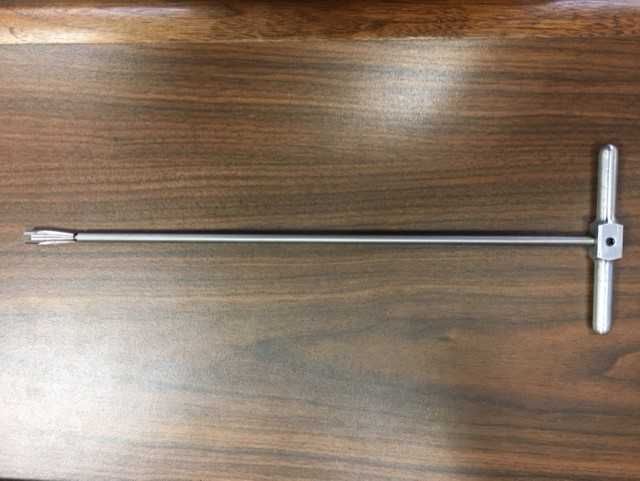

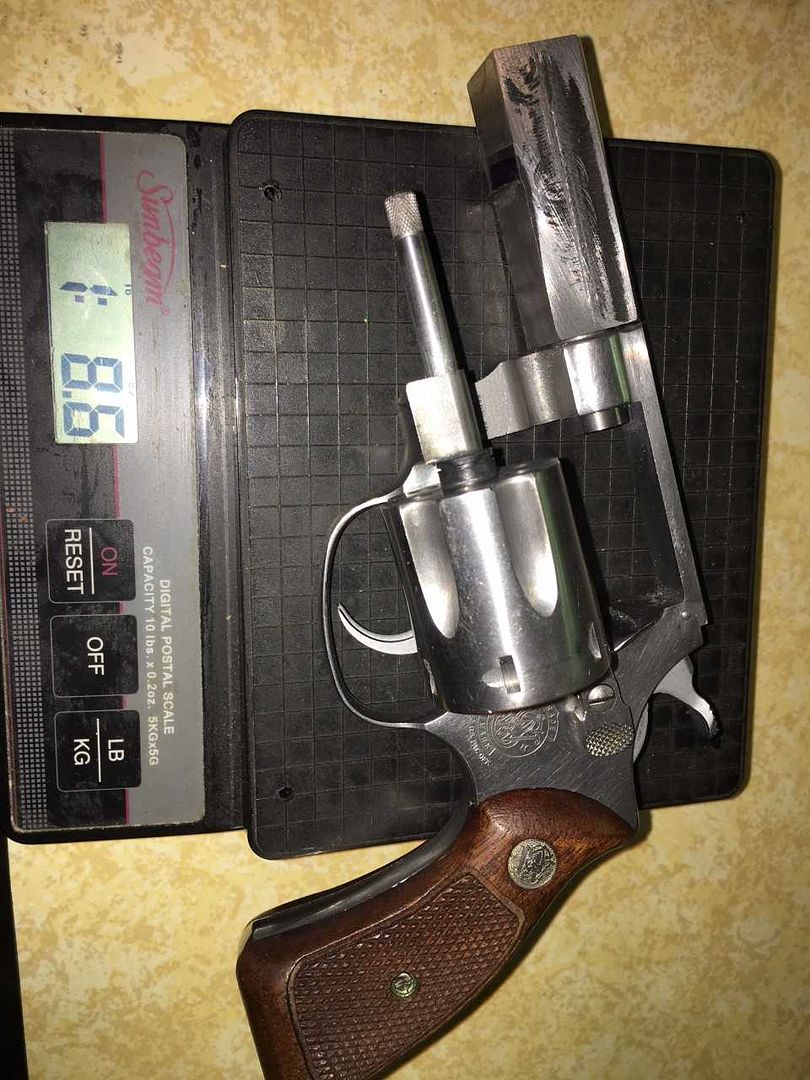

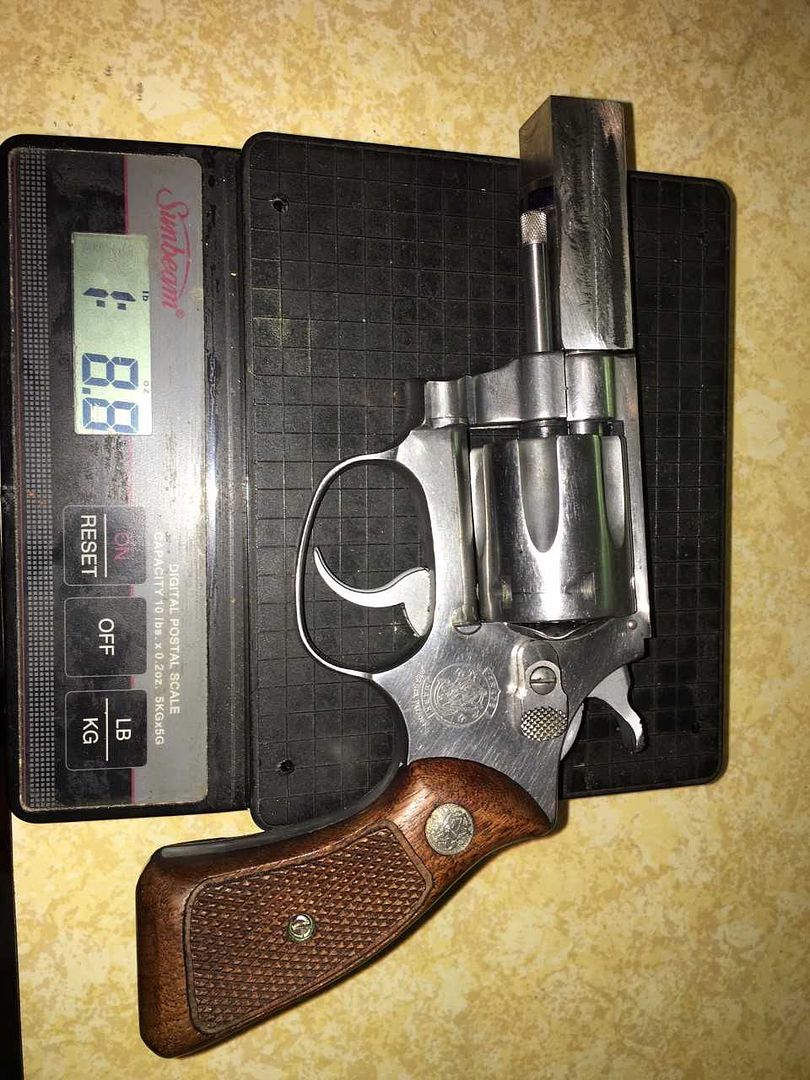

An update on the 3" octagon barrel. Since the last report, I finally torqued the stubby 3" round barrel into the frame, stamped a witness mark, and machined the underside to clear the ejector rod and crane...except this machining was left a bit shallow to make it a perfect square for octagoning. Had I machined enough from the bottom to clear the ER, I would have been dimensionally lost and unable to octagon using v-blocks. It's close but lacks about .010" from allowing the ER to clear. I also reamed the forcing cone with this handy-dandy Brownells reamer...again, about 30 seconds of work there:

I was able to mill the bottom and index off of that surface to mill the sides. I didn't have time to mill the top, so not a square yet, and I will leave enough material on top to allow for an integral front sight ramp, just like I left material on the bottom for the ER stud:

After the top is machined, and I have a perfect square in the rear of the barrel, I will use v-blocks to mill facets on the square corners, thus creating an octagon shape. I would never try this on a long barrel, but octagoning the short 2.25" of this barrel shouldn't create much dimensional drift, or at least none the naked eye can detect. Unfortunately, my standard machinist's v-blocks are too deep for this small barrel, so I'll need to use them to make shallow vees in some square stock aluminum and use those as pseudo v-blocks. Again, I left the barrel under-rotated by one turn, since I'm not ready to torque it on yet. You can see the crane and ER don't quite have the clearance under the barrel to seat all the way:

Machining a few bits is much easier than stockmaking, and it is the stockmaking portion that has me held up on all my other projects, but I'm glad I'm making progress on something, anyway.

TBR