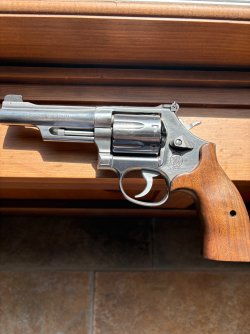

I recently picked up my 686 mountain gun which I ordered the day after they were announced at SHOT show. I carefully examined it at my dealer prior to completing the paperwork and found that the barrel was not canted, the timing was good, the barrel cylinder gap was excellent and there was no endshake. The right sided grip has a slight gap next to the side plate, but I chose to ignore this. I find the grips very comfortable.

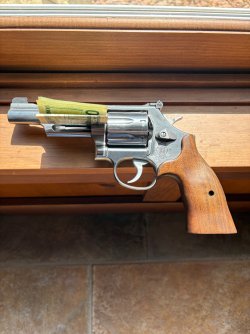

On closer examination at home, I noticed that there is a very significant .032" gap between the top surface of the crane and the frame when viewed from the left side. Fit is good when looking at the crane to frame fit from the muzzle end. By comparison, my older Smith & Wesson 629-4 has only a few thousandths gap in the same location.

The ball detent appears to fit into the crane well, and there is no discernible play when trying to wiggle the cylinder up and down, is this something that I should address with Smith & Wesson or just choose to ignore as the rest of the revolver seems good?

Thanks.

On closer examination at home, I noticed that there is a very significant .032" gap between the top surface of the crane and the frame when viewed from the left side. Fit is good when looking at the crane to frame fit from the muzzle end. By comparison, my older Smith & Wesson 629-4 has only a few thousandths gap in the same location.

The ball detent appears to fit into the crane well, and there is no discernible play when trying to wiggle the cylinder up and down, is this something that I should address with Smith & Wesson or just choose to ignore as the rest of the revolver seems good?

Thanks.