Almost all of my reloading over the years has been with revolver calibers { 357 mag., 38 special. , 44 mag.& special., 45 colt. 454 Casull, etc. } and it has been a long time since I reloaded any 9 mm, or 45 ACP . I have always been a fan of Hi-Powers { have 3 } and I got a smokin' deal on a new Springfield / Armory SA-35 { 9mm } a few weeks ago. I currently have 400 rounds of reloaded 115 gr and 124 gr. round nose lead reloads on hand I was using for my other H/P's , but has been a long time since I last shot them. I have been hesitant to try them out in this new gun, as the last time I shot these I had a lot of failure to feed issues . I use a RCBS rock crusher single stage press and their carbide 9mm die set. I have been told by a couple shooting buddies I need what they call a "pass through die " to size the brass all the way to the base of the brass and that should cure my feed issues . I have never heard of this die, and was looking for any opinions ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sizing question .

- Thread starter Roofuss

- Start date

Register to hide this ad

The FTF issue may/may not happen on your new toy.

Personally, give them a try on your new pistol before buying the new checker die.

Personally, give them a try on your new pistol before buying the new checker die.

The FTF issue may/may not happen on your new toy.

Personally, give them a try on your new pistol before buying the new checker die.

I will as soon as our weather improves , lol ! All might be fine with the new SA, but most likely still have the issue with the others.

Yep, try a couple of magazines full and see how they run. Or, if that doesn't appeal to you, dismount the barrel and do a "plunk" test with a couple of boxes. That will not necessary indicate the lack of a feeding problem but it will certainly indicate a potential chambering problem. A "pass thru" die is merely a sizing technique that requires you shove the cartridge case all the way thru, rather than the "in and out" method used in most reloading. That eliminates the small "band" at the bottom of the case which MIGHT interfere with normal function. With most guns it is not necessary.

- Joined

- Aug 19, 2009

- Messages

- 1,391

- Reaction score

- 1,298

I have heard of such a die but can't say I ever saw one and never felt I had any need for one either. In my experience if I had chambering issues related to sizing it was normally due to hasty (and incorrect) adjustment of the sizing die. Basically, didn't make sure it touched the shell holder and thus didn't full length size the brass. There are "small base" dies available in some calibers that work the brass more near the head. Usually intended for brass used in oversize chambers or full auto weapons which often see extra expansion.

I have a small base die in 45 ACP that came with an RCBS set but have only used it on some brass that was fired in an M3 subgun. It did give failure to chamber issues in a 1911 so I used the small base die and it cured that issue.

With a new gun before I went investing in more dies I would do a simple chamber test. Take the gun apart and start dropping the reloaded rounds into the chamber and seeing if they seat properly. A simple test which I have done more than once over the years when I had any question about whether rounds were sized properly for the gun I wanted to use them in. If they seat properly I would go ahead and shoot them. If they gave any issues at that point I would be looking for another possible cause for the feed issues (bullet profile versus feed ramp, underloaded and not cycling fully, etc.).

If they don't fall in and seat properly in the new barrel the old mistake fixer would come out and I would tear them down and start over. Making sure that they were properly full length sized and checking the first ones loaded for fit.

PS; One other possibility, though an uncommon one, is a faulty sizing die. I did (once!) get a sizing die that was improperly made and gave me issues with some of my loads in a couple different guns. The barrel test showed it was not sizing the full case properly and a replacement die cured the problem .............

I have a small base die in 45 ACP that came with an RCBS set but have only used it on some brass that was fired in an M3 subgun. It did give failure to chamber issues in a 1911 so I used the small base die and it cured that issue.

With a new gun before I went investing in more dies I would do a simple chamber test. Take the gun apart and start dropping the reloaded rounds into the chamber and seeing if they seat properly. A simple test which I have done more than once over the years when I had any question about whether rounds were sized properly for the gun I wanted to use them in. If they seat properly I would go ahead and shoot them. If they gave any issues at that point I would be looking for another possible cause for the feed issues (bullet profile versus feed ramp, underloaded and not cycling fully, etc.).

If they don't fall in and seat properly in the new barrel the old mistake fixer would come out and I would tear them down and start over. Making sure that they were properly full length sized and checking the first ones loaded for fit.

PS; One other possibility, though an uncommon one, is a faulty sizing die. I did (once!) get a sizing die that was improperly made and gave me issues with some of my loads in a couple different guns. The barrel test showed it was not sizing the full case properly and a replacement die cured the problem .............

Hasbeen1945

Absent Comrade

Usually not a problem with handguns. But with dies and chambers. There are min and max specs. If you happen to have a chamber with minimum specs and you buy a die that has maximum specs. Well you can see the problem.

nksmfamjp

Member

…I got a smokin' deal on a new Springfield / Armory SA-35 { 9mm } a few weeks ago. I currently have 400 rounds of reloaded 115 gr and 124 gr. round nose lead reloads on hand I was using for my other H/P's , but has been a long time since I last shot them. I have been hesitant to try them out in this new gun, as the last time I shot these I had a lot of failure to feed issues . I use a RCBS rock crusher single stage press and their carbide 9mm die set. I have been told by a couple shooting buddies I need what they call a "pass through die " to size the brass all the way to the base of the brass and that should cure my feed issues . I have never heard of this die, and was looking for any opinions ?

Great new pistol. Let’s see it!

I’m not sure where your friends got that idea from. In general that pass through sizing is unnecessary. I find that normal dies produce fine ammo. I suspect that your oal may be too short or too long. That is a total guess. At what length does a dummy round just pass a plunk test? Where are yours seated vs that?

Last, in a safe area, measure a loaded round. Feed it 5 times. Check oal again. Did it move? If it did, you need more or less crimp, usually.

Last, does it still not feed? Where in the feed/extract cycle does it stop?

The failure to feed issue with the 9mm has also been a problem in my other H/P guns, and because of weather here, I have been unable to got to my local range to shoot the SA-35. One of my shooting buds said he had the issue with his Kimber, and also a Glock . He stated his Dillon press & die set sizes his 9mm all the way down to the base, and his RCBS does not do so and leaves a small area just above the base that it does not size, thus presenting the issue. Guess I'm going to have to wait till my weather improves and will take them out and see what happens. Worse comes to worse, I'll break 'em all down, and start over I guess.....!

ggibson511960

Member

Reloaded ammunition will always have to compromise on case body diameter. 9 mm Parabellum is tapered 0.011 in. from case mouth to extractor groove. No carbide die can duplicate that taper because die makers economize the carbide ring thickness instead making it full length, hence the bulge. They must compromise on the carbide ring diameter, probably biasing it toward the case mouth to properly hold the bullet, but in so doing they inevitably leave a shoulder on the wall to introduce a potential feeding snag. A push-through die will have a different problem in that the entire case body will end up the same diameter. SAAMI allows 0.007 under-tolerance so there is no way to duplicate that 0.011 in. taper. I suppose one could always drive a case into a non-carbide die that was properly tapered, then drive it out, but who wants to go to all that trouble? I'm annoyed with my .38 Special/.357 Mag. carbide dies for leaving a bulge, when SAAMI says those cases are supposed to be "cylindrical". Somebody should, or could, be making high effort dies to restore fired cases to SAAMI dimensional specs without bulges and discontinuities. It would be difficult. Thick shell holders are an obstacle, but there must be a market, especially for nit picking reloaders seeking ultimate accuracy and feeding reliability.

Somebody should, or could, be making high effort dies to restore fired cases to SAAMI dimensional specs without bulges and discontinuities. It would be difficult. Thick shell holders are an obstacle, but there must be a market, especially for nit picking reloaders seeking ultimate accuracy and feeding reliability.

Just as an after thought, would a shell holder being too thick cause this issue , asking for a friend, lol ?

Just as an after thought, would a shell holder being too thick cause this issue , asking for a friend, lol ?

Have you tried the "Plunk Test"? I have 2, 9mm pistols that need a bit shorter handload (and one won't chamber Winchester 147 gr, factory loads). Depending on what kind of FTF you are experiencing, failure to feed at all or incomplete chambering, the remedy can be one of several different methods. BTW, My plain old "junky" Lee 9mm dies have performed flawlessly for a bit over 20 years, Never a feed /chambering problem associated with the dies. Never any sizing "bulges"...

Last edited:

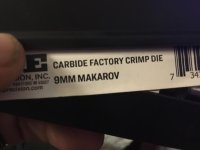

I have pass-through dies for 9mm and for .40S&W. (Made from LEE Factory Crimp Dies).

I shoot a lot of "range trash brass" left from competition and practice. which includes lots of multiple reloaded brass.

In my experience, any 9mm brass that is serviceable can be adequately resized in a PROPERLY ADJUSTED 9mm sizing die without the need for "pass through" sizing.

On the .40S&W brass that has been shot in USPSA OPEN guns with oversized chambers, I have to use the pass-through sizer to return the bulged brass to SAAMI standards to use in ordinary guns.

The .40S&W brass that I fired in my Brn HiPo is adequately resized with an ordinary sizing die.

I shoot a lot of "range trash brass" left from competition and practice. which includes lots of multiple reloaded brass.

In my experience, any 9mm brass that is serviceable can be adequately resized in a PROPERLY ADJUSTED 9mm sizing die without the need for "pass through" sizing.

On the .40S&W brass that has been shot in USPSA OPEN guns with oversized chambers, I have to use the pass-through sizer to return the bulged brass to SAAMI standards to use in ordinary guns.

The .40S&W brass that I fired in my Brn HiPo is adequately resized with an ordinary sizing die.

Last edited:

GypsmJim

Member

- Joined

- Oct 16, 2009

- Messages

- 4,061

- Reaction score

- 7,081

I had a single problem with a single 9mm reload. It wouldn't fit my Glock, but it fit the other nines I had, incliuding a 39-2.

I bought a pass-thru die and it didn't solve the problem with the Glock.

Now, I simply do a plunk test all the time with the Glock barrel. If it fits there, it fits everywhere. If it doesn't pass, I mark it for 39-2 usage only.

I have yet to buy any 9mm brass. My club is rented by the State Police every so often, and the range brass in the can is more than I can use in a lifetime. Good news, bad news, I guess. Now I need to check them all.

I bought a pass-thru die and it didn't solve the problem with the Glock.

Now, I simply do a plunk test all the time with the Glock barrel. If it fits there, it fits everywhere. If it doesn't pass, I mark it for 39-2 usage only.

I have yet to buy any 9mm brass. My club is rented by the State Police every so often, and the range brass in the can is more than I can use in a lifetime. Good news, bad news, I guess. Now I need to check them all.

A simple answer to your question

We have 3 different 9 MM pistols.

Do you have a case gage, 'Loaded Cartridge Gage', for 9 MM? Your problem is cartridge case mouth crimp either / or bulged case (from a Glock) just below the middle of the case. Case crimp will stop the cartridge from entering the case gage.

To solve case bulge, buy a Lee Carbide Crimp Die. Follow the die instructions and your problems are solved.

After buying the above die for 9 MM, 38 Spl / 357 Mag, 40 S&W, and 45 ACP I stopped having failure to feed problems.

We have 3 different 9 MM pistols.

Do you have a case gage, 'Loaded Cartridge Gage', for 9 MM? Your problem is cartridge case mouth crimp either / or bulged case (from a Glock) just below the middle of the case. Case crimp will stop the cartridge from entering the case gage.

To solve case bulge, buy a Lee Carbide Crimp Die. Follow the die instructions and your problems are solved.

After buying the above die for 9 MM, 38 Spl / 357 Mag, 40 S&W, and 45 ACP I stopped having failure to feed problems.

Gripgrabber

US Veteran

cmj8591

Member

You shouldn't have to do anything special when sizing your 9mm brass for that SA35. I'm not sure how you would use a "pass through" sizing die for a tapered 9mm case. I know they make them for 10mm/40/357 Sig, but those are straight walled cases. It seems like a bit of a gimmick to me. As someone suggested, If you have questions about if you're sizing properly, take the barrel out of your gun and make sure that one of your loaded rounds drops in freely. If you want to shell out a couple of bucks, you can get a sizing gauge to test if your loaded rounds are over sized. You can keep it on your bench and quickly use it without dealing with your gun. There's no need to overthink this. RCBS equipment is usually very good so just set it up like the instructions tell you and you'll be good.

venomballistics

Member

your "sizing" issue may very well be a crimping issue.

While the seat / crimp die often does a decent job as a one shot deal, it's not always the case. this is especially true of auto cartridges.

basically, the two operations are mutually exclusive in nature.

The seating function moves the bullet within the case, the crimp stops that motion. If you're loading for a tight chambered gun, the case mouth ends up oversized for your chamber and it won't quite go into battery.

If you back the die off so that it does not crimp, but only seats the bullet to depth, THEN back off the seating punch and run the die down for your crimp, more often than not, the issue is resolved.

if this solves the problem, it's worth considering a Lee collet crimp die to save having to adjust your seat die between functions every loading session.

While the seat / crimp die often does a decent job as a one shot deal, it's not always the case. this is especially true of auto cartridges.

basically, the two operations are mutually exclusive in nature.

The seating function moves the bullet within the case, the crimp stops that motion. If you're loading for a tight chambered gun, the case mouth ends up oversized for your chamber and it won't quite go into battery.

If you back the die off so that it does not crimp, but only seats the bullet to depth, THEN back off the seating punch and run the die down for your crimp, more often than not, the issue is resolved.

if this solves the problem, it's worth considering a Lee collet crimp die to save having to adjust your seat die between functions every loading session.

Similar threads

- Replies

- 81

- Views

- 3K