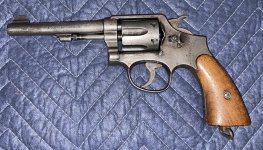

Questions about a Smith and Wesson M&P Victory model

in 38 S&W. 5-inch barrel.

Numerous British proof? Marks on Barrel, Frame, each chamber on Cylinder with a crown and BNP which I now understand that stands for Birmingham Nitro Powder?

There is also a stamp on left side frame with crossing swords and numbers or letters.

I won’t pose all of my questions. Will make this initial post brief and hopefully the experts can guide me on what other features / dimensions I need to look for.

Yes, I know the finish is shot. But this one did not get reamed out to .38 special. Timing is good and locks up tight believe it or not. Looking at the finish you would think it was abused mechanically as well.

ALL SERIAL numbers match on cylinder, frame, butt, star wheel, and cylinder crane.

First question. This firearm was sent over to Britain and that is where the Crown proof stamps were added? Once the British stamps were placed. Then this firearm was issued to British soldiers?

And since this made it back to the states without any import marks like surplus stamps, etc. Does that mean a soldier probably brought it back from the war into the U.S.?

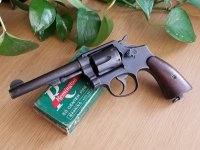

Second question. When I acquired it, I was told it was never reamed out for 38 special and that was true by trying a 38 special and of course it sticks way out on all chambers.

But my dilemma now is that ONE chamber does NOT index the .38 short correctly. The chamber ledge is not deep enough and the casing sticks out enough where I’m afraid to shut the cylinder and have the casing wedge against the back of the frame.

HOW did this get by factory inspection and THEN British inspection? Using feeler gauges the gap from the fwd. surface of the rim to the aft surface of the cylinder is approx. .031 inch. All the others there is about a .0015 gap. I never understood indexing to the fwd. end of the brass casing AND the fwd. end of the casing’s rim.

Almost seems like you’re double indexing. I guess the chamber index edge was to make it so you couldn’t use the wrong ammo. Like the 38 special or even a .357.

I have more questions but this will be a start of conversation and see where that leads.

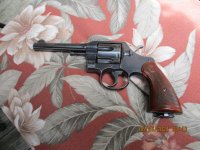

I’m assuming that the fairly low number of V-197209 would be early in the war? I guess I also thought the Lend-Lease Victories did NOT have a “V” on them. I thought I read that somewhere but apparently, they did.

What does the .767” and 3 ½ ton mean on left side of barrel. Were those stamps from Britain inspectors?

Here are some dimensions I took. The ammo I got was from Fiocchi called Heritage. They call it 38 S&W short. I could only find it in 145 grain and this is FMJ.

The ammo in my opinion seems VERY loose in chambers compared to my 1905 which I got out just to have something to compare to. A 38 short will NOT chamber in the 1905. Case diameter is too big.

Dimensions on 3 of the Brit chambers Inside diameters are .3895 inch. The 1905 is .3795 inch. So .010 difference.

38 special case dia. Is .375 and 38 short case dia. Is .381. So, the Brit chamber has .004 clearance and 1905 has .002 clearance. I have no idea what tolerance should be chamber dia. to casing diameter.

I know the picture that shows the chambers appears that some do not have the index ledge, but they all do. A .38 special sticks way out.

Once again, my main concern is that one chamber not indexing the cartridge as I would expect. Any ideas what to do?

in 38 S&W. 5-inch barrel.

Numerous British proof? Marks on Barrel, Frame, each chamber on Cylinder with a crown and BNP which I now understand that stands for Birmingham Nitro Powder?

There is also a stamp on left side frame with crossing swords and numbers or letters.

I won’t pose all of my questions. Will make this initial post brief and hopefully the experts can guide me on what other features / dimensions I need to look for.

Yes, I know the finish is shot. But this one did not get reamed out to .38 special. Timing is good and locks up tight believe it or not. Looking at the finish you would think it was abused mechanically as well.

ALL SERIAL numbers match on cylinder, frame, butt, star wheel, and cylinder crane.

First question. This firearm was sent over to Britain and that is where the Crown proof stamps were added? Once the British stamps were placed. Then this firearm was issued to British soldiers?

And since this made it back to the states without any import marks like surplus stamps, etc. Does that mean a soldier probably brought it back from the war into the U.S.?

Second question. When I acquired it, I was told it was never reamed out for 38 special and that was true by trying a 38 special and of course it sticks way out on all chambers.

But my dilemma now is that ONE chamber does NOT index the .38 short correctly. The chamber ledge is not deep enough and the casing sticks out enough where I’m afraid to shut the cylinder and have the casing wedge against the back of the frame.

HOW did this get by factory inspection and THEN British inspection? Using feeler gauges the gap from the fwd. surface of the rim to the aft surface of the cylinder is approx. .031 inch. All the others there is about a .0015 gap. I never understood indexing to the fwd. end of the brass casing AND the fwd. end of the casing’s rim.

Almost seems like you’re double indexing. I guess the chamber index edge was to make it so you couldn’t use the wrong ammo. Like the 38 special or even a .357.

I have more questions but this will be a start of conversation and see where that leads.

I’m assuming that the fairly low number of V-197209 would be early in the war? I guess I also thought the Lend-Lease Victories did NOT have a “V” on them. I thought I read that somewhere but apparently, they did.

What does the .767” and 3 ½ ton mean on left side of barrel. Were those stamps from Britain inspectors?

Here are some dimensions I took. The ammo I got was from Fiocchi called Heritage. They call it 38 S&W short. I could only find it in 145 grain and this is FMJ.

The ammo in my opinion seems VERY loose in chambers compared to my 1905 which I got out just to have something to compare to. A 38 short will NOT chamber in the 1905. Case diameter is too big.

Dimensions on 3 of the Brit chambers Inside diameters are .3895 inch. The 1905 is .3795 inch. So .010 difference.

38 special case dia. Is .375 and 38 short case dia. Is .381. So, the Brit chamber has .004 clearance and 1905 has .002 clearance. I have no idea what tolerance should be chamber dia. to casing diameter.

I know the picture that shows the chambers appears that some do not have the index ledge, but they all do. A .38 special sticks way out.

Once again, my main concern is that one chamber not indexing the cartridge as I would expect. Any ideas what to do?