My new son bought an AR at a gunshow which looks to be a build using mostly Aero Precision parts. The rifle looked to be unfired and when we got to the range found out why. The rifle would not cycle the bolt. Gas block seemed slightly out of adjustment but readjusting the block didn't help.

We put a known good bolt carrier group into the AP rifle and everything functioned like it should. We put the BCG from the AP rifle in another rifle and that rifle would not cycle the bolt when fired. The rifle fires but the BCG only goes back about 3/8".

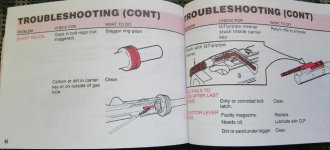

So we started swamping BCG parts around trying to pin down the part causing the malfunction. The only part that would not function in any rifle was the bolt carrier from the AP rifle. The gas key seemed tight and properly staked. What can go wrong on a bolt carrier? I've never seen this problem before and it's frustrating.

Gas key port was clear. New son took the rifle to a local to him gunsmith for evaluation. The gunsmith told him it was probably a headspace issue, it would cost $35 to fully diagnose plus repair. Gunsmith didn't use a go-no go gauge. He decided that since the bolt worked in a different bolt carrier he would simply replace the bolt carrier. We examined the fired cases and didn't see any indication of excessive head space. Thanks for the suggestions.

We put a known good bolt carrier group into the AP rifle and everything functioned like it should. We put the BCG from the AP rifle in another rifle and that rifle would not cycle the bolt when fired. The rifle fires but the BCG only goes back about 3/8".

So we started swamping BCG parts around trying to pin down the part causing the malfunction. The only part that would not function in any rifle was the bolt carrier from the AP rifle. The gas key seemed tight and properly staked. What can go wrong on a bolt carrier? I've never seen this problem before and it's frustrating.

Gas key port was clear. New son took the rifle to a local to him gunsmith for evaluation. The gunsmith told him it was probably a headspace issue, it would cost $35 to fully diagnose plus repair. Gunsmith didn't use a go-no go gauge. He decided that since the bolt worked in a different bolt carrier he would simply replace the bolt carrier. We examined the fired cases and didn't see any indication of excessive head space. Thanks for the suggestions.

Last edited: