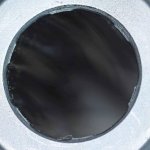

Is your picture above of a 625-8JM's muzzle?

As far as I'm aware the 625-8JM is a (5) groove barrel & is EDM/ECM rifled, the same as the 25-13, 325TR, & 325NGs I have. Your picture shows (6) grooves?

I have a 625-8PC & S&W says it has the broached rifling. It does have a (6) grooved rifling. They also call it "deep cut" but my measurements show there's no meaningful difference, that I can measure, from the others.

They all have grooves that run .0042" to .0047" deep. 45's are not noted for having deep grooves.

Very few of my S&W have done well with cast lead bullets & I converted to using only plated or jacketed bullets in them some time ago, to avoid that grief, and they are very accurate with either. I prefer .452" plated but .451" does fine too. Throats run .452".

I don't know what problem(s) your's might have, or what S&W did to try & correct your accuracy complaint, but mine have had a few things that needed addressing.

My 625PC had a barrel constriction, at the frame, right out of the box. A .443" pin gage, the largest that can be inserted into the muzzle, would fall smoothly thru the barrel until it got to where the barrel threads into the frame & would firmly be stopped there.

A .442" pin gage would pass the constriction. When firing coated cast lead bullets in it they started leading at that point. I hand lapped the constriction out but while the leading was reduced it was still generalized.

It might be worth checking to see if you have a barrel constriction.

The way S&W finishes the crown on virtually all their revolvers is largely disappointing to me. The rifling often has very poor presentation at the crown. Aesthetically not pleasing & potentially it can diminish grouping. I usually re-chamfer those.

Just a couple thoughts.

.

625PC, before chamfering

.

.

.

.

625PC, after chamfering, before polishing

.

.

.

.

.

.

.

627PC, before chamfering

.

.

.

.

627PC, after chamfering, before polishing

.

.