-BTM-

Member

What an adventure. My previous thread on the topic was about how every traditional method failed. Bent too many punches, Time to make some stuff. Yes I bought a lathe.

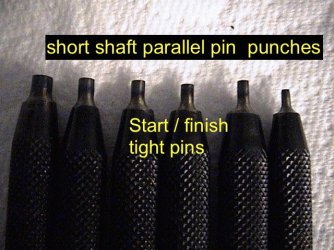

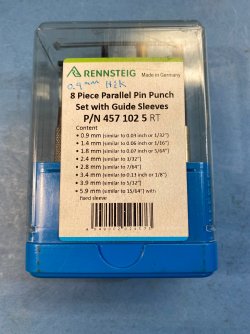

Ended up adapting a puller set to work like an arbor press. Still bent the shaft. Made a little pin holder and cut some short-medium-long pins to keep the stick out/unsupported section short and changed them as it went through.

The press required very little force, worked great. The pin was a nightmare from both ends to the middle. My theory is the barrel was swapped out and pin pounded in w/o redoing the groove in the barrel. The frame holes vary from frame to frame.

Ended up adapting a puller set to work like an arbor press. Still bent the shaft. Made a little pin holder and cut some short-medium-long pins to keep the stick out/unsupported section short and changed them as it went through.

The press required very little force, worked great. The pin was a nightmare from both ends to the middle. My theory is the barrel was swapped out and pin pounded in w/o redoing the groove in the barrel. The frame holes vary from frame to frame.

Attachments

Last edited: