|

|

|

10-19-2018, 11:20 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,349

Likes: 2,225

Liked 6,208 Times in 1,042 Posts

|

|

M1006 - Fixing bad action job

M1006 - Fixing bad action job

Hiya Gents,

I alluded to some of this in my other thread re: replacing the trigger play spring.

Here's the rest of the story...

My letter carrier deliver this M1006 to me the other day. I was told it was wildly inaccurate and had a broken play spring. I was asked to go through it in detail, replace the broken spring and test fire to evaluate accuracy.

As I go about digging the drawbar out of the frame, alarms bells start going off... Uh Oh! someone has been mucking about in here ahead of me  And it doesn't look pretty.

In the end I wound up replacing the hammer, sear, drawbar, trigger.

I thought I'd share what I found in there and why I replaced these particular components. In the following photos I have fixtured the replacement together with the bad part on the right hand side.

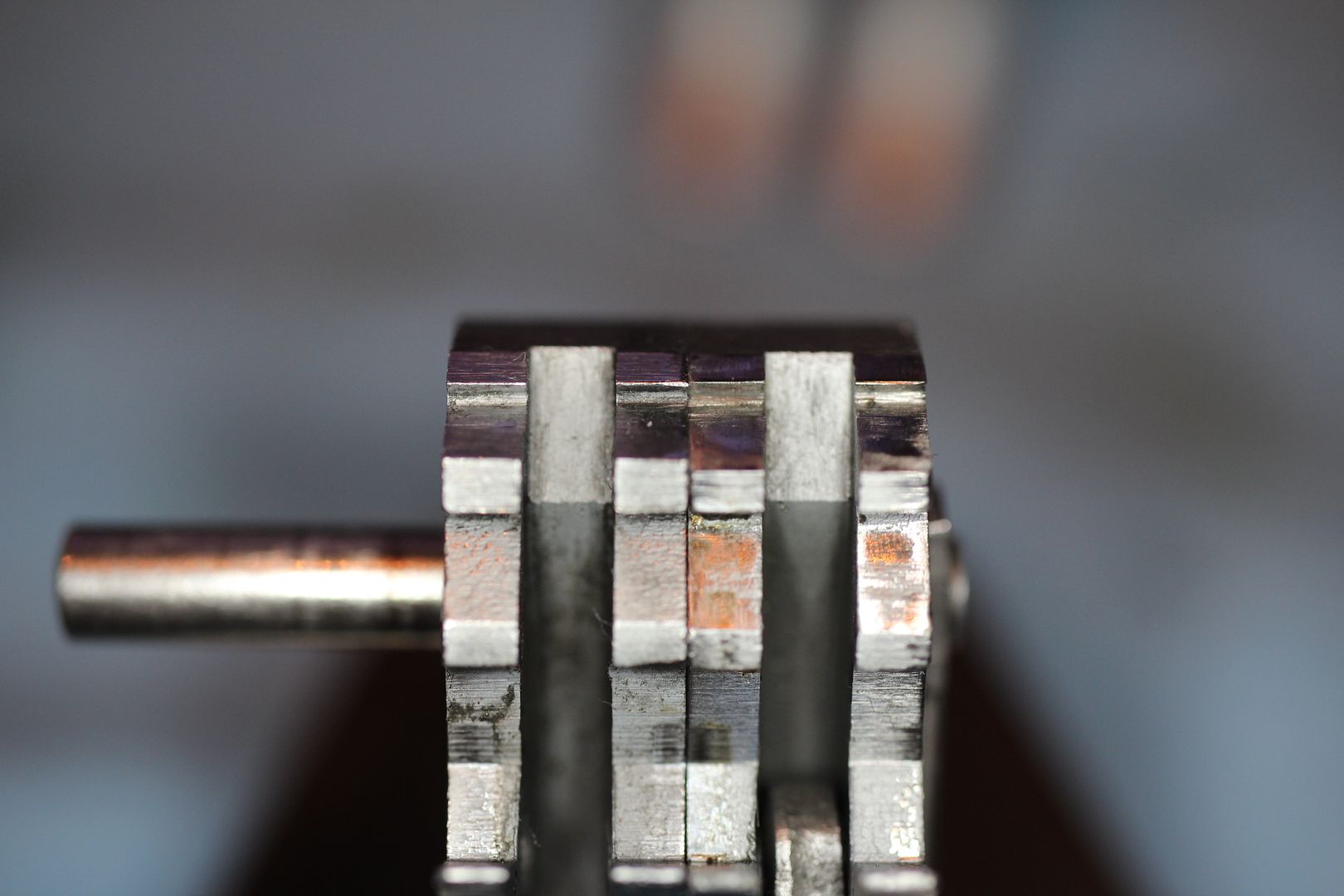

Hammer came out first so lets take a closer look.

Bad hammer on the right here. The three hammer notches as oriented in the pic are, the fullcock notch at the top, pickup notch in the middle and throw notch at the bottom.

Fullcock notch on the right has been deepened and lengthened. the effect of which is to shorten hammer throw. All the edges that should be sharp & angular have been rolled over and polished. The relief cut (flat above the fullcock notch) is rolled over in both axes such that it's now a shallow convex dome shape.

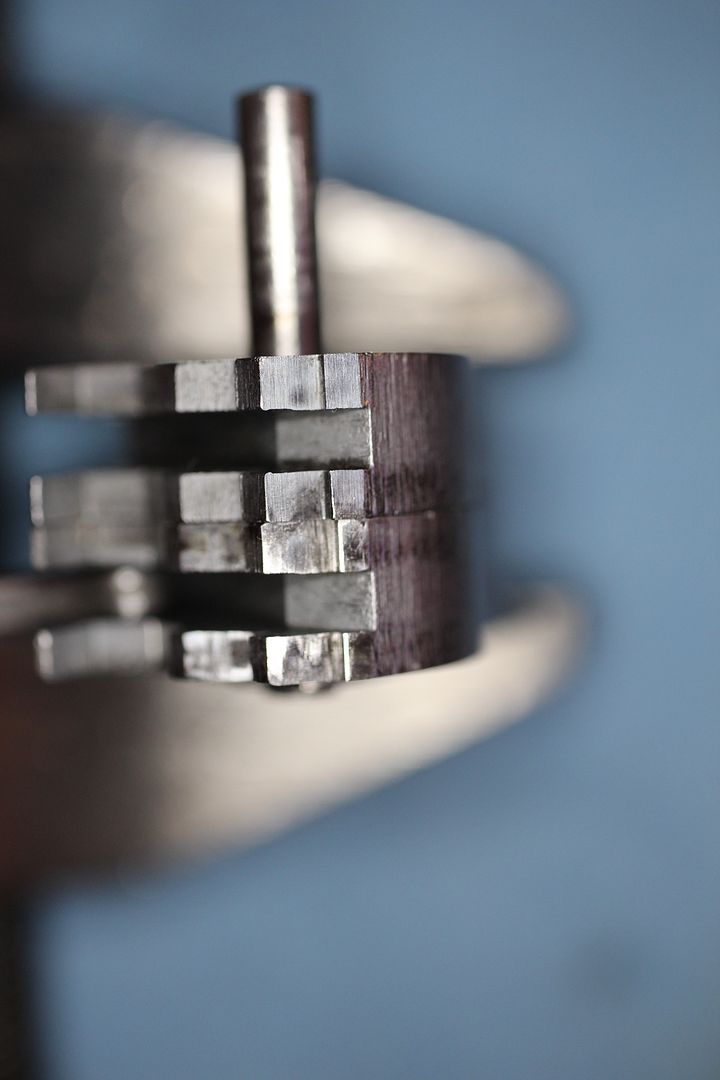

Viewed from another angle.

The bottom of the full cock notch no longer has any angles but has been cut into a shallow concave radius. I also see where the throw notch has been polished and the edges rolled over there as well.

On to the sear...

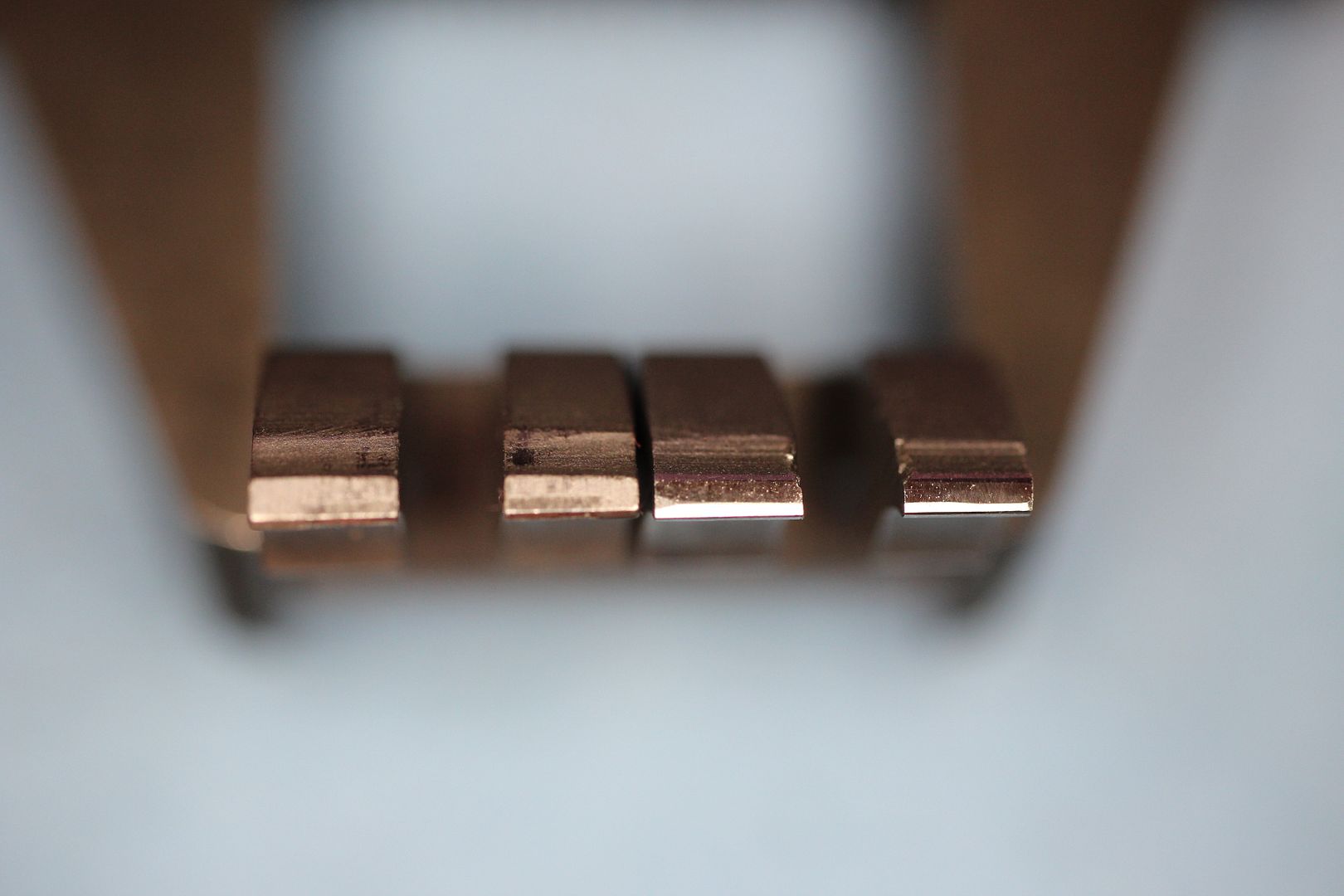

Bad sear on the right. Sear angles have been blunted and rolled over, sear legs are unequal in length now. Overall the sear has been shortened somewhat. But it's shiney

Another view.

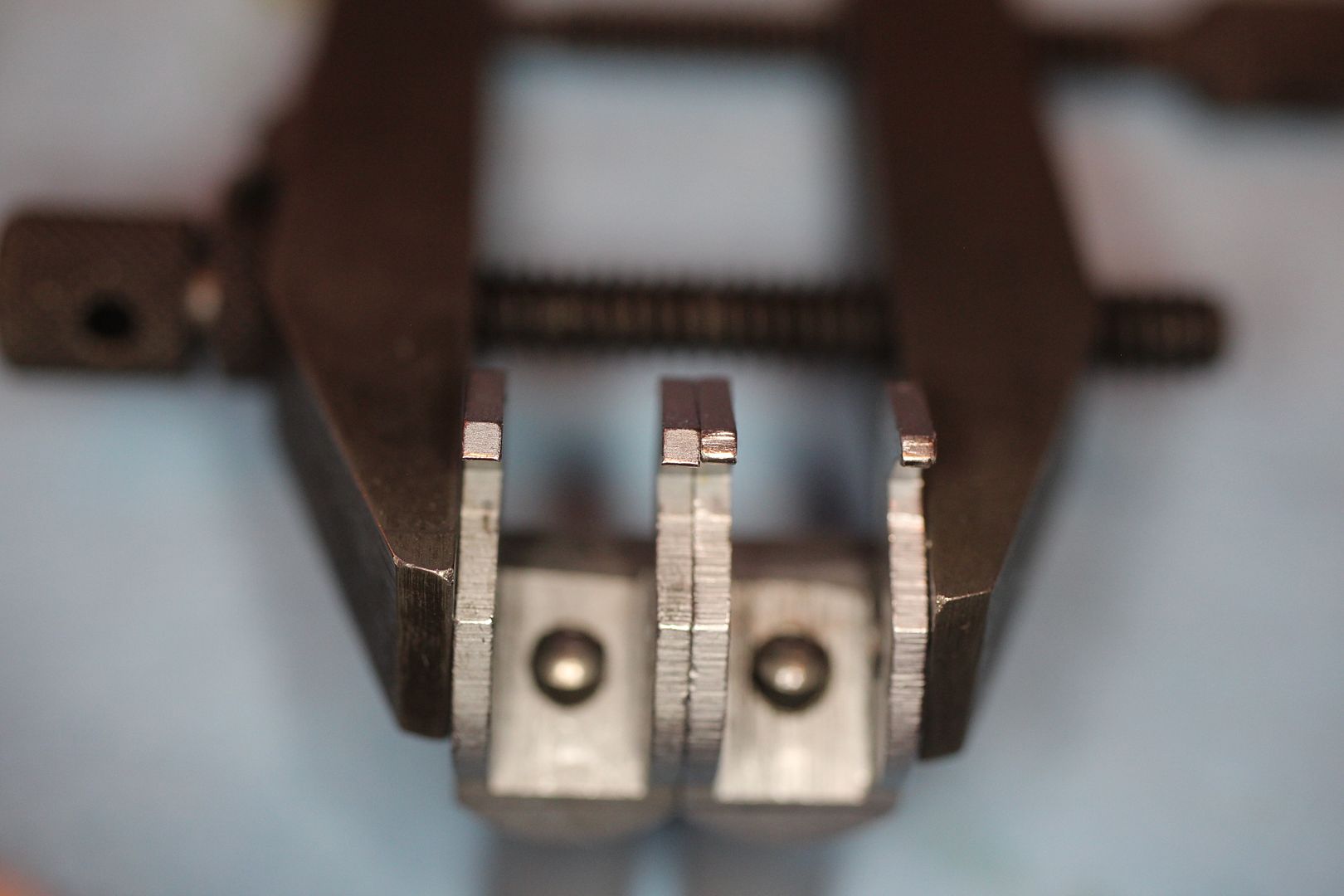

Drawbar.

Again with the sanding & polishing at the trigger interface. messing with this area is of absolutely no benefit. The sharp bottom of that shallow angle cut has been rounded and scalloped out on the sides such that what was once a shallow angle cut is now a curved ditch which freely allows the trigger legs to skate around instead of pivot at the apex of the shallow angle cut as they were meant too.

When I put 2 & 2 together after seeing half of the play spring torn off, in my minds eye I see a rapidly spinning felt bob catching the lower leg of the play spring and Rip/Fling

The drawbar ought to look like this. Nice straight shallow angle cut with a sharp apex wherein the trigger hooks pivot.

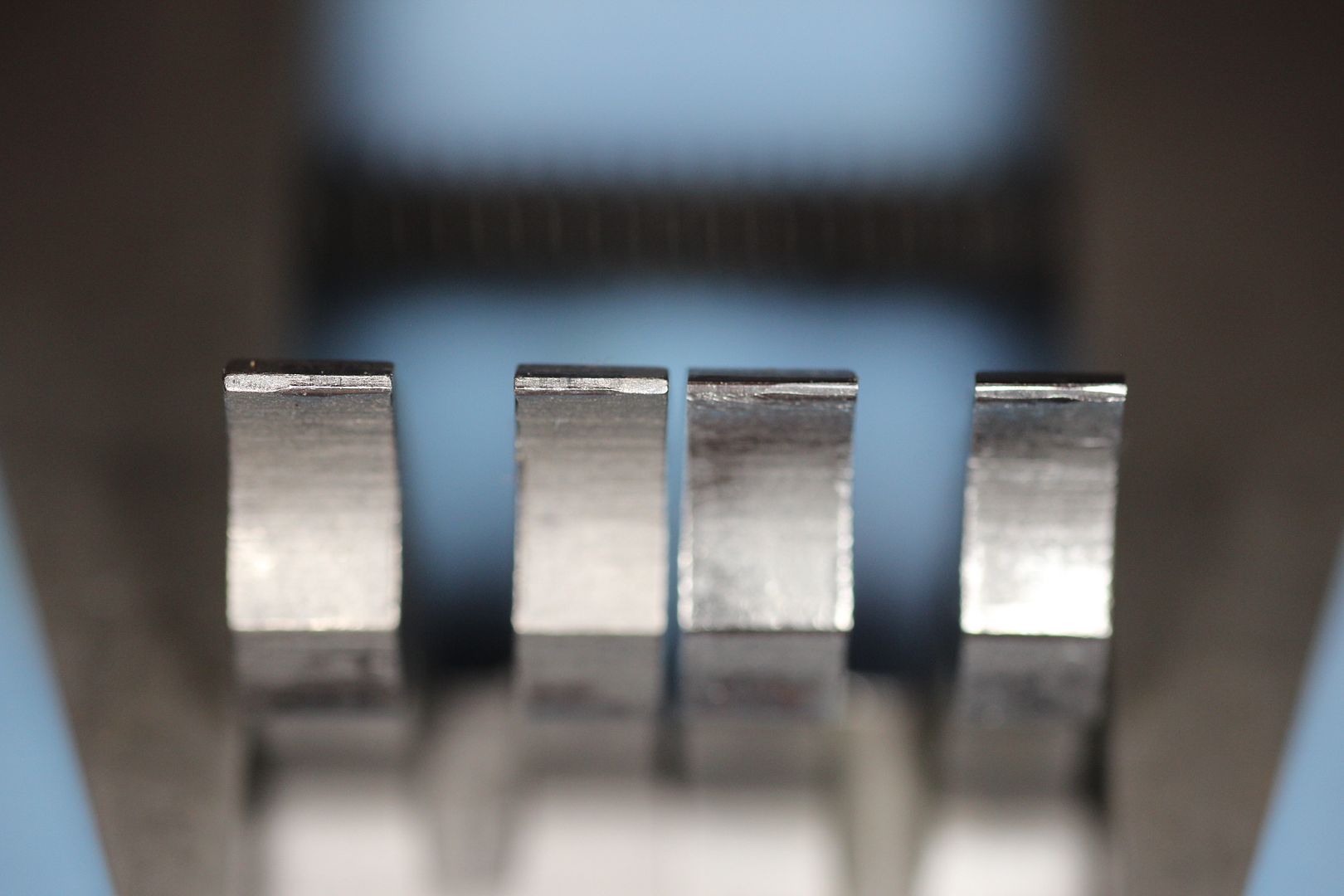

Trigger...

Oh Good Grief!  Bad one on the right again.

Hooks significantly shortened, blunted/rounded over & polished.

So instead of pivoting nicely at the apex of the drawbar cut we greatly increased the bearing surface between trigger & drawbar making sure the trigger hooks free to scrub about.

Viewed from the side.

Hammer & trigger flats sanded & polished.

Serves no purpose at all unless the intent was to remove the flash chrome exposing the underlying carbon steel thereby promoting rust.

Those are the highlights. Aside from these parts, there were a number of other things that could have actually benefited from some work and would have resulted in quantifiable improvement to the trigger feel, but were left untouched

You know, this stuff kinda saddens me a little. There's noone making any new carbon steel bits for these guns and the supply of replacements is finite and dwindling. A few NOS parts turn up from time to time but mostly were relegated to the used bin. When someone presumably unknowingly goes in there and ruins a bunch of stuff, well, you know  And some of the things done here were just utterly pointless of no benefit whatsoever

I like to think I am pretty handy with file and stone but there's no way I would ever mess with sear angles and hammer notches freehand.

I guess you can call this a cautionary tale. I'm not one to ever begrudge someone working on their own stuff but in this case I'll merely say if you don't own a stoning fixture with the proper adapters...

And at least a pint of stones & files on the ready line...

Plus, of course the knowledge & skills to use these things... Just don't, you'll only make it worse.

Anyway, the gun is all back together with the new bits, and some fresh bead blasting, headspace gauged good, extractor tension set & 7#, crown cleaned up, front sight moved to the centerline (was way off to the left), gobs & gobs & gobs of sticky green marine grease cleaned out of everywhere. I'm heading over to the Concordia Parish SO range in the morning for a test drive.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 20 Users Like Post:

|

18DAI, Barrie, cololab, DCW, Frank Black, GaryS, HCH, Jeppo, JohnHL, kraynky, LoadedRound, mjk5757, nocents, RedCardinal, Sevens, SMSgt, TercGen, tlawler, TTSH, vigil617 |

10-19-2018, 11:32 PM

|

|

SWCA Member

|

|

|

Join Date: Feb 2017

Location: Davidson County, NC

Posts: 2,117

Likes: 7,803

Liked 4,137 Times in 1,414 Posts

|

|

|

|

The Following 2 Users Like Post:

|

|

10-19-2018, 11:35 PM

|

|

SWCA Member

|

|

|

Join Date: Feb 2017

Location: Davidson County, NC

Posts: 2,117

Likes: 7,803

Liked 4,137 Times in 1,414 Posts

|

|

So, I guess you're saying I shouldn't move ahead with my plan to improve actions with a bench grinder?

|

|

The Following 5 Users Like Post:

|

|

10-20-2018, 01:32 AM

|

|

Absent Comrade

|

|

|

Join Date: Sep 2005

Location: GSO NC

Posts: 6,106

Likes: 23,604

Liked 13,195 Times in 2,860 Posts

|

|

Step away from the grinder Jeppo and let me see your hands!

I didn't know action work was a menu option BMCM......I'm going to need a 3rd source of employment next year.   Regards 18DAI

__________________

7 +1 Rounds of hope & change

|

|

The Following 5 Users Like Post:

|

|

10-20-2018, 01:46 AM

|

|

SWCA Member

|

|

|

Join Date: Aug 2013

Location: Foothills of the Ozarks

Posts: 3,596

Likes: 10,661

Liked 5,587 Times in 2,179 Posts

|

|

Sometimes, 18 (like above) the best action job is returning everything to the original configuration.

John

|

|

The Following 4 Users Like Post:

|

|

10-20-2018, 12:59 PM

|

|

Member

|

|

|

Join Date: Apr 2007

Location: Virginia

Posts: 8,760

Likes: 19,473

Liked 11,848 Times in 5,383 Posts

|

|

Quote:

Originally Posted by Jeppo

So, I guess you're saying I shouldn't move ahead with my plan to improve actions with a bench grinder?  |

Quote:

Originally Posted by 18DAI

Step away from the grinder Jeppo and let me see your hands!

I didn't know action work was a menu option BMCM......I'm going to need a 3rd source of employment next year.   Regards 18DAI |

[Bubba voice on] So I guess that means I shouldn't use my Dremel to do a trigger job on my Model 439? [Bubba voice off]

Seriously, I am continually amazed at what people will do to an otherwise fine firearm in an attempt to make it better and the end result is that it is worse or even dangerous.

|

|

The Following 3 Users Like Post:

|

|

10-22-2018, 02:15 PM

|

|

Member

|

|

|

Join Date: Apr 2011

Posts: 31

Likes: 0

Liked 30 Times in 11 Posts

|

|

Repairing 1006 butchery

Repairing 1006 butchery

So a couple of weeks ago I decided to gift my brother in a southern state a pair of S&W 3rd Generation pistols.

I went digging in the back of the safe and found a LNIB 5906.

OK, that will work for a 9mm.

Dig a little deeper, here's a 1006 in 10mm I bought used from a different Forum.

Off to my FFL, and have the 5906 shipped to a FFL in the southern state.

Now the 1006 clearly needs some love & attention before it goes to my brother. Where should I send it?

Then it hit me! Ship that used 1006 to BMCM.

My FFL is quite confused, the 5906 ships directly to the southern state FFL. The 1006 ships to a different southern state Gunsmith/FFL for Spa treatment. Then it finally goes to the same FFL where the 5906 went. OK, paperwork is all figured out.

In just over one week BMCM brought the 1006 back to life.

The 1006 parts BMCM replaced was significantly larger than the short list above.

He test fired the 1006 with no malfunctions and a sub one inch group at 15 yards. He communicated regularly.

BMCM brings new meaning to Gunsmith service & communication for me.

Here is something to think about when you purchase a used firearm on a Forum. Especially considering the age of the 1006. (early 1990's) You have no guarantee somebody

(a previous owner) has not performed butchery where you can't see it. I never detail stripped the 1006 after purchasing it.

I won't make that mistake again.

I am the guilty party for the excessive quantity of grease on the 1006. I will try and use less when I send another 3rd Generation pistol to BMCM.

I have a 1076 that needs a trip to the Spa.

My brother got his new to him 5906 out to the range yesterday.

The 1006 should be in his hands soon.

The 3rd Generation pistols were the pinnacle of S&W metal framed semi automatic pistols.

My brother's comments after his range trip yesterday.

Solid.

Smooth.

BMCM, Thank You!

|

|

The Following 6 Users Like Post:

|

|

10-22-2018, 08:35 PM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Quote:

Originally Posted by cee_Kamp

Here is something to think about when you purchase a used firearm on a Forum. Especially considering the age of the 1006. (early 1990's) You have no guarantee somebody (a previous owner) has not performed butchery where you can't see it. I never detail stripped the 1006 after purchasing it. I won't make that mistake again.

|

My worst nightmare.  I've been reasonably lucky so far, but I know that someday I'm gonna get the big zingaroo. It's inevitable. I'm as careful as an old man can reasonably be, but nobody's perfect.

|

|

The Following 2 Users Like Post:

|

|

10-22-2018, 08:52 PM

|

|

SWCA Member

|

|

|

Join Date: Feb 2017

Location: Davidson County, NC

Posts: 2,117

Likes: 7,803

Liked 4,137 Times in 1,414 Posts

|

|

Quote:

Originally Posted by TTSH

My worst nightmare.  I've been reasonably lucky so far, but I know that someday I'm gonna get the big zingaroo. It's inevitable. I'm as careful as an old man can reasonably be, but nobody's perfect.  |

Like the 908 I bought at auction and parts fell out when I took off the grips?

|

|

The Following 2 Users Like Post:

|

|

10-23-2018, 09:56 AM

|

|

Junior Member

|

|

|

Join Date: Dec 2013

Location: MA

Posts: 7,707

Likes: 13,905

Liked 9,470 Times in 4,391 Posts

|

|

Quote:

Originally Posted by Jeppo

Like the 908 I bought at auction and parts fell out when I took off the grips?  |

Yeah, kinda like that!

The obvious is pretty obvious. Even I can figure out that stuff (well, most of the time).  I've rejected many dozens of 3rd Gens for cosmetic issues and obvious problems.

It's the deeply hidden Bubba-type stuff that scares me. And since I would never pass on a messed-up gun to anyone else, I'd take the big hit. So far, so good... but it could happen tomorrow.

Twice in the last 5 years I've missed problems (albeit relatively minor) that I should have picked up quickly on an initial inspection. These old eyes just aren't as good as they used to be.

|

|

The Following User Likes This Post:

|

|

10-23-2018, 11:05 AM

|

|

SWCA Member

|

|

|

Join Date: Feb 2017

Location: Davidson County, NC

Posts: 2,117

Likes: 7,803

Liked 4,137 Times in 1,414 Posts

|

|

The 908 turned out to not be a big deal thanks to our generous forum colleagues. Otherwise, I've been bitten twice. Once on the big auction site and (surprisingly) once here.

I won a NIB 39-2 and cautioned the seller to pack it well. When it arrived, it was indeed NIB but had a divit on the front grip that looks very much like somebody hit it with a punch. Nice and round; well into the metal.

The one that surprised me on this forum was a "rare" transition 2nd to 3rd generation pistol. That one arrived with a rear sight that was apparently adjusted with a sledge hammer.

In both cases, the guns were photographed in a way that these issues could not be seen.

|

|

The Following 2 Users Like Post:

|

|

10-23-2018, 12:10 PM

|

|

US Veteran

|

|

|

Join Date: Dec 2002

Location: MA

Posts: 7,345

Likes: 7,534

Liked 5,583 Times in 2,558 Posts

|

|

I always knew that I was not supposed to do heart surgery. Now I know that I am not supposed to do action jobs on 1006 pistols for exactly the same reason!

__________________

Formerly Model520Fan

|

|

The Following 3 Users Like Post:

|

|

10-23-2018, 02:55 PM

|

|

Member

|

|

|

Join Date: Mar 2013

Location: Central Kentucky

Posts: 3,090

Likes: 11,425

Liked 5,133 Times in 1,952 Posts

|

|

I recently traded into a nice 25-5 4" in 45 colt. I trigger felt rather good actually. However, the nosy side of me (call it suspicious if you will) had me removing the side plate for a "good cleaning".

While I don't have pictures yet (I reassembled it) I am on the lookout for a new hammer, & possibly a trigger. Someone appears to have used a dremel buffing wheel and rubbing compound on the trigger contact surfaces. Well past the hardened surface I'm certain.

I'm still happy with it for what I have in it, but it ain't over yet........

While I'm pretty comfortable tinkering with my Marlins, I don't feel confident enough to do more that parts swapping on a S&W.

I really enjoyed the photos & discussions above.

|

10-23-2018, 09:28 PM

|

|

Member

|

|

|

Join Date: Oct 2011

Location: Canada

Posts: 2,357

Likes: 675

Liked 714 Times in 534 Posts

|

|

I had a Proper trigger job done on my last 45apc. I know the Gunsmith did not use a axe to trim any of the parts down at all. Dremels are a nice tool but can run up to 35,000RPM on high which heats the metal up quite a bit as well as shaves it down also. Once highly heated it can really hurt the metal in some parts causing it to wear much faster. Not Good for a gun thats heavily used at all.

|

10-24-2018, 08:10 AM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,217 Times in 4,509 Posts

|

|

Thanks for another great tutorial, Master Chief. You provide such a service to the membership here, including those of us who would never think of trying any gun modifications ourselves but who might be tempted to seek out someone. I'm sure most gunsmiths know what they are doing, but it's helpful to see a cautionary tale about what can happen. All I know is, you'll be the one to do any work on my Third Gens!

__________________

Ukraine -- now more than ever

|

|

The Following 3 Users Like Post:

|

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

|

|

|

|