dwever

Well-known member

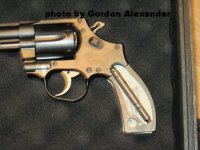

Important Note: The Grant Cunningham extolls the features of the Korth (distributed by Nighthawk made by Korth - yes that Nighthawk) revolver, he works for neither Korth or Nighthawk. Suggested retail for Mongoose with 4" barrel: $3,499.

Particularly interesting are his comments about what it would cost in 2016 to manufacture a Colt Python.

[ame]https://m.youtube.com/watch?v=QG39eqH3ZUE[/ame]

Particularly interesting are his comments about what it would cost in 2016 to manufacture a Colt Python.

[ame]https://m.youtube.com/watch?v=QG39eqH3ZUE[/ame]

Attachments

Last edited: