|

|

|

|

04-12-2020, 06:21 PM

|

|

Member

|

|

|

Join Date: Mar 2015

Location: Ohio

Posts: 7,856

Likes: 9,472

Liked 14,855 Times in 5,050 Posts

|

|

Those are NOT inexpensive hunks of wood you've got! And the "Target Champion" notation on the packaging refers to the series of Performance Center pistols made for the European market and shipped to WISCHO, many of which (most, even?) came with Nill grips that were likely teamed up with the pistol when it got to Germany.

The Target Champion 9mm guns were very, very much like the Performance Center PPC-9 pistols. Double-stack 9mm.

|

|

The Following 4 Users Like Post:

|

|

04-12-2020, 07:31 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Quote:

Originally Posted by g-dad

Bill, your work looks great and I like the stocks you'll be using. What will a "dunk in the molten salt bath" accomplish?

|

Thanks... And the dunk yields a extraordinarily tough satin black case hardened finish. Ferritic nitrocarburizing aka, Nitron, Isonite, Tenifer, Melonite and several other trade names I don't recall at the moment.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 9 Users Like Post:

|

|

04-12-2020, 07:37 PM

|

|

Member

|

|

|

Join Date: Jun 2014

Location: Kentucky

Posts: 173

Likes: 215

Liked 240 Times in 92 Posts

|

|

A true work of art!

I cannot wait to see the finished pics!

|

|

The Following 3 Users Like Post:

|

|

04-12-2020, 07:50 PM

|

|

Member

|

|

|

Join Date: Oct 2007

Location: Central Texas

Posts: 1,489

Likes: 2,637

Liked 1,588 Times in 713 Posts

|

|

I always enjoy BMCM’s work.

__________________

Pine_Worker

Ex-LEO, NRA Life

|

|

The Following 5 Users Like Post:

|

|

04-12-2020, 09:42 PM

|

|

Member

|

|

|

Join Date: Dec 2003

Location: HOUSTON, TEXAS

Posts: 10,183

Likes: 7,175

Liked 14,373 Times in 5,411 Posts

|

|

Nice job! When I see "distressed" S&W's for sale, the seller usually a pawn shop, expects mint in box prices. I would like to save one or two someday, when I grow up.

|

|

The Following 3 Users Like Post:

|

|

04-13-2020, 10:01 PM

|

|

Member

|

|

|

Join Date: Jul 2012

Location: USA

Posts: 1,111

Likes: 5,684

Liked 1,664 Times in 730 Posts

|

|

Always so impressed with your work Bill, can't wait to see the finished product on this one!

|

|

The Following 5 Users Like Post:

|

|

04-15-2020, 01:28 PM

|

|

Member

|

|

|

Join Date: Jan 2001

Location: Delaware, Ohio

Posts: 308

Likes: 28

Liked 114 Times in 64 Posts

|

|

Awesome stuff here! I really enjoy reading about and seeing work done by the owners who are not gunsmiths but have a helluva lot of talent. Nothing like watching a piece of functional artwork come to life out of a pile of parts, tools, and whatever else is needed for the build. I can’t wait till this is finished!!

BMCM.....the only question I have for you is......when are you gonna work ME in for one like yours??

|

|

The Following User Likes This Post:

|

|

04-15-2020, 04:12 PM

|

|

Member

|

|

|

Join Date: Jun 2018

Location: Beautiful Scenic NJ

Posts: 276

Likes: 692

Liked 374 Times in 149 Posts

|

|

I think BMCM counts as a gunsmith...

|

|

The Following 3 Users Like Post:

|

|

04-15-2020, 05:22 PM

|

|

Member

|

|

|

Join Date: Jan 2013

Posts: 2,668

Likes: 3,512

Liked 1,578 Times in 912 Posts

|

|

Such an improvement upon its as received condition.

It looked like the previous owner cleaned and lubed it with used chewing tobacco.

Your stippling is gorgeous. I have an early 5906 that wants to be the twin of what yours is going to be.

I'm only two states east of you, so shipping shouldn't be too much.

__________________

What would Jim Cirillo do?

|

|

The Following 2 Users Like Post:

|

|

04-16-2020, 09:44 AM

|

|

US Veteran

|

|

|

Join Date: Jul 2004

Location: Coonass Country, La.

Posts: 1,426

Likes: 231

Liked 601 Times in 362 Posts

|

|

BMCM does great armorers work. He took my 5906 completely apart, cleaned every nook and crannie, went over all the internal parts and springs, bead blasted the frame, lubed all the parts, and it was a totally different 5906 when he was done.

Below is the only before pic (1st pic) and after.

__________________

How many guns are too many?

|

|

The Following 7 Users Like Post:

|

|

05-10-2020, 09:30 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Evening Gents,

Getting sort of caught up on some other work so I was able to squeeze in a bit of work on this project today.

Finished up the 'jackhammering' and adjusted the contour on trigger guard front...

Adjusted the contour a bit here at the trigger guard root, I may modify this some more, we'll see...

Between a mounted stone and a 2cut pillar file, fixed this area where the steel was proud of the wood...

Then smoothed out the lumps in the contour with a 2cut crossing needle file...

And, identified another issue that will need fixing.

Here with the left grip panel in place you can see it fits nice and flush to the side of the frame...

Likewise if when the right panel is held in position it's perfectly flush against the steel...

However, when both panels are in place there is a gap than can be shifted side to side as the grips are moved left 'n' right side to side. The gap shown here at the top of the right panel measures about twenty thousandths...

So, what I'll need to do is carefully shave about ten thousandths off of each panel along the meeting surface at the backstrap indicated here...

I'll set up a small surface plate with, I think some 400 grit abrasive paper and thin each panel a little bit at a time while test fitting on the frame frequently. Gotta go slow and check often since any wood I take off cannot be put back. I certainly don't want to wind up with an open gap down the back

And after all the tinkering, ran the frame through the blast cabinet again...

And the other side...

Seems to be shaping up more 'r less ok so far.

That's all for now. Next up we get the grip panels correctly fitted. Then using the panels and a transfer punch, mark the frame for a drill & tap session on the milling machine.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 33 Users Like Post:

|

1775usmarine, 18DAI, Ben-Kenobi, brucev, cjt50, cnette01, DMcBB, easymoney72, Erocksmash, g-dad, GerSan69, guzzitaco, hammy5150, jbtrucker, Jeppo, kobsw, ladder13, mbliss57, mclovinuga, nocents, Ohsheepdog, Old_Cop, robrossk, Ruger Nut, Sevens, Shooter Mike, snowman.45, Steve912, TercGen, toddstang, Trooper224, veeklog1, vigil617 |

05-10-2020, 10:06 PM

|

|

US Veteran

|

|

|

Join Date: Jul 2004

Location: Coonass Country, La.

Posts: 1,426

Likes: 231

Liked 601 Times in 362 Posts

|

|

Bill, you're a 3rd Gen God! Man, you do some of the finest armorer work that I have ever seen. I can't wait to see the finished product.

__________________

How many guns are too many?

|

|

The Following User Likes This Post:

|

|

05-10-2020, 10:27 PM

|

|

Member

|

|

|

Join Date: Aug 2010

Posts: 328

Likes: 17

Liked 40 Times in 26 Posts

|

|

That looks great. I can't wait to see it finished.

__________________

5903TSW 5904 5906 6906 4006

|

|

The Following User Likes This Post:

|

|

05-10-2020, 11:33 PM

|

|

Member

|

|

|

Join Date: Jun 2014

Location: Kentucky

Posts: 173

Likes: 215

Liked 240 Times in 92 Posts

|

|

I think I have been looking forward to updates on this thread more than I have Christmas or my birthday!

|

|

The Following User Likes This Post:

|

|

05-10-2020, 11:37 PM

|

|

Member

|

|

|

Join Date: Feb 2020

Location: Indiana

Posts: 21

Likes: 97

Liked 35 Times in 14 Posts

|

|

I really wasn't on board with the jackhammering, but seeing it all done it looks really nice!

|

|

The Following 2 Users Like Post:

|

|

05-27-2020, 12:18 PM

|

|

Member

|

|

|

Join Date: Mar 2013

Posts: 166

Likes: 1,276

Liked 281 Times in 103 Posts

|

|

Bill, Any new updates on this fine looking 5906

|

05-27-2020, 03:01 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Working on getting the fixturing setup to hold the wood panels in various positions for some machining operations. I've ordered some MIC6 precision cast tooling plate along with some other stuff to tackle the mods on the grip panels. Update will follow soon as my supplies/materials are delivered.

It's just a fact that my personal fun projects take a back seat when I have other folks guns here for work so progress updates can sometimes be delayed a bit

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 10 Users Like Post:

|

|

05-27-2020, 11:30 PM

|

|

US Veteran

|

|

|

Join Date: Jul 2004

Location: Coonass Country, La.

Posts: 1,426

Likes: 231

Liked 601 Times in 362 Posts

|

|

Bill, as soon as I get another 3rd Gen gun I will be making the 2 hour ride to your home to have it "BMCM" approved.

__________________

How many guns are too many?

|

05-30-2020, 11:05 AM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,217 Times in 4,509 Posts

|

|

Bill, when you get a chance, I'd love to hear more about the molten salt bath that's ahead. Is this something you've invested in at your shop, or will you be sending this out to a vendor? Seeing your note that the process is what produces the Melonite (trade name) finish, I'm intrigued that this is something that could be done "at home" with the right setup. Not that I plan to try it myself, of course!

Just thought it might be good for a post or two while we await with you the arrival of your tooling for the grips project. By the way, I've never heard of the individual pieces referred to as "scales." Is this "inside baseball" among you gunsmiths, or is there a nautical heritage to that term?

__________________

Ukraine -- now more than ever

|

|

The Following User Likes This Post:

|

|

05-31-2020, 11:09 AM

|

|

Member

|

|

|

Join Date: Aug 2005

Location: Central Kentucky

Posts: 349

Likes: 196

Liked 318 Times in 102 Posts

|

|

Quote:

Originally Posted by BMCM

Thanks... And the dunk yields a extraordinarily tough satin black case hardened finish. Ferritic nitrocarburizing aka, Nitron, Isonite, Tenifer, Melonite and several other trade names I don't recall at the moment.

Cheers

Bill

|

Cost wise, how much do they usually run? I'm leaning toward going this way with my project. I'm also wondering if the barrel bushing can be removed before the said dunk.

Thanks,

Les

|

05-31-2020, 03:22 PM

|

|

SWCA Member

|

|

|

Join Date: Aug 2013

Location: Foothills of the Ozarks

Posts: 3,596

Likes: 10,669

Liked 5,588 Times in 2,179 Posts

|

|

Quote:

Originally Posted by vigil617

Bill, when you get a chance, I'd love to hear more about the molten salt bath that's ahead. Is this something you've invested in at your shop, or will you be sending this out to a vendor? Seeing your note that the process is what produces the Melonite (trade name) finish, I'm intrigued that this is something that could be done "at home" with the right setup. Not that I plan to try it myself, of course!

Just thought it might be good for a post or two while we await with you the arrival of your tooling for the grips project. By the way, I've never heard of the individual pieces referred to as "scales." Is this "inside baseball" among you gunsmiths, or is there a nautical heritage to that term?  |

The only place where I have heard the term "scales" used as a reference to grips is the two-piece, removable handles on folding knives.

The only "nautical heritage" to which I am aware (and I am a "land lubber") are those things that are scraped off before frying the fish!

John

|

|

The Following 2 Users Like Post:

|

|

05-31-2020, 05:31 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Quote:

Originally Posted by vigil617

Bill, when you get a chance, I'd love to hear more about the molten salt bath that's ahead. Is this something you've invested in at your shop, or will you be sending this out to a vendor? Seeing your note that the process is what produces the Melonite (trade name) finish, I'm intrigued that this is something that could be done "at home" with the right setup. Not that I plan to try it myself, of course!  |

Molten salt bath... Not table salt by any stretch. Cyanide salts and some other elements. This is not something I'd be messing with unless my intent was to turn my homestead into a Superfund site. I'll do all the metal work and preparation then ship the parts off to H&M for dunking. That's as far into the process as I get. The chemicals involved as well as the process are quite hazardous. I imagine that's why you don't see a lot of providers. Ferritic nitrocarburizing - Wikipedia

Quote:

Originally Posted by vigil617

Just thought it might be good for a post or two while we await with you the arrival of your tooling for the grips project. By the way, I've never heard of the individual pieces referred to as "scales." Is this "inside baseball" among you gunsmiths, or is there a nautical heritage to that term?  |

Scales... I've heard and used that term for years referring to slim flat grip panels on knives tools and firearms. Typical usage refers to pieces of raw material before fashioning into usable parts. such as seen here...

Knife Scales | Rockler Woodworking & Hardware

But in many cases used in referring to grip panels that are slim & flat such as those found guns like a Baby Browning, 1911, or 645 like this here...

Ascend™ 1911 Grips - G10 Machined Pistol Grips | Rail Scales

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 5 Users Like Post:

|

|

05-31-2020, 05:49 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Quote:

Originally Posted by prochi2k

Cost wise, how much do they usually run? I'm leaning toward going this way with my project. I'm also wondering if the barrel bushing can be removed before the said dunk.

Thanks,

Les

|

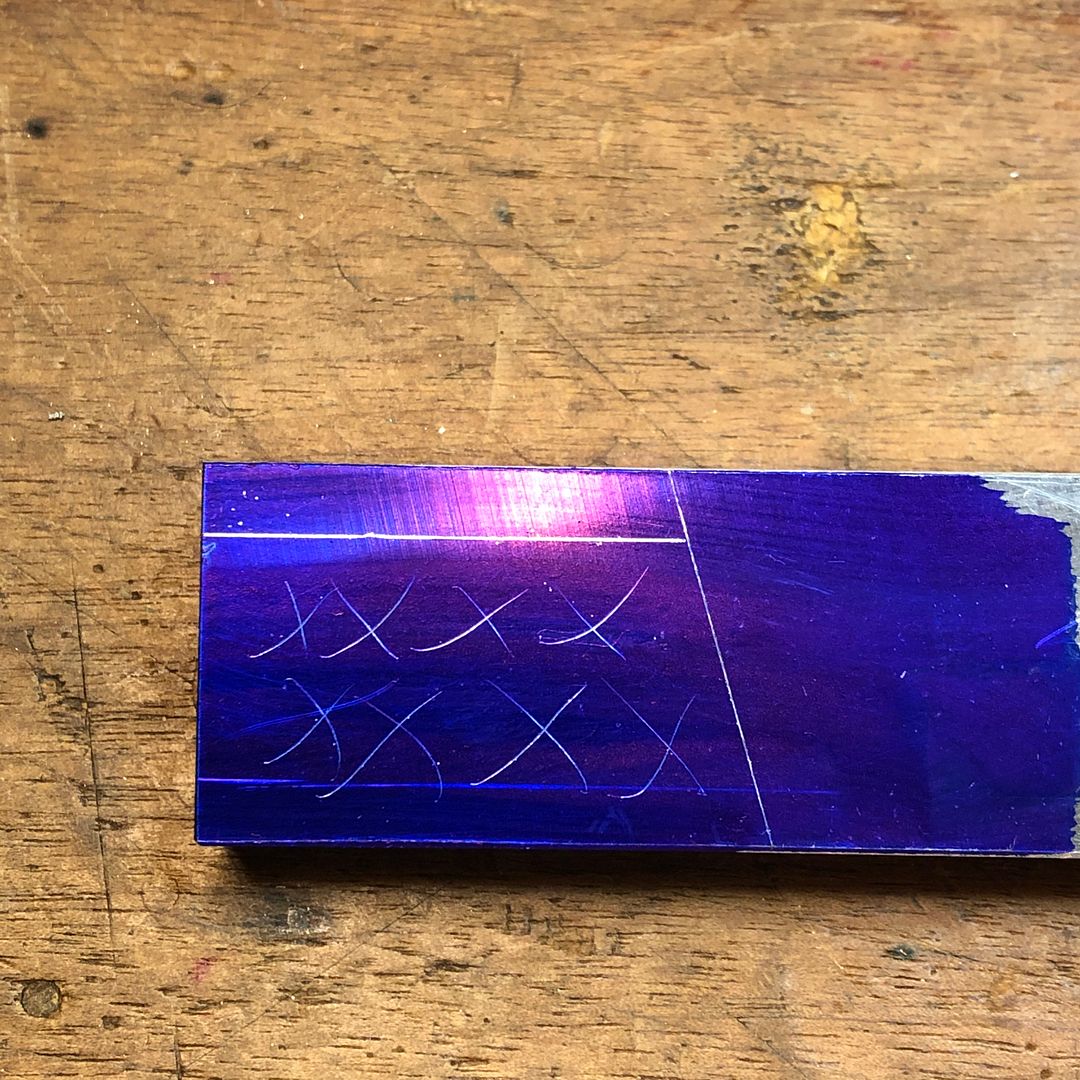

It's been a few years since I had some parts processed. Back then it was $100 for a slide that was already prepped. I left the bushing in place so that got nitrided as well. You really cannot remove that pressed in barrel bushing without destroying it. These folks did the work... H&M Blacknitride+™ | The New Standard in Steel Hardening

Slides prepped prior to shipping looked like this...

And upon return like this...

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 19 Users Like Post:

|

1775usmarine, 18DAI, 3wire, Ben-Kenobi, brucev, Erocksmash, gc70, GerSan69, guzzitaco, Jeppo, kobsw, mclovinuga, nocents, Sevens, Shooter Mike, stansdds, TercGen, veeklog1, vigil617 |

06-02-2020, 05:55 AM

|

|

Member

|

|

|

Join Date: Jun 2009

Location: Texas

Posts: 35

Likes: 0

Liked 9 Times in 6 Posts

|

|

Great work

__________________

Shiny, lets be bad guys!

|

06-04-2020, 06:37 AM

|

|

Member

|

|

|

Join Date: Jul 2010

Location: Toledo, Ohio

Posts: 741

Likes: 604

Liked 853 Times in 384 Posts

|

|

I really wish I had the talent to do stuff like BMCM does.

I have to say, I have some guns that came in nasty, but nothing as bad as this gun was to start with. Wow. I would have been pretty upset if I got a gun that bad. Worst I have ever received was a Dan Wesson 15-2 that had an amazing load of unburned powder in it, to the point it was difficult to cock it. Looks pretty good these days..but it took a lot of work, just to get the blue shined up again.

The other gun was an Israeli surplus Tanfoglio CZ clone that had some sort of sticky goo all through the insides of it and a mag full of dead baby spiders. It looked great outside, and once cleaned up, it's my favorite of all the guns I own:

|

|

The Following 8 Users Like Post:

|

|

06-04-2020, 05:44 PM

|

|

Member

|

|

|

Join Date: Aug 2005

Location: Central Kentucky

Posts: 349

Likes: 196

Liked 318 Times in 102 Posts

|

|

Quote:

Originally Posted by BMCM

It's been a few years since I had some parts processed. Back then it was $100 for a slide that was already prepped. I left the bushing in place so that got nitrided as well. You really cannot remove that pressed in barrel bushing without destroying it. These folks did the work... H&M Blacknitride+™ | The New Standard in Steel Hardening

Cheers

Bill |

Thanks for the info Bill!

I've decided instead of having the slide Melonite processed to just purchase a M6904 slide and go from there.

|

|

The Following User Likes This Post:

|

|

06-06-2020, 10:42 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Evening Gents,

All my supplies were delivered so it's about time to get a bit of woodworking sorted out.

This here is the area that requires a clearance cut for the right side decocker body lever...

In order to make that clearance cut we need some means to hold the scale securely. Can't just clamp it in a vise without breaking or crushing it and that raised boss on the inner surface is in the way if we want to bolt it down to something...

So, what we're going to do is machine a simple fixture to fasten the grip to which will enable holding the part in the mill vise. What we have here is a 6" piece of 1/2" x 1" precision cast tooling plate I cut from stock. This will become our fixture...

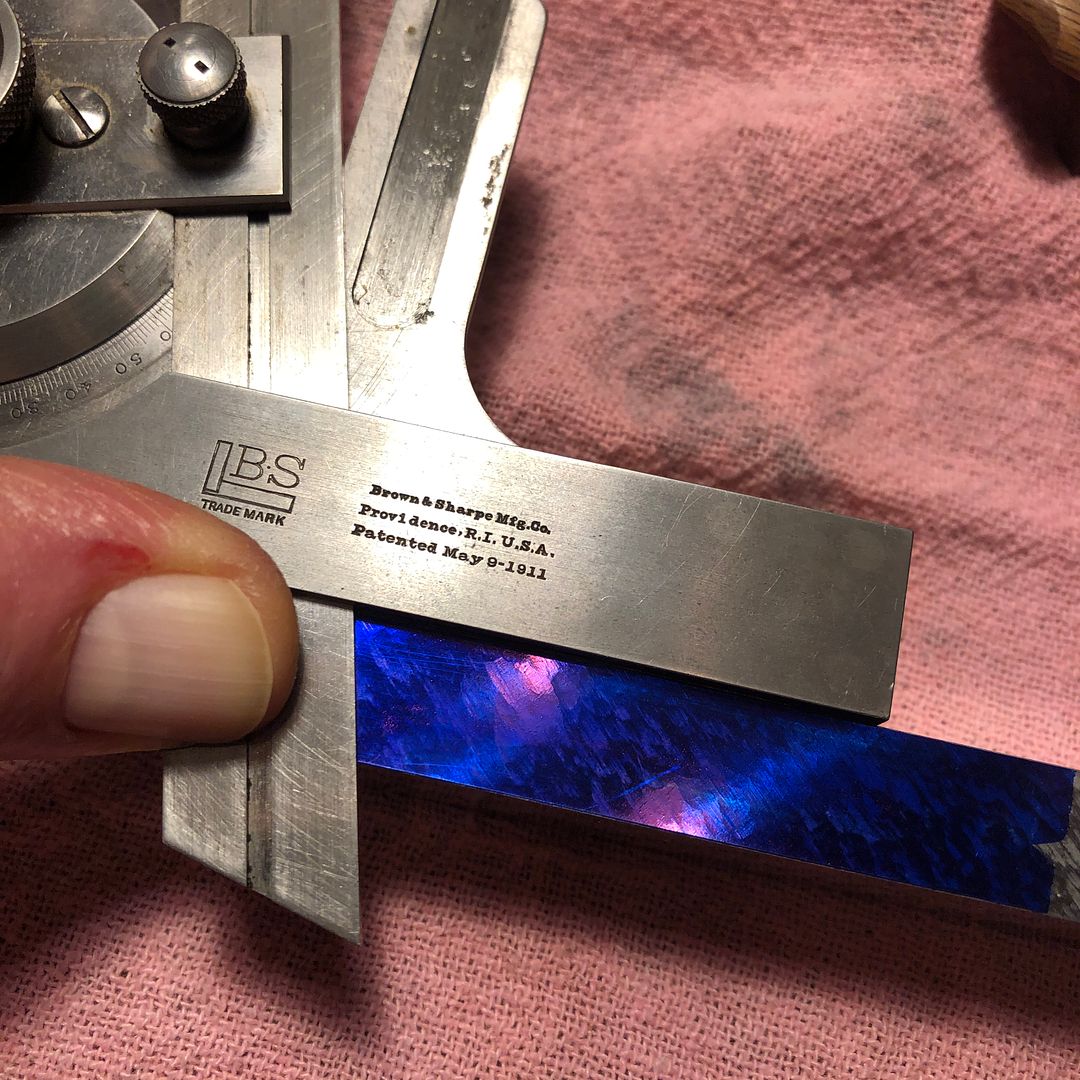

First we need to break out my trusty vernier protractor...

And use that to capture the angle of that boss on the inside surface of the grip...

Ok 74° then...

Splash some layout dye on out fixture and transfer the angle with a scribe...

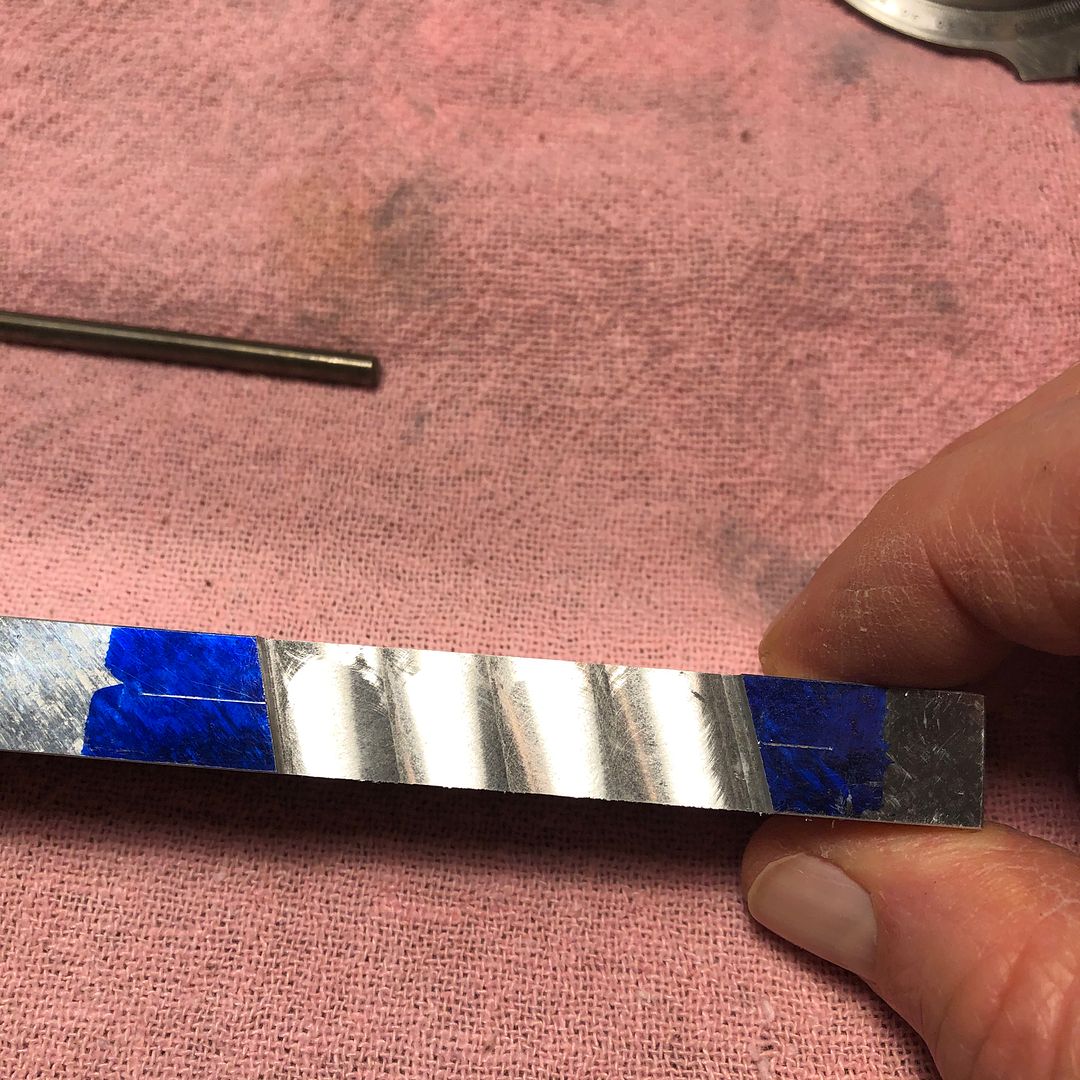

In order to mark the other end we need to measure the length of that boss first...

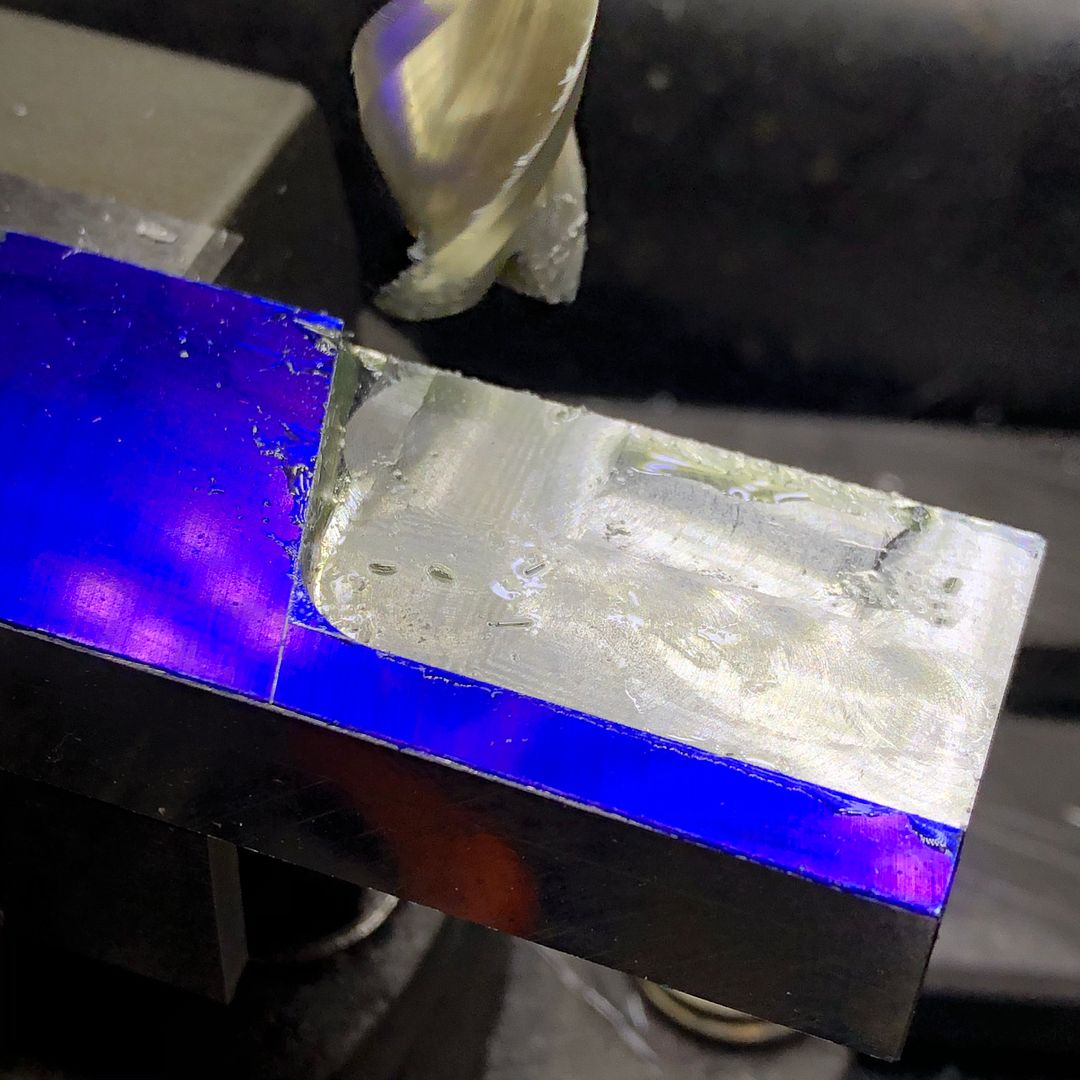

There's the area the needs to be milled out so the grip will fit flat & snug to the fixture...

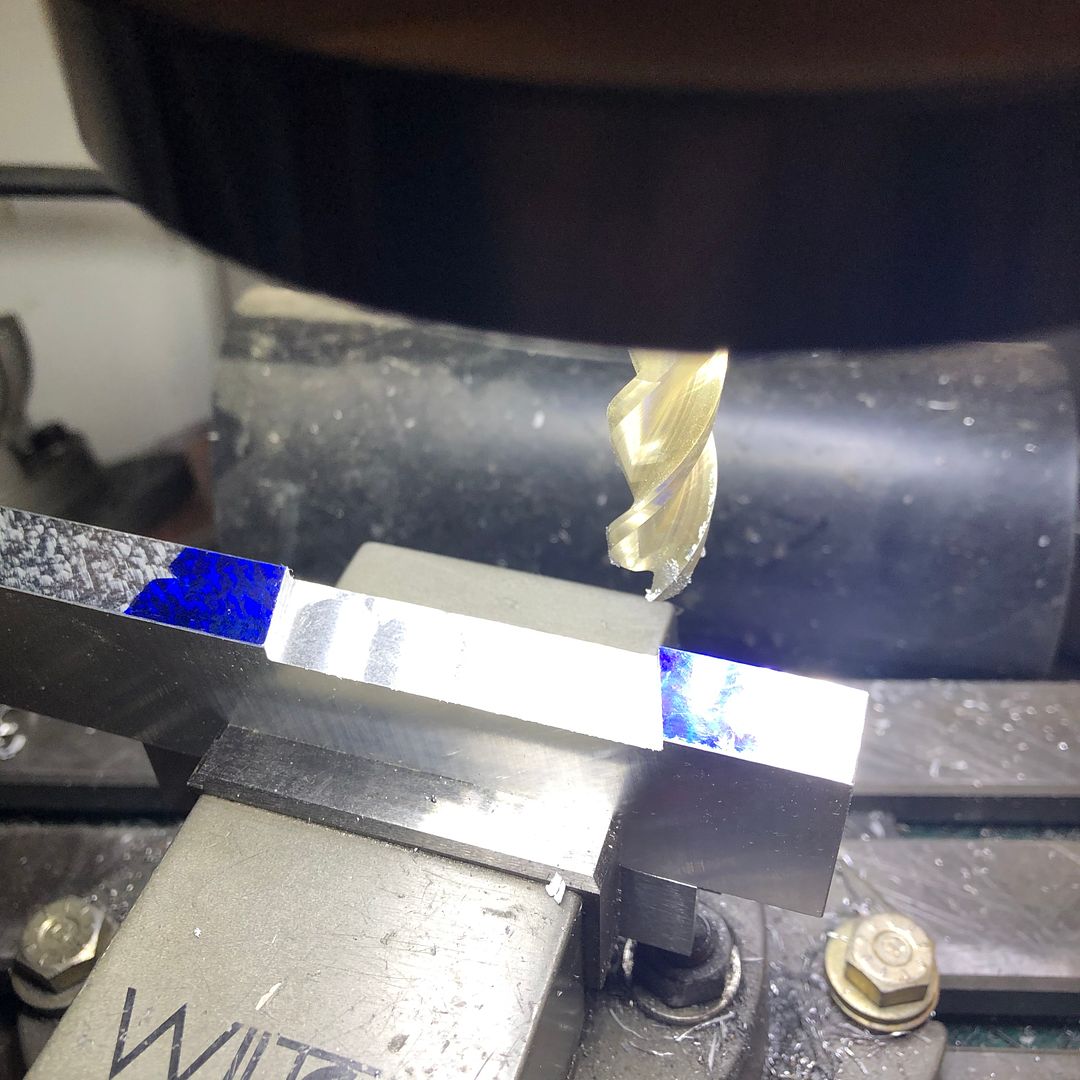

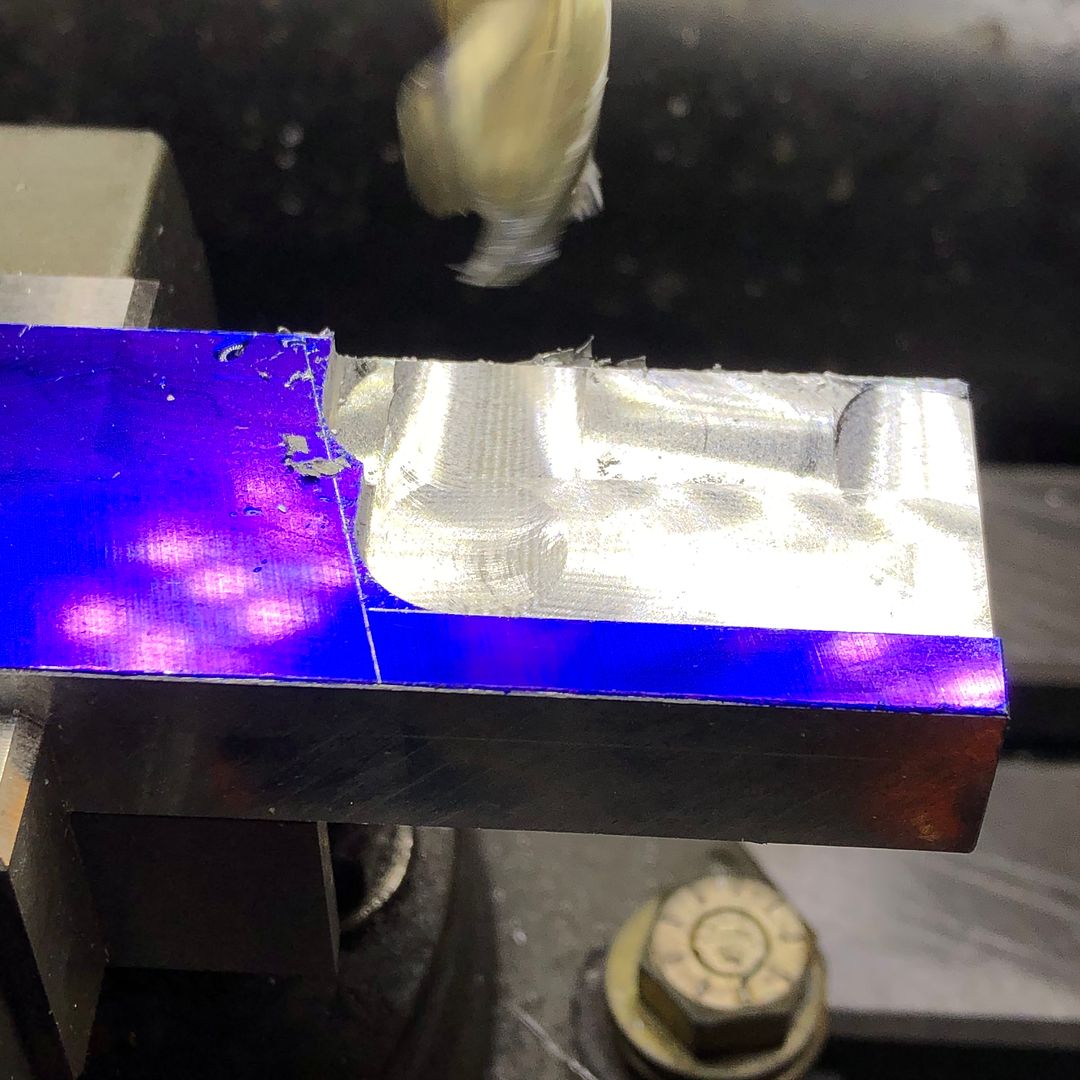

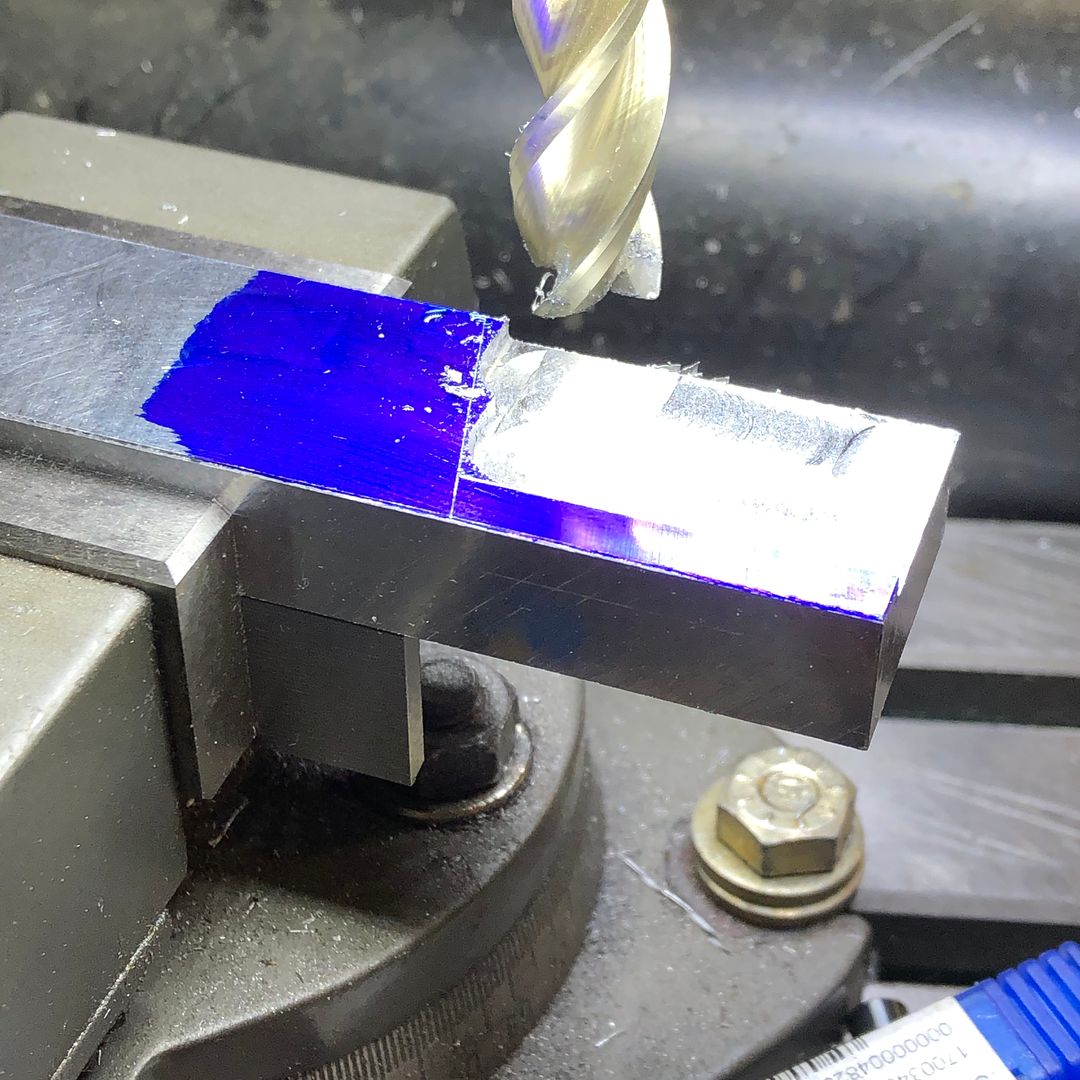

Over on the mill, swing the vise over to 74° and make some chips...

Now we need to set up for drilling & tapping. First scribe a line down the middle of the fixture where we're going to drill...

Then align by eye, both holes centered over the scribed line...

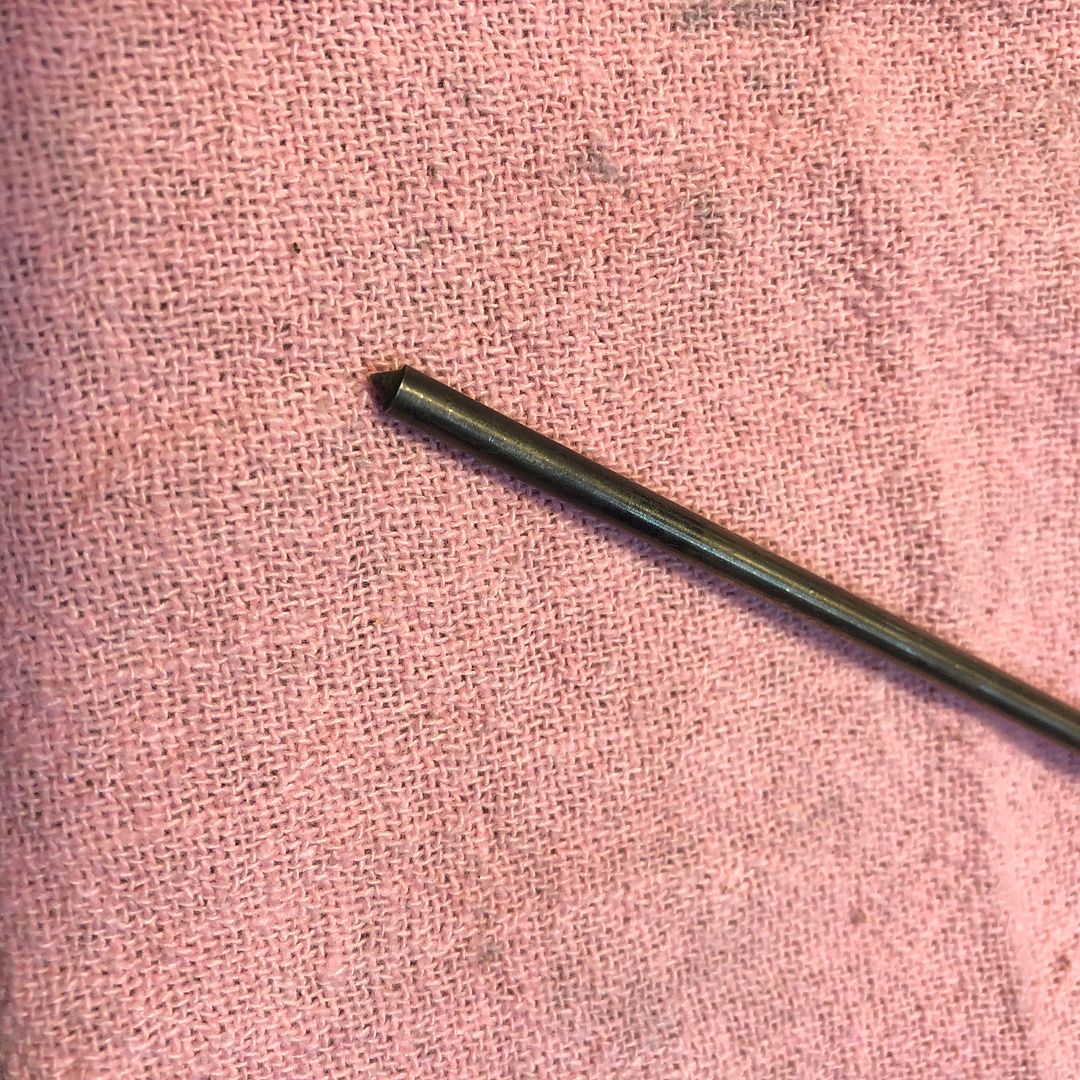

Then mark our spots with a 4mm transfer punch...

And there we go, drilled & tapped for M4 .7pitch ...

Perfect fit and holding securely...

Now to determine what milling cutter to use I need to take the left panel and measure the existing cut with a radius gauge. 3/8" radius means I need to use a 3/4" cutter...

Over on the mill, so far so good but I was lucky. I neglected to lock down the vise after adjusting the angle and it turned a bit. That could have been disastrous if the vise spun into the cutter but fortunately it only turned about 1 degree...

Adjusted the vise angle and locked it down this time

Finished the cut to depth...

Perfect mirror image...

Mocked up on the gun and it's perfect...

That's all for now...

More woodworking coming soon. Still have quite a bit more work to do fitting the wood.

Stay well & stay safe out there.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 30 Users Like Post:

|

18DAI, Ben-Kenobi, brucev, DMcBB, Erocksmash, g-dad, GerSan69, Grumpyman, guzzitaco, hemiram, Hersh328, Ingramite, jbtrucker, Jeppo, JohnHL, kobsw, ladder13, mclovinuga, nocents, prochi2k, robrossk, shorty40, skjos, snowman.45, stansdds, TercGen, toddstang, Trooper224, veeklog1, vigil617 |

06-06-2020, 11:18 PM

|

|

Member

|

|

|

Join Date: Sep 2018

Location: Pompano Beach, FL

Posts: 575

Likes: 1,131

Liked 2,142 Times in 379 Posts

|

|

AMAZING !!!

|

|

The Following User Likes This Post:

|

|

06-06-2020, 11:33 PM

|

|

Member

|

|

|

Join Date: Mar 2017

Location: SW Florida

Posts: 2,144

Likes: 3,411

Liked 3,159 Times in 1,026 Posts

|

|

Absolutely fantastic, I may need to look for a set of those woods for the DPA...

__________________

This is the way....

|

|

The Following User Likes This Post:

|

|

06-07-2020, 01:30 AM

|

|

Member

|

|

|

Join Date: Sep 2013

Posts: 114

Likes: 1,372

Liked 234 Times in 75 Posts

|

|

This has to be the best post that I have ever read on any gun forum, ever.

The pictures, the procedure , and the information.

Great post.

|

|

The Following 6 Users Like Post:

|

|

06-07-2020, 06:30 AM

|

|

Member

|

|

|

Join Date: Jan 2011

Location: Crawford County PA

Posts: 3,709

Likes: 4,394

Liked 6,713 Times in 2,420 Posts

|

|

Pay attention, this is how a professional works.

__________________

Made it, Ma! Top of the world!

|

|

The Following 3 Users Like Post:

|

|

06-07-2020, 08:45 AM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,217 Times in 4,509 Posts

|

|

Quote:

Originally Posted by Shooter Mike

This has to be the best post that I have ever read on any gun forum, ever.

The pictures, the procedure , and the information.

Great post.

|

Mike, you ain't seen nothin' yet!

Look up some of BMCM's other threads about different repair and customizing projects and you will find similarly amazing, detailed, and well-written descriptions -- all with Bill's flair for humor -- that will capture your attention for hours. This man is the real deal.

Bill, one observation on this part of the M5906 project: who'd a thought that the grip screws would be metric?

Is it your experience in other S&W projects that metric, as opposed to National Coarse ("standard") or National Fine ("SAE"), threads are often used? As an American manufacturer with plants here in the States, S&W puzzles me by this choice. I know gunsmiths must use a lot of very small, fine threads, so maybe there are comparable American thread systems besides the ones I've mentioned, but as for metric, I'm surprised, that's all.

__________________

Ukraine -- now more than ever

Last edited by vigil617; 06-07-2020 at 08:49 AM.

|

|

The Following 5 Users Like Post:

|

|

06-07-2020, 01:59 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Quote:

Originally Posted by vigil617

Bill, one observation on this part of the M5906 project: who'd a thought that the grip screws would be metric?

Is it your experience in other S&W projects that metric, as opposed to National Coarse ("standard") or National Fine ("SAE"), threads are often used? As an American manufacturer with plants here in the States, S&W puzzles me by this choice. I know gunsmiths must use a lot of very small, fine threads, so maybe there are comparable American thread systems besides the ones I've mentioned, but as for metric, I'm surprised, that's all. |

Well, these grips are crafted in Germany by the Karl Nill, Nills-Griffe Company. I gather Metric is a thing over there on that side of the pond  . Were you to check any of the top shelf PC guns that were originally equipped with Nills wood grips, I'd wager every one of them are fastened with the very same M4 screws that Nills supplied to S&W with the grips.

I don't really have issues with Metric per se. What really gives me heartburn is when I'm working on some machinery or vehicle and I find a mishmash of fastener standards. I've come across this a number of times on vehicles ans it's really REALLY annoying. Imagine, for example, all the fasteners on the accessory belt driven junk is Imperial and where all the brackets are fastened to the engine and all the engine bolts are Metric. So I need two complete sets of tools to repair the cursed thing  Makes me want to go visit the company CEO that made that piece of junk and punch him right square in the face

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 8 Users Like Post:

|

|

06-07-2020, 07:49 PM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,217 Times in 4,509 Posts

|

|

Quote:

Originally Posted by BMCM

Well, these grips are crafted in Germany by the Karl Nill, Nills-Griffe Company. I gather Metric is a thing over there on that side of the pond  . Were you to check any of the top shelf PC guns that were originally equipped with Nills wood grips, I'd wager every one of them are fastened with the very same M4 screws that Nills supplied to S&W with the grips.

I don't really have issues with Metric per se. What really gives me heartburn is when I'm working on some machinery or vehicle and I find a mishmash of fastener standards. I've come across this a number of times on vehicles ans it's really REALLY annoying. Imagine, for example, all the fasteners on the accessory belt driven junk is Imperial and where all the brackets are fastened to the engine and all the engine bolts are Metric. So I need two complete sets of tools to repair the cursed thing  Makes me want to go visit the company CEO that made that piece of junk and punch him right square in the face

Cheers

Bill |

<smh> Of course. The screws that came with the Nills grips are metric, and those screws are what you used to secure the grips on your fixture. Perfectly sensible.

Now, though, for the ultimate attachment of the grips to the frame, aren't you faced with the choice of either using the Nills screws and having to re-tap the 5906 frame (filling the old holes with weld first), or using the old 5906 grip screws with the new grips to avoid the re-tapping? Do the holes even match up to begin with?

__________________

Ukraine -- now more than ever

|

|

The Following User Likes This Post:

|

|

06-07-2020, 08:23 PM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Ahh but you are assuming the 5906 has holes drilled to begin with. Plain Jane no frills 5906 is not drilled & tapped so I'm more 'r less at liberty to use anything that strikes my fancy. The limiting factors are 1) the diameter & depth of the counterbore housing the screw head in the wood and 2) the combines thickness of material the screw must fit through and 3) the thickness of the steel on the sides of the magwell through which we drill & tap and the shank of the screw must hold fast.

In this case the head of the supplied M4 screws and the counterbore in the grip is precisely 8mm in diameter. The screw heads are also relatively thin being a tad over 2mm thick and the threaded shank is only 4mm long. I have ID'd a 316L stainess screw that's close but with a 6mm long shank that I'd need to trim.

I have not been able to find any Imperial screws that have a 8mm diameter head that will precisely fit the wood. Then again I haven't really looked that hard for SAE screws. What I'd really like to find is a set of screw in titanium either slotted or torx that I can flame anodize

As it stands currently I'm not seeing any reason to reinvent the wheel, I'll roll with the screws supplied. Plus i already have to tooling to drill and tap the frame for M4 x 0.70mm

Cheers

Bill

__________________

Because they don't make a .46

Last edited by BMCM; 06-07-2020 at 10:03 PM.

|

|

The Following 7 Users Like Post:

|

|

06-07-2020, 11:42 PM

|

|

Member

|

|

|

Join Date: Oct 2007

Location: Central Texas

Posts: 1,489

Likes: 2,637

Liked 1,588 Times in 713 Posts

|

|

This guy is amazing!

__________________

Pine_Worker

Ex-LEO, NRA Life

|

|

The Following User Likes This Post:

|

|

07-05-2020, 01:17 AM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Happy Independence Day Gents,

Got a little bit done on this project today sitting around the homestead doing by social distancing bit. If truth be told, I was social distancing long before there was a pandemic

Anyway, lets get to work shall we?

So, what I need to be able to do here is hold this grip panel by the area under my thumb pretty rigidly in order to perform a couple machine ops on the opposite end...

We're going to use another piece of that half by one inch tooling plate about 6 inches long to make another fixture to hold these grips. First order of business, we need to take a few measurements...

We'll need to know the height of that raised boss in the middle and the radius of those curved edges on that boss...

And, we need the width of that groove between the spine and the boss here...

5/16" radius gauge tells me a 5/8" diameter cutter will match that curve. I don't have one but as long as I go a touch smaller we'll be fine. I'll use a 1/2" cutter.

That gap measure a bit over 3/16"

We already know the angle on the boss is 74° from the previous installment so my vernier protractor is so set and I have the caliper locked down at 0.195"...

Splash some layout dye on our piece of tooling plate and using those tools, scribe the area the needs milling out onto the stock...

Now over on the mill, we have our marked stock propped up on a couple parallels in the vise and aligned parallel to the Y axis. Cutting 0.080" deep with a 1/2" 3 flute carbide end mill turning at around 900RPM...

Then we swing the vise over to 74° and lock it down to for the cleanup cut on the angle...

So far so good...

Clean it up and back to the bench to check the fit, Good to go...

Now we flip it over and take our M4 transfer punch and mark the fixture for a drill & tap operation...

Drilled the fixture with a #30 bit then tapped metric M4-.7 pitch

Grip fits on there nice and secure with a single screw snugged up...

Now we repeat all those steps again on the opposing end and side of the fixture so I can hold the other panel in the same fashion...

With that done, we will next turn our attention to the frame...

A little layout dye...

Set the grip in place making sure it's snugged up tight at the top then mark for drilling with our M4 transfer punch...

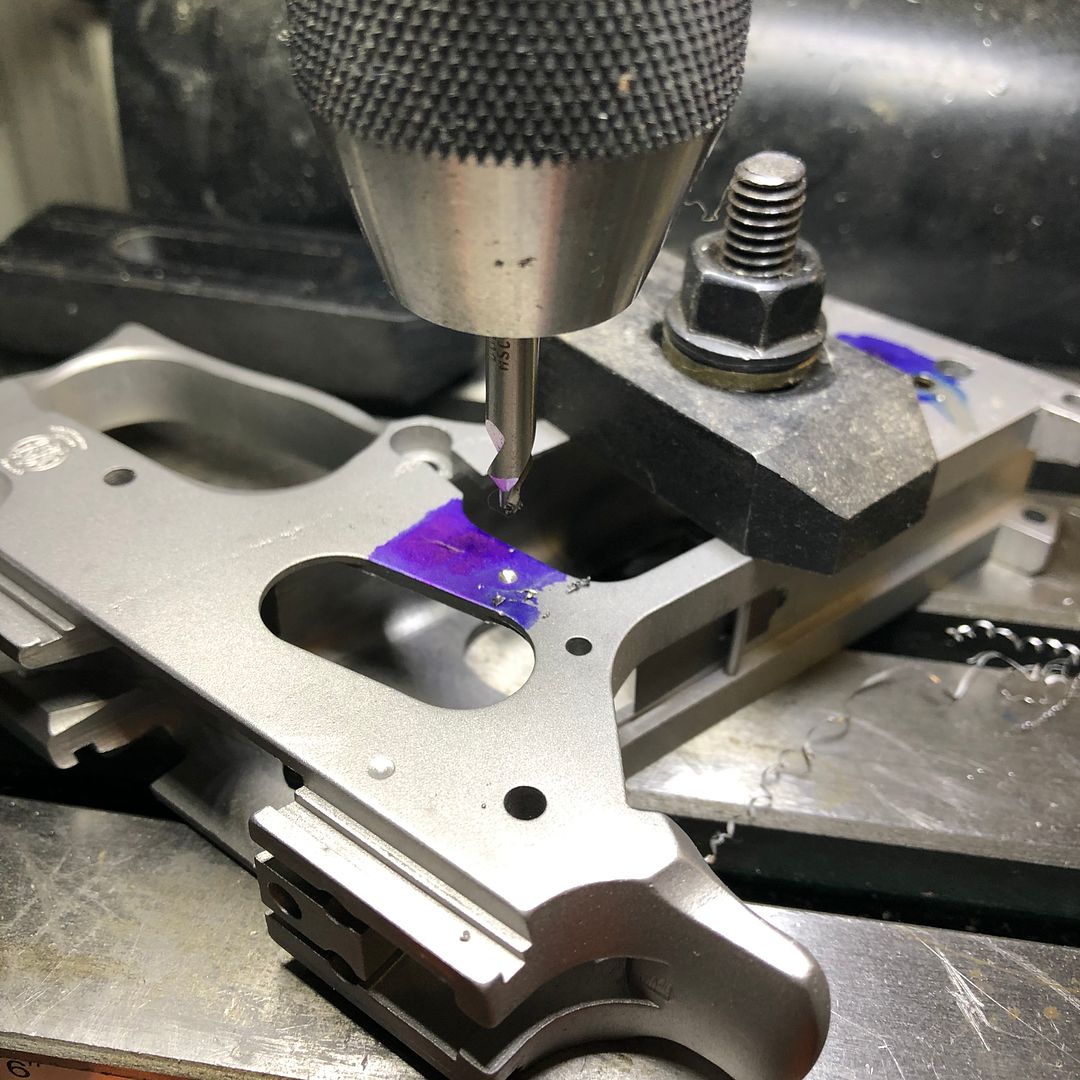

Once we have both sides, all four holes, marked... Frame gets strapped down on the mill table for drilling & tapping. Here we're spotting the first hole with a small center drill...

Swap bits to a #30 cobalt drill and poke the hole clean through...

Starboard side done. Flipped over and re-secured to tackle the port side...

I power tapped all four holes right on the mill but neglected to capture any pics of that. Just chucked the tap and with the spindle running at about 170RPM just lowered the quill and let the machine do the work. Turned out just fine, Looks like I got the holes located where they ought to be  ...

Now we get ready to put that new fixture to work. First fasten securely the port side panel...

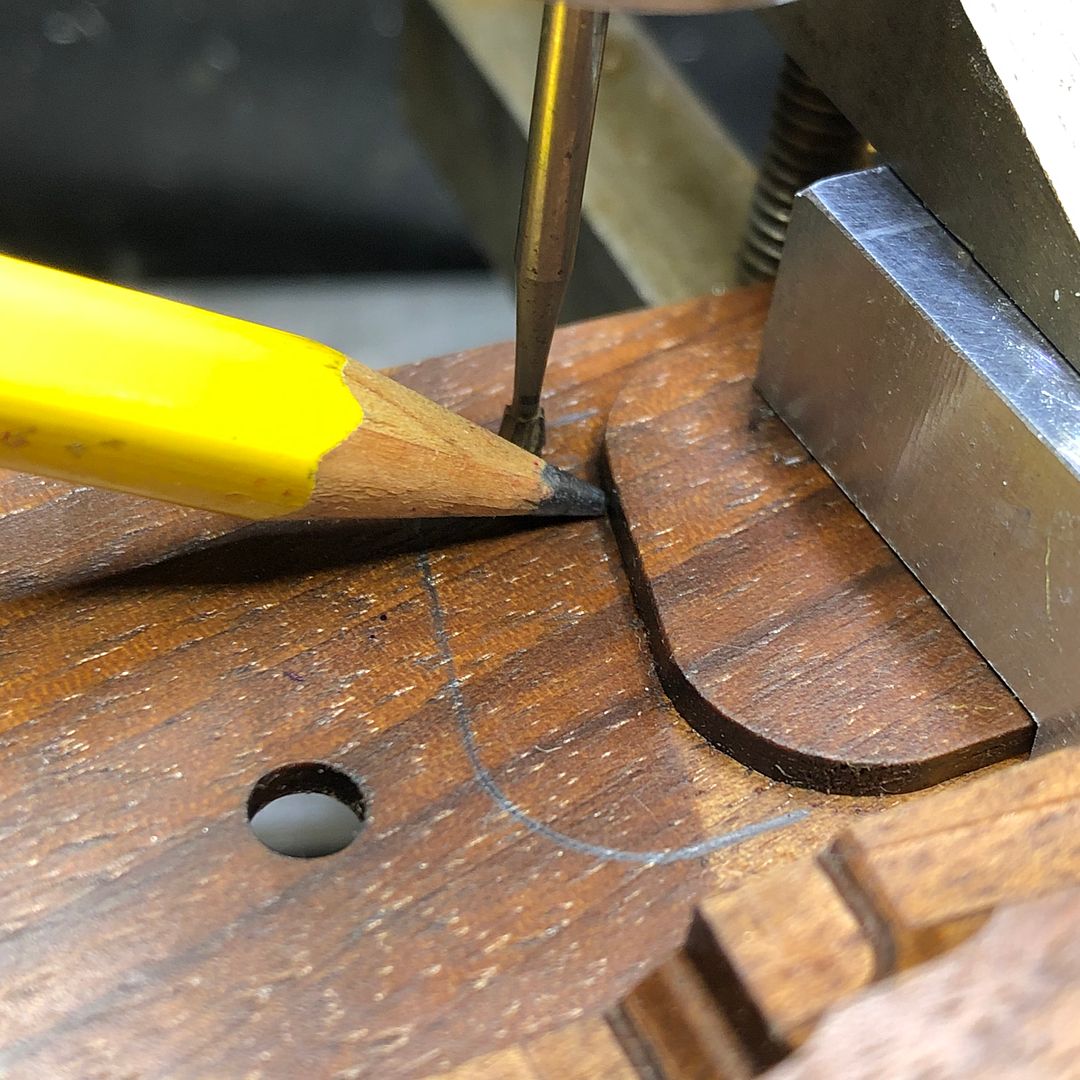

Then flip 'er over and take a pencil to outline the area below the boss where the frame window is unfilled...

Like so...

Swap panels and repeat that step with the starboard side panel...

Now with both panels marked we're gonna take that little tiny dovetail cutter and head over to the mill with our new fixture to make some adjustments...

Here's the setup. Starboard panel on the fixture, clamped in the vise, vise swung to 74° left and locked...

What we're going to do here is take that tiny dovetail cutter and make a beveled undercut on the bottom edge of that raised boss along here...

Then traverse the Y axis a bit and make a plunge cut in the center of that marked area to create a dovetail slot about 0.050" deep right about there...

There's our little undercut done...

And there's the slot...

Then we repeat those steps. With the port side fasten to the other end/side of the fixture then clamped in the vise which is now rotated to 74° right...

When we're all done we have opposing sides each with a matching small undercut and dovetail slot...

The point of all that is to provide and mechanical anchorage for some filler compound I'm going to use to enlarge the boss to fit the frame window which we're going to cast in place on the frame.

We'll be playing with that stuff in a day or two, stay tuned.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 19 Users Like Post:

|

1775usmarine, 18DAI, 3wire, cjt50, cnette01, DMcBB, easymoney72, GaryS, guzzitaco, JohnHL, kobsw, KWIndy, Old_Cop, stansdds, Steve912, TercGen, veeklog1, vigil617, WTN1271 |

07-05-2020, 09:14 AM

|

|

US Veteran

|

|

|

Join Date: May 2012

Location: Greenville, NC

Posts: 6,500

Likes: 19,952

Liked 14,217 Times in 4,509 Posts

|

|

Bill, I gotta say, using that little dovetail cutter instead of a straight end mill is genius. Genius, I say! The joints that you will achieve with your filler compound will be so much stronger and stable that way. That's some head you got on you!

Happy Fourth of July, Master Chief!

__________________

Ukraine -- now more than ever

|

|

The Following 3 Users Like Post:

|

|

07-05-2020, 09:38 AM

|

|

US Veteran

|

|

|

Join Date: Mar 2010

Location: Pompano Beach Fl

Posts: 634

Likes: 2,418

Liked 887 Times in 342 Posts

|

|

You have more talent in two seconds than I have had in 74 years. My hat is off to you!

|

|

The Following 2 Users Like Post:

|

|

07-05-2020, 11:55 AM

|

|

Member

|

|

|

Join Date: Jul 2010

Location: Central VA

Posts: 8,657

Likes: 1,569

Liked 9,427 Times in 4,225 Posts

|

|

Bill, I’m enjoying this series of your posts way beyond measure. You have graphically demonstrated the two classes of people who work on guns, the “Parts Changers” like myself who simply take existing parts and try to put them together in a way that will work, and the “True Gunsmiths” who make, modify and fit parts in such a way as to perfect the vision of a particular gun. Thank you for the inspiration.

Froggie

|

|

The Following 4 Users Like Post:

|

|

11-30-2020, 07:22 AM

|

|

Member

|

|

|

Join Date: Dec 2018

Location: Indianapolis, IN

Posts: 99

Likes: 34

Liked 91 Times in 47 Posts

|

|

How is this project going BMCM?

Any updates?

|

|

The Following 2 Users Like Post:

|

|

12-23-2020, 11:42 PM

|

|

Member

|

|

|

Join Date: Jun 2018

Location: Beautiful Scenic NJ

Posts: 276

Likes: 692

Liked 374 Times in 149 Posts

|

|

Hey Bill, any news? We’re all waiting with baited breath to see how this 5906 turns out!

|

12-26-2020, 01:36 AM

|

|

US Veteran

|

|

|

Join Date: Jun 2012

Location: SW Mississippi

Posts: 1,350

Likes: 2,227

Liked 6,218 Times in 1,043 Posts

|

|

Well, the thing is I have folks paying me to fix up or mod their guns of which I have several on the bench right now. I just don't feel it's right for me to be mucking about with my personal stuff when folks are paying me to work on their stuff. I think I'll be picking this 5906 project back up soon after the holidays however, stay tuned.

Cheers

Bill

__________________

Because they don't make a .46

|

|

The Following 10 Users Like Post:

|

|

05-30-2021, 10:55 AM

|

|

Member

|

|

|

Join Date: Jun 2018

Location: Beautiful Scenic NJ

Posts: 276

Likes: 692

Liked 374 Times in 149 Posts

|

|

Bill! Any movement on this project? It’s just too cool to leave alone!

|

|

The Following 2 Users Like Post:

|

|

|

|

Posting Rules

Posting Rules

|

|

|

|

|