Lance Boyle

Member

- Joined

- Jul 15, 2012

- Messages

- 156

- Reaction score

- 149

I have been working on a SWC accuracy load for practice. I’ve had a Lyman 358446 mold and just started working with an NOE 360477 mold. I wasn’t getting anything all that great or better than Hornadynswadge SWC.

I had recently got some AA2 as MtGianni recommended. I started with 3.6 grains in a Federal .38 case and did some test batches with .358” and .360 sized. Ho hum off the bench. Not terribly surprising.

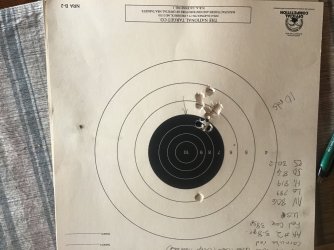

Then I loaded another step up with 3.8 grains of AA2 in a .38 Federal case. Same .358” and .360 sized bullets. Only this time I saw that my .360 sizing didn’t hit the front band, there’s no lock nut on the threaded stem on the Lyman sizer. So I sized some more fully hitting the front band. i shot three lots of ten figuring I’d shoot the ones with the unsized front band.

sized 0.358”

sized .360 completely

the sized .360 and the front band unsized. remained about 0.362”

I had recently got some AA2 as MtGianni recommended. I started with 3.6 grains in a Federal .38 case and did some test batches with .358” and .360 sized. Ho hum off the bench. Not terribly surprising.

Then I loaded another step up with 3.8 grains of AA2 in a .38 Federal case. Same .358” and .360 sized bullets. Only this time I saw that my .360 sizing didn’t hit the front band, there’s no lock nut on the threaded stem on the Lyman sizer. So I sized some more fully hitting the front band. i shot three lots of ten figuring I’d shoot the ones with the unsized front band.

sized 0.358”

sized .360 completely

the sized .360 and the front band unsized. remained about 0.362”