I'm don't have much "expertise" in the auto arena, but I have picked up some info on the e-nickel finish Colt used to do.

The part I don't know about is the actual "satin" nickel finish which is the same as bright nickel but applied to a satin surface. Meaning the gun gets a different polish to create a satin nickel gun. I'm not sure if Colt ever offered their autos in "satin", but revolvers never were.(Although I wouldn't discount a custom request)

With that said, the e-nickel or electro-less nickel finish was originally started in the Colt Custom Shop around 1978/79. It wasn't cataloged until 1982 (at least in Python terms), so pretty much any gun prior to that was done in the CS. The neat thing is, they used regular blued models already produced, then stripped the finish and e-nickeled them "on demand". This is why all of them have the CS label stating the finish.

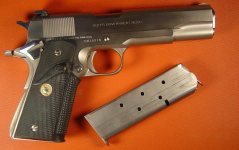

Now, I have heard internet conjecture state the e-nickel finish is actually more durable than regular nickel, and this being one of the reasons Colt switched to it. From what people say here, it sounds like it's not that great on durability, so I imagine it was just to produce more "hype" for an already scarce variation. My theory is, Colt started using the e-nickel because it was simply cheaper than bright nickel, and it started at a time Colt was actively cutting costs and increasing production. E-nick started to replace bright nickel, but then both were phased out in favor of STS. Which I believe ended up being even cheaper in terms of "overall" production cost, but could be wrong.

For the Python, Colt called the e-nick finish "Royal ColtGuard". Nothing special except the higher degree of polish that Pythons always got. The other models were just called ColtGuard or e-nickel.