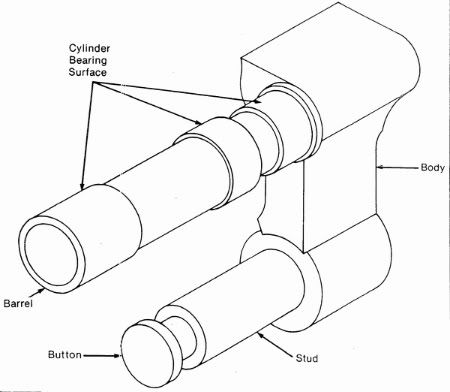

YOKE ENDPLAY

To adjust the yoke screw:

Use a file and lightly file the bottom of the screw until the cylinder swings without a lot of resistance. I like them with a bit of drag, but not binding.

If you tried the screws, then the yoke stud is too long (or the slot is worn) and needs to be adjusted.

You need to flatten the button of the yoke. Find a 1 inch round bar (Babbitt bar would be nice) and place the yoke body on it. Using a hammer lightly tap the button (on the corner) to make it flatter, (peen only 1/2 way around) then if you need to, file out the slot where the screw fits so it can be tightened up. Only file what you have to, or it will be loose again. You're trying to narrow the slot opening where the screw goes (Look for the screw rub mark). Your not trying to move the whole 9 yards, just deform the slot.

Tap lightly, check the fit often.