This post is late coming, and I want to callout Bill @BMCM for his outstanding service and wealth of knowledge he openly shares in making projects happen.

A little backstory. I picked an early adjustable sight 5906, listed as "like new" and reportedly unfired at the time the seller purchased it (a few months prior). It only had a couple so-so resolution photos taken in low lighting, but no major signs of abuse. It was a good price and I figured what the heck, better jump on it before someone else does.

Well....it was decidedly no where near "like new". The entire surface had some level of scratching (carefully photographed at the right angle to obscure) and the internals showed a good bit of wear. While it was rougher than I was led to believe, I did see some potential, and bought it with a few extra mags thrown in. Funny thing is, I had picked up an abrasive blast cabinet enroute. Maybe hedging bets a bit after reading the forum thread on replicating the factory finish and being suspect of the photos. But, I came to the realization my compressor was insufficient for the task at hand however, and it was a very limited use case to justify buying another one.

At this point I reached out to @BMCM who provices various services for our beloved Gen 3's.

We ran thru the service options he provides and let me tell ya, if it can be done....he does it! I intially went with a full cosmetic refresh only as functionally the gun was working well and the trigger was broken in with a lighter than usual pull. The upside to no where near "like new", a slicked up action maybe . After I was pulling together a parts list and checked in with Bill, I opted to have him machine the slide to give it a much needed improvement, Decock only safety lever (still some at Numrich). That with the mag disconnect going away are much needed improvements imo.

. After I was pulling together a parts list and checked in with Bill, I opted to have him machine the slide to give it a much needed improvement, Decock only safety lever (still some at Numrich). That with the mag disconnect going away are much needed improvements imo.

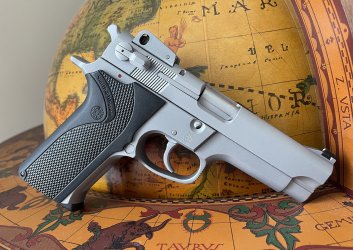

I did not think to get before pics including the couple light dings and wear polished beaver tail. But I think this gives a sense of what the finish was like before Bill worked his magic. Picture all of it with similar scratches, some denser in other areas, along with the couple nicks / dings mentioned.

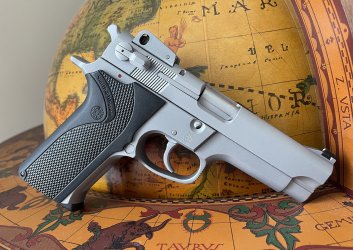

And after its visit to Mississippi:

The end results speak for themselves, but I cant say enough about what a pleasure it was working with Bill. I opted to fully disassemble the gun and reassemble. While I had some familiarity with most of the process, he offered some advice from years of working with these guns. The consumate gunsmith with eye for detail, he noticed some parts in the background on some pics I sent and called those out for evaluation / replacement to avoid issues down the road (old style ejector prone to breakage and sprung sideplate). Helped with part numbers and sourcing of the unobtainium right side decock lever.

His post on the how to check the timing spec of the decocker / sear release was the last piece on getting her back together to ensure all was working as it should

Very much appreciate his patience, information, and work quality. I wouldn't hesitate recommending Bill for any work you may need. In fact, I sent him my 1066 a few months later to get the decocker maching. Thanks Bill!

A little backstory. I picked an early adjustable sight 5906, listed as "like new" and reportedly unfired at the time the seller purchased it (a few months prior). It only had a couple so-so resolution photos taken in low lighting, but no major signs of abuse. It was a good price and I figured what the heck, better jump on it before someone else does.

Well....it was decidedly no where near "like new". The entire surface had some level of scratching (carefully photographed at the right angle to obscure) and the internals showed a good bit of wear. While it was rougher than I was led to believe, I did see some potential, and bought it with a few extra mags thrown in. Funny thing is, I had picked up an abrasive blast cabinet enroute. Maybe hedging bets a bit after reading the forum thread on replicating the factory finish and being suspect of the photos. But, I came to the realization my compressor was insufficient for the task at hand however, and it was a very limited use case to justify buying another one.

At this point I reached out to @BMCM who provices various services for our beloved Gen 3's.

We ran thru the service options he provides and let me tell ya, if it can be done....he does it! I intially went with a full cosmetic refresh only as functionally the gun was working well and the trigger was broken in with a lighter than usual pull. The upside to no where near "like new", a slicked up action maybe

I did not think to get before pics including the couple light dings and wear polished beaver tail. But I think this gives a sense of what the finish was like before Bill worked his magic. Picture all of it with similar scratches, some denser in other areas, along with the couple nicks / dings mentioned.

And after its visit to Mississippi:

The end results speak for themselves, but I cant say enough about what a pleasure it was working with Bill. I opted to fully disassemble the gun and reassemble. While I had some familiarity with most of the process, he offered some advice from years of working with these guns. The consumate gunsmith with eye for detail, he noticed some parts in the background on some pics I sent and called those out for evaluation / replacement to avoid issues down the road (old style ejector prone to breakage and sprung sideplate). Helped with part numbers and sourcing of the unobtainium right side decock lever.

His post on the how to check the timing spec of the decocker / sear release was the last piece on getting her back together to ensure all was working as it should

Very much appreciate his patience, information, and work quality. I wouldn't hesitate recommending Bill for any work you may need. In fact, I sent him my 1066 a few months later to get the decocker maching. Thanks Bill!