I spent a lot of time developing my 6.5 reload. First what type of gun are you shooting this round out of...bolt or semi? What is your intended application...precision target, hunting round, or plinking?

As 6string mentioned above you must first measure your chamber so you know where the ogive touches the rifling of said bullet. Hornady sells a tool for this. Then once you know that you have to figure out the "jump" distance of the ogive to rifling (trial and error and testing rounds). This is what matters, not so much OAL and cannelure.

And of course that's after you have decided on your powder, primer, and brass you want to use. Then sizing, trimming, neck tension, and runout.

But I digress, it really depends on your usage for the round and how much you want to get into the weeds. I have an extensive development notebook to include bullet jump and powder variation in weight. Faster was not always better too.

When I was done testing I ended up with .250" MOA and was quite pleased and considered done. Keep in mind that for the benchrest shooters out there this ain't good enough lol. I target shoot at distance out to and including 1000y for fun not competition. It's stupid accurate too, golfballs at 300y is easy. I really enjoyed the development phase.

My cartridge specifics: Hornady brass, Hornady 140g ELD Match bullet, H4350 powder, Federal GM primer, 1.910 trim length, .002 neck tension, .015" bullet jump, .001" or less runout, and 2661 FPS.

Good luck and have fun with this!

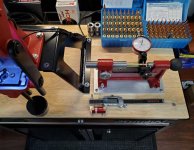

Some pics