Walter Rego

Member

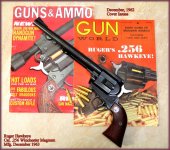

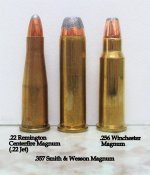

As I am rapidly approaching retirement age and at the peak of my earnings potential I have been attempting to add guns that I have always wanted to my collection. They will be the ones I keep and shoot occasionally when I downsize. I have always wanted a Ruger Hawkeye pistol. I like the oddballs, I also own a first year production Smith & Wesson Model 53 in .22 Centerfire Magnum AKA .22 Jet caliber. The .256 Winchester Magnum and .22 Jet are both based upon the .357 S&W Magnum parent case.

Only around 3300 Hawkeyes were manufactured, most within the first year of production which was from late 1962 to the end of 1963. I received a Ruger factory letter which stated that this gun was manufactured in December 1963. It came with the half of the warranty card that the owner would retain which had November 23 1964 written on it and the original owners manual. This model was a slow seller, it is unknown how long it sat in Ruger's vault before shipping or sat on a shelf at the hardware store where it was purchased.

Factory ammo has about dried up except at expensive collector's pricing. It is now a handloading only proposition, brass can be formed from .357 cases but that requires annealing and expensive, multi-die forming and trimming die sets. I did find some new .256 brass at $1.00 a piece (ouch !) and standard Redding dies so I have some ammo loaded and ready to try. Does anyone here load for this caliber and do you have any favorite loads or tips ?

Only around 3300 Hawkeyes were manufactured, most within the first year of production which was from late 1962 to the end of 1963. I received a Ruger factory letter which stated that this gun was manufactured in December 1963. It came with the half of the warranty card that the owner would retain which had November 23 1964 written on it and the original owners manual. This model was a slow seller, it is unknown how long it sat in Ruger's vault before shipping or sat on a shelf at the hardware store where it was purchased.

Factory ammo has about dried up except at expensive collector's pricing. It is now a handloading only proposition, brass can be formed from .357 cases but that requires annealing and expensive, multi-die forming and trimming die sets. I did find some new .256 brass at $1.00 a piece (ouch !) and standard Redding dies so I have some ammo loaded and ready to try. Does anyone here load for this caliber and do you have any favorite loads or tips ?