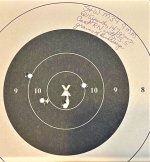

Yes, it's slow twists and heavy bullets that don't get along so if those numbers are correct then it's something else. Keyholing is because the bullet is not spinning fast enough to stabilize. Period.

I've been working with 147 gr bullets and a Springfield 1911 all summer. So far the .356's are not optimum. .357 diameter performs better and even .358 does well but at the maximum powder charge weights I start to see signs of over pressure. I'm going with .357.

You could go to .357 and/or up the powder charge. Another way to get it to spin faster is increased velocity. Might want to skip the relatively fast Bullseye and go with something a bit slower like Universal/Unique to get the velocity up. I've used 3.5gr of Bullseye in the Springfield and it shot as well as most loads with .357 diameter bullets. But as I recall at the moment that's a minimum load. If so try pushing it a bit harder.

As a side note, none of the cast bullet loads I've tried will shoot as well as jacketed bullets in the 9mm. But I've gotten close. I'm not a big fan of "good enough" accuracy but with lead bullets in the 9mm I might just have to accept that.

Of course the proper thing to do is slug your barrel. Then go .001 to .002 over that diameter and check that they will chamber of course.

Loading Cast Bullets in the 9mm Luger | Cast Bullet Association