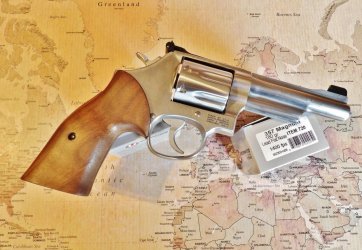

With the new no-lock models, I've been curious as to why S&W didn't revert the frame contour beneath the hammer to the sharper curve from the pre-lock guns. It appears I now have my answer. While reading through this excellent review of a new 629 Mountain Gun, the author mentions and showcases a photo of a new drop-safety mechanism. This mechanism takes the space dedicated to the internal lock lockwork and interfaces in the same spots with the same hammers used in the IL models. I'm not especially certain why the existing drop safeties weren't considered enough, but there has been some theorizing that California's regs are to blame. Who knows. I do like the pre-lock frame contour better, but the new frame curvature doesn't look too bad in person.

Source with photos (scroll down to the New Drop Safety section):

https://revolverguy.com/lipseys-exclusive-sw-model-629-mountain-gun/

Deep into writing this article, I learned that S&W had incorporated a new drop safety into the No-Lock frame of the Mountain Gun. Smith & Wesson did away with the internal lock, but they used the space to add an additional drop safety in the same area. It explained why the “arch” of the new style frame was maintained.

There is much less going on with the new drop safety than there was with the internal lock. The drop safety parts consist of a single plate and a small coil spring (the hammer appears identical to the MIM hammer used with the internal lock). The plate has a raised post at its rear that fits into a hole in the frame to anchor it. A tab sticking off its’ front engages a slot cut into the frame wall to keep it in place. There is a “nub” on the plate that rides in the groove on the left side of the hammer, like the locking tab did on the internal lock.

Source with photos (scroll down to the New Drop Safety section):

https://revolverguy.com/lipseys-exclusive-sw-model-629-mountain-gun/

Last edited: