SR38 Improvements

Its been a while since I posted, but its taken this long to arrive at a definite update on load testing and improvements made to the Sarsilmaz SR38 revolver. During the summer I did load testing with several factory brands and results were disappointing. Without showing endless photos of the same thing, no matter the load, the SR38 turned in 4-5" groups at 30 feet. Some loads increased that to 6" spacing. It was the usual pattern you see of two or three rounds grouping and then unpredictable flyers. Not much improvement even when sandbag benched.

The first photo is the "after" results explained in this post. The SR38 can be improved, but it took some work and a trip to the gunsmith.

By late summer, I began to reload .38 special loads with .357 diameter lead bullets, and later .358 diameter lead bullets to see if it would help grouping. Neither bullet size or changes in load velocities grouped any better than factory ammo. My usual shooting is for bullseye so I tend to load at 800 fps or less with semi-wadcutters or DEWC at 148 grains. After tweaking velocities I wasn't getting good results "as is." I was eventually successful, but not due to my superb reloading skills.

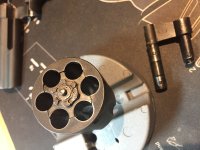

By now most of you revolver guys know where this is going, and I finally had to admit the cylinder chambers might be part of the problem. Bought my first ever set of pin gauges and measurements showed uniform chambers, but only in pairs. Two adjacent chambers would agree at .357 minus, then the next two would be .358 minus, then next pair at .357 plus. Somewhat reluctantly, I had a local gunsmith ream the cylinder to the largest chamber size, ending with all 6 at .3582. Barrel slugged to .3553 so the result is on the margins of a good chamber to barrel diameter relationship at a .0029 inch difference.

While the revolver was in the shop, I also had him ream the barrel throat with an 11 degree cut. As I said in earlier posts, the lockup on the SR38 is a bit loose compared to a good Smith, and the slightly wider throat with the longer approach angle eases the bullet alignment in theory. These two changes are debated (a lot) in revolver circles, but the results were impressive in this gun. The target photo is an average grouping at 25 yards benched after reaming work with Federal 38C standard 158gr 770 fps target load with a round nose lead bullet. These were shot using a sandbag and mounting a mini-red dot. My worse group of the day was free hand at 2" grouups. A Burris fast fire III was used in the initial range sight-in, and later switched out for a Vortex Venom 6 MOA you see in the photo.

Turns out an Allchin SKS mount for Smith L & N frames, will fit the rear sight recess channel on the top of the SR38 - if you take about a thousand off each side of the aligning lug (of the mount!) with some judicious stoning. Once fitted, it is held in place with two screws that come with the mount, also intended for a Smith & Wesson, so more cloning is in evidence. So far, mount has stayed secure, although testing was limited to 100 rounds of my soft shooting reloads, and 50 rounds of magnum loads. I do like the LPA style sight that comes on the SR38 but have to admit the red dot improved this shooter's grouping at bullseye distances.

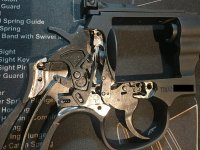

Finally, last week, the SR38 was disassembled and the internals stoned and polished in accordance with Jerry Miculek's "Trigger Job" DVD produced back in the day. Still available from BANG, Inc. and an excellent resource for tuning up a Smith revolver, it also was right in line with working on the SR38. My son and I worked on both this SR38 and a Smith at the same time, and did nearly identical work. We smoothed out contact points in the hammer, trigger and return spring housing. We didn't touch the sear surfaces, but did buff most contact points. And where I am trying out Jerry's reduced power mainspring in my 625, we left the SR38 with its stock springs. Side note: the SR38 hammer spring is a clone or a genuine "power rib" type as made by Wolff. I believe it is the source of the smooth feel to the DA cycling of the gun. The internals work we did made it all that much smoother.

Original DA was close to 10 lbs with the strain screw all the way in. In my earlier post, a slight let off of the screw would produce an 8.5lb pull in DA, but the feel was loose. Original SA pull was averaging 5lbs.

After tuning work, DA is down just below 8lbs and consistent with a positive feel, no stacking, with strain screw turned all the way in. Single action is now 3 lbs. 12oz on average and break is clean, but I wouldn't say light. Overall cycling in both DA and SA was noticeably improved compared to the stock gun. Of course, the best outcome is 1-2" groupings with the right size bullet and loads at 25 yards. With even more care on the trigger, likely to get even better.

The only thing left to do with this revolver is shoot it. And perhaps change springs some day and touch the sear surfaces if they don't improve on their own. My latest opinion is the SR38 is still a good value that can be a great one. The new shot groupings show the SR38 can be successfully improved, albeit with some traditional revolver gunsmithing and home tuning work.

Total cost of improvements was $78.00 on top of the original $400 dollar investment and 3-4 hours of disassembly, light stoning and buffing work. It's hard to judge at this point whether the improvements move the gun into genuine Smith territory in most respects, but its close....for a clone.