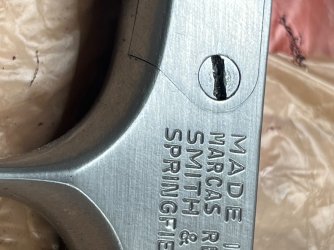

The 67-1 No. 2 (why do I feel British when I describe it that way?) has been hard scrubbed, medium scrubbed, and light scrubbed with both 7447 maroon and 7448 grey scotchbrite.

It's time to start thinking about 2152hq's burnishing technique.

I wanted to have an idea of what I was getting into before I started, so I set up a test using a leftover barrel from a model 64.

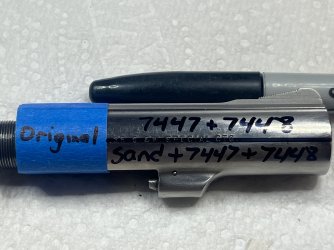

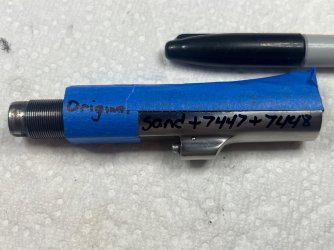

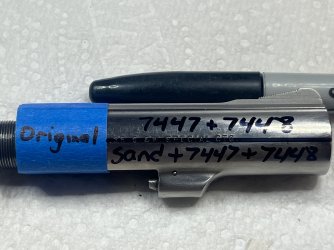

Step 1 was to tape off part of the barrel so it stayed untouched for comparison. Next, I layed out a test pattern to try 4 different finishing combinations. I needed to know if there was going to be a difference in the final finish between areas that had to be sanded for scratch and dent fixes and areas that were only scrubbed. I also needed to know if both scotchbrite grits were necessary.

Here's how the test pattern broke out:

After figuring out the pattern, the top half was taped off so I could sand the bottom half with 120, 180, 220, 320, 400, and 600 grit paper.

After the bottom half of both sides was sanded, the top piece of tape was removed and the entire exposed areas of both sides were scrubbed, one side with 7447 only and the other with 7447 and 7448.

At the drill press with the carding wheel installed, I used enough WD40 on the metal to keep it wet but not so much that the wheel threw anything noticeable onto the target I put behind the wheel as an indicator.

I kept the pressure on the wheel very light and moved the piece quite a bit in random directions. I had to re-wet the barrel several times on both sides by putting a couple of drops on and smearing it around with my fingers. I used the reflection of the lights off the steel to judge the wetness.

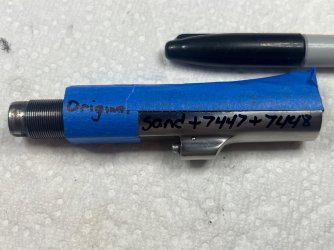

Finally it was the moment of truth. The tape covering the original finish was removed and we had this…

7447 only:

7447 + 7448:

To be really clear, the area closest to the threads is the original finish.

Wow

Stay tuned for how the gun turns out. I won't have time tomorrow night but Saturday morning we'll be burnishing.

Edit because I forgot a picture: Here's the test barrel next to the gun as it is now…