DWalt

Member

I have written before about using 4227 in reloading .30 Carbine. In summary, it works OK, but even with the case nearly full, the MV is only around 1700 ft/sec. The good part of that is it does not fling fired cases very far, so they are not so easily lost.

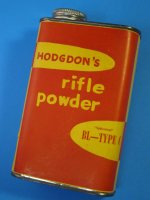

Last month, I made up a batch of .300 Savage brass from .308 brass. As luck would have it, at the local gun show several weeks ago I found a baggie of dirty and tarnished factory .300 Savage cases, 58 of them - for $5. Needless to say I bought them and gave them an overnight soaking in citric acid solution to make them look much better. As I had an old can of H4227 (I mean probably from the earliest days of Hodgdon Powder), I decided to use it to load up some low power cast bullets loads in .300 Savage, seeing as how I had over 300 165 grain gas-checked lead bullets of the Spitzer style I had no other use for. I didn't have any recipes using H4227 for the .300, but the Lyman cast bullet handbook showed some mild .308 Win loads using between 22 and 28 grains of IMR 4227 with that same bullet. So I loaded up 24 .300 Savage cases with 23 grains of H4227, as there is very little difference between the .308 Win and .300 Savage cases, except for the neck length. It turned out to be a great load which chronographed at around 2000 ft/sec MV, and functioned the action of my Remington Model 81 reliably, without throwing the cases too far. And that load was very easy on my old shoulder - Model 81s are not noted for their pleasant recoil. Best of all, I was getting 2"-3" 5-shot groups with open sights at 50 yards over sandbags from the bench, and with that gun, that's nearly miraculous.

I just finished up loading 87 more rounds of .300 Savage with that H4227 lead bullet load, will be going out in a couple of weeks to shoot them all up in my other Model 81. It should be fun.

Last month, I made up a batch of .300 Savage brass from .308 brass. As luck would have it, at the local gun show several weeks ago I found a baggie of dirty and tarnished factory .300 Savage cases, 58 of them - for $5. Needless to say I bought them and gave them an overnight soaking in citric acid solution to make them look much better. As I had an old can of H4227 (I mean probably from the earliest days of Hodgdon Powder), I decided to use it to load up some low power cast bullets loads in .300 Savage, seeing as how I had over 300 165 grain gas-checked lead bullets of the Spitzer style I had no other use for. I didn't have any recipes using H4227 for the .300, but the Lyman cast bullet handbook showed some mild .308 Win loads using between 22 and 28 grains of IMR 4227 with that same bullet. So I loaded up 24 .300 Savage cases with 23 grains of H4227, as there is very little difference between the .308 Win and .300 Savage cases, except for the neck length. It turned out to be a great load which chronographed at around 2000 ft/sec MV, and functioned the action of my Remington Model 81 reliably, without throwing the cases too far. And that load was very easy on my old shoulder - Model 81s are not noted for their pleasant recoil. Best of all, I was getting 2"-3" 5-shot groups with open sights at 50 yards over sandbags from the bench, and with that gun, that's nearly miraculous.

I just finished up loading 87 more rounds of .300 Savage with that H4227 lead bullet load, will be going out in a couple of weeks to shoot them all up in my other Model 81. It should be fun.

Last edited: