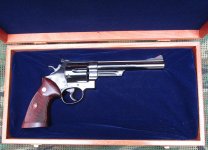

I recently posted a video of a stock refinishing job that was done by BigSwoll58 On YouTube.

To my eyes, it was a very nice job, but apparently for some is not the " Proper "way to refinish Stocks.

Any info on stock refinishing or techniques?

I may try refinishing a couple of mine, or even picking up some Decent enough that that can be refinished To top Notch.

For the experts Out there thought BigSwoll58 was doing it wrong, I'd be interested to know what the right way would be.

Again, my eyes, they looked great, and he did use a real hardware oil based high gloss finish, which might have been the issue for some who want to do it, the way they did it at the factory.

Any info would be helpful.

Thanks

To my eyes, it was a very nice job, but apparently for some is not the " Proper "way to refinish Stocks.

Any info on stock refinishing or techniques?

I may try refinishing a couple of mine, or even picking up some Decent enough that that can be refinished To top Notch.

For the experts Out there thought BigSwoll58 was doing it wrong, I'd be interested to know what the right way would be.

Again, my eyes, they looked great, and he did use a real hardware oil based high gloss finish, which might have been the issue for some who want to do it, the way they did it at the factory.

Any info would be helpful.

Thanks