I am excited about the work I have done on my reloading effort so far, so I think some photos and a description of my reloading bench are in order.

I do not have a lot of space for a full reloading bench right now (can't afford a big place as a grad student). Thus, I want my reloading bench to be small, and I figure portable is a virtue for the time being as well. Some searching for portable reloading benches online allowed me to see many articles and posts across many forums about others' efforts. This inspired me to choose a Black & Decker Workmate as the foundation of my reloading bench.

I lucked out in acquiring my Workmate. I mentioned I was looking for a Workmate in casual conversation with a grad school friend one day, and she said she had an older model Workmate she was not using that I could have. After taking a look at it I gave her a fair offer and bought it!

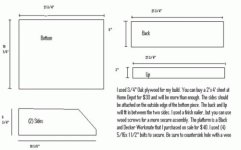

I then did a lot of measuring and imagining to figure out a way to turn the Workmate into a reloading bench. Ultimately, I decided on a tabletop of 3/4" maple plywood measuring 29" wide and 17" deep. The plywood is attached to the Workmate using three 1/4" x 2 1/2" carriage bolts with washers and nuts. My Lee turret press is attached near the unsecured corner with three 1/4" x 3" hex bolts with steel washers and nuts below and neoprene washers on top where the hex head contacts the press. These bolts also secure this corner of the plywood, as I figured another carriage bolt in this location would get in the way. With everything bolted on (rather than nailed or screwed on), this means I can still use the Workmate for other projects if the need arises, so this gives me a good amount of flexibility right now.

The photos show the reloading bench with just the press, and the press with with the turret, 38 Special dies, and priming system installed. The reloading bench will be indoors, but it looks best in photos when on the back patio.

I do have a Lee powder measure as well that I will be using. I plan to have it attached to an extra piece of plywood. I will be using the carriage bolts to secure it when in use. More on that at a later time.

I do not have a lot of space for a full reloading bench right now (can't afford a big place as a grad student). Thus, I want my reloading bench to be small, and I figure portable is a virtue for the time being as well. Some searching for portable reloading benches online allowed me to see many articles and posts across many forums about others' efforts. This inspired me to choose a Black & Decker Workmate as the foundation of my reloading bench.

I lucked out in acquiring my Workmate. I mentioned I was looking for a Workmate in casual conversation with a grad school friend one day, and she said she had an older model Workmate she was not using that I could have. After taking a look at it I gave her a fair offer and bought it!

I then did a lot of measuring and imagining to figure out a way to turn the Workmate into a reloading bench. Ultimately, I decided on a tabletop of 3/4" maple plywood measuring 29" wide and 17" deep. The plywood is attached to the Workmate using three 1/4" x 2 1/2" carriage bolts with washers and nuts. My Lee turret press is attached near the unsecured corner with three 1/4" x 3" hex bolts with steel washers and nuts below and neoprene washers on top where the hex head contacts the press. These bolts also secure this corner of the plywood, as I figured another carriage bolt in this location would get in the way. With everything bolted on (rather than nailed or screwed on), this means I can still use the Workmate for other projects if the need arises, so this gives me a good amount of flexibility right now.

The photos show the reloading bench with just the press, and the press with with the turret, 38 Special dies, and priming system installed. The reloading bench will be indoors, but it looks best in photos when on the back patio.

I do have a Lee powder measure as well that I will be using. I plan to have it attached to an extra piece of plywood. I will be using the carriage bolts to secure it when in use. More on that at a later time.

Attachments

Last edited: