Alrighty, lets take care of the magazines eh?

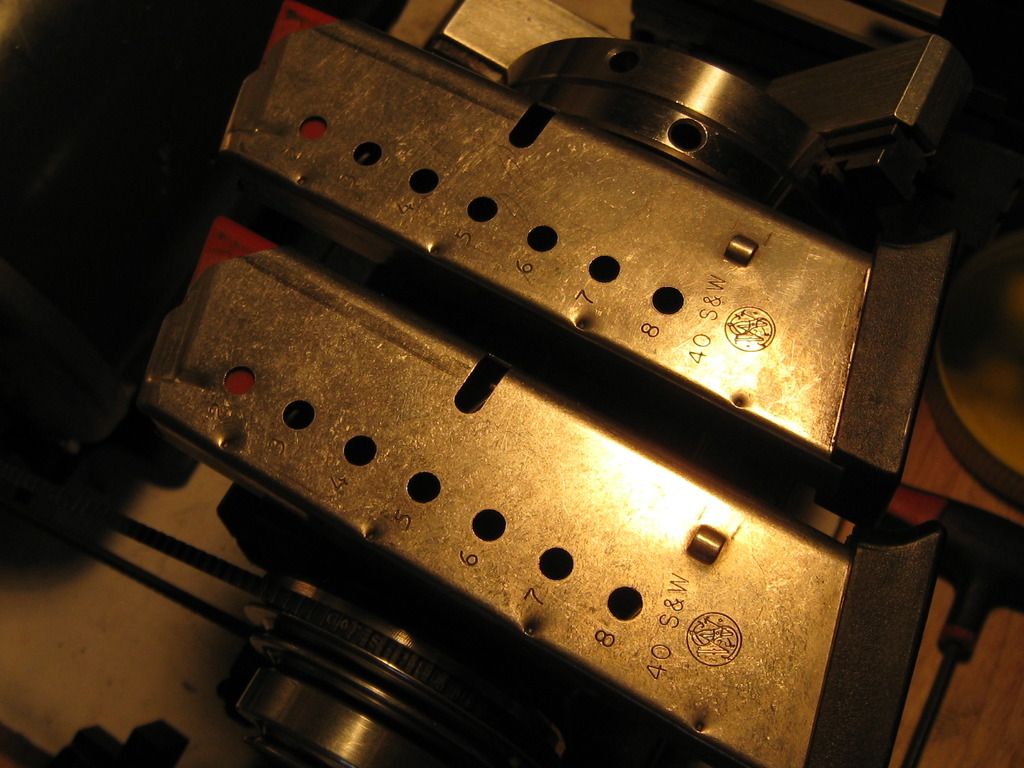

There are a number of things that need adjusting so these may accommodate 10mm Auto fodder.

That spacer running along the spine needs to go.

Need to do something about these indents (four per side) that are securing that spacer.

This indent right below the feed lips is likely to cause problems too.

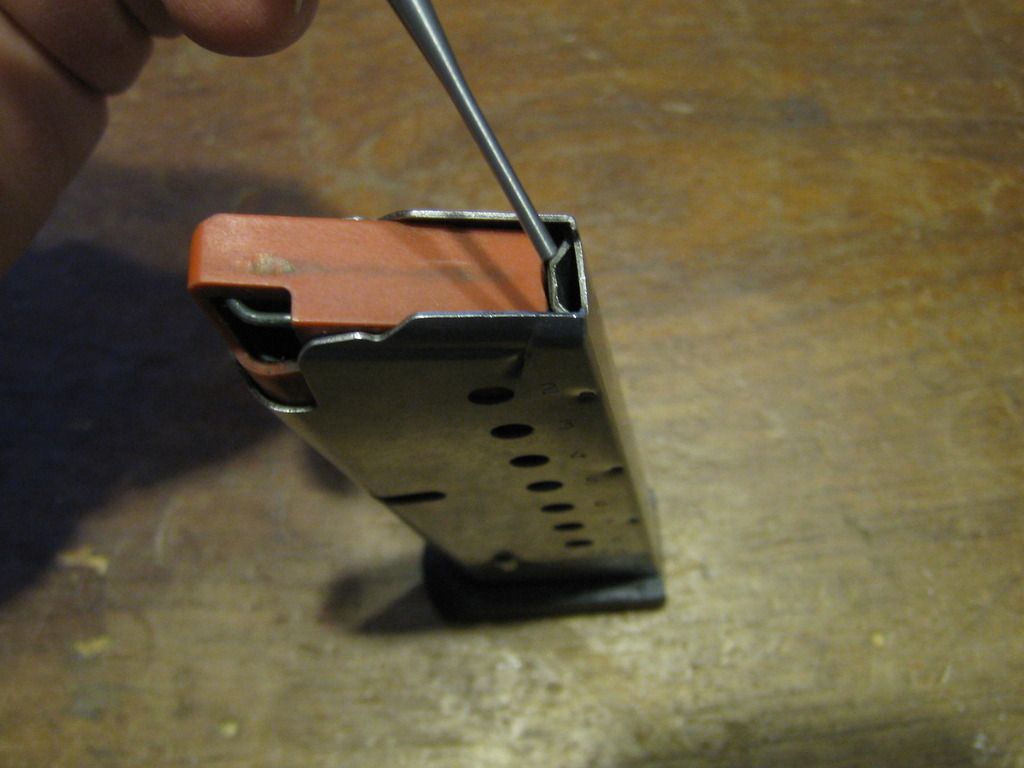

I think I'll get that spacer out of there first. Strip the magazine down then rest the base on my bench with the spine overhanging the edge a bit. Then with a punch & hammer, give it a few whacks.

Until the spacer is sticking out enough to grab with some pliers.

And yank it right out of there.

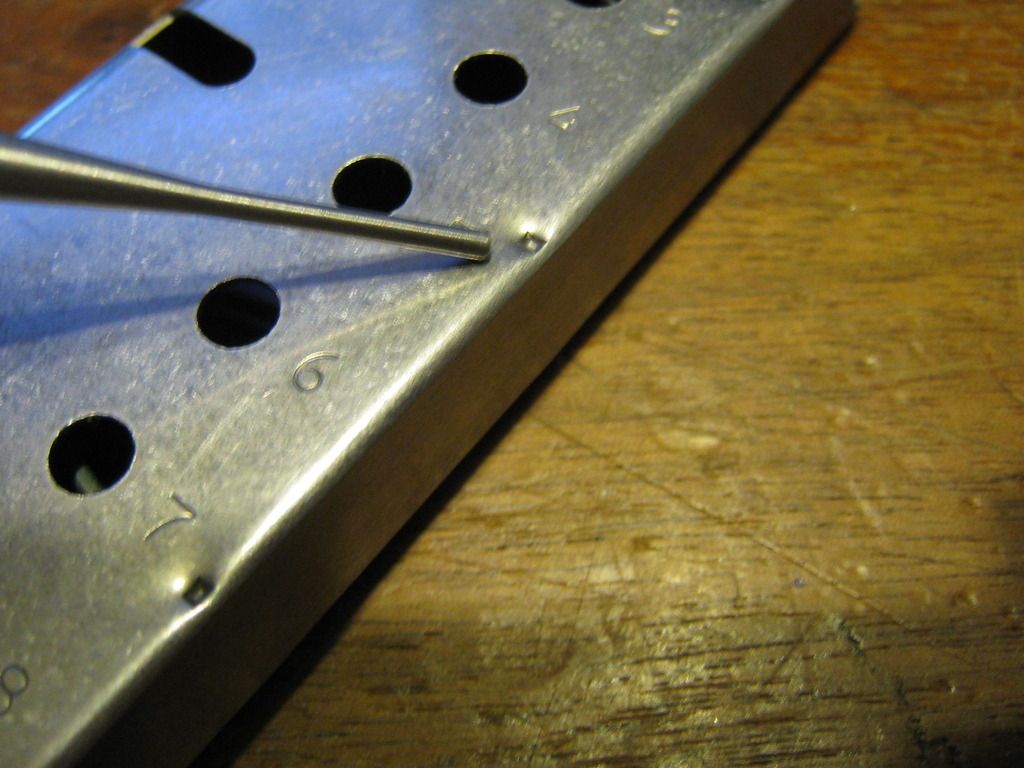

Now lets see about those indents up at the feed lips. As you can see they won't allow a 10mm follower to rise all the way up. I'm a little reluctant to go grinding in there with a power tool so lets go look in the tooling & materials drawer and see if we can come up with something else.

Hey! how about this piece of hex bar, this might work.

If I shove if in there this way...

Then cram it past the indents...

Then squash the thing in the vise...

Huh!, it worked

Still have a problem though. While the follower slides freely over the full length, we can't load more then two rounds because those indents along the spine are in the way.

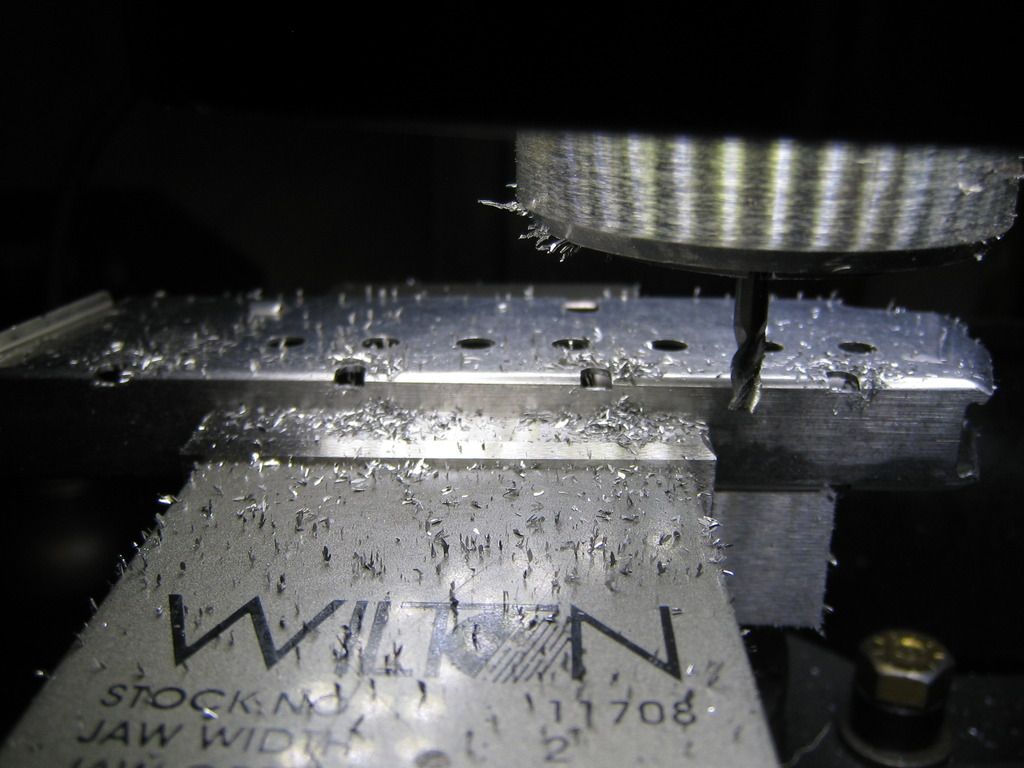

Off to the milling machine.

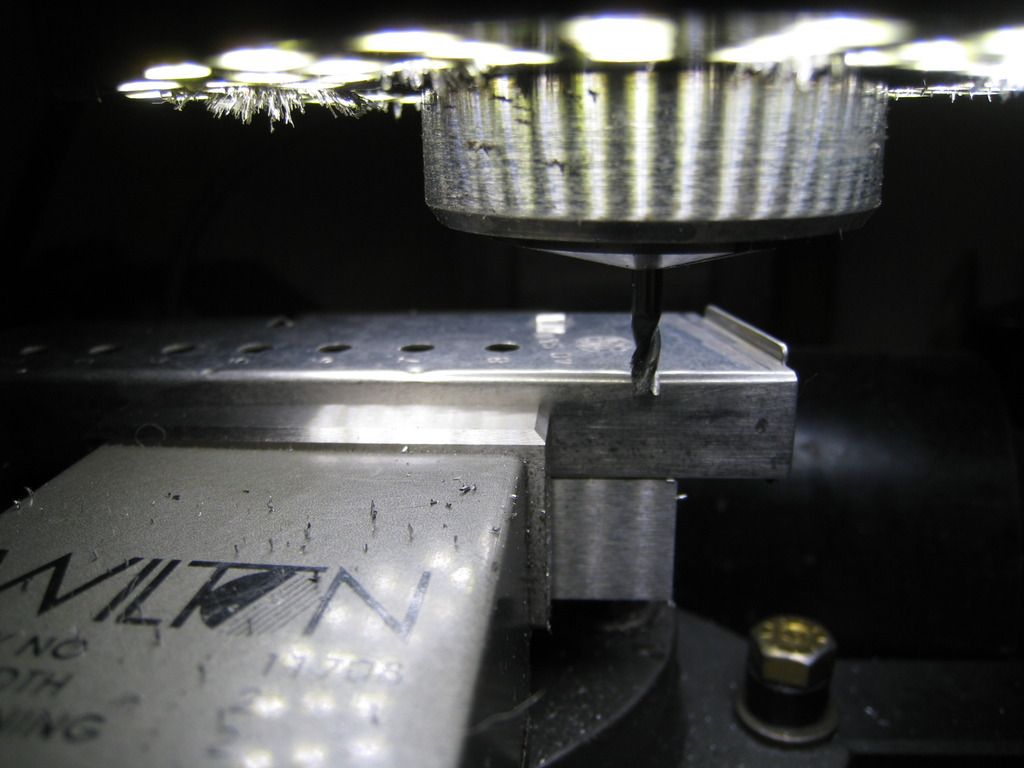

Here's a pair of 1/8" end mills. If you look close, the one on the left has an included radius where the one on the right does not. I'll use the tool on the left since I want the avoid having any sharp 90° inside angles where a crack might develop and propagate. Much less likely to have any problems if the bottom of these cuts have a small radius.

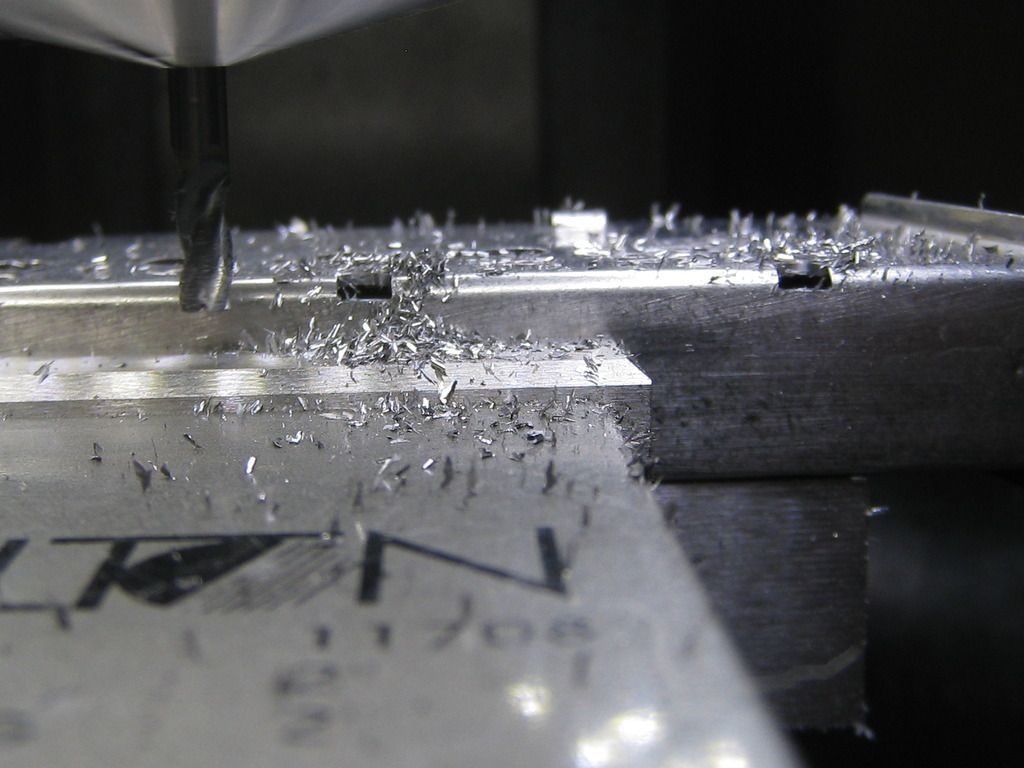

There's our little carbide tool with the radius in the collet getting ready to make the first cut. I'm going to cut 0.050" below the sides and feeding in 0.140" past touch off.

Two cuts done, fourteen to go. Just aligning by hand with the old Mk2 Mod1 Eyeball

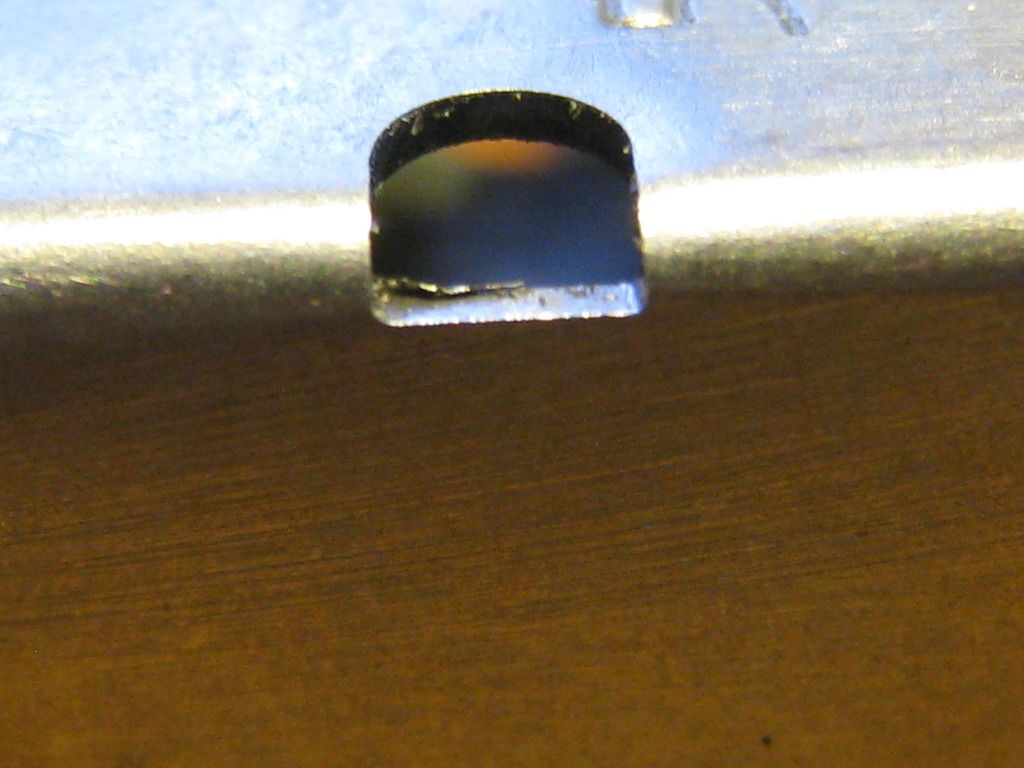

This one is done. Just need to clean up and do a little deburring in those cuts, reassemble and we are done.

Closeup shot here you can clearly see the included radius left by that end mill. Looks like I still have a little deburring left to do.

All done for now. Both mags load and feed well however, that old yellow follower tends to tilt a little as the mag nears full capacity. The orange 40 follower tilts even more. I do have some 10mm white followers inbound though so both of these will be changed up soon and that ought to address the tilting issue.

So, next I'll be taking a closer look at recoil springs. I already have an "off the shelf" spring that will work here. What I want to do that I haven't yet is measure the spring space with the action fully open to determine exactly how much spring I can stuff in there. I also need to account for the bushing which takes up a little bit of that spring space.

Cheers

Bill