I've decided to make a Dirty Harry Holster for my CO2 Umarex Smith & Wesson M29.

Living in France I cannot put any things else than this kind of gun in a holster, equally restricted to at home worn, since I don't want to take the risk to be shot in the street by a policemen equipped with a real gun…

My pleasure being to make leather works, Dirty Harry holster being very particular, this project is a challenge I was not sure to lead successfully to the end, but nevertheless I have made it as near as possible to the original model.

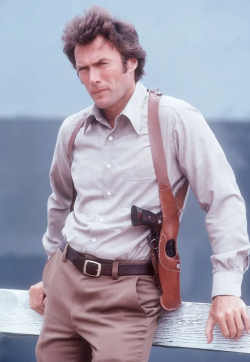

Yesterday I began the adventure by watching for the umpteenth time Magnum Force, in which Clint Eastwood wears the famous holster of which he drops out the no less famous M29 to make the law respected.

Looking at picture on the Web, I drew a pattern of the general holster form, using my Umarex Copy of M29 to control the dimensions. The barrel is 8"3/8.

I spoke of this holster particularity. It is fully open at back allowing an easy fast draw out. To keep inside the gun, the holster in fitted with a spring that maintains its two back sides against the gun with sufficient pressure avoiding any risk of fall.

A round cutting of the outside face at the level of the cylinder increases the keeping of the revolver in the holster, without avoiding fast draw out.

Right spring tension is the condition of efficiency of the system.

It depends of the diameter of the spring and of its bending in the right shape.

I had steel wires of 2 mm diameter, used to make spring to suspend flower pots. I used one to shape the spring that is U form.

The main difficulty is to sew the spring leather cover without hitting the spring with the needle.

I cut two pieces of leather of about 2.4 mm thickness, U shaped. I put the spring between and I glued the edge of the two leather pieces, and manually sewed them with care.

I shaped the spring, as closed as possible to the faces of the holster.

To maintain the spring in place I sewed the leather sandwich in which the spring had taken place in four places on the main body of the holster.

But before proceeding to this installation that is in fact the last one of my making, after having watched this video

I had installed the spring as shown by Sam Andrews.

I learnt a lot doing this holster and I'm now able to identify my mistakes:

First one is the diameter à of the U spring, I think that 3 mm should certainly be preferable to 2 mm.

The U shape at back side should be nearer to the back edge holster body.

Perhaps this modification could be sufficient to avoid using Sam Andrews spring system, what should simplify the making.

For this holster I used vegetable tanned leather, of 4 mm and 2.4 mm thickness.

The springs are made of steel spring wire.

Fawn color is obtained with a water dye.

I must confess that this size of holster and gun are not made for me who is a "short man" but fitted very well Clint Estwood that is a tall man

Living in France I cannot put any things else than this kind of gun in a holster, equally restricted to at home worn, since I don't want to take the risk to be shot in the street by a policemen equipped with a real gun…

My pleasure being to make leather works, Dirty Harry holster being very particular, this project is a challenge I was not sure to lead successfully to the end, but nevertheless I have made it as near as possible to the original model.

Yesterday I began the adventure by watching for the umpteenth time Magnum Force, in which Clint Eastwood wears the famous holster of which he drops out the no less famous M29 to make the law respected.

Looking at picture on the Web, I drew a pattern of the general holster form, using my Umarex Copy of M29 to control the dimensions. The barrel is 8"3/8.

I spoke of this holster particularity. It is fully open at back allowing an easy fast draw out. To keep inside the gun, the holster in fitted with a spring that maintains its two back sides against the gun with sufficient pressure avoiding any risk of fall.

A round cutting of the outside face at the level of the cylinder increases the keeping of the revolver in the holster, without avoiding fast draw out.

Right spring tension is the condition of efficiency of the system.

It depends of the diameter of the spring and of its bending in the right shape.

I had steel wires of 2 mm diameter, used to make spring to suspend flower pots. I used one to shape the spring that is U form.

The main difficulty is to sew the spring leather cover without hitting the spring with the needle.

I cut two pieces of leather of about 2.4 mm thickness, U shaped. I put the spring between and I glued the edge of the two leather pieces, and manually sewed them with care.

I shaped the spring, as closed as possible to the faces of the holster.

To maintain the spring in place I sewed the leather sandwich in which the spring had taken place in four places on the main body of the holster.

But before proceeding to this installation that is in fact the last one of my making, after having watched this video

I had installed the spring as shown by Sam Andrews.

I learnt a lot doing this holster and I'm now able to identify my mistakes:

First one is the diameter à of the U spring, I think that 3 mm should certainly be preferable to 2 mm.

The U shape at back side should be nearer to the back edge holster body.

Perhaps this modification could be sufficient to avoid using Sam Andrews spring system, what should simplify the making.

For this holster I used vegetable tanned leather, of 4 mm and 2.4 mm thickness.

The springs are made of steel spring wire.

Fawn color is obtained with a water dye.

I must confess that this size of holster and gun are not made for me who is a "short man" but fitted very well Clint Estwood that is a tall man