When I first started doing Smith & Wesson action jobs I was all over the place on spring weights. For the hammer spring, I would take each gun to the range and progressively back out the strain screw until I got misfires, turn the screw back in 1/4 turn past where the misfires stopped, and then shorten the strain screw so that it could be bottomed out and produce the same hammer tension.

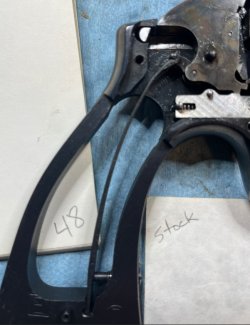

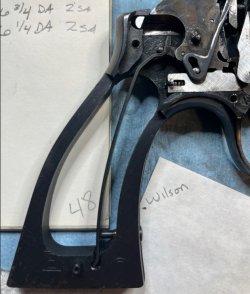

It didn't take too long to figure out that all of them were right around 48 ounces. I stopped doing the misfire test on every gun and just set the hammer tension to 48 ounces on the bench. That technique has worked well for the last year.

Rebound springs though have been a different animal. For a long time I was on a quest to achieve the lightest possible trigger pull weights and still have the gun be reliable. I've gotten to the point now that "lightest possible" is no longer a good thing and I've had to back off......a 6 pound double action pull is cool, but the 18 ounce single action pull that comes with it is not something that most people can deal with.

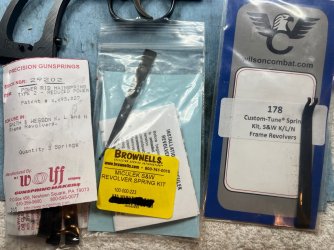

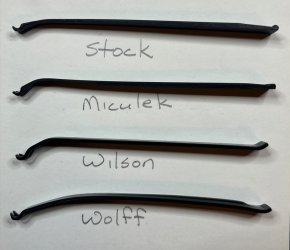

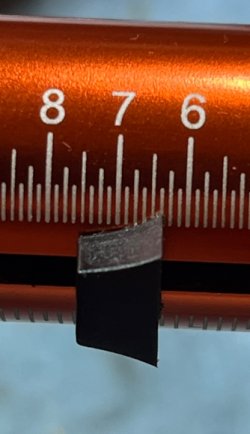

It's time to put some numbers on rebound springs and find "my" combination to use going forward. In this article we're going to start with a stock, dirty gun and get some baseline measurements, then clean and lubricate it and take another set of measurements, then start messing around with spring weights to see what actually happens. We're going to go deep into rebound springs, then come back to the hammer spring and experiment with different ways to achieve the 48 ounce hammer tension target.

Some definitions:

- Hammer tension: the amount of tension in ounces required to move the hammer with the trigger in the full rear position.

- Trigger tension: the amount of tension in ounces required to hold the trigger in the full rearward position after the hammer has dropped.

- Double action pull: the average of 6 double action trigger pulls, measured in pounds.

- Singe action pull: the average of 6 single action trigger pulls, also measured in pounds.

Our test mule for this project is a 4" Model 19 from 1975 that probably has not been cleaned this century.

Our baseline numbers without doing anything other than checking to ensure the gun was empty:

Hammer tension: over 72 ounces (maxed out the 72 ounce scale)

Trigger tension: 48 ounces

DA pull: 10 3/8 pounds with a 1 3/4 pound variance between high and low

SA pull: 3 1/2 pounds, very little if any variance

It didn't take too long to figure out that all of them were right around 48 ounces. I stopped doing the misfire test on every gun and just set the hammer tension to 48 ounces on the bench. That technique has worked well for the last year.

Rebound springs though have been a different animal. For a long time I was on a quest to achieve the lightest possible trigger pull weights and still have the gun be reliable. I've gotten to the point now that "lightest possible" is no longer a good thing and I've had to back off......a 6 pound double action pull is cool, but the 18 ounce single action pull that comes with it is not something that most people can deal with.

It's time to put some numbers on rebound springs and find "my" combination to use going forward. In this article we're going to start with a stock, dirty gun and get some baseline measurements, then clean and lubricate it and take another set of measurements, then start messing around with spring weights to see what actually happens. We're going to go deep into rebound springs, then come back to the hammer spring and experiment with different ways to achieve the 48 ounce hammer tension target.

Some definitions:

- Hammer tension: the amount of tension in ounces required to move the hammer with the trigger in the full rear position.

- Trigger tension: the amount of tension in ounces required to hold the trigger in the full rearward position after the hammer has dropped.

- Double action pull: the average of 6 double action trigger pulls, measured in pounds.

- Singe action pull: the average of 6 single action trigger pulls, also measured in pounds.

Our test mule for this project is a 4" Model 19 from 1975 that probably has not been cleaned this century.

Our baseline numbers without doing anything other than checking to ensure the gun was empty:

Hammer tension: over 72 ounces (maxed out the 72 ounce scale)

Trigger tension: 48 ounces

DA pull: 10 3/8 pounds with a 1 3/4 pound variance between high and low

SA pull: 3 1/2 pounds, very little if any variance

Last edited: