keithherrington

Member

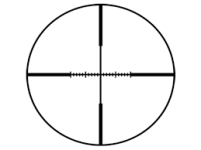

Over the last three years I've been building and tuning a rifle that specifically shoots 7.5X55 Swiss GP-11 ammo, which as some of you may know is extraordinarily high quality government ball ammunition often found for as little as $.50 a round. The basis for the rifle was a Model 700 action, a Pacific Tool and Gauge bolt, Xtreme CS-22 trigger, three pre-fitted Brux 28" medium Palma contour barrels, and a McMillan Baker Special stock with thumbwheel cheekrest, Anschutz rail and Tubb three-way adjustable buttplate. The scope is a Leupold 6.5-20X50 LR with their Windplex reticle, and a CDS elevation knob calibrated to the cartridge trajectory.

From the beginning the gun has demonstrated two characteristics: extreme accuracy (sub 3/4MOA under all conditions), and an aperiodic tendency to misfire. On each case a second strike of the primer set the cartridge off. This would happen 2-3 times out of 10, which I just didn't care for at all.

My new gunsmith, Dale Woolum of Charlottesville, VA addressed the problem, then took it out for a test run. He shot it a total of 17 times without a hitch and got the following target...at 300 yards. Velocity averaged 2666fps, about 86fps above a K31's nominal velocity, with an E.S. of 43 and a S.D. of 13.7.

What Dale determined the problem to be was marginal firing pin strikes. The firing pin was just too light to work consistently with hard GP-11 primers. He decided to make the firing pin heavier by almost 16%. Original weight was 59.18 grams and the new weight with the tungsten collar was 68.53 grams. Below are pictures of the collar and the firing pin assembly all put back together.

The last picture shows the result of the extra weight. From top to bottom: GP-11 hit by the original weight pin, GP-11 hit by the new heavier pin and a reloaded round, hit by a K-31 firing pin.

Dale makes heavier firing pins for a variety of bench rest gun and precision rifles and in each case he claims to get more consistent ignition and accuracy.

Keith

From the beginning the gun has demonstrated two characteristics: extreme accuracy (sub 3/4MOA under all conditions), and an aperiodic tendency to misfire. On each case a second strike of the primer set the cartridge off. This would happen 2-3 times out of 10, which I just didn't care for at all.

My new gunsmith, Dale Woolum of Charlottesville, VA addressed the problem, then took it out for a test run. He shot it a total of 17 times without a hitch and got the following target...at 300 yards. Velocity averaged 2666fps, about 86fps above a K31's nominal velocity, with an E.S. of 43 and a S.D. of 13.7.

What Dale determined the problem to be was marginal firing pin strikes. The firing pin was just too light to work consistently with hard GP-11 primers. He decided to make the firing pin heavier by almost 16%. Original weight was 59.18 grams and the new weight with the tungsten collar was 68.53 grams. Below are pictures of the collar and the firing pin assembly all put back together.

The last picture shows the result of the extra weight. From top to bottom: GP-11 hit by the original weight pin, GP-11 hit by the new heavier pin and a reloaded round, hit by a K-31 firing pin.

Dale makes heavier firing pins for a variety of bench rest gun and precision rifles and in each case he claims to get more consistent ignition and accuracy.

Keith

Attachments

Last edited: