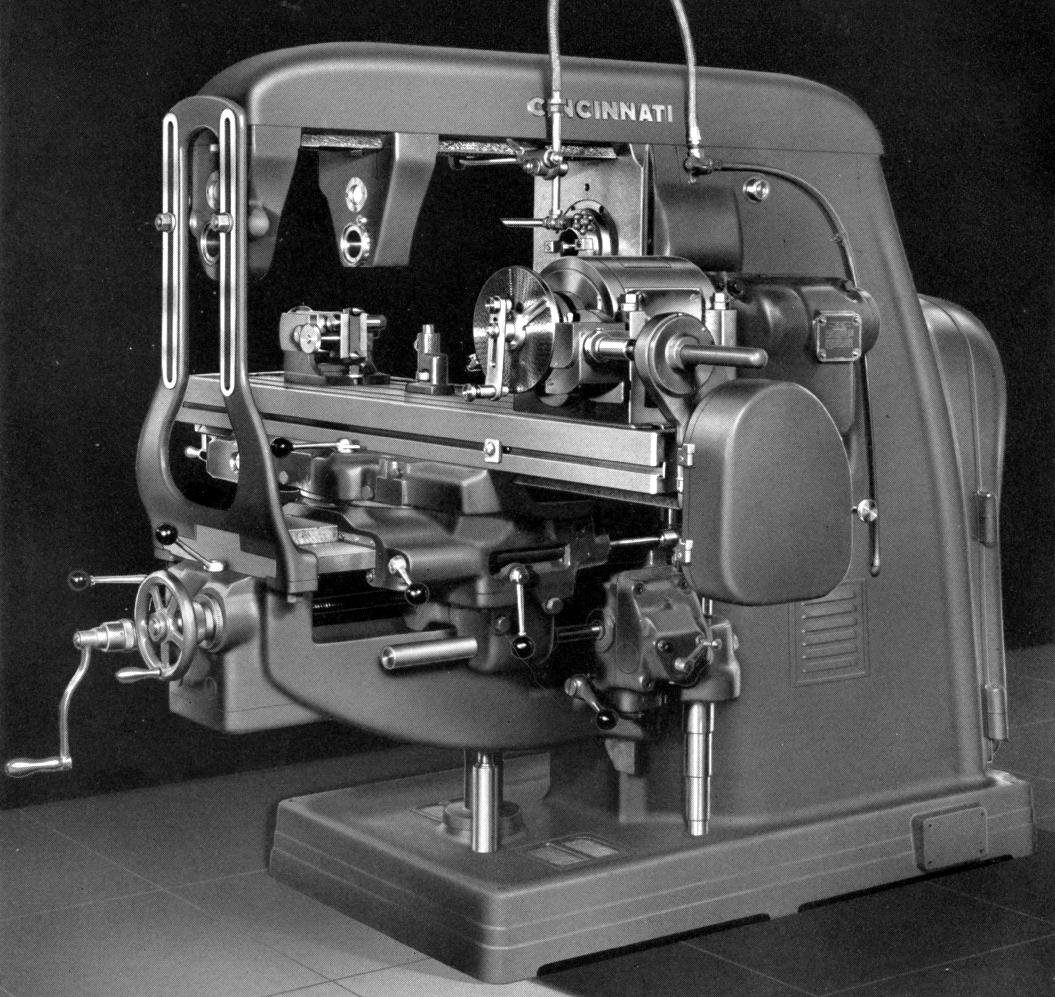

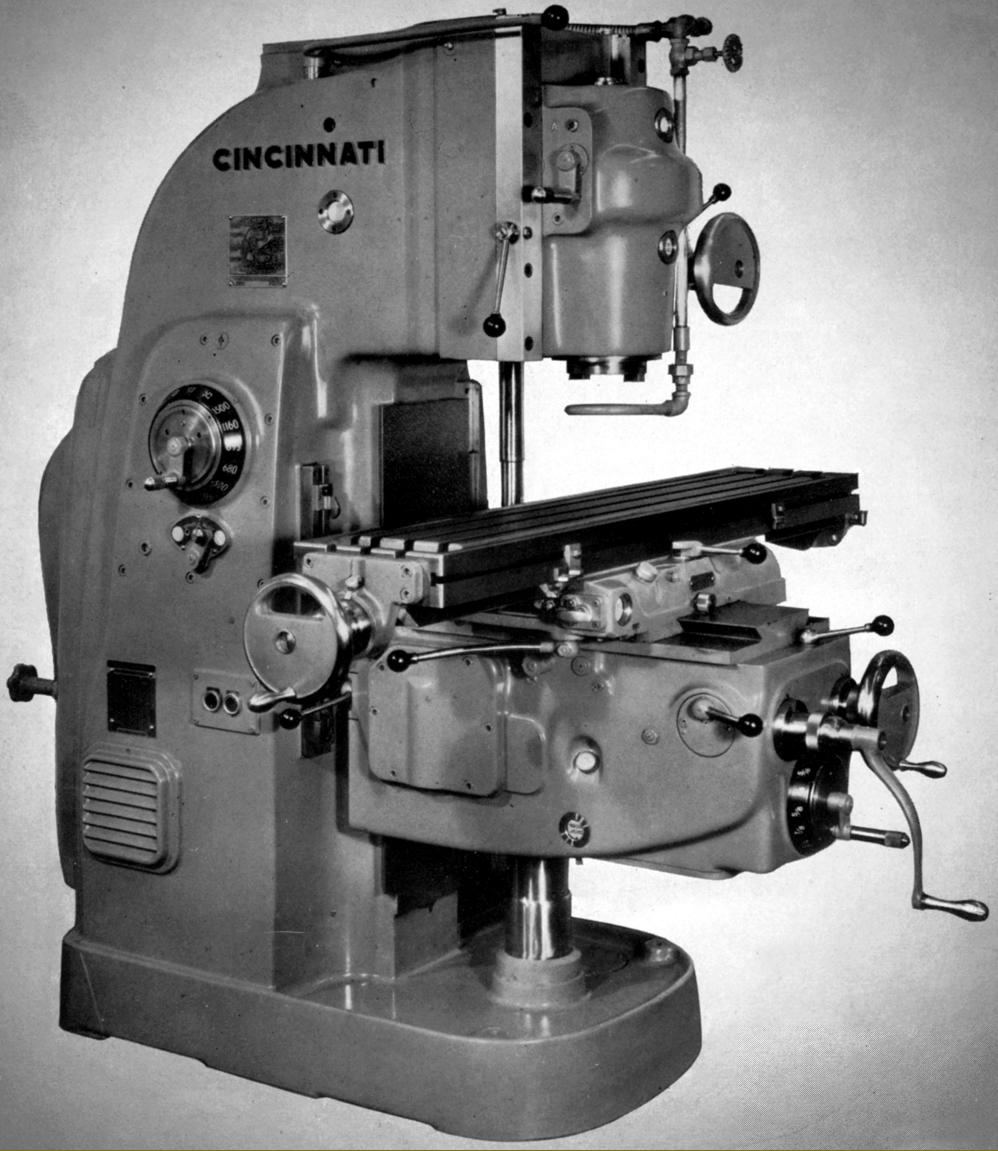

My dad retired from Cincinnati Milacron, formerly Cincinnati Milling Machine Co.

From the webz:

The milling machine business of the Cincinnati Screw & Tap Co. was formed into Cincinnati Milling Machine Co. in 1889 by Fred Holz, who subsequently sold out to Frederick A. Geier in 1905. The business was successful. In the mid-1920s they acquired the patents for centerless grinding and then worked with the Timken Company to perfect the technology. The resulting machinery allows Timken to produce automotive bearings that were both lower cost and higher precision than their predecessors.

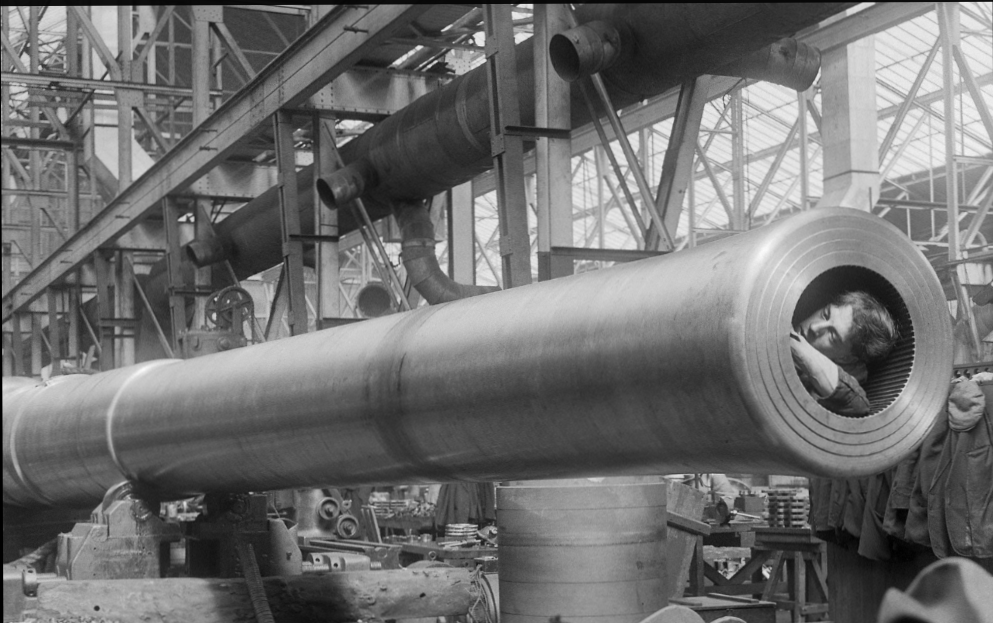

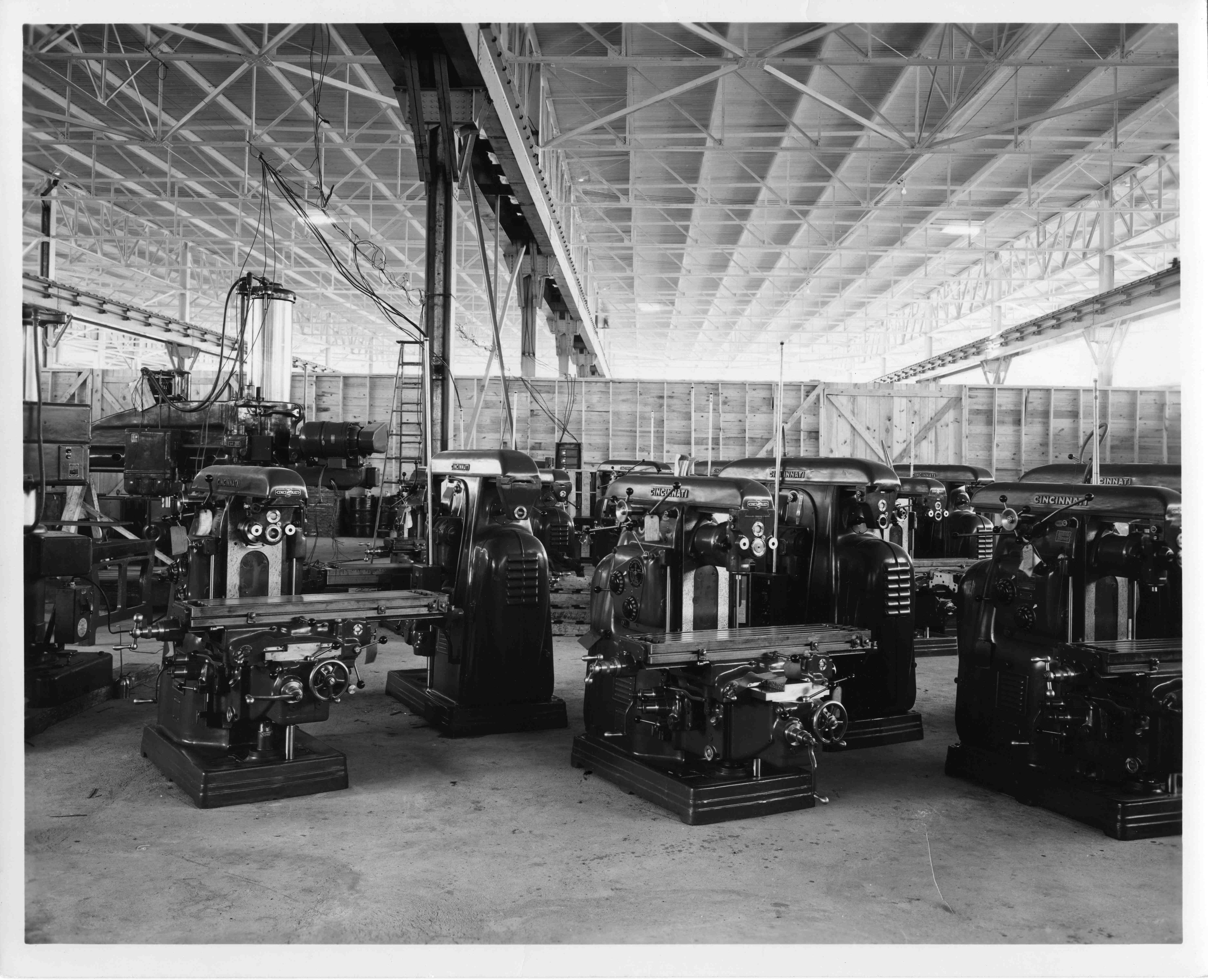

Frederick A. Geier died in 1934, and although Geier's son, Frederick V. Geier, was felt by some to be too young, he took charge and ran the company for the next quarter century. The younger Geier had a college education, considerable experience as a machinist, and had served in the military during World War I when he fixed production problems with 75 mm cannon. During a trip to Germany in the early 1930s Geier realized that another war was inevitable and upon his return he aggressively expanded his company's production capabilities (by 1939 they were the largest in the US), and when he realized that the then-future Allies would not be able to machine the barrels of big naval guns, he tooled up his factory to do just that. During the Second World War, all of the country's largest guns were machined by Cincinnati Milling Machine Co.

In 1970, having diversified beyond milling machines, the name was changed to Cincinnati Milacron. In 1974 they acquired Heald Machine Co. for their line of grinding machinery. Now known simply as Milacron LLC, the company now specializes in machinery for the plastics industry.