stefanveres

Member

Hi,

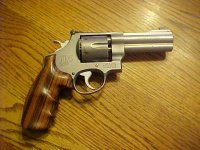

I would like to cast bullets for my 625-8 5" revolver.

I shoot IPSC so I need to be fast.

Which mold would you recomend ( I think about 230 grain bullets).

I was thinking about Lee molds.

I would allso like to know more about how are you lubing the bullets ( I have the Lee mold for .357mag RN bullets, that I can lube with LEE LIQUID ALOX).

Regards,

Stefan

I would like to cast bullets for my 625-8 5" revolver.

I shoot IPSC so I need to be fast.

Which mold would you recomend ( I think about 230 grain bullets).

I was thinking about Lee molds.

I would allso like to know more about how are you lubing the bullets ( I have the Lee mold for .357mag RN bullets, that I can lube with LEE LIQUID ALOX).

Regards,

Stefan

Last edited: