GCF

Member

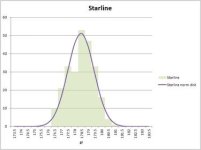

Noticed that Starline is now producing .308 Win brass. Anyone try it yet?

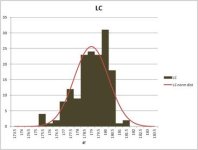

If so, how is the neck thickness, primer pocket, flash hole, & weight uniformity?

They say that the brass is thicker near the base - resulting in slightly lower internal capacity. Milspec 7.62mm comes to mind. How has this affected your standard accuracy loads?

I normally load .308 for my R700 LTR, w/ Lapua brass, but have been a fan of Starline for revolvers - for a long time. Hope to give their new offering a try, in the near future.

If so, how is the neck thickness, primer pocket, flash hole, & weight uniformity?

They say that the brass is thicker near the base - resulting in slightly lower internal capacity. Milspec 7.62mm comes to mind. How has this affected your standard accuracy loads?

I normally load .308 for my R700 LTR, w/ Lapua brass, but have been a fan of Starline for revolvers - for a long time. Hope to give their new offering a try, in the near future.