- Joined

- Sep 16, 2023

- Messages

- 602

- Reaction score

- 1,104

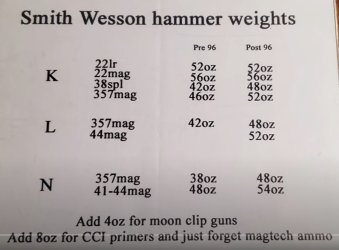

I’m curious if you have a hammer tension “benchmark” weight for a 22 Rimfire. Seems they need to be higher for reliable ignition.

That's the extreme example to illustrate the concept.Just to

thats an interesting point, but I don’t think the rebound spring is ever at full extension unless you cut it wayyyy short

I need to get one to work on first….eventually I will.Thanks for taking the time to write this up. What are the chances of getting you to work your magic on J frame with the external hammer?

I’m curious if you have a hammer tension “benchmark” weight for a 22 Rimfire. Seems they need to be higher for reliable ignition.

There's some data points here which may give you some reference points to start with - when you eventually get to working a J.I need to get one to work on first….eventually I will.

That's 56 ounces. With Federal or Winchester primers you would probably be OK. With your ammo (primers), you probably need to be in the 64 to 70 ounce range.

want a .22 or a .38?I need to get one to work on first….eventually I will.

You are correct, sir. A smith that had a lot of things pass his bench could develop a feel I aspire to, but I’m stuck with what I’ve got. That’s why I love these threads that give us a starting point it might take years to reach otherwise.The responses are very technical in these times. Back in the day, a smith would work on the action by feel, a little cut here, stoning there, polishing here and there, and checked their work in a couple of unique ways; a master factory smith I knew well, would cover the firing pin hole with his thumb, then pull thru dbl action...if the pin nearly broke the skin on his thumb, the tension was good...another time I watched as he held the revolver vertical, inserted a pencil, eraser first into the barrel, pulled thru dbl action and watched to see how high the pencil was launched by the pin...today all these "hacks" would be perceived as too subjective...but in the day, some marvelous PPC and duty revolvers were made this way.

Thanks for your comments about the mainspring. I have used Wolff’s reduced power spring with good results but need to try a Wilson. He wasn’t making them when I got started tinkering with revolvers.Maybe you could share with the rest of us how to do a 3 lb. DA trigger pull?