closed/locked in the slide.

Doing this same clearance test on my 1006 & 1076 barrels, the Go gauge turned freely. The No-Go gauge in the 4013/1013 & 1076 barrels kept them from closing. Oddly, my 1006 would just close, though tighly, with the No-Go gauge in !?

Where the reamer extended the 40 S&W's chamber length you could see a slight difference in diameter but it was not detectible, or measurable, when inserting any pin gage or sized cartridge in it. The mouth end of the chamber still measured right at .427" though.

.

1013 chamber

(-02b)

.

.

I compared the other chamber measurements after reaming & the head end and throat increased ~.001" to .431" & .4018" respectively. The freebore was reduced slightly but to a still comfortable .109", as best I can measure.

.

1013 chamber

(-01b)

.

.

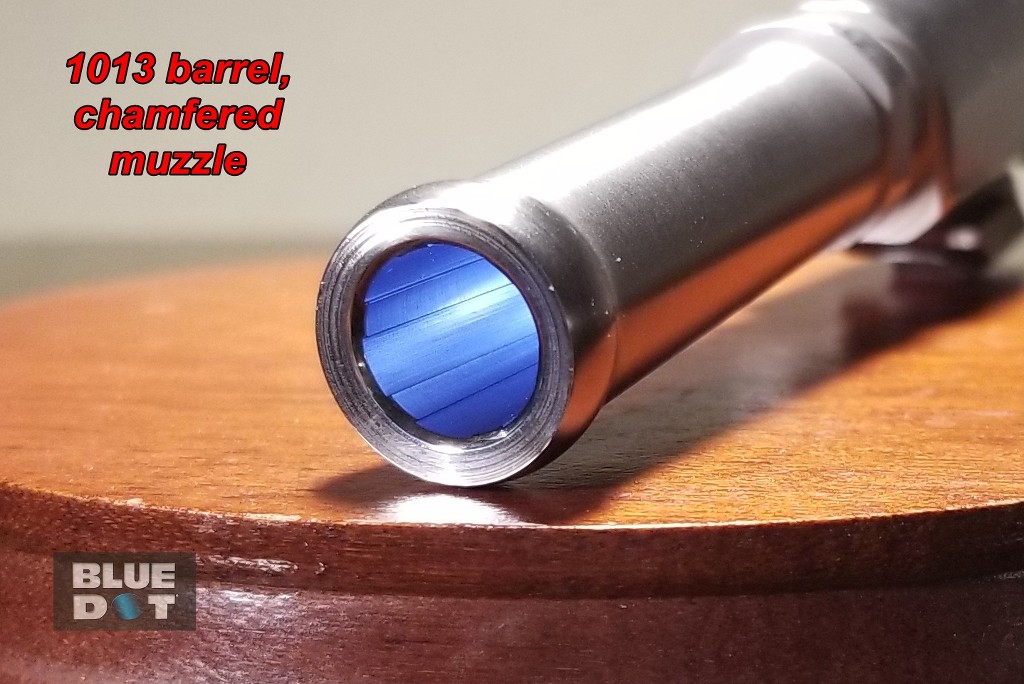

One thing I noticed on the Numrich 4013 barrel, when I checked it out after receiving it, was that my .390" pin gage, the largest that would enter the muzzle, would slight freely down the bore until about midway & stop. My .389" gage passed easily.

After reaming the chamber I had planned on hand lapping the bore to remove that minor restriction but found out that the .390" gage now went smoothly thru the bore. It would seem that restriction was at the point where the rifling is chamfered into the freebore/leade, which got reamed out (remember that slightly different reamer angle?), and now was fine. Cool!

Also, I chamfered the crown to give the rifling a better presentation at the muzle (FWIW) & minimally filed off the lightly stamped "40 S&W" from the barrel & polished it up.

.

Chamfer muzzle

(-04b)

.

1013 magazine & barrel

(-02b)

.

.

On the magazine mod, I did it kind of like the OP in the CS40 to 10mm thread did it, not like most do it. Instead of drilling out the tack welds I just put the mag vertically in my vise & used a small 1/4" chisel to carefully start separating the spacer from the mag's back. Once it was lifted enough I tapped the chisel deeper & after it got past the first tack weld the spacer just popped out.

They actually look more like sharp indentations instead of tack welds. I see no evidence of welds marks on my spacer. The inside protrusions were minimized using a fine tooth file allowing the follower to slide freely.

Using the 4013 mag's body & butt plate I used a 10mm white follower, 10mm mag catch plate, & a factory 10mm magazine spring with (1) turn cut-off, to fill it out. Eight rounds snugly fit in but seven seems more like a comfortable fit to me. Everything I tried cycled/feed without issue.

.

.

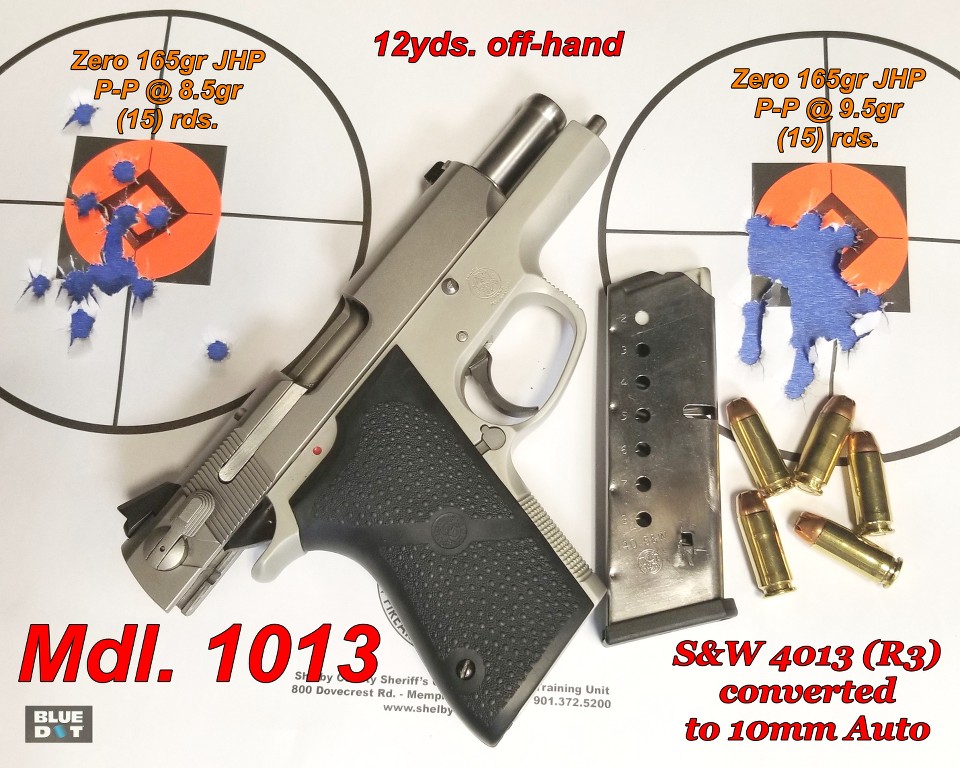

Got it to the range to fire it as a 1013 & all went well. Shot (70) rounds thru it starting with a few light 10mm loads & working up to what I routinely use in my 1006 & 1076.

I used the same bullets I use in my 40 S&W loads, Zero's 165gr JHP. My "lite" 10mm load (10ea.) was P-P@ 7.5gr, a mid 40S&W load, which would actually be a little slower in the larger case. The others loads (20ea.) were P-P @ 8.5 & 9.5gr on my personal 10.0gr max. Also shot some loaded with 11.5gr of Blue Dot too.

Everything feed & extracted fine. The 1013's ejection was mostly to my 5 o'clock, where my other 10s go, but a bunch went out the side, 3 o'clock, & some straight over my head. A little more erratic that normal but I'm sure the higher slide/ejection speed & the longer ejector's nose are the culprit? All & all not too bad considering.

The only noteworthy issue was (2) failures to lock the slide back on the last round. I wondered if maybe some Wolff XP mag springs would help on that matter?

It consistently shot several inches low (unlike in 4013 mode) so a LPA adjustable rear sight looks like it might be a good fix for that. I had to cover up the 2" bullseye with the front sight to get the best results.

That short barrel has a pretty good BARK with 10mm loads.

.

1013 Target

(-01e)

.

.

.

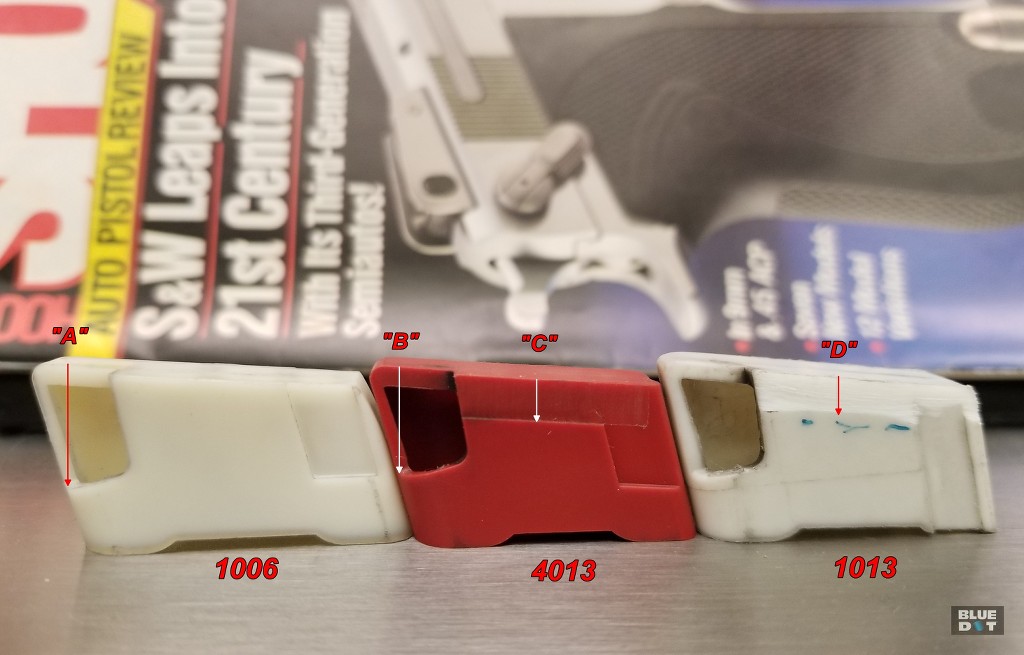

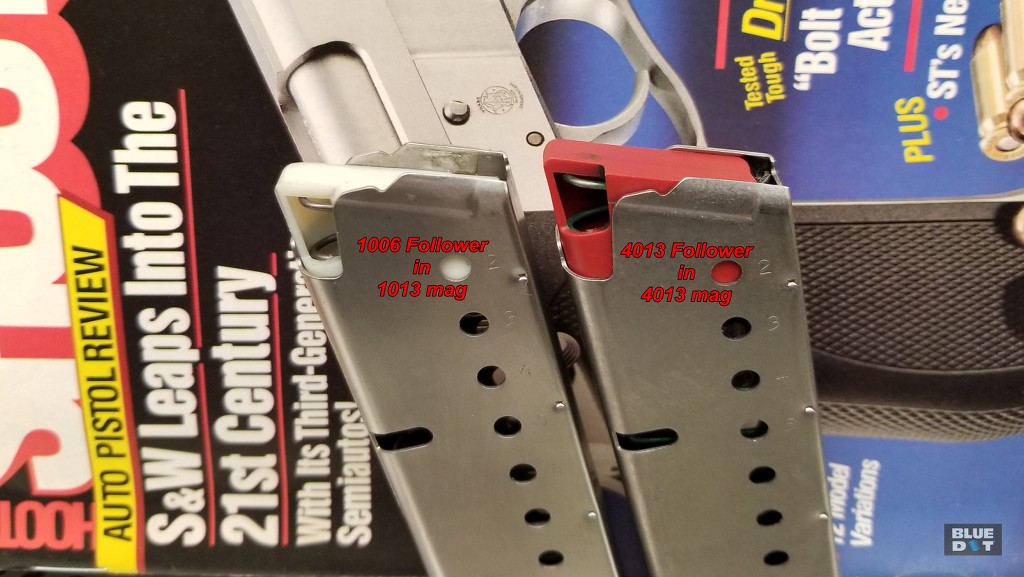

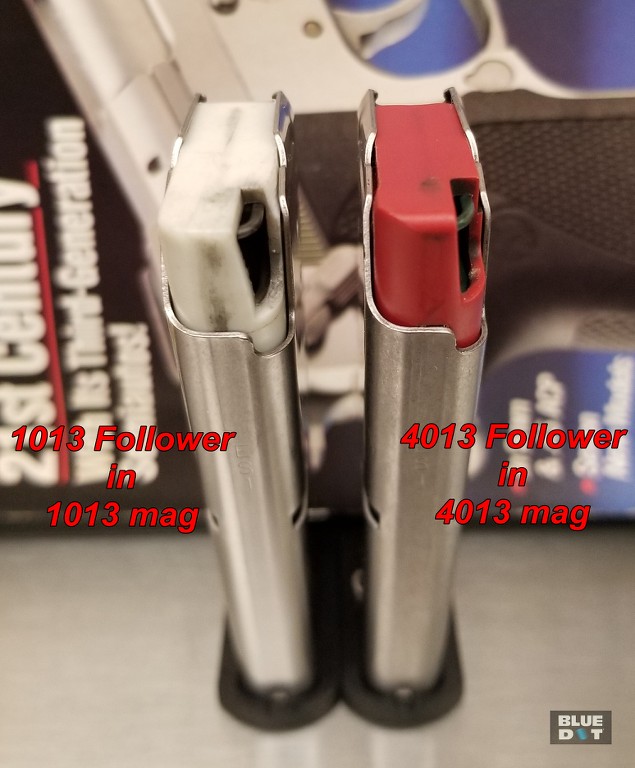

Concerning the failures to lock the slide back. Some semi-related work (on a second 4013 I just bought, 4013(B). ) had me noticing the differences/revisions in 4013 followers & it dawned on me to look closer at the position of the 1006 follower in the 1013 mag. Apparently I missed some of the previous notes on using the 1006 followers in the modified 4013 (1013) mags?

First off, two things, the mouth/opening of the 1006 mags are slightly wider than the mouth of the 4013 mags. The depth & width of their lower bodies are the same. Secondly, the notch/opening on the left side of the followers (where the follower pushs up on the slide stop's arm) are slightly different too, the 1006's opening being longer vertically (distances "A" & "B" noted in my attached pic).

.

Followers 1006-4013-1013

(-01c)

.

.

So, the 1006 followers go freely to the top of their 1006 mags but the 1006 followers are too wide to go freely to the top of the 1013 mag.

.

Followers 1006-4013 installed in mags

(-01a)

.

Followers 1006-4013 installed in mags

(-02a)

.

.

S&W apparently saw a similar issue (?) on the 4013 mags & revised them to have a slight chamfer to the top left & right sides (notation "C" in my pic), because of the rebated lips on the mags, to allow them to freely feed to the top.

(Note: the 4013 mags evolved, as typical of others, & there are several versions. I used the ones without the additional vertical indention in the mag lips to further hold the top round.)

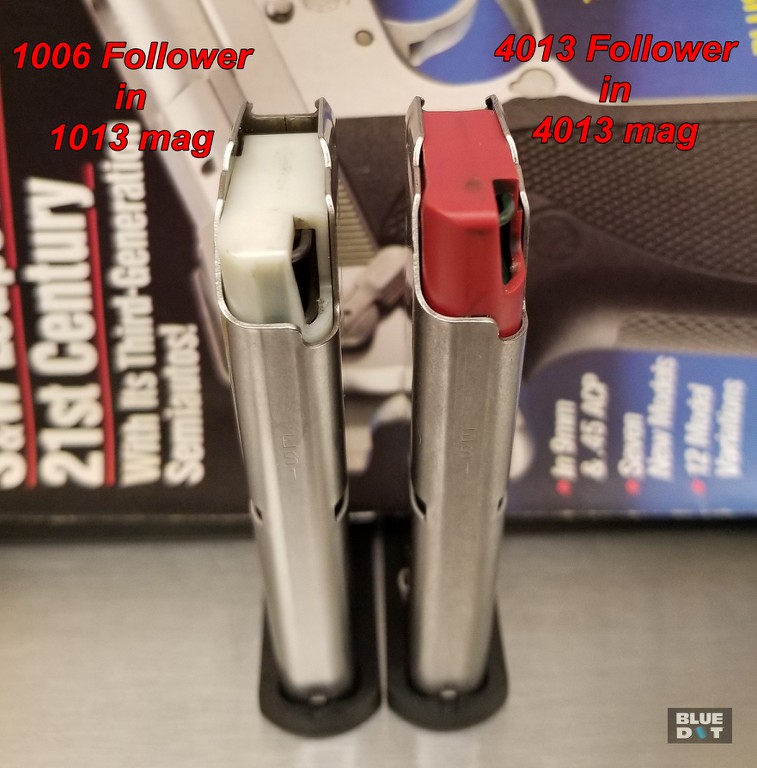

The 1006 followers are ~.440" wide across their top while the 4013 "chamfered" followers are ~.390". By carefully chamfering the corresponding points on the 1006 followers (notation "D" in my pic) to ~.400" wide the (1013) follower will freely go to the top of the 1013 mag.

Without this full range of movement the follower can't forcefully push up the slide stop to consistently lock the slide back on the last round irregardless of spring force.

I chamfered mine by first making a reference line ~.170" down from the top of the follower to give it a similar chamfer (notation "C" & "D"). I used a Dremel mini-sanding drum, on low speed & a small long nose Vise-grip plier, loosely clamped in place, to provide a guide & restrict where I cut. I later used a small fine cut file to smooth out the surface.

.

Followers 1013-4013 installed in mags

(-01a)

.

Followers 1013-4013 installed in mags

(-02a)

.

.

Next up, off to the range again, this time to try it configured as a 1016; 1013 upper & 4516 lower.

Tried using it with:

1)- a stock 4516 mag with a Wolff XP spring,

and with

2)- a 4516 mag (4516 body, base plate & butt plate) with a 10mm follower & a 4013 S&W spring.

Both feed & extracted fine. A couple times, with the second mag, the slide didn't stay back after the last round. Probably should have used a 10mm mag spring for more strength in forcing the slide stop up.

Surprisingly ejection consistency was worse as a 1016, IMO. I lost a majority of my brass due to being ejected to my 3 o'clock & then bouncing forward off the wall.

One issue I did have though was the 4516's slide stop lever tried to back out (from recoil?) & it barely caught the slide's stop notch half way (last round) denting it's corner & jamming up the slide momentarily. I didn't shoot it much more after that as a 1016. (The 4516's slide stop lever does push out relatively easy compared to the 1013/4013(A)'s, but not as hard as my other 4013(B), though it never happened before as a 4516.) I will try it again later with a tighter slide stop.

Reconfigured back as a 1013, using the modified 10mm follower mentioned above, the slide stayed back after the last round every time. I think this problem is now solved.

Total 10mm round count shot in the 1013 is 150.

.

.

I was originally planning on installing a XP Wolff mainspring (22# or 23# to assist in helping slow down the slide) but couldn't find one in my stash. I found out why, they don't make an extra power spring for the Short-Group "B", only standard or reduced power springs.

So I decided to see if I could make an XP mainspring by modifying some other mainspring.

(The 4013 slide/barrel weighs 17oz. while the 1076 & 1006 slide/barrel weigh 19.0 & 19.7oz. respectively.)

Let me briefly explain what I did:

I used a Wolff 23# Type "A"/Long mainspring (#27523) & shortened it to ~1.645" long & found it gives 4-5#s more resistance/pressure on the slide than the Wolff 20# Type "B"/Short mainspring (#26920). This is roughly (2) turns longer than the standard power 20# spring.

With no barrel or recoil spring assembly installed the standard 20# spring exerted 8# of resistance against the slide's rearward movement. The 1.645" spring exerted 13#.

The two springs have essentially the same O.D.s at .273" & .278" & their wire diameters run .048" & .051", repectively.

The cut-off end of the mainspring (using a Dremel cut-off disk) was bent inward to give it a flatter profile, & that end went into the mainspring's plunger. The factory turned end went on against the hammer strut's flange.

.

Wolff XP mainspring mod for 1013

(-01b)

.

.

As an expected side affect of the stronger mainspring, the SA trigger pull increased from 6.5# to 7.5#. The DA pull also feels like it increased but my scale doesn't go over 8# so I can't confirm what the change was.

.

Lastly, in the 1013 I used the same ISMI GLC-22 flat wire recoil spring that I'd been using in it as a 4013. I initially started using them when you couldn't find the dual/nested S&W springs & thought it performed well but my home-made test setup changed my mind.

Previously I made a little test setup to get a better idea on how well increasing the mainspring power worked in resisting the slide & found those flat wire recoil springs were not as strong as I had thought. I reconfirmed that again on the 1013.

The S&W dual/nested springs give you about 3#s more resistance, at full compression, than the GLC-22#. And at the point where the slide is cocking the hammer & the barrel unlocking (under recoil), the combined force of the dual recoil springs & my XP mainspring gives an increase of 4# (from 18# to 22#).

I installed this arrangement, along with the 1013 barrel & 1013 magazine, in the 4013(B) with Novak sights, & will try everything as my "new" 1013 setup next trip to the range.

Going to a Wolff 21# recoil spring over the S&W inner spring later is an option, if needed.

Adding a LPA adjustable rear sight & retesting the 1016 setup will be the next.

.

S&W 4013(R3)s: Night Sights & Novaks

(-01b)

.