Didn't want to thread drift on the 9mm coke dies. Who really made the first carbide Dies for reloading? I keep hearing about RCBS but for some reason thought it was another company(Lyman)?. I even have some Herter's carbide sizers from days of yore.. They have some humongous carbide rings in them. I have carbide dies in all straight cases and in 223 308 and 30-06. Did anyone make carbide 30 carbine dies??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speaking of CarbideDies!!

- Thread starter Skeet 028

- Start date

Register to hide this ad

Alk8944

US Veteran

The first carbide dies I recall were, I believe, Forster back in the 1960s, and they were unbelievably expensive, about $100 for just the sizer. Based on inflation that $100 in say 1968 would be more than $900 in 2024 dollars! As I said, they were incredibly expensive! I would think that Star could likely have been first since they made tools for high volume re-loading such as police departments.

If anyone knows more about this I would be happy to hear what they have to say. I did find an on-line reference that said Star and Loadamatic carbide sizers were available as early as late 1950s. The way that was worded it could have been a guess however.

I would think a good source of information would be Freddie Huntington of HDS, Huntington Die Specialties. I believe that has been bought out like everything else in the industry though. Freddie is the son of Fred T. Huntington, founder of RCBS. Freddie was running shipping for RCBS in 1964 when I worked for RCBS.

Yes, there are carbide dies for .30 Carbine, or used to be. They did/do require lubrication though due to the taper in the case as force needed to size the cases was simply too high and the cases could still stick in the sizer die without lube. In this case the primary benefit of carbide was tool longevity.

If anyone knows more about this I would be happy to hear what they have to say. I did find an on-line reference that said Star and Loadamatic carbide sizers were available as early as late 1950s. The way that was worded it could have been a guess however.

I would think a good source of information would be Freddie Huntington of HDS, Huntington Die Specialties. I believe that has been bought out like everything else in the industry though. Freddie is the son of Fred T. Huntington, founder of RCBS. Freddie was running shipping for RCBS in 1964 when I worked for RCBS.

Yes, there are carbide dies for .30 Carbine, or used to be. They did/do require lubrication though due to the taper in the case as force needed to size the cases was simply too high and the cases could still stick in the sizer die without lube. In this case the primary benefit of carbide was tool longevity.

Last edited:

Ivan the Butcher

Member

I have my first set of 30 Carbine dies from 1980/81, Carbide wasn't available yet for 30 Carbine. Standard straight dies were $17.99 back then. The next year the carbide sizer or complete set came out at $60 for just the sizer! I notice in my accumulation I now have 2 H.S. steel and 2 carbide sizers I don't remember where I came up with the second set off each, but they had to be used and cheap!

Back in those days, case sizing lube was a messy jell that you rolled on using a type of pad and then wiped or washed off: VERY TIME CONSUMING! I started using BreakFree aerosol by 1984. Break Free won't foul primers. A commercial loader friend of mine then thought he would be smart and use a Teflon lube on a batch of 10,000 308 Win. He ended up pulling them all apart and installing new primers. (I cautioned all my other friends because the powder was fouled to a small degree too.)

Hollywood Die company had the oldest carbide dies I knew of, but would assume the big arsenals were before them! Hollywood offered any cartridge carbide dies in the late 1960's for $175 (1969 price), that same friend had 30-30, 308, and 30-06 dies, he had to place a small dab of lube on each shoulder before sizing. I don't know what product he used. He had a carbide 223 set from Dillon very early on, and hand lubed those also.

The only bottle neck carbide sizer I own is for 357 Sig. from Dillon. Paid up front and waited 14 months for a sizer that requires lubing and is no easier to use than the HS steel sizer! (wasted $180!)

On large batched of 223 and 308, I currently use RCBS AR series dies. they are FL/Small base sizers, and taper crimp seaters., and in a Black Box. I have 223, 308, and 300BO. I use Hornady Spray lube, deal with crimped primers then wet tumble with Stainless Steel pins (usually 3 hours) The load on my Dillion 550 with a standard sizing die that doesn't engage the case in any way (just to stabilize the case for priming)

I did a 20,000-round batch of 223 in 1984, using SB RCBS dies and a small bit of spray on Break Free with the cases not cleaned afterward. I have about 3000 of them left and 40 years this fall; they still work fine.

For my long range bolt action loads, I use Redding Competition FL dies with Neck sizing collets selected for neck wall thickness. My slow twist Cooper 21, 223, gets 1/8 MOA groups at 100 yards, My 1:8 twist Savage gets .3 to .5 MOA at 1000 yards, My Savage 308 10 BAS gets .25 MOA at 500 yards and my Savage 338 Lapua 110 BA gets .25 MOA at 200 yards.

The ammo from that 1984 batch gets .25 MOA from bolt or AR at 100 yards.

Taking the time to do research and testing before a large batch is well worth it. I try to have all the components before I start loading. Trying for: Single batch of powder, of primers and bullets. Huge batches of cases are impossible for single lot! Test firing around 20 to 50 rounds before production is the final check that everything fits well and the components are compatible. (some primer/powder combinations don't play well together!)

Most case mouth activated powder drops have their best consistency with ball powders. (I like WW748 and H335 for 223, and 748 for 308, and used WW 296/H110 for 30 Carbine) I find Varget is better for 223 & 308 accuracy but does pretty bad in most of my powder drops! (I drop a short charge, and bring up to weight on a good/very good beam scale.)

The above is all based on Rifle cartridges, my pistol ammo is mass produced with good data and doesn't show enough difference at 25 yards to require extra effort.

Ivan

Back in those days, case sizing lube was a messy jell that you rolled on using a type of pad and then wiped or washed off: VERY TIME CONSUMING! I started using BreakFree aerosol by 1984. Break Free won't foul primers. A commercial loader friend of mine then thought he would be smart and use a Teflon lube on a batch of 10,000 308 Win. He ended up pulling them all apart and installing new primers. (I cautioned all my other friends because the powder was fouled to a small degree too.)

Hollywood Die company had the oldest carbide dies I knew of, but would assume the big arsenals were before them! Hollywood offered any cartridge carbide dies in the late 1960's for $175 (1969 price), that same friend had 30-30, 308, and 30-06 dies, he had to place a small dab of lube on each shoulder before sizing. I don't know what product he used. He had a carbide 223 set from Dillon very early on, and hand lubed those also.

The only bottle neck carbide sizer I own is for 357 Sig. from Dillon. Paid up front and waited 14 months for a sizer that requires lubing and is no easier to use than the HS steel sizer! (wasted $180!)

On large batched of 223 and 308, I currently use RCBS AR series dies. they are FL/Small base sizers, and taper crimp seaters., and in a Black Box. I have 223, 308, and 300BO. I use Hornady Spray lube, deal with crimped primers then wet tumble with Stainless Steel pins (usually 3 hours) The load on my Dillion 550 with a standard sizing die that doesn't engage the case in any way (just to stabilize the case for priming)

I did a 20,000-round batch of 223 in 1984, using SB RCBS dies and a small bit of spray on Break Free with the cases not cleaned afterward. I have about 3000 of them left and 40 years this fall; they still work fine.

For my long range bolt action loads, I use Redding Competition FL dies with Neck sizing collets selected for neck wall thickness. My slow twist Cooper 21, 223, gets 1/8 MOA groups at 100 yards, My 1:8 twist Savage gets .3 to .5 MOA at 1000 yards, My Savage 308 10 BAS gets .25 MOA at 500 yards and my Savage 338 Lapua 110 BA gets .25 MOA at 200 yards.

The ammo from that 1984 batch gets .25 MOA from bolt or AR at 100 yards.

Taking the time to do research and testing before a large batch is well worth it. I try to have all the components before I start loading. Trying for: Single batch of powder, of primers and bullets. Huge batches of cases are impossible for single lot! Test firing around 20 to 50 rounds before production is the final check that everything fits well and the components are compatible. (some primer/powder combinations don't play well together!)

Most case mouth activated powder drops have their best consistency with ball powders. (I like WW748 and H335 for 223, and 748 for 308, and used WW 296/H110 for 30 Carbine) I find Varget is better for 223 & 308 accuracy but does pretty bad in most of my powder drops! (I drop a short charge, and bring up to weight on a good/very good beam scale.)

The above is all based on Rifle cartridges, my pistol ammo is mass produced with good data and doesn't show enough difference at 25 yards to require extra effort.

Ivan

Lifetyme was probably first!

I believe the first carbide dies were produced right after WWII by a company called Carbide Die Services, which sold the dies under the trade name “Lifetyme” dies.

They were offered for use with Star Machine Works progressive reloading presses. These use a unique die thread, not the standard thread as used by RCBS, Lyman, Dillon, Hornady and virtually every other manufacturer today.

So, if you don’t own, or know about, Star Machine Works you may be unaware of all of this.

Lifetyme dies were manufactured to very high standards. Each carbide sizing die was not only made for a specific cartridge (obviously), they were made for use with a specific bullet diameter and case manufacturer. (Your reloads look like factory ammo, not like a miniature Coca Cola bottle!)

Incidentally, Star Machine Works reloaders have, since their introduction in the 1930s, been widely considered to be the finest progressive reloader ever made. The original Dillon RL 1000 was pretty much a Star copy.

Demand for Star reloaders greatly exceeded manufacturing capacity. They were made in a small San Diego machine shop by a handful of machinists. Reloaders were built to order, usually assembled and tuned for a specific load for a specific chambering.

Star didn’t do much, if any advertising. Business was by word of mouth. They were also very expensive. This was partly intentional, to taper the backlog of orders to a manageable level.

The company is now gone (closed in the 1990s, I think?), but there are still legions of loyal followers.

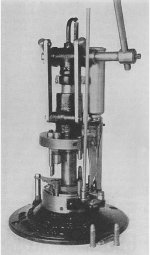

The attached photo is from American Rifleman in 1934. This is the Star “Progesssive” made only in 38 Special. They were widely sold to police departments. The Star “Universal” came later, and it could be set up to load different cartridges.

I believe the first carbide dies were produced right after WWII by a company called Carbide Die Services, which sold the dies under the trade name “Lifetyme” dies.

They were offered for use with Star Machine Works progressive reloading presses. These use a unique die thread, not the standard thread as used by RCBS, Lyman, Dillon, Hornady and virtually every other manufacturer today.

So, if you don’t own, or know about, Star Machine Works you may be unaware of all of this.

Lifetyme dies were manufactured to very high standards. Each carbide sizing die was not only made for a specific cartridge (obviously), they were made for use with a specific bullet diameter and case manufacturer. (Your reloads look like factory ammo, not like a miniature Coca Cola bottle!)

Incidentally, Star Machine Works reloaders have, since their introduction in the 1930s, been widely considered to be the finest progressive reloader ever made. The original Dillon RL 1000 was pretty much a Star copy.

Demand for Star reloaders greatly exceeded manufacturing capacity. They were made in a small San Diego machine shop by a handful of machinists. Reloaders were built to order, usually assembled and tuned for a specific load for a specific chambering.

Star didn’t do much, if any advertising. Business was by word of mouth. They were also very expensive. This was partly intentional, to taper the backlog of orders to a manageable level.

The company is now gone (closed in the 1990s, I think?), but there are still legions of loyal followers.

The attached photo is from American Rifleman in 1934. This is the Star “Progesssive” made only in 38 Special. They were widely sold to police departments. The Star “Universal” came later, and it could be set up to load different cartridges.

Attachments

Last edited:

smoothshooter

Member

Didn't want to thread drift on the 9mm coke dies. Who really made the first carbide Dies for reloading? I keep hearing about RCBS but for some reason thought it was another company(Lyman)?. I even have some Herter's carbide sizers from days of yore.. They have some humongous carbide rings in them. I have carbide dies in all straight cases and in 223 308 and 30-06. Did anyone make carbide 30 carbine dies??

Yes. I have an RCBS .30 Carbine die.

I knew of the Lyfetime carbides and knew either them or Lyman made the first carbides. Nice to know this info. I'm going to look up the Herter's carbide sizers. I bought one years ago60's?? and don'remember the price...but Herter's did not make their dies..they contracted them out...I even have some dies made for them by RCBS

starmachineworks.com still has reloaders for sale and most parts and dies I bought one last year

gwpercle

Member

Lyfetime or Lifetyme ... it was spelled funny ... was the name I remember ... mid 1960's ...I knew of the Lyfetime carbides and knew either them or Lyman made the first carbides. Nice to know this info. I'm going to look up the Herter's carbide sizers. I bought one years ago60's?? and don'remember the price...but Herter's did not make their dies..they contracted them out...I even have some dies made for them by RCBS

that advertised carbide sizers but the very first set I bought were Lyman A-A (All American) in 45 acp ... the carbide ring was about a quarter inch wide and deep and the edge of the die body rolled over to hold it in place ... the little roll of metal kept you from screwing the die in too far and having the carbide ring touch the shell holder ... you could crack the carbide ring if you did that .

I also remember them being expensive ... my only carbide for several years untill Richard Lee came out with affordable Lee Carbide Sizers !

Gary

Last edited:

Lyman made the first mass produced ones I think. Others may have been earlier. I have multiple sets of dies from the 1960s or 70s in black cardboard boxes. I use them now although I purchased them used over the years

Similar threads

- Locked

- Replies

- 0

- Views

- 233

- Locked

- Replies

- 14

- Views

- 2K

- Replies

- 2

- Views

- 337

- Replies

- 8

- Views

- 1K