I was given 3 boxes of what I believe is surplus .308. Possibly Greek.

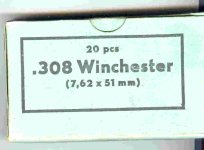

They come in Blue cardboard boxes that say 20pcs .308 Winchester (7.62X51 mm)

Looking at the back of the brass cases it says:

308W

a zero at 9 and 3 o'clock

83

Any thoughts if they are corrosive or none corrosive.

Thanks, Dave

They come in Blue cardboard boxes that say 20pcs .308 Winchester (7.62X51 mm)

Looking at the back of the brass cases it says:

308W

a zero at 9 and 3 o'clock

83

Any thoughts if they are corrosive or none corrosive.

Thanks, Dave